Structure and Mössbauer Analysis of Melt-Spun Fe-Pd Ribbons Containing Ni and Co

Abstract

:1. Introduction

2. Experimental Section

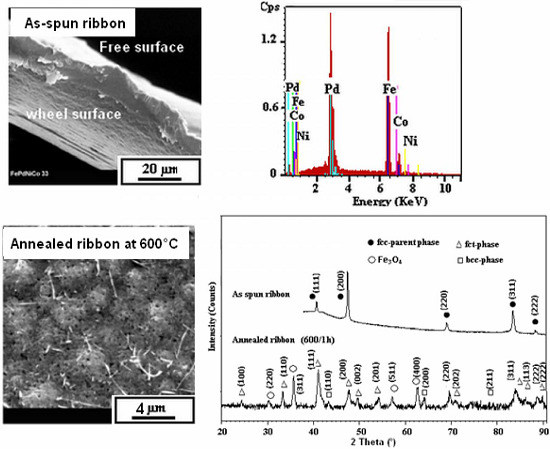

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nakayama, T.; Kikuchi, M.; Fukamichi, K. Young’s modulus and the Delta E effect of Fe-Pd Invar alloys. J. Phys. F 1980, 10, 715. [Google Scholar] [CrossRef]

- Gehanno, V.; Marty, A.; Gilles, B.; Samson, Y. Magnetic domains in epitaxial ordered FePd (001) thin films with perpendicular magnetic anisotropy. Phys. Rev. B 1997, 55, 12552. [Google Scholar] [CrossRef]

- Cui, J.; Shield, T.W.; James, R.D. Phase transformation and magnetic anisotropy of an iron—Palladium ferromagnetic shape-memory alloy. J. Acta Mater. 2004, 52, 35–47. [Google Scholar] [CrossRef]

- Kato, H.; Liang, Y.; Taya, M. Stress-induced fcc/fct phase transformation in Fe–Pd alloy. Scr. Mater. 2002, 46, 471–475. [Google Scholar] [CrossRef]

- Matsui, M.; Shimizu, T.; Yamada, H.; Adachi, K. Magnetic properties and thermal expansion of Fe-Pd invar alloys. J. Magn. Magn. Mater. 1980, 15, 1201–1202. [Google Scholar] [CrossRef]

- Oshima, R.; Sugiyama, M. Martensite transformations in FePd alloys. J. Phys. IV 1982, 43, C4-383–C4-388. [Google Scholar]

- Sugiyama, M.; Oshima, R.; Fujita, F.E. Martensite transformations in FePd alloy system. Trans. Jpn. Inst. Met. 1984, 25, 585. [Google Scholar] [CrossRef]

- Muto, S.; Oshima, R.; Fujita, F.E. Nucleation and growth in martensitic transformations of ordered Fe3Pt alloys. Metall. Trans. A 1988, 19, 2931–2936. [Google Scholar] [CrossRef]

- Tanaka, K.; Oshima, R.; Fujita, F.E. Role of annealing twin in the formation of variant structure of bct martensite in Fe-Pd alloy. Mater. Trans. JIM 1991, 32, 325–330. [Google Scholar] [CrossRef]

- Sanchez-Alarcos, V.; Perez-Landazabal, J.I.; Recarte, V.; Gómez-Polo, C.; Rodríguez-Velamazán, J.A. Correlation between composition and phase transformation temperatures in Ni–Mn–Ga–Co ferromagnetic shape memory alloys. Acta Mater. 2008, 56, 5370–5376. [Google Scholar] [CrossRef]

- Sanchez-Alarcos, V.; Recarte, V.; Perez-Landazabal, J.I.; González, M.A.; Rodríguez-Velamazán, J.A. Effect of Mn addition on the structural and magnetic properties of Fe–Pd ferromagnetic shape memory alloys. J. Acta Mater. 2009, 57, 4224–4232. [Google Scholar] [CrossRef]

- Stern, R.A.; Wiiloughby, S.D.; Ramirez, A.; MacLaren, J.M.; Cui, J.; Pan, Q.; James, R.D. Electronic and structural properties of Fe3Pd-Pt ferromagnetic shape memory alloys. J. Appl. Phys. 2002, 91, 7818–7820. [Google Scholar] [CrossRef]

- Lin, Y.C.; Lee, H.T.; Jen, S.U.; Chen, Y.T. Magnetic structure of an Fe-Pd-Rh alloy. J. Appl Phys. 2007, 101. [Google Scholar] [CrossRef]

- Jen, S.U.; Chen, Y.T.; Tsai, T.L.; Lin, Y.C. Magnetostrictive strains in polycrystalline FePdRh alloy. J. Appl Phys. 2008, 103. [Google Scholar] [CrossRef]

- Brand, R.A. NORMOS-98 Mössbauer Fitting Program Package; WissEl GmbH: Stanberg, Germany, 1998. [Google Scholar]

- Gutfleisch, O.; Lyubina, J.; Müller, K.H.; Schultz, L. FePt hard magnets. Adv. Eng. Mater. 2005, 7, 208–212. [Google Scholar] [CrossRef]

- Khitouni, M.; Kolsi, A.W.; Njah, N. The effects of boron additions on the disordering and crystallite refinement of Ni3Al powders during mechanical milling. Ann. Chim. Sci. Matér. 2003, 28, 17–29. [Google Scholar] [CrossRef]

- Khitouni, M.; Njah, N.; Gilbon, D. The effect of boron on the reordering of Ni3Al powders produced by filing. Scr. Mater. 2004, 50, 77–81. [Google Scholar] [CrossRef]

- Seguı́, C.; Pons, J.; Cesari, E.; Muntasell, J.; Font, J. Characterization of a hot-rolled Cu-Al-Ni-Ti shape memory alloy. Mater. Sci. Eng. A 1999, 273–275, 625–629. [Google Scholar] [CrossRef]

- Recarte, V.; Perez-Landazabal, J.I.; Gomez-Polo, C.; Campo, J.; Garitaonandia, J.S. Influence of atomic rearrangements on the magnetic properties of a thermally treated disordered Fe21Pd79 alloy. J. Non-Cryst. Solids 2001, 287, 96–99. [Google Scholar] [CrossRef]

- Ryzhenko, B.V.; Sidorenko, F.A.; Karpov, Y.G.; Gel’d, P.V. Effective fields at Fe57 nuclei and magnetic structure of palladium-iron alloys. Phys. JETP 1977, 73, 1032–1044. [Google Scholar]

- Petrov, Yu.I.; Shafranovskii, E.A.; Krupyanskii, Yu.F.; Esin, S.V. Discrete Structure of the Hyperfine Field Distribution at Fe Nuclei in the Bulk FePd Alloy and Its Nanoparticles. Phys. Chem. 2004, 399, 269–274. [Google Scholar] [CrossRef]

- Claussen, I.; Brand, R.A.; Hahn, H.; Mayr, S.G. Relaxation scenarios in Fe–Pd and Fe–Pd–Cu ferromagnetic shape memory splats: Short range order and microstructure. Scr. Mater. 2012, 66, 163–166. [Google Scholar] [CrossRef]

- Gehanno, V.; Auric, P.; Marty, A.; Gilles, B. Structural and magnetic properties of epitaxial Fe0.5Pd0.5 thin films studied by Mössbauer spectroscopy. J. Magn. Magn. Mater. 1998, 188, 310–318. [Google Scholar] [CrossRef]

- Kamali-M, S.; Bergman, A.; Andersson, G.; Stanciu, V.; Häggström, L. Local Magnetic Effects of Interface Alloying in Fe/Co Superlattices. J. Phys. Condens. Matter 2006, 18, 5807–5824. [Google Scholar] [CrossRef] [PubMed]

- Kamali, S.; Häggström, L.; Sahlberg, M.; Wäppling, R. Magnetic and interface properties of Fe0.82Ni0.18/Co(001) superlattices. J. Phys. Condens. Matter 2011, 23. [Google Scholar] [CrossRef] [PubMed]

- Kamali, S.; Blixt, A.M.; Häggström, L.; Wäppling, R.; Stanciu, V.; Nordblad, P. Magnetic properties of a Fe0.82Ni0.18/V(001) superlattice studied by Mössbauer spectroscopy. J. Magn. Magn. Mater. 2004, 272–276, 1263–1265. [Google Scholar] [CrossRef]

- Häggström, L.; Soroka, I.; Kamali, S. Thickness Dependent Crystallographic Transition in Fe/Ni Superlattices. J. Phys. Conf. Ser. 2010, 217. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rekik, H.; Chemingui, M.; Bachaga, T.; Cherif, A.; Bruna, P.; Sunol, J.J.; Khitouni, M. Structure and Mössbauer Analysis of Melt-Spun Fe-Pd Ribbons Containing Ni and Co. Metals 2015, 5, 1020-1028. https://doi.org/10.3390/met5021020

Rekik H, Chemingui M, Bachaga T, Cherif A, Bruna P, Sunol JJ, Khitouni M. Structure and Mössbauer Analysis of Melt-Spun Fe-Pd Ribbons Containing Ni and Co. Metals. 2015; 5(2):1020-1028. https://doi.org/10.3390/met5021020

Chicago/Turabian StyleRekik, Hanen, Mahmoud Chemingui, Tarek Bachaga, Amal Cherif, Pere Bruna, Joan Joseph Sunol, and Mohamed Khitouni. 2015. "Structure and Mössbauer Analysis of Melt-Spun Fe-Pd Ribbons Containing Ni and Co" Metals 5, no. 2: 1020-1028. https://doi.org/10.3390/met5021020

APA StyleRekik, H., Chemingui, M., Bachaga, T., Cherif, A., Bruna, P., Sunol, J. J., & Khitouni, M. (2015). Structure and Mössbauer Analysis of Melt-Spun Fe-Pd Ribbons Containing Ni and Co. Metals, 5(2), 1020-1028. https://doi.org/10.3390/met5021020