Insights into Machining of a β Titanium Biomedical Alloy from Chip Microstructures

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Workpiece Material

3.2. Machining Chip Characteristics

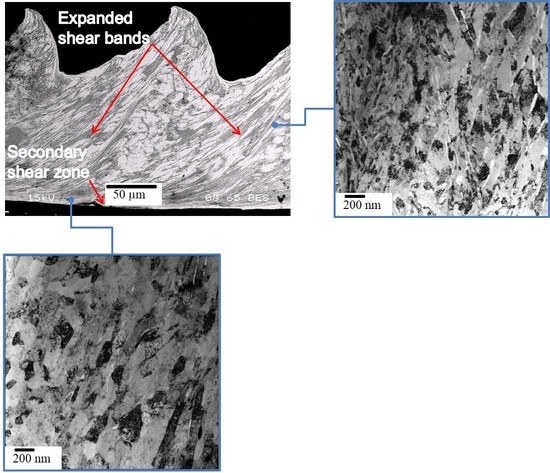

3.3. Transmission Electron Microscopy (TEM) Analysis of Expanded Shear Band Region

3.4. TEM Analysis of Secondary Shear Zone

4. Discussion

5. Conclusions

- High levels of deformation in the primary shear zone promote extensive refinement of the β phase within expanded shear band regions approximately 100 µm in width to almost equiaxed grains with sizes below 100 nm in regions of intense deformation, while α phase laths frequently occupy the grain boundaries aligned to the shear direction. There is a transition to firstly elongated β grains and then to larger diamond-shaped β grains in adjoining regions of less intense deformation. The presence of a high density of α phase laths across the entire expanded shear band region suggests that temperatures in this region are likely in the range of 400–600 °C during cutting.

- For the secondary shear zone, large strains at the cutting interface result in recrystallised, approximately equiaxed grains with nanocrystalline grain sizes around 20–50 nm, while further (1–2 µm) from the interface the β grains become highly elongated in the shear direction with grains in the order of 100 nm in width and 0.5 to 1 μm in length. At the cutting interface, an absence of the α phase indicates that the temperatures exceed the alloy’s 720 °C β transus temperature. At 5–10 µm, from the cutting interface a mixture of large elongated β grains and long α phase laths are observed. The microstructural variation across the secondary shear zone reflects the decay of strain and temperature away from the cutting interface.

- The microstructural characterisation of the chips infers information on the temperature fields present across the chips during cutting. The highest cutting temperatures occur within the secondary shear zone at the cutting interface, associated with proportionately high levels of heat generation due to deformation and friction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical biocompatabilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Ping, D.H.; Mitarai, Y.; Yin, F.X. Microstructure and shape memory behavior of a Ti-30Nb-3Pd alloy. Scr. Mater. 2005, 52, 1287–1291. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, G.; Ma, X.Q.; Dargusch, M.S.; Han, J.Y.; Yu, S. Development of biomedical near beta titanium alloys. In Materials Science Forum: 4th International Light Metals Technology Conference; Trans Tech Publications: Zurich, Switzerland, 2009. [Google Scholar]

- Kent, D.; Wang, G.; Yu, Z.; Dargusch, M.S. Pseudoelastic behaviour of a β Ti-25Nb-3Zr-3Mo-2Sn alloy. Mater. Sci. Eng. A 2010, 527, 2246–2252. [Google Scholar] [CrossRef]

- Kent, D.; Wang, G.; Yu, Z.; Ma, X.; Dargusch, M.S. Strength enhancement of a biomedical titanium alloy through a modified accumulative roll bonding technique. J. Mech. Behav. Biomed. Mater. 2011, 4, 405–416. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.; Wong, Y.S.; Zareena, A.R. Machinability of titanium alloys. JSME Int. J. Ser. C 2003, 46, 107–115. [Google Scholar] [CrossRef]

- Yang, X.; Liu, C.R. Machining titanium and its alloys. Mach. Sci. Technol. 1999, 3, 107–139. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Machado, A.R.; Wallbank, J. Machining of titanium and its alloys—A review. Proc. Inst. Mech. Eng. Part B 1990, 204, 53–60. [Google Scholar] [CrossRef]

- Uzer, B.; Toker, S.M.; Cingoz, A.; Bagci-Onder, T.; Gerstein, G.; Maier, H.J.; Canadinc, D. An exploration of plastic deformation dependence of cell viability and adhesion in metallic implant materials. J. Mech. Behav. Biomed. Mater. 2016, 60, 177–186. [Google Scholar] [CrossRef] [PubMed]

- Rashid, R.A.R.; Sun, S.; Wang, G.; Dargusch, M.S. Machinability of a near beta titanium alloy. Proc. Inst. Mech. Eng. Part B 2011, 225, 2151–2162. [Google Scholar] [CrossRef]

- Rashid, R.A.R.; Sun, S.; Wang, G.; Dargusch, M.S. Experimental investigation of various chip parameters during machining of the Ti25Nb3Mo3Zr2Sn beta titanium alloy. Adv. Mat. Res. 2013, 622, 366–369. [Google Scholar] [CrossRef]

- Schneider, J.; Dong, L.; Howe, J.Y.; Meyer, H.M. Microstructural characterization of Ti-6Al-4V metal chips by focused ion beam and transmission electron microscopy. Metall. Mater. Trans. A 2011, 42, 3527–3533. [Google Scholar] [CrossRef]

- Zhan, H.; Zeng, W.; Wang, G.; Kent, D.; Dargusch, M. On the deformation mechanisms and strain rate sensitivity of a metastable β Ti-Nb alloy. Scr. Mater. 2015, 107, 34–37. [Google Scholar] [CrossRef]

- Zhan, H.; Wang, G.; Kent, D.; Dargusch, M. The dynamic response of a metastable β Ti-Nb alloy to high strain rates at room and elevated temperatures. Acta Mater. 2016, 105, 104–113. [Google Scholar] [CrossRef]

- Ye, G.G.; Xue, S.F.; Ma, W.; Dai, L.H. Onset and evolution of discontinuously segmented chip flow in ultra-high-speed cutting Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2017, 88, 1161–1174. [Google Scholar] [CrossRef]

- Hughes, G.D.; Smith, S.D.; Pande, C.S.; Johnson, H.R.; Armstrong, R.W. Hall-petch strengthening for the microhardness of twelve nanometer grain diameter electrodeposited nickel. Scr. Metall. 1986, 20, 93–97. [Google Scholar] [CrossRef]

- Zhentao, Y.; Lian, Z. Influence of martensitic transformation on mechanical compatibility of biomedical β type titanium alloy tlm. Mater. Sci. Eng. A 2006, 438, 391–394. [Google Scholar] [CrossRef]

- Kent, D.; Pas, S.; Zhu, S.; Wang, G.; Dargusch, M.S. Thermal analysis of precipitation reactions in a Ti–25nb–3mo–3zr–2sn alloy. Appl. Phys. A 2012, 107, 835–841. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Li, Z.; Ma, R.; Zhao, S.; Xie, F.; Zhang, X. Shear localization and microstructure in coarse grained beta titanium alloy. Mater. Sci. Eng. A 2016, 652, 287–295. [Google Scholar] [CrossRef]

- Ye, G.G.; Xue, S.F.; Jiang, M.Q.; Tong, X.H.; Dai, L.H. Modeling periodic adiabatic shear band evolution during high speed machining Ti-6Al-4V alloy. Int. J. Plast. 2013, 40, 39–55. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Garay, A.; Iriarte, L.M.; Armendia, M.; Marya, S.; Le Maître, F. Machinability of titanium alloys (Ti6Al4V and Ti555.3). J. Mater. Process. Technol. 2009, 209, 2223–2230. [Google Scholar] [CrossRef]

- Joshi, S.; Pawar, P.; Tewari, A.; Joshi, S.S. Effect of β phase fraction in titanium alloys on chip segmentation in their orthogonal machining. CIRP J. Manuf. Sci. Technol. 2014, 7, 191–201. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M.S. Characteristics of cutting forces and chip formation in machining of titanium alloys. Int. J. Mach. Tool. Manuf. 2009, 49, 561–568. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Sun, S.; Kim, J.W.; Li, T.; Trimby, P.; Cairney, J. Effect of tool wear evolution on chip formation during dry machining of ti-6al-4v alloy. Int. J. Adv. Manuf. Tech. 2018, 126, 13–17. [Google Scholar] [CrossRef]

- Oxley, P.L.B. Mechanics of Machining; Ellis Horwood: New York, NY, USA, 1989. [Google Scholar]

- Zhan, H.; Zeng, W.; Wang, G.; Kent, D.; Dargusch, M. Microstructural characteristics of adiabatic shear localization in a metastable beta titanium alloy deformed at high strain rate and elevated temperatures. Mater. Charact. 2015, 102, 103–113. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, F.; Zhou, B.M.; Li, X.M.; Zheng, H.G.; Zhang, Q.M. Microstructural characterization and evolution mechanism of adiabatic shear band in a near beta-ti alloy. Mater. Sci. Eng. A 2011, 528, 2787–2794. [Google Scholar] [CrossRef]

- Davies, M.A.; Ueda, T.; M’Saoubi, R.; Mullany, B.; Cooke, A.L. On the measurement of temperature in material removal processes. CIRP Ann. Manuf. Technol. 2007, 56, 581–604. [Google Scholar] [CrossRef]

- Lane, B.; Whitenton, E.; Madhavan, V.; Donmez, A. Uncertainty of temperature measurements by infrared thermography for metal cutting applications. Metrologia 2013, 50, 637–653. [Google Scholar] [CrossRef]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining. Int. J. Mach. Tool. Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Sutter, G.; Ranc, N. Temperature fields in a chip during high-speed orthogonal cutting—an experimental investigation. Int. J. Mach. Tool. Manuf. 2007, 47, 1507–1517. [Google Scholar] [CrossRef]

- Tay, A.O.; Stevenson, M.G.; De Vahl Davis, G. Using the finite element method to determine temperature distributions in orthogonal machining. Proc. Inst. Mech. Eng. 1974, 188, 627–638. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kent, D.; Rahman Rashid, R.; Bermingham, M.; Attar, H.; Sun, S.; Dargusch, M. Insights into Machining of a β Titanium Biomedical Alloy from Chip Microstructures. Metals 2018, 8, 710. https://doi.org/10.3390/met8090710

Kent D, Rahman Rashid R, Bermingham M, Attar H, Sun S, Dargusch M. Insights into Machining of a β Titanium Biomedical Alloy from Chip Microstructures. Metals. 2018; 8(9):710. https://doi.org/10.3390/met8090710

Chicago/Turabian StyleKent, Damon, Rizwan Rahman Rashid, Michael Bermingham, Hooyar Attar, Shoujin Sun, and Matthew Dargusch. 2018. "Insights into Machining of a β Titanium Biomedical Alloy from Chip Microstructures" Metals 8, no. 9: 710. https://doi.org/10.3390/met8090710

APA StyleKent, D., Rahman Rashid, R., Bermingham, M., Attar, H., Sun, S., & Dargusch, M. (2018). Insights into Machining of a β Titanium Biomedical Alloy from Chip Microstructures. Metals, 8(9), 710. https://doi.org/10.3390/met8090710