Experiment of Process Strategy of Selective Laser Melting Forming Metal Nonhorizontal Overhanging Structure

Abstract

:1. Introduction

2. Materials and Methods

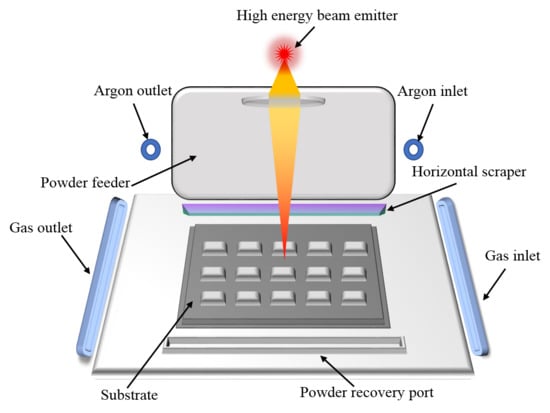

2.1. Materials and Experimental Setup

2.2. Forming Experiment

3. Results and Discussion

3.1. 316L Forming Surface Quality Analysis

3.2. 316L Surface Roughness

3.3. Chrome–Nickel Alloy Steel Forming Surface Quality Analysis

3.4. Chrome–Nickel Alloy Steel Surface Roughness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Raj, B.; Mudali, U.K. Materials development and corrosion problems in nuclear fuel reprocessing plants. Prog. Nucl. Energy 2006, 48, 283–313. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Gu, D.D.; Wang, Z.Y.; Shen, Y.F.; Li, Q.; Li, Y.F. In-situ TiC particle reinforced Ti–Al matrix composites: Powder preparation by mechanical alloying and Selective Laser Melting behavior. Appl. Surf. Sci. 2009, 255, 9230–9240. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Chianeh, V.A.; Hosseini, H.R.M.; Nofar, M. Micro structural features and mechanical properties of Al–Al 3 Ti composite fabricated by in-situ powder metallurgy route. J. Alloys Compd. 2009, 473, 127–132. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Vaerenbergh, J.V.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyping J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Van Vaerenbergh, J. Benchmarking of SLS/SLM processes. In Proceedings of the Ims Rapid Manufacturing Network Rapid Product Development Session Enabling Processes, Stuttgart, Germany, 20 October 2005. [Google Scholar]

- Yasa, E.; Craeghs, T.; Badrossamay, M.; Kruth, J.P. Rapid manufacturing research at the catholic university of leuven. In Proceedings of the US—TURKEY Workshop On Rapid Technologies, Istanbul, Turkey, 24–25 September 2009. [Google Scholar]

- Lott, P.; Schleifenbaum, H.; Meiners, W.; Wissenbach, K.; Hinke, C.; Bültmann, J. Design of an optical system for the in situ process monitoring of selective laser melting (slm). Physics Procedia. 2011, 12, 683–690. [Google Scholar] [CrossRef]

- Khan, M.; Sheikh, N.A.; Jaffery, S.H.I.; Ali, L.; Alam, K. Numerical simulation of meltpool instability in the selective laser melting (slm) process. Lasers Eng. 2014, 28, 319–336. [Google Scholar]

- Alkahari, M.R.; Furumoto, T.; Ueda, T.; Hosokawa, A. Melt pool and single track formation in selective laser sintering/selective laser melting. Adv. Mater. Res. 2014, 933, 196–201. [Google Scholar] [CrossRef]

- Yong-qiang, Y.; Jian-bin, L.; Di, W.; Zi-yi, L. A study of 316L stainless steel non-horizontal overhanging surface in selective laser melting. Mater. Sci. Eng. 2011, 19, 94–99. [Google Scholar]

- Jun, H.; Yi-ping, T.; Bing-heng, L.; Dian-liang, W. Research on supporting design rules for non-horizontal undersurface of parts in rapid prototyping by light curing. Chin. J. Mech. Eng. 2004, 40, 155–159. [Google Scholar]

- Tao, M. Research on several key problems in rapid prototyping technology of laser selective sintering. Ph.D. Thesis, Jiangsu University, Jiangsu, China, 2003. [Google Scholar]

| Number | Test Plan | Laser Power (W) | Exposure Time (μs) | Point Distance (μm) | Hatch Space (μm) | Scanning Strategy | Remark | |

|---|---|---|---|---|---|---|---|---|

| 1 | Noumenon1 | 200 | 80 | 40 | 110 | Meander | The system scans the boundary once by default. | |

| 2 | Noumenon2 | 200 | 80 | 40 | 110 | Chessboard | ||

| 3 | Noumenon3 | 200 | 80 | 40 | 110 | Stripe | ||

| 4 | Support | |||||||

| 5 | Boundary1 | 110 | 100 | 20 | 100 | Scan the boundary again according to the setting parameters. | ||

| 6 | Boundary2 | 160 | 100 | 20 | 100 | |||

| 7 | Boundary3 | 200 | 100 | 20 | 100 | |||

| 8 | Upper surface1 | 110 | 80 | 40 | 110 | Meander | Scan once by setting parameters. | |

| 9 | Upper surface2 | 160 | 80 | 40 | 110 | Meander | ||

| 10 | Upper surface3 | 200 | 80 | 40 | 110 | Meander | ||

| 11 | Upper surface4 | 110 | 80 | 40 | 110 | Meander | Scan again by setting parameters. | |

| 12 | Upper surface5 | 160 | 80 | 40 | 110 | Meander | ||

| Number | Test Plan | Number | Test Plan |

|---|---|---|---|

| 1 | Noumenon1 | 2 | Noumenon2 |

| 3 | Noumenon3 | 4 | Noumenon1 + Support |

| 5 | Noumenon1 + Boundary1 | 6 | Noumenon1 + Boundary2 |

| 7 | Noumenon1 + Boundary3 | 8 | Noumenon1 + Upper surface1 |

| 9 | Noumenon1 + Upper surface2 | 10 | Noumenon1 + Upper surface3 |

| 11 | Noumenon1 + Upper surface4 | 12 | Noumenon1 + Upper surface5 |

| Number | Test Plan | Laser Power (W) | Exposure Time (μs) | Point Distance (μm) | Hatch Space (μm) | Scanning Strategy | Remark |

|---|---|---|---|---|---|---|---|

| 1 | Noumenon1 | 100 | 80 | 40 | 100 | Meander | |

| 2 | Boundary1 | 80 | 80 | 40 | 40 | Count 1 time | |

| 3 | Boundary2 | 80 | 80 | 40 | 40 | Count 2 times | |

| 4 | Boundary3 | 80 | 80 | 40 | 40 | Count 4 times | |

| 5 | Boundary4 | 80 | 80 | 40 | 40 | Count 10 times |

| Group | X (mm) | x’ (mm) | x1 (mm) | y (mm) | y’ (mm) | y2 (mm) | z (mm) | z’ (mm) | z3 (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 5.09 | 0.09 | 5 | 5.08 | 0.08 | 7.07 | 7.15 | 0.08 |

| 2 | 5 | 5.15 | 0.15 | 5 | 5.12 | 0.12 | 7.07 | 7.29 | 0.12 |

| 3 | 5 | 5.11 | 0.11 | 5 | 5.09 | 0.09 | 7.07 | 7.18 | 0.11 |

| 4 | 5 | 5.04 | 0.04 | 5 | 5.05 | 0.05 | 7.07 | 7.08 | 0.01 |

| 5 | 5 | 5.06 | 0.06 | 5 | 5.07 | 0.07 | 7.07 | 7.13 | 0.06 |

| 6 | 5 | 5.14 | 0.14 | 5 | 5.16 | 0.16 | 7.07 | 7.35 | 0.28 |

| 7 | 5 | 5.21 | 0.21 | 5 | 5.22 | 0.22 | 7.07 | 7.43 | 0.36 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Wang, P.; Liu, Y.; Han, G. Experiment of Process Strategy of Selective Laser Melting Forming Metal Nonhorizontal Overhanging Structure. Metals 2019, 9, 385. https://doi.org/10.3390/met9040385

Shi W, Wang P, Liu Y, Han G. Experiment of Process Strategy of Selective Laser Melting Forming Metal Nonhorizontal Overhanging Structure. Metals. 2019; 9(4):385. https://doi.org/10.3390/met9040385

Chicago/Turabian StyleShi, Wentian, Peng Wang, Yude Liu, and Guoliang Han. 2019. "Experiment of Process Strategy of Selective Laser Melting Forming Metal Nonhorizontal Overhanging Structure" Metals 9, no. 4: 385. https://doi.org/10.3390/met9040385

APA StyleShi, W., Wang, P., Liu, Y., & Han, G. (2019). Experiment of Process Strategy of Selective Laser Melting Forming Metal Nonhorizontal Overhanging Structure. Metals, 9(4), 385. https://doi.org/10.3390/met9040385