Burnishing of FSW Aluminum Al–Cu–Li Components

Abstract

:1. Introduction

2. Analysis of FSW 2050 Aluminum Alloys

- Nugget zone (NZ): Affected by plastic deformation. Area of practically equiaxial grains due to recrystallization caused by frictional heat.

- Thermo-mechanically affected zone (TMAZ): Region adjacent to the nugget, where the grains are plastically deformed; however, due to the lower temperature, there is no recrystallization.

- Heat-affected zone (HAZ): Region next to TMAZ; there is no plastic deformation but there are microstructure changes due to process heat.

- Base metal (BM): Rest of material not influenced by the welding process.

3. Burnishing Tests: Parameter Influence on Surface Quality

4. Preliminary Tests

4.1. Preliminary Test on Raw Material

4.2. Preliminary Tests on Welded Part with T8 Heat Treatment

5. Tests on FSW Components

5.1. 2050 Aluminum Alloy with T8 Heat Treatment and FSW

5.2. Aluminum Alloy 2050 with T3 Heat Treatment, FSW, and T8 Heat Treatment

6. Surface and Sub-Surface Analysis

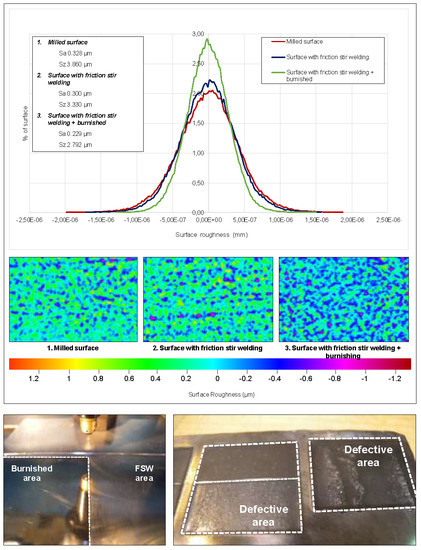

6.1. Surface Analysis

6.2. Sub-Surface Hardness and Microstructure

7. Conclusions

- The most determinant factor in the increase of surface hardness is the pressure; this effect is emphasized when burnishing is applied parallel to weld direction.

- Radial width and burnishing direction do not have a clear influence.

- The surface hardness can be increased on the order of 60% for tested aluminum alloys. For the aluminum without post-weld heat treatment, the influence of ball-burnishing was higher in the weld zone where the material was softer and, consequently, more hardenable by plastic deformation.

- The layer of hardened material also depends strongly on the burnishing pressure. A pressure of 10 MPa affected a surface layer of 0.5 mm thickness, while a pressure of 30 MPa affected a layer of practically 1.00 mm thickness.

- The microstructure of the material is not damaged after the burnishing process.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Improvements Relating to Friction Welding. Patent EP 0615480 B1, 6 December 1991. [Google Scholar]

- Texier, D.; Atmani, F.; Bocher, P.; Nadeau, F.; Chen, J.; Zedan, Y.; Vanderesse, N.; Demers, V. Fatigue performances of FSW and GMAW aluminum alloys welded joints: Competition between microstructural and structural-contact-fretting crack initiation. Int. J. Fatigue 2018, 116, 220–233. [Google Scholar] [CrossRef]

- Wu, H.; Chen, Y.-C.; Strong, D.; Prangnell, P. Stationary shoulder FSW for joining high strength aluminum alloys. J. Mater. Process. Technol. 2015, 221. [Google Scholar] [CrossRef]

- Patel, A.R.; Kotadiya, D.J.; Kapopara, J.M.; Dalwadi, C.G.; Patel, N.P.; Rana, H.G. Investigation of mechanical properties for hybrid joint of aluminium to polymer using friction stir welding (FSW). Mater. Today Proc. 2018, 5, 4242–4249. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; de Figueiredo, M.A.V.; de Castro, P.M.S.T. Fatigue behaviour of FSW and MIG weldments for two aluminium alloys. Theor. Appl. Fract. Mech. 2007, 48, 169–177. [Google Scholar] [CrossRef]

- Jenarthanan, M.P.; Varma, C.V.; Manohar, V.K. Impact of friction stir welding (FSW) process parameters on tensile strength during dissimilar welds of AA2014 and AA6061. Mater. Today Proc. 2018, 5, 14384–14391. [Google Scholar] [CrossRef]

- Rodríguez, A.; López de Lacalle, L.N.; Celaya, A.; Lamikiz, A.; Albizuri, J. Surface improvement of shafts by the deep ball-burnishing technique. Surf. Coat. Technol. 2012, 206, 2817–2824. [Google Scholar] [CrossRef]

- Jayaraman, N.; Prevéy, P.; Mahoney, M. Fatigue life improvement of an aluminium alloy FSW with low plasticity burnishing. In Proceedings of the 132th TMS Annual Meeting, San Diego, CA, USA, 2–6 March 2003. [Google Scholar]

- Huang, Y.; Wan, L.; LV, S.; Zhang, J.; Fu, G. In-situ rolling friction stir welding for joining AA2219. Mater. Des. 2013, 50, 810–816. [Google Scholar] [CrossRef]

- Başak, H.; Özkan, S.; Taşkesen, A. Application of burnishing process on friction stir welding and investigation of the effect of burnishing process on the surface roughness, hardness and strength. Exp. Tech. 2011, 35, 8–16. [Google Scholar] [CrossRef]

- Abdullah, R.; Beithou, N. Burnishing Effects on Friction Stir Welding of Al-Alloy 7075 T6. Glob. J. Res. Eng. Mech. Mech. Eng. 2014, 14, 12–19. [Google Scholar]

- Krasnowski, C.; Hamilton, S.; Dymek, S. Influence of the tool shape and weld configuration on microstructure and mechanical properties of the Al 6082 alloy FSW joints. Arch. Civ. Mech. Eng. 2015, 15, 133–141. [Google Scholar] [CrossRef]

- Sachinkumar, S.; Chakradhar, D. Effect of FSW on microstructure and hardness of AA6061/SiC/fly ash MMCs. Mater. Today Proc. 2018, 5, 17866–17872. [Google Scholar] [CrossRef]

- Lequeu, P.; Lassince, P.; Warner, T. Aluminum alloy development for the airbus A380. Adv. Mater. Process 2007, 165, 41–44. [Google Scholar]

- Buahombura, P.; Miyashita, Y.; Otsuka, Y.; Mutoh, Y.; Nobushiro, S. Fatigue crack growth behavior in weld nugget zone of FSWed similar and dissimilar aluminum alloys joint. In Proceedings of the 1st International Joint Symposium on Joining and Welding; Woodhead Publishing: Cambridge, UK, 2013; pp. 225–230. [Google Scholar] [CrossRef]

- Krishna, P.M.; Simhachalam, M.; Ramanaiah, N. Effect of ageing on mechanical properties of dissimilar friction stir welded aluminum alloy (AA2024 and AA6351) joints. J. Appl. Sci. 2012, 12, 1053–1057. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Fernández, A.; Celaya, A.; Lamikiz, A.; López de Lacalle, L.N. Improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Lasers Eng. 2014, 56, 113–120. [Google Scholar] [CrossRef]

- Uriarte, L.; Azcárate, S.; Herrero, A.; Lopez de Lacalle, L.N.; Lamikiz, A. Mechanistic modelling of the micro end milling operation. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2008, 222, 23–33. [Google Scholar] [CrossRef]

| 2050 ALUMINIUM ALLOY | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| COMPOSITION | Si | Fe | Cu | Mn | Mg | Zn | Li | Ag | Zr |

| 0.08 | 0.10 | 3.2 3.9 | 0.2 0.5 | 0.2 0.6 | 0.25 | 0.7 1.7 | 0.2 0.7 | 0.06 0.14 | |

| PROPERTIES | KIC (MPa·m1/2) | Hardness T3 (Brinell Hardness Number-BHN) | Hardness T8 (Brinell Hardness Number-BHN) | ||||||

| ≈37 | 120 | 160 | |||||||

| State | Radial Width of Depth (ab (mm)) | Pressure | |||

|---|---|---|---|---|---|

| 10 MPa | 20 MPa | 30 MPa | 40 MPa | ||

| Initial | 0 | 0.47 | 0.47 | 0.47 | 0.47 |

| Burnishing | 0.05 | 0.23 | 0.26 | 0.36 | - |

| 0.1 | 0.20 | 0.28 | 0.31 | - | |

| 0.2 | 0.32 | 0.53 | 0.71 | 1.02 | |

| 0.3 | 0.61 | 0.95 | 0.98 | 1.51 | |

| 0.4 | 0.93 | 1.43 | 1.87 | 2.14 | |

| 0.5 | 1.96 | 2.54 | 3.22 | 3.76 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez, A.; Calleja, A.; López de Lacalle, L.N.; Pereira, O.; González, H.; Urbikain, G.; Laye, J. Burnishing of FSW Aluminum Al–Cu–Li Components. Metals 2019, 9, 260. https://doi.org/10.3390/met9020260

Rodríguez A, Calleja A, López de Lacalle LN, Pereira O, González H, Urbikain G, Laye J. Burnishing of FSW Aluminum Al–Cu–Li Components. Metals. 2019; 9(2):260. https://doi.org/10.3390/met9020260

Chicago/Turabian StyleRodríguez, Adrián, Amaia Calleja, Luis Norberto López de Lacalle, Octavio Pereira, Haizea González, Gorka Urbikain, and Julien Laye. 2019. "Burnishing of FSW Aluminum Al–Cu–Li Components" Metals 9, no. 2: 260. https://doi.org/10.3390/met9020260

APA StyleRodríguez, A., Calleja, A., López de Lacalle, L. N., Pereira, O., González, H., Urbikain, G., & Laye, J. (2019). Burnishing of FSW Aluminum Al–Cu–Li Components. Metals, 9(2), 260. https://doi.org/10.3390/met9020260