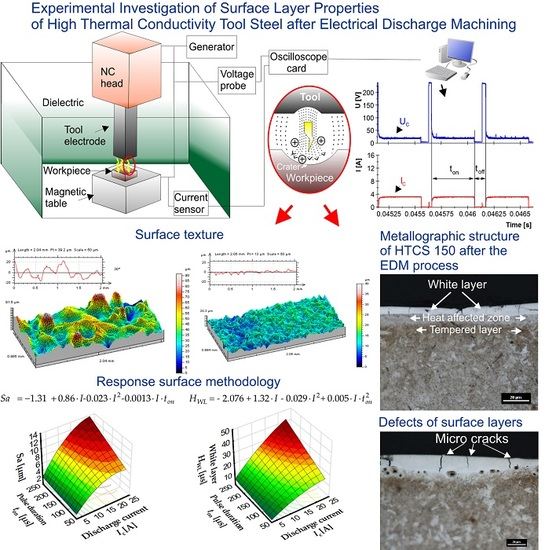

Experimental Investigation of Surface Layer Properties of High Thermal Conductivity Tool Steel after Electrical Discharge Machining

Abstract

:1. Introduction

2. Materials and Methods

2.1. Measurement Circuit of Voltage Current Waveforms

- Ic: height of the peak current during discharging;

- Uc: discharge voltage;

- ton: pulse duration time, the time required for the current to rise and fall during discharging; and

- toff: time interval, which is the time from the end of one pulse to the beginning of the next pulse with the current.

2.2. Experimental Design

2.3. Measuring Surface Layer Properties

- arithmetic mean of the deviations from the mean Sa (average value of the absolute heights over the entire surface). The Sa parameter responds to the 2D roughness profile parameters Ra. It may be obtained by adding the individual height values without regard to sign and dividing the sum by the number of the data matrix, where M is the number of points per profile, N the number of profiles and z, x, y are the height of the profile at a specific point.

- density of the top Sds (a number of summits of a unit sampling area), which relies on the eight nearest neighbor summit definition where a peak is defined if it is higher than its eight nearest neighbors:

- arithmetic mean curvature to the top Ssc. This parameter obtains the mean form of the peaks which are pointed or rounded, according to the mean value of the curvature of the surface at these points.

3. Results and Discussions

3.1. Surface Texture

3.2. Modeling Surface Roughness Parameters Using Response Surface Methodology

3.3. Surface Layer Properties

3.4. Modeling of White Layer Thickness Using Response Surface Methodology

3.5. Defects of Surface Layers: Micro Cracks

3.6. Influence of Sequential Machining on Surface Layers Properties

4. Conclusions

- The roughness parameter Sa was the range of 2.11–11.8 µm and corresponded to finishing and roughing machining. Sa was mainly dependent on the discharge current. Furthermore, the increase of discharge current increased the amount of eroded material in a single pulse, thus leading to higher roughness.

- Surface roughness hybrid parameters Sds and Ssc described the shape of the roughness vertices. The arithmetic mean curvature to the top Ssc was in the range of 0.07–0.153 1/µm and the density of the top Sds was in the range of 113–522 pks/mm2. For the highest values of discharge current and pulse time, the lowest density of the top Sds and the height values of the roughness parameters Ssc and Sa were obtained. The increase in discharge current and pulse time caused increases in the amount of eroded material, which provided a higher roughness profile with larger distances between the individual vertices and rounded tops. For finishing parameters with the shortest pulse times and the smallest current values, the surface roughness was characterized by a high density of vertices with sharpened edges.

- The thermal, chemical and mechanical processes occurring during the electrical discharges caused the creation of a surface layer containing a white layer, heat affected zones and a tempered layer. The thickness of each layer depended on the discharge current and pulse time. A minimal thickness of the investigated layers was observed for the lowest discharge energy.

- The main elements of the surface layers that influence the surface integrity properties are the thickness of the white layer. The average thickness of the white layer was in the range of 5–34.5 µm and depends mainly on the amount of thermal energy supplied to the workpiece. Increasing the pulse time at the lowest current did not significantly change the HWL value.

- Images of the metallographic structure showed defects in the surface layers as micro cracks. The micro cracks mostly occurred on the surface of the crater and were usually directed perpendicular to the heat affected zone.

- Sequential processing of the EDM typical for production processes such as roughing, semi-finishing and finishing operations, showed that the average thickness of the white layer of sample sequential manufacturing was equal to HWL = 5.5 μm. This value corresponded to the average layer thickness obtained in single finishing processing but had a twice as large thickness of the tempered layer (HT = 20 μm). These differences were a result of the residue after the heat flux in the roughing operation and could be minimized by the appropriate selection of finishing parameters.

- Developed regression equations can be used in electrical discharge machining as a guideline for the selection of process parameters to achieve the desired surface layers properties.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Skoczypiec, S.; Ruszaj, A. A sequential electrochemical–electrodischarge process for micropart manufacturing. Precis. Eng. 2014, 38, 680–690. [Google Scholar] [CrossRef]

- Sawicki, J.; Paczkowski, T. Effect of the hydrodynamic conditions of electrolyte flow on critical states in electrochemical machining. EPJ Web Conf. 2015, 92, 02078. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Sundaram, M.M.; Malshe, A.P. Review of Electrochemical and Electrodischarge Machining. Procedia CIRP 2013, 6, 13–26. [Google Scholar] [CrossRef]

- Oniszczuk-Świercz, D.; Świercz, R. Surface texture after wire electrical discharge machining. In Proceedings of the 26th International Conference on Metallurgy and Materials, Brno, Czech Republic, 24–26 May 2017. in press. [Google Scholar]

- Krajewski, A.; Włosiński, W.; Chmielewski, T.; Kołodziejczak, P. Ultrasonic-vibration assisted arc-welding of aluminum alloys. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 60, 841–852. [Google Scholar] [CrossRef]

- Chmielewski, T.; Golański, D.; Włosiński, W.; Zimmerman, J. Utilizing the energy of kinetic friction for the metallization of ceramics. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 201–207. [Google Scholar] [CrossRef]

- Gostimirovic, M.; Kovac, P.; Sekulic, M.; Skoric, B. Influence of discharge energy on machining characteristics in EDM. J. Mech. Sci. Technol. 2012, 26, 173–179. [Google Scholar] [CrossRef]

- Świercz, R.; Oniszczuk-Świercz, D. Influence of electrical discharge pulse energy on the surface integrity of tool steel 1.2713. In Proceedings of the 26th International Conference on Metallurgy and Materials, Brno, Czech Republic, 24–26 May 2017. in press. [Google Scholar]

- Ho, K.H.; Newman, S.T. State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Marashi, H.; Jafarlou, D.M.; Sarhan, A.A.D.; Hamdi, M. State of the art in powder mixed dielectric for EDM applications. Precis. Eng. 2016, 46, 11–33. [Google Scholar] [CrossRef]

- Hui, Z.; Liu, Z.; Cao, Z.; Qiu, M. Effect of Cryogenic Cooling of Tool Electrode on Machining Titanium Alloy (Ti–6Al–4V) during EDM. Mater. Manuf. Process. 2016, 31, 475–482. [Google Scholar] [CrossRef]

- Dewangan, S.; Biswas, C.K.; Gangopadhyay, S. Influence of Different Tool Electrode Materials on EDMed Surface Integrity of AISI P20 Tool Steel. Mater. Manuf. Process. 2014, 29, 1387–1394. [Google Scholar] [CrossRef]

- Cusanelli, G.; Hessler-Wyser, A.; Bobard, F.; Demellayer, R.; Perez, R.; Flükiger, R. Microstructure at submicron scale of the white layer produced by EDM technique. J. Mater. Process. Technol. 2004, 149, 289–295. [Google Scholar] [CrossRef]

- Shrestha, T.; Alsagabi, S.F.; Charit, I.; Potirniche, G.P.; Glazoff, M.V. Effect of Heat Treatment on Microstructure and Hardness of Grade 91 Steel. Metals 2015, 5, 131–149. [Google Scholar] [CrossRef]

- Spadło, S.; Kozak, J.; Młynarczyk, P. Mathematical Modelling of the Electrical Discharge Mechanical Alloying Process. Procedia CIRP 2013, 6, 422–426. [Google Scholar] [CrossRef]

- Spadło, S.; Młynarczyk, P.; Łakomiec, K. Influence of the of electrical discharge alloying methods on the surface quality of carbon steel. Int. J. Adv. Manuf. Technol. 2017, 89, 1529–1534. [Google Scholar] [CrossRef]

- Radziejewska, J. Influence of laser-mechanical treatment on surface topography, erosive wear and contact stiffness. Mater. Des. 2011, 32, 5073–5081. [Google Scholar] [CrossRef]

- Murray, J.W.; Clare, A.T. Repair of EDM induced surface cracks by pulsed electron beam irradiation. J. Mater. Process. Technol. 2012, 212, 2642–2651. [Google Scholar] [CrossRef]

- Radziejewska, J.; Skrzypek, S.J. Microstructure and residual stresses in surface layer of simultaneously laser alloyed and burnished steel. J. Mater. Process. Technol. 2009, 209, 2047–2056. [Google Scholar] [CrossRef]

- Kim, J.-M.; Ha, T.-H.; Park, J.-S.; Kim, H.-G. Effect of Laser Surface Treatment on the Corrosion Behavior of FeCrAl-Coated TZM Alloy. Metals 2016, 6, 29. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martínez, S.; Ukar, E.; López de Lacalle, L.N. Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 2012, 212, 516–522. [Google Scholar] [CrossRef]

- Kozak, J.; Rozenek, M.; Dabrowski, L. Study of electrical discharge machining using powder-suspended working media. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 1597–1602. [Google Scholar] [CrossRef]

- Klocke, F.; Lung, D.; Antonoglou, G.; Thomaidis, D. The effects of powder suspended dielectrics on the thermal influenced zone by electrodischarge machining with small discharge energies. J. Mater. Process. Technol. 2004, 149, 191–197. [Google Scholar] [CrossRef]

- Lauwers, B. Surface Integrity in Hybrid Machining Processes. Procedia Eng. 2011, 19, 241–251. [Google Scholar] [CrossRef]

- Chmielewski, T.; Golański, D.A. New method of in-situ fabrication of protective coatings based on Fe–Al intermetallic compounds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 611–616. [Google Scholar] [CrossRef]

- Chmielewski, T.; Golański, D.; Włosiński, W. Metallization of ceramic materials based on the kinetic energy of detonation waves. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 449. [Google Scholar] [CrossRef]

- Kunieda, M.; Lauwers, B.; Rajurkar, K.P.; Schumacher, B.M. Advancing EDM through Fundamental Insight into the Process. CIRP Ann. Manuf. Technol. 2005, 54, 64–87. [Google Scholar] [CrossRef]

- Hayakawa, S.; Kusafuka, Y.; Itoigawa, F.; Nakamura, T. Observation of Material Removal from Discharge Spot in Electrical Discharge Machining. Procedia CIRP 2016, 42, 12–17. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Grigor’ev, S.N.; Okun’kova, A.A.; Porvatov, A.N. Monitoring of electric discharge machining by means of acoustic emission. Russ. Eng. Res. 2016, 36, 244–248. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Porvatov, A.N.; Grigor’ev, S.N. Vibroacoustic Monitoring of the Major Parameters of Electrical Discharge Machining. Meas. Technol. 2017, 59, 1228–1233. [Google Scholar] [CrossRef]

- Spadło, S.; Dudek, D. Investigation of the shape accuracy of cylindrical holes machined by EDM process. J. Mach. Eng. 2012, 12, 98–104. [Google Scholar]

- Oniszczuk, D.; Świercz, R. An investigation into the impact of electrical pulse character on surface texture in the EDM and WEDM process. Adv. Manuf. Sci. Technol. 2012, 36, 43–53. [Google Scholar]

- Straka, L.; Corný, I.; Pitel’, J.; Hašová, S. Statistical Approach to Optimize the Process Parameters of HAZ of Tool Steel EN X32CrMoV12-28 after Die-Sinking EDM with SF-Cu Electrode. Metals 2017, 7, 35. [Google Scholar] [CrossRef]

- Mondal, R.; De, S.; Mohanty, S.K.; Gangopadhyay, S. Thermal Energy Distribution and Optimization of Process Parameters during Electrical Discharge Machining Of AISI D2 Steel. Mater. Today Proc. 2015, 2, 2064–2072. [Google Scholar] [CrossRef]

- Rahang, M.; Patowari, P.K. Parametric Optimization for Selective Surface Modification in EDM Using Taguchi Analysis. Mater. Manuf. Process. 2016, 31, 422–431. [Google Scholar] [CrossRef]

- Salcedo, A.T.; Arbizu, I.P.; Pérez, C.J.L. Analytical Modelling of Energy Density and Optimization of the EDM Machining Parameters of Inconel 600. Metals 2017, 7, 166. [Google Scholar] [CrossRef]

- Ramasawmy, H.; Blunt, L.; Rajurkar, K.P. Investigation of the relationship between the white layer thickness and 3D surface texture parameters in the die sinking EDM process. Precis. Eng. 2005, 29, 479–490. [Google Scholar] [CrossRef]

- Straka, Ľ.; Čorný, I.; Piteľ, J. Properties Evaluation of Thin Microhardened Surface Layer of Tool Steel after Wire EDM. Metals 2016, 6, 95. [Google Scholar] [CrossRef]

- Sanchez, J.A.; Pombo, I.; Cabanes, I.; Ortiz, R.; Lopez de Lacalle, L.N. Electrical discharge truing of metal-bonded CBN wheels using single-point electrode. Int. J. Mach. Tools Manuf. 2008, 48, 362–370. [Google Scholar] [CrossRef]

- Rovalma Company Web. Available online: http://rovalma.com/product/htcs-150/ (accessed on 1 September 2017).

| Levels | Parameters | |

|---|---|---|

| Discharge Current Ic (A) | Pulse Duration ton (μs) | |

| −1.41 | 3 | 50 |

| −1 | 6 | 80 |

| 0 | 14 | 150 |

| 1 | 21 | 220 |

| +1.41 | 24 | 250 |

| Ex. No. | Parameters | Sa (µm) | Sds (pks/mm2) | Ssc (1/µm) | |

|---|---|---|---|---|---|

| Discharge Current Ic (A) | Pulse Duration ton (μs) | ||||

| 1. | 6 | 80 | 4.6 | 315 | 0.113 |

| 2. | 21 | 80 | 7.53 | 203 | 0.112 |

| 3. | 6 | 220 | 2.65 | 345 | 0.071 |

| 4. | 21 | 220 | 11.4 | 137 | 0.151 |

| 5. | 14 | 50 | 7.01 | 258 | 0.138 |

| 6. | 14 | 250 | 10.4 | 113 | 0.139 |

| 7. | 3 | 150 | 2.11 | 522 | 0.070 |

| 8. | 24 | 150 | 11.8 | 127 | 0.125 |

| 9. | 14 | 150 | 9.76 | 141 | 0.153 |

| 10. | 14 | 150 | 9.33 | 144 | 0.139 |

| Investigated Parameters | Calculate Regression Statistics | |||

|---|---|---|---|---|

| Ratio R | F/Fkr | p-Value | Standard Error of Estimate | |

| Sa | 0.96 | 21.58 | 0.0013 | 1.255 |

| Sds | 0.96 | 25.34 | 0.0008 | 43.53 |

| Ssc | 0.98 | 29.67 | 0.0011 | 0.008 |

| Ex. No. | Parameters | Average Thickness of the White Layer HWL (μm) | |

|---|---|---|---|

| Discharge Current Ic (A) | Pulse Duration ton (μs) | ||

| 1. | 6 | 80 | 6.5 |

| 2. | 21 | 80 | 21.2 |

| 3. | 6 | 220 | 9.5 |

| 4. | 21 | 220 | 34.4 |

| 5. | 14 | 50 | 13.5 |

| 6. | 14 | 250 | 27.2 |

| 7. | 3 | 150 | 5.24 |

| 8. | 24 | 150 | 31.3 |

| 9. | 14 | 150 | 21.2 |

| 10. | 14 | 150 | 22.5 |

| Investigated Parameter | Calculate Regression Statistics | |||

|---|---|---|---|---|

| Ratio R | F/Fkr | p-Value | Standard Error of Estimate | |

| HWL | 0.99 | 226.43 | 0.00001 | 1.17 |

| Operation | Parameters | Manufacturing Depth (mm) | |||

|---|---|---|---|---|---|

| Discharge Current Ic (A) | Discharge Voltage U (V) | Pulse Duration ton (μs) | Pulse Interval toff (μs) | ||

| Roughing | 24 | 25 | 150 | 50 | 0.1 |

| Semi finishing | 14 | 25 | 80 | 30 | 0.05 |

| Finishing | 3 | 25 | 150 | 50 | 0.05 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świercz, R.; Oniszczuk-Świercz, D. Experimental Investigation of Surface Layer Properties of High Thermal Conductivity Tool Steel after Electrical Discharge Machining. Metals 2017, 7, 550. https://doi.org/10.3390/met7120550

Świercz R, Oniszczuk-Świercz D. Experimental Investigation of Surface Layer Properties of High Thermal Conductivity Tool Steel after Electrical Discharge Machining. Metals. 2017; 7(12):550. https://doi.org/10.3390/met7120550

Chicago/Turabian StyleŚwiercz, Rafał, and Dorota Oniszczuk-Świercz. 2017. "Experimental Investigation of Surface Layer Properties of High Thermal Conductivity Tool Steel after Electrical Discharge Machining" Metals 7, no. 12: 550. https://doi.org/10.3390/met7120550

APA StyleŚwiercz, R., & Oniszczuk-Świercz, D. (2017). Experimental Investigation of Surface Layer Properties of High Thermal Conductivity Tool Steel after Electrical Discharge Machining. Metals, 7(12), 550. https://doi.org/10.3390/met7120550