Effects of Thinner Compliant Electrodes on Self-Clearability of Dielectric Elastomer Actuators

Abstract

:1. Introduction

2. Mechanism of Self-Clearing

3. Materials and Methods

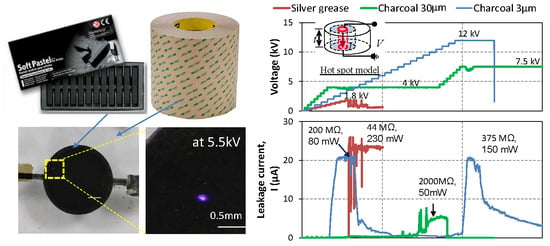

4. Results and Discussion

4.1. Material Characterization

4.2. Device Characterization

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pelrine, R.; Kornbluh, R.; Pei, Q.; Joseph, J. High-speed electrically actuated elastomers with strain greater than 100%. Science 2000, 287, 836–839. [Google Scholar] [CrossRef] [PubMed]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; IET: London, UK, 1992; Volume 9. [Google Scholar]

- Plante, J.S.; Dubowsky, S. Large-scale failure modes of dielectric elastomer actuators. Int. J. Solids Struct. 2006, 43, 7727–7751. [Google Scholar] [CrossRef] [Green Version]

- Muffoletto, D.; Martinez, A.; Burke, K.; Zirnheld, J. Electrode composition and partial discharges and their role in the breakdown of dielectric elastomer films. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1756–1762. [Google Scholar] [CrossRef]

- Stark, K.; Garton, C. Electric strength of irradiated polythene. Nature 1955, 176, 1225–1226. [Google Scholar] [CrossRef]

- Huang, J.; Shian, S.; Diebold, R.M.; Suo, Z.; Clarke, D.R. The thickness and stretch dependence of the electrical breakdown strength of an acrylic dielectric elastomer. Appl. Phys. Lett. 2012, 101, 122905. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.; Liu, K.; Wang, Y.; Zou, J.; Gu, G.; Zhu, X. Automatic design of soft dielectric elastomer actuators with optimal spatial electric fields. IEEE Trans. Robot. 2019, 35, 1150–1165. [Google Scholar] [CrossRef] [Green Version]

- Gisby, T.; Xie, S.; Calius, E.; Anderson, I. Leakage current as a predictor of failure in dielectric elastomer actuators. Electroactive Polymer Actuators and Devices (EAPAD) 2010. In Proceedings of the International Society for Optics and Photonics, San Diego, CA, USA, 8–11 March 2010; Volume 7642, p. 764213. [Google Scholar]

- La, T.G.; Lau, G.K. Inhibiting electro-thermal breakdown of acrylic dielectric elastomer actuators by dielectric gel coating. Appl. Phys. Lett. 2016, 108, 012903. [Google Scholar] [CrossRef]

- Lau, G.K.; La, T.G.; Foong, E.S.W.; Shrestha, M. Stronger multilayer acrylic dielectric elastomer actuators with silicone gel coatings. Smart Mater. Struct. 2016, 25, 125006. [Google Scholar] [CrossRef]

- Christensen, L.R.; Hassager, O.; Skov, A.L. Electro-Thermal model of thermal breakdown in multilayered dielectric elastomers. AIChE J. 2019, 65, 859–864. [Google Scholar]

- La, T.G.; Lau, G.K.; Shiau, L.L.; Tan, A.W.Y. Muscle-like high-stress dielectric elastomer actuators with oil capsules. Smart Mater. Struct. 2014, 23, 105006. [Google Scholar] [CrossRef]

- Shaw, D.; Cichanowski, S.; Yializis, A. A changing capacitor technology-failure mechanisms and design innovations. IEEE Trans. Electr. Insul. 1981, 16, 399–413. [Google Scholar] [CrossRef]

- La, T.G.; Lau, G.K. Very high dielectric strength for dielectric elastomer actuators in liquid dielectric immersion. Appl. Phys. Lett. 2013, 102, 192905. [Google Scholar] [CrossRef]

- Acome, E.; Mitchell, S.; Morrissey, T.; Emmett, M.; Benjamin, C.; King, M.; Radakovitz, M.; Keplinger, C. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science 2018, 359, 61–65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Finis, G.; Claudi, A. On the dielectric breakdown behavior of silicone gel under various stress conditions. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 487–494. [Google Scholar] [CrossRef]

- Yuan, W.; Hu, L.; Yu, Z.; Lam, T.; Biggs, J.; Ha, S.M.; Xi, D.; Chen, B.; Senesky, M.K.; Grüner, G.; et al. Fault-tolerant dielectric elastomer actuators using single-walled carbon nanotube electrodes. Adv. Mater. 2008, 20, 621–625. [Google Scholar] [CrossRef]

- Yuan, W.; Brochu, P.; Ha, S.M.; Pei, Q. Dielectric oil coated single-walled carbon nanotube electrodes for stable, large-strain actuation with dielectric elastomers. Sensors Actuators Phys. 2009, 155, 278–284. [Google Scholar] [CrossRef]

- Stoyanov, H.; Brochu, P.; Niu, X.; Lai, C.; Yun, S.; Pei, Q. Long lifetime, fault-tolerant freestanding actuators based on a silicone dielectric elastomer and self-clearing carbon nanotube compliant electrodes. RSC Adv. 2013, 3, 2272–2278. [Google Scholar] [CrossRef]

- Michel, S.; Chu, B.T.; Grimm, S.; Nüesch, F.A.; Borgschulte, A.; Opris, D.M. Self-healing electrodes for dielectric elastomer actuators. J. Mater. Chem. 2012, 22, 20736–20741. [Google Scholar] [CrossRef]

- Lau, G.K.; Chua, S.L.; Shiau, L.L.; Tan, A.W.Y. Self-clearing dielectric elastomer actuators using charcoal-powder electrodes. Electroactive Polymer Actuators and Devices (EAPAD) 2012. In Proceedings of the International Society for Optics and Photonics, San Diego, CA, USA, 12–15 March 2012; Volume 8340, p. 834016. [Google Scholar]

- Hsien Low, S.; Lynn Shiau, L.; Lau, G.K. Large actuation and high dielectric strength in metallized dielectric elastomer actuators. Appl. Phys. Lett. 2012, 100, 182901. [Google Scholar] [CrossRef]

- Low, S.H.; Lau, G.K. Bi-axially crumpled silver thin-film electrodes for dielectric elastomer actuators. Smart Mater. Struct. 2014, 23, 125021. [Google Scholar] [CrossRef]

- Chua, S.L.; Neo, X.H.; Lau, G.K. Multi-walled carbon nanotubes (MWCNT) as compliant electrodes for dielectric elastomer actuators. Electroactive Polymer Actuators and Devices (EAPAD) 2011. In Proceedings of the International Society for Optics and Photonics, San Diego, CA, USA, 7–10 March 2011; Volume 7976, p. 79760V. [Google Scholar]

- Baechler, C.; Gardin, S.; Abuhimd, H.; Kovacs, G. Inkjet printed multiwall carbon nanotube electrodes for dielectric elastomer actuators. Smart Mater. Struct. 2016, 25, 055009. [Google Scholar] [CrossRef]

- Schlatter, S.; Rosset, S.; Shea, H. Inkjet printing of carbon black electrodes for dielectric elastomer actuators. Electroactive Polymer Actuators and Devices (EAPAD) 2017. In Proceedings of the International Society for Optics and Photonics, Portland, OR, USA, 26–29 March 2017; Volume 10163, p. 1016311. [Google Scholar]

- Tseng, S.H.; Tai, N.H.; Hsu, W.K.; Chen, L.J.; Wang, J.H.; Chiu, C.C.; Lee, C.Y.; Chou, L.J.; Leou, K.C. Ignition of carbon nanotubes using a photoflash. Carbon 2007, 45, 958–964. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Klein, N.; Burstein, E. Electrical pulse breakdown of silicon oxide films. J. Appl. Phys. 1969, 40, 2728–2740. [Google Scholar] [CrossRef]

- 3M. Technical Data of 3M VHB Tape. 2011. Available online: https://www.alliedelec.com/m/d/e4e1ef3b96100de3bc461d617b0cdfa2.pdf (accessed on 1 January 2020).

- McGough, K.; Ahmed, S.; Frecker, M.; Ounaies, Z. Finite element analysis and validation of dielectric elastomer actuators used for active origami. Smart Mater. Struct. 2014, 23, 094002. [Google Scholar] [CrossRef]

- Chemtronic. Technical Data Sheet of CircuitWorks. Silver Conductive Grease. 2019. Available online: https://www.chemtronics.com/circuitworks-silver-conductive-grease (accessed on 1 January 2020).

- Shan, W.; Lu, T.; Majidi, C. Soft-matter composites with electrically tunable elastic rigidity. Smart Mater. Struct. 2013, 22, 085005. [Google Scholar] [CrossRef]

- Yue, S.Y.; Ouyang, T.; Hu, M. Diameter dependence of lattice thermal conductivity of single-walled carbon nanotubes: Study from ab initio. Sci. Rep. 2015, 5, 15440. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Y. Specific heat of single-walled carbon nanotubes: A lattice dynamics study. J. Phys. Soc. Jpn. 2003, 72, 2256–2259. [Google Scholar]

- MG Chemical. Technical Data Sheet 846: Carbon Conductive Grease. 2018. Available online: https://www.mgchemicals.com/products/grease-for-electronics/electrically-conductive-grease/carbon-conductive-grease/ (accessed on 1 January 2020).

- Khizhnyak, P.; Chechetkin, A.; Glybin, A. Thermal conductivity of carbon black. J. Eng. Phys. 1979, 37, 1073–1075. [Google Scholar] [CrossRef]

- Wikipedia contributors. Silver Oxide—Wikipedia, The Free Encyclopedia. Available online: https://en.wikipedia.org/wiki/Silver_oxide (accessed on 1 October 2020).

| VHB Substrate | Single Walled Carbon Nanotubes | Carbon-Black Load Grease | Silver-Particle Load Grease | Charcoal Powder (This Work) | |

|---|---|---|---|---|---|

| Electrical resistivity at 25 C (cm) | 3.1 × 10 [31] | 2.5 × 10 [18] | 114 [37] | 10 × 10 [33] | 13.7 × 10 |

| Thermal conductivity at 25 C (W/m/K) | 0.16 [34] | 3500 [35] | 0.2–0.3 [38] | 5.6 [33] | Poor |

| Heat capacity at 25 C (J/kg/K ) | 2010 [34] | 686 [36] | 710 of graphite | 240 of bulk Silver | Like graphite |

| Ignition temperature (C) | 350 (This work) | 475 in [28] | 315 [37] | 280 of AgO2 [39] | 450 (This work) |

| Layer thickness (m) | 30 to 100 | 0.005 to 0.25 | Less than 100 | Less than 100 | 3 to 30 |

| Self clearability | - | Success | Failure | Failure | Success |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lau, G.-K.; Shiau, L.-L.; Chua, S.-L. Effects of Thinner Compliant Electrodes on Self-Clearability of Dielectric Elastomer Actuators. Actuators 2020, 9, 121. https://doi.org/10.3390/act9040121

Lau G-K, Shiau L-L, Chua S-L. Effects of Thinner Compliant Electrodes on Self-Clearability of Dielectric Elastomer Actuators. Actuators. 2020; 9(4):121. https://doi.org/10.3390/act9040121

Chicago/Turabian StyleLau, Gih-Keong, Li-Lynn Shiau, and Soo-Lim Chua. 2020. "Effects of Thinner Compliant Electrodes on Self-Clearability of Dielectric Elastomer Actuators" Actuators 9, no. 4: 121. https://doi.org/10.3390/act9040121

APA StyleLau, G. -K., Shiau, L. -L., & Chua, S. -L. (2020). Effects of Thinner Compliant Electrodes on Self-Clearability of Dielectric Elastomer Actuators. Actuators, 9(4), 121. https://doi.org/10.3390/act9040121