The Low Strain Rate Response of As-Cast Ti-6Al-4V Alloy with an Initial Coarse Lamellar Structure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedures

3. Results

4. Discussion

4.1. Globularization

4.2. Deformation Behavior of the β Phase

4.3. Flow Instabilities

5. Conclusions

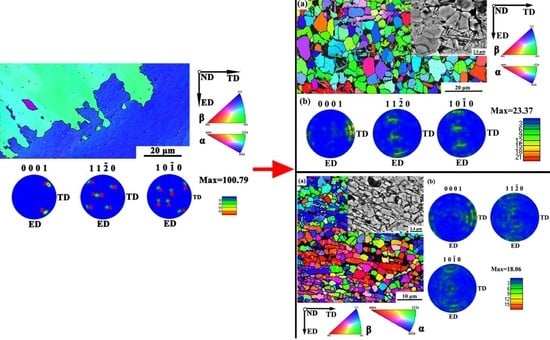

- In the ranges 900–950 °C and 10−3–10−2 s−1, globularization of the lamellar structure occurred. The process of globularization could be considered as a type of CDRX, and grain boundaries were formed by β penetrating the α platelets by diffusion. After globularization, the initial α {0001} texture softened, and the {0001} texture rotated to the TD direction. The globularization process resulted in texture randomization and the increasing strain rate led to more randomization.

- In the ranges 900–950 °C and 10−2–10−1 s−1, flow instabilities occurred; the instability mechanism was mainly flow localization, even cracking.

- In the β range, DRX occurred at a temperature of 1050 °C and a strain rate of 10−3 s−1.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, W.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti–6Al–4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Qu, S.J.; Feng, A.H.; Shen, J. Achieving grain refinement and enhanced mechanical properties in Ti–6Al–4V alloy produced by multidirectional isothermal forging. Mater. Sci. Eng. A 2017, 692, 127–138. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Luo, L.; Hu, W. Effects of processing variables and heat treatments on Al/Ti–6Al–4V interface microstructure of bimetal clad-plate fabricated via a novel route employing friction stir lap welding. J. Alloy. Compd. 2016, 658, 904–913. [Google Scholar] [CrossRef]

- Boyer, R.; Welsch, G.; Collings, E.W. (Eds.) Materials Properties Handbook: Titanium Alloys; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Prasad, Y.V.; Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G. A study of beta processing of Ti–6Al–4V: Is it trivial? J. Eng. Mater. Technol. 2001, 123, 355–360. [Google Scholar] [CrossRef]

- Prasad, Y.V.; Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G. Microstructural modeling and process control during hot working of commercial Ti–6Al–4V: Response of lamellar and equiaxed starting microstructures. Mater. Manuf. Process. 2000, 15, 581–604. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V. Unstable flow during supratransus working of Ti–6Al–4V. Mater. Lett. 2001, 47, 133–139. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Morgan, J.T.; Malas, J.C.; Frazier, W.G.; Prasad, Y.V. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4V. Mater. Sci. Eng. A 2000, 279, 289–299. [Google Scholar] [CrossRef]

- Ding, R.; Guo, Z.; Wilson, A. Microstructural evolution of a Ti–6Al–4V alloy during thermomechanical processing. Mater. Sci. Eng. A 2002, 327, 233–245. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V. Microstructural mechanisms during hot working of commercial grade Ti–6Al–4V with lamellar starting structure. Mater. Sci. Eng. A 2002, 325, 112–125. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Qu, S.J.; Feng, A.H.; Shen, J.; Chen, D.L. Hot deformation behavior of Ti–6Al–4V alloy: Effect of initial microstructure. J. Alloy. Compd. 2017, 718, 170–181. [Google Scholar] [CrossRef]

- Salem, A.A.; Semiatin, S.L. Anisotropy of the hot plastic deformation of Ti–6Al–4V single-colony samples. Mater. Sci. Eng. A 2009, 508, 114–120. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. The thermomechanical processing of alpha/beta titanium alloys. JOM 1997, 49, 33–39. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Viswanathan, G.B.; Denkenberger, R.; Furrer, D.; Fraser, H.L. The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy. Acta Mater. 2003, 51, 4679–4691. [Google Scholar] [CrossRef]

- Stanford, N.; Bate, P.S. Crystallographic variant selection in Ti–6Al–4V. Acta Mater. 2004, 52, 5215–5224. [Google Scholar] [CrossRef]

- Stefansson, N.; Semiatin, S.L.; Eylon, D. The kinetics of static globularization of Ti–6Al–4V. Metall. Mater. Trans. A 2002, 33, 3527–3534. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Brown, J.O.; Brown, T.M.; DeLo, D.P.; Bieler, T.R.; Beynon, J.H. Strain-path effects during hot working of Ti–6Al–4V with a colony-alpha microstructure. Metall. Mater. Trans. A 2001, 32, 1556–1559. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Stefansson, N.; Doherty, R.D. Prediction of the kinetics of static globularization of Ti–6Al–4V. Metall. Mater. Trans. A 2005, 36, 1372–1376. [Google Scholar] [CrossRef]

- Stefansson, N.; Semiatin, S.L. Mechanisms of globularization of Ti–6Al–4V during static heat treatment. Metall. Mater. Trans. A. 2003, 34, 691–698. [Google Scholar] [CrossRef]

- Weiss, I.; Froes, F.H.; Eylon, D.; Welsch, G.E. Modification of alpha morphology in Ti–6Al–4V by thermalmechanical processing. Metall. Trans. A. 1986, 17A, 1935–1947. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Morgan, J.T.; Malas, J.C.; Frazier, W.G.; Prasad, Y.V. Hot deformation mechanisms in ELI grade Ti–6Al–4V. Scr. Mater. 1999, 41, 283–288. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Murzinova, M.; Salishchev, G.; Semiatin, S.L. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011, 59, 4138–4150. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Mazur, A.; Salishchev, G.; Lojkowski, W. Effect of hydrostatic extrusion at 600–700 °C on the structure and properties of Ti–6Al–4V alloy. Mater. Sci. Eng. A 2008, 485, 39–45. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Salishchev, G.A.; Galeyev, R.M.; Valiakhmetov, O.R.; Mironov, S.Y.; Semiatin, S.L. Production of submicrocrystalline structure in large-scale Ti–6Al–4V billet by warm severe deformation processing. Scr. Mater. 2004, 51, 1147–1151. [Google Scholar] [CrossRef]

- Mironov, S.; Murzinova, M.; Zherebtsov, S.; Salishchev, G.A.; Semiatin, S.L. Microstructure evolution during warm working of Ti–6Al–4V with a colony-α microstructure. Acta Mater. 2009, 57, 2470–2481. [Google Scholar] [CrossRef]

| Al | V | Fe | Ti | Si | C | O | N | H |

|---|---|---|---|---|---|---|---|---|

| 6.08 | 4.03 | 0.14 | Bal. | 0.013 | 0.018 | 0.11 | 0.0047 | 0.0008 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Qu, S.; Feng, A.; Hu, X.; Shen, J. The Low Strain Rate Response of As-Cast Ti-6Al-4V Alloy with an Initial Coarse Lamellar Structure. Metals 2018, 8, 270. https://doi.org/10.3390/met8040270

Zhang Z, Qu S, Feng A, Hu X, Shen J. The Low Strain Rate Response of As-Cast Ti-6Al-4V Alloy with an Initial Coarse Lamellar Structure. Metals. 2018; 8(4):270. https://doi.org/10.3390/met8040270

Chicago/Turabian StyleZhang, Zhixiong, Shoujiang Qu, Aihan Feng, Xin Hu, and Jun Shen. 2018. "The Low Strain Rate Response of As-Cast Ti-6Al-4V Alloy with an Initial Coarse Lamellar Structure" Metals 8, no. 4: 270. https://doi.org/10.3390/met8040270

APA StyleZhang, Z., Qu, S., Feng, A., Hu, X., & Shen, J. (2018). The Low Strain Rate Response of As-Cast Ti-6Al-4V Alloy with an Initial Coarse Lamellar Structure. Metals, 8(4), 270. https://doi.org/10.3390/met8040270