Refined Microstructure and Enhanced Hardness in Friction Stir-Welded AZ31 Magnesium Alloy Induced by Heat Pipe with Different Cooling Liquid

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Heat Pipe-Assisted Friction Stir Welding Setup and Welding Procedure

2.3. Measurement of Temperature Field

2.4. Microstructural Characterizations

2.5. Measurement of Hardness

3. Results and Discussion

3.1. Thermal Cycle Curve

3.2. Duration of the Temperature above 200 °C

3.3. Macrostructure of the Joint

3.4. Microstructure of the Joint

3.5. Hardness of the Joints

4. Conclusions

- (1)

- The peak temperatures of the feature points at both advancing side (AS, 380 °C) and retreating side (RS, 372 °C) during the conventional friction stir welding process are higher than those (367 °C at AS and 345 °C at RS) under the assistance of the heat pipe with ambient water. After using ice water as cooling liquid, the peak temperatures of the featured points at both AS (339 °C) and RS (321 °C) are further reduced.

- (2)

- Owing to the application of heat pipe, the durations of high temperature at both AS and RS continuously decrease as the cooling intensity enhances. Correspondingly, the cooling rates of the feature points increase after applying the heat pipe. Especially, the cooling rates of the featured points A3 and R3 respectively decrease by 0.64 °C/s and 2.38 °C/s under the assistance of the heat pipe with ice water compared with the conventional condition.

- (3)

- The width of the top area (6.86 mm) and the middle area (4.18 mm) of the weld nugget zone (WNZ) decreases obviously when the heat pipe is applied in the FSW process with the ambient temperature water as cooling liquid, compared with those (9.08 mm of the top area and 5.45 mm of the middle area) under the conventional condition. Moreover, the top area (5.28 mm) and the middle area (3.81 mm) has a further reduction in the width when ice water is employed as cooling liquid. However, the difference in the width of the bottom parts is not obvious due to the relatively low cooling effect of the heat pipe on this area.

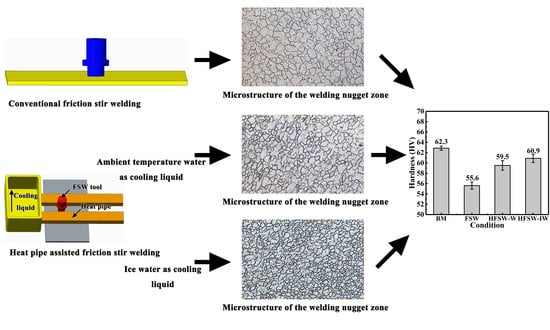

- (4)

- The microstructure of the WNZ becomes refined (average grain size: 16.8 μm) when the heat pipe is applied in the FSW process with the cooling liquid of ambient temperature water compared with that under the conventional condition (average grain size: 19.2 μm). After applying ice water as the cooling liquid, the average grain size in WNZ becomes 12 μm. Hence, the hardness of WNZ rises up to 59.5 HV when heat pipe is applied in the FSW process compared with the conventional condition (55.6 HV) due to the significant decrease in grain size. The larger increase in the hardness (60.9 HV) is presented when ice water is used as cooling liquid.

Author Contributions

Funding

Conflicts of Interest

References

- Commin, L.; Dumont, M.; Masse, J.E.; Barrallier, L. Friction stir welding of AZ31 magnesium alloy rolled sheets: Influence of processing parameters. Acta Mater. 2009, 57, 326–334. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fata, A.; Faraji, G.; Mashhadi, M.M. Hot tensile deformation behavior of Mg-Zn-Al magnesium alloy tubes processed by severe plastic deformation. J. Alloys Compd. 2018, 742, 442–453. [Google Scholar] [CrossRef]

- Luo, X.C.; Zhang, D.T.; Zhang, W.W.; Qiu, C.; Chen, D.L. Tensile properties of AZ61 magnesium alloy produced by multi-pass friction stir processing: Effect of sample orientation. Mater. Sci. Eng. A 2018, 725, 398–405. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, Y.; Wang, T.; Zhang, Q.; Wei, X.; Fang, X.; Zhu, G.; Gao, S. Microstructure and mechanical properties of AZ31 magnesium alloy sheets processed by constrained groove pressing. Mater. Sci. Eng. A 2019, 745, 450–459. [Google Scholar] [CrossRef]

- Wang, Z.-X.; Chen, G.-Q.; Chen, L.-Y.; Xu, L.; Lu, S. Degradation Behavior of Micro-Arc Oxidized ZK60 Magnesium Alloy in a Simulated Body Fluid. Metals 2018, 8, 724. [Google Scholar] [CrossRef]

- Čapek, J.; Knapek, M.; Minárik, P.; Dittrich, J.; Máthis, K. Characterization of deformation mechanisms in Mg alloys by advanced acoustic emission methods. Metals 2018, 8, 1–11. [Google Scholar]

- Li, Q.; Yan, X.; Luo, L.; Xu, F.; Wu, G.; Liu, C.; Jing, Y.; Liu, Y.; Lu, J. Mechanical properties and corrosion behaviors of AZ31 alloy with dual-phase glass-crystal coating. Mater. Charact. 2019, 154, 200–211. [Google Scholar] [CrossRef]

- Subramanian, J.; Loh, Z.; Seetharaman, S.; Hamouda, A.S.; Gupta, M. Microstructure and mechanical properties of Mg-5Nb metal-metal composite reinforced with nano SiC ceramic particles. Metals 2012, 2, 178–194. [Google Scholar] [CrossRef]

- Malarvizhi, S.; Balasubramanian, V. Effect of welding processes on AA2219 aluminium alloy joint properties. Trans. Nonferrous Met. Soc. China 2011, 21, 962–973. [Google Scholar] [CrossRef]

- He, Z.B.; Peng, Y.Y.; Yin, Z.M.; Lei, X.F. Comparison of FSW and TIG welded joints in Al-Mg-Mn-Sc-Zr alloy plates. Trans. Nonferrous Met. Soc. China 2011, 21, 1685–1691. [Google Scholar] [CrossRef]

- Chen, Y.; He, C.; Yang, K.; Zhang, H.; Wang, C.; Wang, Q.; Liu, Y. Effects of microstructural inhomogeneities and micro-defects on tensile and very high cycle fatigue behaviors of the friction stir welded ZK60 magnesium alloy joint. Int. J. Fatigue 2019, 122, 218–227. [Google Scholar] [CrossRef]

- Hiscocks, J.; Diak, B.J.; Gerlich, A.P.; Daymond, M.R. Strain localisation and failure of dissimilar magnesium-based alloy friction stir welds. Sci. Technol. Weld. Join. 2018, 23, 628–634. [Google Scholar] [CrossRef]

- Mishra, R.S.; De, P.S.; Kumar, N. Friction Stir Welding and Processing; Springer: Berlin, Germany, 2014; ISBN 9783319486048. [Google Scholar]

- Shinde, G.; Gajghate, S.; Dabeer, P.S.; Seemikeri, C.Y. Low cost friction stir welding: A review. Mater. Today Proc. 2017, 4, 8901–8910. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y. A review on biomedical titanium alloys: Recent progress and prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Wang, L.; Xie, L.; Lv, Y.; Zhang, L.C.; Chen, L.; Meng, Q.; Qu, J.; Zhang, D.; Lu, W. Microstructure evolution and superelastic behavior in Ti-35Nb-2Ta-3Zr alloy processed by friction stir processing. Acta Mater. 2017, 131, 499–510. [Google Scholar] [CrossRef]

- Wahid, M.A.; Khan, Z.A.; Siddiquee, A.N. Review on underwater friction stir welding: A variant of friction stir welding with great potential of improving joint properties. Trans. Nonferrous Met. Soc. China 2018, 28, 193–219. [Google Scholar] [CrossRef]

- Dobriyal, R.P.; Dhindaw, B.K.; Muthukumaran, S.; Mukherjee, S.K. Microstructure and properties of friction stir butt-welded AE42 magnesium alloy. Mater. Sci. Eng. A 2008, 477, 243–249. [Google Scholar] [CrossRef]

- Pan, F.; Xu, A.; Deng, D.; Ye, J.; Jiang, X.; Tang, A.; Ran, Y. Effects of friction stir welding on microstructure and mechanical properties of magnesium alloy Mg-5Al-3Sn. Mater. Des. 2016, 110, 266–274. [Google Scholar] [CrossRef]

- Silva-Magalhães, A.; De Backer, J.; Martin, J.; Bolmsjö, G. In-situ temperature measurement in friction stir welding of thick section aluminium alloys. J. Manuf. Process. 2019, 39, 12–17. [Google Scholar] [CrossRef]

- Swarnkar, A.; Kumar, R.; Suri, A.; Sahay, A. A review on Friction Stir Welding: An environment friendly welding technique. In Proceedings of the 2016 IEEE Region 10 Humanitarian Technology Conference (R10-HTC), Agra, India, 21–23 December 2016; pp. 1–4. [Google Scholar]

- Darras, B.; Kishta, E. Submerged friction stir processing of AZ31 Magnesium alloy. Mater. Des. 2013, 47, 133–137. [Google Scholar] [CrossRef]

- Lu, S.; Chen, J.; Jia, X.D.; Wang, Z.X.; Gong, J.J. Thermal cycle characteristics of AM 50 magnesium alloy welded by FSW. Key Eng. Mater. 2009, 419–420, 533–536. [Google Scholar] [CrossRef]

- Mehta, K.P.; Carlone, P.; Astarita, A.; Scherillo, F.; Rubino, F.; Vora, P. Conventional and cooling assisted friction stir welding of AA6061 and AZ31B alloys. Mater. Sci. Eng. A 2019, 759, 252–261. [Google Scholar] [CrossRef]

- Liu, H.J.; Zhang, H.J.; Huang, Y.X.; Yu, L. Mechanical properties of underwater friction stir welded 2219 aluminum alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 1387–1391. [Google Scholar] [CrossRef]

- Wang, B.B.; Chen, F.F.; Liu, F.; Wang, W.G.; Xue, P.; Ma, Z.Y. Enhanced mechanical properties of friction stir welded 5083Al-H19 joints with additional water cooling. J. Mater. Sci. Technol. 2017, 33, 1009–1014. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, Y.; Ji, S.; Xiong, L. Fatigue properties of Ti-6Al-4V alloy friction stir welding joint obtained under rapid cooling condition. J. Manuf. Process. 2018, 36, 238–247. [Google Scholar] [CrossRef]

- Xu, N.; Ueji, R.; Morisada, Y.; Fujii, H. Modification of mechanical properties of friction stir welded Cu joint by additional liquid CO2 cooling. Mater. Des. 2014, 56, 20–25. [Google Scholar] [CrossRef]

- Ramaiyan, S.; Chandran, R.; Santhanam, S.K.V. Effect of cooling conditions on mechanical and microstructural behaviours of friction stir processed AZ31B Mg alloy. Mod. Mech. Eng. 2017, 7, 144–160. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, W.; Chen, S.J.; Yao, S.G. Effect of flat heat pipe on the properties of the FSW joint. Mater. Sci. Forum 2016, 850, 693–699. [Google Scholar] [CrossRef]

- Mustaffar, A.; Phan, A.N.; Reay, D.; Boodhoo, K. Concentric annular heat pipe characterisation analysis for a drying application. Appl. Therm. Eng. 2019, 149, 275–286. [Google Scholar] [CrossRef]

- Grover, G.M.; Cotter, T.P.; Erickson, G.F. Structures of very high thermal conductance. J. Appl. Phys. 1964, 35, 1990–1991. [Google Scholar] [CrossRef]

- Han, X.; Wang, X.; Zheng, H.; Xu, X.; Chen, G. Review of the development of pulsating heat pipe for heat dissipation. Renew. Sustain. Energy Rev. 2016, 59, 692–709. [Google Scholar] [CrossRef]

- Mahdavi, M.; Tiari, S.; De Schampheleire, S.; Qiu, S. Experimental study of the thermal characteristics of a heat pipe. Exp. Therm. Fluid Sci. 2018, 93, 292–304. [Google Scholar] [CrossRef]

- Xiahou, G.; Zhang, J.; Ma, R.; Liu, Y. Novel heat pipe radiator for vertical CPU cooling and its experimental study. Int. J. Heat Mass Transf. 2019, 130, 912–922. [Google Scholar] [CrossRef]

- Gajalakshmi, K.; Palanivel, S.; Nalini, N.J.; Saravanan, S.; Raghukandan, K. Grain size measurement in optical microstructure using support vector regression. Optik (Stuttg) 2017, 138, 320–327. [Google Scholar]

- Lu, S.; Xiao, S.Y.; Qi, F.; Chen, J. Microstructure and mechanical property along 3D directions of AZ31 magnesium joint welded by FSW. Adv. Mater. Res. 2012, 567, 187–191. [Google Scholar] [CrossRef]

- Albakri, A.N.; Mansoor, B.; Nassar, H.; Khraisheh, M.K. Thermo-mechanical and metallurgical aspects in friction stir processing of AZ31 Mg alloy—A numerical and experimental investigation. J. Mater. Process. Technol. 2013, 213, 279–290. [Google Scholar] [CrossRef]

- Milagre, M.X.; Mogili, N.V.; Donatus, U.; Giorjão, R.A.R.; Terada, M.; Araujo, J.V.S.; Machado, C.S.C.; Costa, I. On the microstructure characterization of the AA2098-T351 alloy welded by FSW. Mater. Charact. 2018, 140, 233–246. [Google Scholar] [CrossRef]

- Huang, Q.; Li, X.; Zhang, G.; Zhang, J.; He, F.; Li, Y. Experimental investigation of the thermal performance of heat pipe assisted phase change material for battery thermal management system. Appl. Therm. Eng. 2018, 141, 1092–1100. [Google Scholar] [CrossRef]

- Shah, P.H.; Badheka, V. An experimental investigation of temperature distribution and joint properties of Al 7075 T651 friction stir welded aluminium alloys. Procedia Technol. 2016, 23, 543–550. [Google Scholar] [CrossRef] [Green Version]

- Serindag, H.T.; Kiral, B.G. Friction stir welding of AZ31 magnesium alloys—A numerical and experimental study. Lat. Am. J. Solids Struct. 2017, 14, 113–130. [Google Scholar] [CrossRef] [Green Version]

- Lu, S.; Yang, D.L.; Xiao, S.Y.; Chen, S.J. Three-dimensional investigation on temperature distribution and mechanical properties of AZ31Mg alloy joint welded by FSW. In Proceedings of the 1st International Joint Symposium on Joining and Welding, Osaka, Japan, 6–8 November 2013; pp. 67–72. [Google Scholar]

- Zhang, S.; Shi, Q.; Liu, Q.; Xie, R.; Zhang, G.; Chen, G. Effects of tool tilt angle on the in-process heat transfer and mass transfer during friction stir welding. Int. J. Heat Mass Transf. 2018, 125, 32–42. [Google Scholar] [CrossRef]

- Chen, G.Q.; Shi, Q.Y.; Li, Y.J.; Sun, Y.J.; Dai, Q.L.; Jia, J.Y.; Zhu, Y.C.; Wu, J.J. Computational fluid dynamics studies on heat generation during friction stir welding of aluminum alloy. Comput. Mater. Sci. 2013, 79, 540–546. [Google Scholar] [CrossRef]

- Chen, G.; Wang, G.; Shi, Q.; Zhao, Y.; Hao, Y.; Zhang, S. Three-dimensional thermal-mechanical analysis of retractable pin tool friction stir welding process. J. Manuf. Process. 2019, 41, 1–9. [Google Scholar] [CrossRef]

- Long, L.; Chen, G.; Zhang, S.; Liu, T.; Shi, Q. Finite-element analysis of the tool tilt angle effect on the formation of friction stir welds. J. Manuf. Process. 2017, 30, 562–569. [Google Scholar] [CrossRef]

- Xin, F.; Ma, T.; Wang, Q. Theoretical analysis of flat heat pipe with graded-porosity wick design. Energy Procedia 2017, 142, 3932–3938. [Google Scholar] [CrossRef]

- Pandiyaraj, P.; Gnanavelbabu, A.; Saravanan, P. Experimental analysis on thermal performance of fabricated flat plate heat pipe using titanium dioxide nanofluid. Mater. Today Proc. 2018, 5, 8414–8423. [Google Scholar] [CrossRef]

- Nguyen, T.T.T.; Kundan, A.; Wayner, P.C.; Plawsky, J.L.; Chao, D.F.; Sicker, R.J. Effects of cooling temperature on heat pipe evaporator performance using an ideal fluid mixture in microgravity. Exp. Therm. Fluid Sci. 2016, 75, 108–117. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.U.; Kim, S.H.; Song, S.W.; Lee, C.S.; Park, S.H. Dynamic recrystallization behavior and microstructural evolution of Mg alloy AZ31 through high-speed rolling. J. Mater. Sci. Technol. 2018, 34, 1747–1755. [Google Scholar] [CrossRef]

- Yang, X.; Ji, Z.; Miura, H.; Sakai, T. Dynamic recrystallization and texture development during hot deformation of magnesium alloy AZ31. Trans. Nonferrous Met. Soc. Chin. 2009, 19, 55–60. [Google Scholar] [CrossRef]

- Mironov, S.; Onuma, T.; Sato, Y.S.; Kokawa, H. Microstructure evolution during friction-stir welding of AZ31 magnesium alloy. Acta Mater. 2015, 100, 301–312. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Zhang, Y.; Lu, W.; Zhang, L.-C.; Wang, L.; Zhang, D. Effect of low-temperature pre-deformation on precipitation behavior and microstructure of a Zr-Sn-Nb-Fe-Cu-O alloy during fabrication. J. Nucl. Sci. Technol. 2016, 53, 496–507. [Google Scholar] [CrossRef]

- Wang, L.; Qu, J.; Chen, L.; Meng, Q.; Zhang, L.-C.; Qin, J.; Zhang, D.; Lu, W. Investigation of deformation mechanisms in β-Type Ti-35Nb-2Ta-3Zr alloy via FSP leading to surface strengthening. Metall. Mater. Trans. A 2015, 46, 4813–4818. [Google Scholar] [CrossRef]

- Afrin, N.; Chen, D.L.; Cao, X.; Jahazi, M. Microstructure and tensile properties of friction stir welded AZ31B magnesium alloy. Mater. Sci. Eng. A 2008, 472, 179–186. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Sang, P.; Zhang, L.; Song, D.; Chu, Y.-Q.; Chai, L.; Zhang, L.-C. Homogenization and growth behavior of second-phase particles in a deformed Zr–Sn-Nb-Fe-Cu-Si-O alloy. Metals 2018, 8, 759. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.C.; Xu, J.; Ma, E. Mechanically Alloyed Amorphous Ti50(Cu0.45Ni0.55)44–xAlxSi4B2 Alloys with Supercooled Liquid Region. J. Mater. Res. 2002, 17, 1743–1749. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.Y.; Xu, T.; Lu, S.; Wang, Z.X.; Chen, S.; Zhang, L.C. Improved hardness and wear resistance of plasma sprayed nanostructured NiCrBSi coating via short-time heat treatment. Surf. Coatings Technol. 2018, 350, 436–444. [Google Scholar] [CrossRef]

- Zhang, L.C.; Shen, Z.Q.; Xu, J. Mechanically milling-induced amorphization in Sn-containing Ti-based multicomponent alloy systems. Mater. Sci. Eng. A 2005, 394, 204–209. [Google Scholar] [CrossRef]

- Yang, Z.N.; Wang, X.B.; Liu, F.; Zhang, F.C.; Chai, L.J.; Qiu, R.S.; Chen, L.Y. Effect of intercritical annealing temperature on microstructure and mechanical properties of duplex Zr-2.5Nb alloy. J. Alloys Compd. 2019, 776, 242–249. [Google Scholar] [CrossRef]

- Zhang, M.; Li, Y.N.; Zhang, F.C.; Wang, X.B.; Chen, L.Y.; Yang, Z.N. Effect of annealing treatment on the microstructure and mechanical properties of a duplex Zr-2.5 Nb alloy. Mater. Sci. Eng. A 2017, 706, 236–241. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Zhang, Y.; Zhang, L.C.; Lu, W.; Wang, L.; Zhang, L.; Zhang, D. Zr-Sn-Nb-Fe-Si-O alloy for fuel cladding candidate: Processing, microstructure, corrosion resistance and tensile behavior. Corros. Sci. 2015, 100, 332–340. [Google Scholar] [CrossRef]

- Chen, L.; Zeng, Q.; Li, J.; Lu, J.; Zhang, Y.; Zhang, L.C.; Qin, X.; Lu, W.; Zhang, L.; Wang, L.; et al. Effect of microstructure on corrosion behavior of a Zr-Sn-Nb-Fe-Cu-O alloy. Mater. Des. 2016, 92, 888–896. [Google Scholar] [CrossRef]

- Kumar, P.P.; Bharat, A.R.; Sai, B.S.; Sarath, R.J.P.; Akhil, P. ScienceDirect Role of microstructure and secondary phase on corrosion behavior of heat treated AZ series magnesium alloys. Mater. Today Proc. 2019, 18, 175–181. [Google Scholar] [CrossRef]

- Xiong, X.; Yang, Y.; Li, J.; Li, M.; Peng, J.; Wen, C. Research on the microstructure and properties of a multi-pass friction stir processed 6061Al coating for AZ31 Mg alloy. J. Magnes. Alloy. 2019, 8, 552–562. [Google Scholar] [CrossRef]

- Zhao, G.; Fan, J.; Zhang, H.; Zhang, Q.; Yang, J.; Dong, H.; Xu, B. Exceptional mechanical properties of ultra-fine grain AZ31 alloy by the combined processing of ECAP, rolling and EPT. Mater. Sci. Eng. A 2018, 731, 54–60. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, H.; Jiang, X.; Yuan, T.; Han, Y.; Li, X. Mechanical properties of electric assisted friction stir welded 2219 aluminum alloy. J. Manuf. Process. 2019, 44, 197–206. [Google Scholar] [CrossRef]

- Chen, L.Y.; Shen, P.; Zhang, L.; Lu, S.; Chai, L.; Yang, Z.; Zhang, L.C. Corrosion behavior of non-equilibrium Zr-Sn-Nb-Fe-Cu-O alloys in high-temperature 0.01 M LiOH aqueous solution and degradation of the surface oxide films. Corros. Sci. 2018, 136, 221–230. [Google Scholar] [CrossRef]

- Chai, L.; Chen, K.; Zhi, Y.; Murty, K.L.; Chen, L.Y.; Yang, Z. Nanotwins induced by pulsed laser and their hardening effect in a Zr alloy. J. Alloys Compd. 2018, 748, 163–170. [Google Scholar] [CrossRef]

- Calin, M.; Zhang, L.C.; Eckert, J. Tailoring of microstructure and mechanical properties of a Ti-based bulk metallic glass-forming alloy. Scr. Mater. 2007, 57, 1101–1104. [Google Scholar] [CrossRef]

- Su, L.H.; Lu, C.; He, L.Z.; Zhang, L.C.; Guagliardo, P.; Tieu, A.K.; Samarin, S.N.; Williams, J.F.; Li, H.J. Study of vacancy-type defects by positron annihilation in ultrafine-grained aluminum severely deformed at room and cryogenic temperatures. Acta Mater. 2012, 60, 4218–4228. [Google Scholar] [CrossRef] [Green Version]

| Al | Zn | Si | Fe | Cu | Mn | Mg |

|---|---|---|---|---|---|---|

| 3.62 | 1.24 | 0.05 | 0.01 | 0.01 | 0.02 | Bal |

| Serial Number | Name | Welding Condition |

|---|---|---|

| 1 | FSW | Joints obtained under the conventional friction stir welding condition. |

| 2 | HFSW-W | Joints obtained when heat pipe is applied into the welding process and the ambient temperature water is employed as cooling liquid in the condensing tank since the time reached 77 s. |

| 3 | HFSW-IW | Joints obtained when heat pipe is applied into the welding process and the ambient temperature water is turned into ice water since the time reached 101 s. |

| Sample | Feature Point (AS/RS) | ||||

|---|---|---|---|---|---|

| A1/R1 | A2/R2 | A3/R3 | A4/R4 | A5/R5 | |

| FSW | 328/289 | 342/308 | 343/333 | 366/351 | 380/375 |

| HFSW-W | 264/225 | 329/288 | 322/313 | 327/323 | 367/346 |

| HFSW-IW | 241/225 | 289/272 | 306/287 | 326/330 | 339/321 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-M.; Chen, L.-Y.; Lu, S.; Zhao, C.; Wang, Y.-H. Refined Microstructure and Enhanced Hardness in Friction Stir-Welded AZ31 Magnesium Alloy Induced by Heat Pipe with Different Cooling Liquid. Metals 2019, 9, 1227. https://doi.org/10.3390/met9111227

Zhang Y-M, Chen L-Y, Lu S, Zhao C, Wang Y-H. Refined Microstructure and Enhanced Hardness in Friction Stir-Welded AZ31 Magnesium Alloy Induced by Heat Pipe with Different Cooling Liquid. Metals. 2019; 9(11):1227. https://doi.org/10.3390/met9111227

Chicago/Turabian StyleZhang, Yu-Meng, Liang-Yu Chen, Sheng Lu, Cuihua Zhao, and Yi-Hao Wang. 2019. "Refined Microstructure and Enhanced Hardness in Friction Stir-Welded AZ31 Magnesium Alloy Induced by Heat Pipe with Different Cooling Liquid" Metals 9, no. 11: 1227. https://doi.org/10.3390/met9111227

APA StyleZhang, Y. -M., Chen, L. -Y., Lu, S., Zhao, C., & Wang, Y. -H. (2019). Refined Microstructure and Enhanced Hardness in Friction Stir-Welded AZ31 Magnesium Alloy Induced by Heat Pipe with Different Cooling Liquid. Metals, 9(11), 1227. https://doi.org/10.3390/met9111227