Microstructure of Semi-Solid Billets Produced by Electromagnetic Stirring and Behavior of Primary Particles during the Indirect Forming Process

Abstract

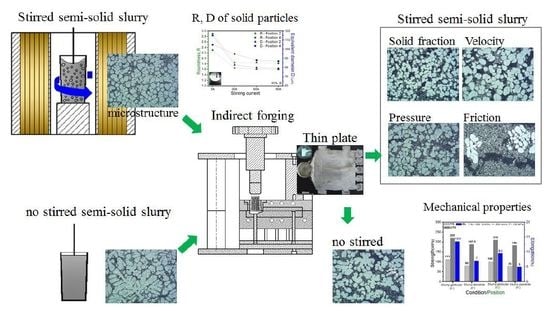

:1. Introduction

2. Experimental Procedure

2.1. Fabrication of the Semi-Solid Billet

2.1.1. Electromagnetic Stirrer

2.1.2. Parameters of Electromagnetic Stirring

2.2. Thin-Plate Forming Process

2.2.1. Die and Punch

2.2.2. Parameters of the Forming Process

2.3. Analysis of Microstructure and Mechanical Properties

2.3.1. Microstructure

2.3.2. Mechanical Properties

3. Results

3.1. Microstructures of the Semi-Solid Billet

3.2. Microstructure of the Thin Plates

3.3. Formability and Mechanical Properties of the Thin Plates

4. Conclusions

- (1)

- For unstirred semi-solid billets, a dendrite structure was dominant, while a fine globular structure was dominant for the stirred semi-solid billets. As the solid fraction increased, the primary α-Al particles became coarser and more irregularly shaped.

- (2)

- The equivalent diameter and roundness of the primary α-Al particles were significantly smaller in the stirred billets than in the unstirred billets. As the solid fraction decreased, and the stirring current increased, the equivalent diameter and roundness of the primary α-Al particles decreased.

- (3)

- The primary α-Al particle sizes were reduced as the compressing velocity was increased, while a greater number of particles could be moved if the compressing pressure was increased. As the path over which the motion occurred became smoother, the fluidity of the particles improved.

- (4)

- As a group of primary bonded α-Al particles was compressed under a large strain rate, the bonds were broken, and the group separated into individual particles. When the primary α-Al particles and residual liquid phase passed through a gate, at which the cross section was narrow, the flow velocity increased significantly, and the particles experienced turbulent flow. As wearing caused by friction and inter-particle collisions during this motion occurred, the particle shapes became increasingly spherical, because the particle sizes decreased, and the corner curvatures were increased. As the distance over which the particles moved increased, the particles were reduced in size and became more spherical.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Metz, S.A.; Flemings, M.C. Fundamental Study of Hot Tearing; American Foundrymen’s Society: Schaumburg, IL, USA, 1970; Volume 78, pp. 453–460. [Google Scholar]

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological Behavior of Sn-15 Pct Pb in the Crystallization Range. Metall. Mater. Trans. A 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Fan, Z.; Fang, X.; Ji, S. Microstructure and mechanical properties of rheo-diecast (RDC) aluminium alloys. Mater. Sci. Eng. A 2005, 412, 298–306. [Google Scholar] [CrossRef]

- Biswas, B.; Hermann, R.; Das, J.; Priede, J.; Gerbeth, G.; Acker, J. Tailoring the microstructure and mechanical properties of Ti–Al alloy using a novel electromagnetic stirring method. Scr. Mater. 2006, 55, 1143–1146. [Google Scholar] [CrossRef]

- Nafisi, S.; Emadi, D.; Shehata, M.T.; Ghomashchi, R. Effects of electromagnetic stirring and superheat on the microstructural characteristics of Al–Si–Fe alloy. Mater. Sci. Eng. A 2006, 432, 71–83. [Google Scholar] [CrossRef]

- Bae, J.B.; Kim, T.W.; Kang, C.G. Experimental investigation for rheology forming process of Al–7% Si aluminum alloy with electromagnetic system. J. Mater. Process. Technol. 2007, 191, 165–169. [Google Scholar] [CrossRef]

- Tzimas, E.; Zavaliangos, A. A comparative characterization of near-equiaxed microstructures as produced by spray casting, magnetohydrodynamic casting and the stress induced, melt activated process. Mater. Sci. Eng. A 2000, 289, 217–227. [Google Scholar] [CrossRef]

- Haga, T.; Suzuki, S. Casting of aluminum alloy ingot for thixoforming using a cooling slope. J. Mater. Process. Technol. 2001, 118, 161–172. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Yue, H.; Zhang, J.; Li, T. Microstructure evolution of A356 alloy under compound field. J. Alloy. Compd. 2009, 484, 458–462. [Google Scholar] [CrossRef]

- Canyook, R.; Wannasin, J.; Wisuthmethangkul, S.; Flemings, M.C. Characterization of flow behavior of semi-solid slurries containing low solid fractions in high-pressure die casting. Acta Mater. 2012, 60, 3501–3510. [Google Scholar] [CrossRef]

- Naflsi, S.; Lashkari, O.; Ghomashchi, R.; Ajersch, F.; Charette, A. Microstructure and rheological behavior of grain refined and modified semi-solid A356 Al–Si slurries. Acta Mater. 2006, 54, 3503–3511. [Google Scholar]

- Oh, S.W.; Bae, J.B.; Kang, C.G. Effect of Electromagnetic Stirring Conditions on Grain Size Characteristic of Wrought Aluminum for Rheo-forging. J. Mater. Eng. Perform. 2008, 17, 57–63. [Google Scholar] [CrossRef]

- Flemings, M.C. Solidification processing. Metall. Trans. 1974, 5, 2121–2134. [Google Scholar] [CrossRef]

- Hunt, J.D.; Jackson, K.A. Nucleation of solid in an undercooled liquid. J. Appl. Phys. 1966, 37, 254–257. [Google Scholar] [CrossRef]

- Seo, P.K.; Kim, D.U.; Kang, C.G. The effect of the gate shape on the microstructural characteristic of the grain size of Al–Si alloy in the semi-solid die casting process. Mater. Sci. Eng. A 2007, 445–446, 20–30. [Google Scholar] [CrossRef]

- Matsumiya, T.; Flemings, M.C. Modeling of Continuous Strip Production by Rheocasting. Metall. Trans. B 1981, 12B, 17–31. [Google Scholar] [CrossRef]

| Si | Mg | Ti | Fe | Ni | Mn | Zn | Pb | Al |

|---|---|---|---|---|---|---|---|---|

| 7.08 | 0.35 | 0.17 | 0.08 | 0.07 | 0.01 | 0.01 | 0.01 | Bal. |

| No. | Temperature (°C)/Solid Fraction (%) | Stirring | Stirring Current (A) |

|---|---|---|---|

| 1 | 600/35 | Yes | 60 |

| 2 (standard) | 590/45 | Yes | 60 |

| 3 | 578/55 | Yes | 60 |

| 4 | 600/35 | No | - |

| 5 | 590/45 | No | - |

| 6 | 578/55 | No | - |

| 7 | 590/45 | Yes | 30 |

| 8 | 590/45 | Yes | 90 |

| No. | Temperature (°C)/Solid Fraction (%) of Billets | Velocity, VP (mm/s) | Pressure, PP (MPa) | Friction Factor (m) |

|---|---|---|---|---|

| 1 | 600/35 | 300 | 200 | 0.4 |

| 2 (standard) | 590/45 | 300 | 200 | 0.4 |

| 3 | 578/55 | 300 | 200 | 0.4 |

| 4 | 590/45 | 300 | 100 | 0.4 |

| 5 | 590/45 | 30 | 200 | 0.4 |

| 6 | 590/45 | 300 | 200 | 0.9 |

| No. | Ultimate Tensile Strength (MPa) | Elongation (%) | Vickers Hardness (HV) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | Max. | Min. | Mean | Max. | Min. | Mean | Max. | Min. | |

| 1 | 190 | 202 | 186 | 7 | 9 | 6 | 64 | 66 | 63 |

| 2 | 205 | 210 | 198 | 8 | 10 | 7 | 65 | 66 | 64 |

| 3 | 188 | 192 | 185 | 5 | 6 | 4 | 66 | 68 | 65 |

| 4 | 175 | 181 | 170 | 6 | 7 | 5 | 67 | 69 | 65 |

| 5 | 160 | 165 | 154 | 6 | 7 | 6 | 62 | 65 | 61 |

| 6 | 125 | 130 | 122 | 3 | 3 | 2 | 89 | 90 | 87 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.K. Microstructure of Semi-Solid Billets Produced by Electromagnetic Stirring and Behavior of Primary Particles during the Indirect Forming Process. Metals 2018, 8, 271. https://doi.org/10.3390/met8040271

Jin CK. Microstructure of Semi-Solid Billets Produced by Electromagnetic Stirring and Behavior of Primary Particles during the Indirect Forming Process. Metals. 2018; 8(4):271. https://doi.org/10.3390/met8040271

Chicago/Turabian StyleJin, Chul Kyu. 2018. "Microstructure of Semi-Solid Billets Produced by Electromagnetic Stirring and Behavior of Primary Particles during the Indirect Forming Process" Metals 8, no. 4: 271. https://doi.org/10.3390/met8040271

APA StyleJin, C. K. (2018). Microstructure of Semi-Solid Billets Produced by Electromagnetic Stirring and Behavior of Primary Particles during the Indirect Forming Process. Metals, 8(4), 271. https://doi.org/10.3390/met8040271