The Effect of Ensiling on the Nutritional Composition and Fermentation Characteristics of Brown Seaweeds as a Ruminant Feed Ingredient

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Seaweed Sampling

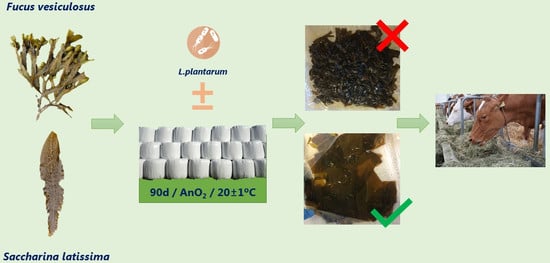

2.2. Laboratory-Scale Silage Preparation

2.3. Silage Fermentation Analysis

2.4. Chemical Composition

2.5. Determination and Stability of Phenolic Compounds

2.6. In Vitro True Dry Matter Digestibility

2.7. Statistical Analysis

3. Results

3.1. Seaweed Characteristics before Ensiling

3.2. Seaweed Characteristics after Ensiling

3.3. Silage Fermentation Characteristics

3.4. Determination and Stability of Phenolic Compounds

3.5. Principal Component Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ferdouse, F.; Holdt, S.L.; Smith, R.; Murua, P.; Yang, Z. The Global Status of Seaweed Production, Trade and Utilization; FAO Globefish Research Programme; Food and Agriculture Organization of the United Nations: Rome, Italy, 2018; ISBN 978-92-5-130870-7. [Google Scholar]

- Buschmann, A.H.; Camus, C.; Infante, J.; Neori, A.; Israel, Á.; Hernández-González, M.C.; Pereda, S.V.; Gomez-Pinchetti, J.L.; Golberg, A.; Tadmor-Shalev, N.; et al. Seaweed production: Overview of the global state of exploitation, farming and emerging research activity. Eur. J. Phycol. 2017, 52, 391–406. [Google Scholar] [CrossRef]

- Evans, F.D.; Critchley, A.T. Seaweeds for animal production use. J. Appl. Phycol. 2014, 26, 891–899. [Google Scholar] [CrossRef]

- Maia, M.R.G.; Fonseca, A.J.M.; Oliveira, H.M.; Mendonça, C.; Cabrita, A.R.J. The Potential Role of Seaweeds in the Natural Manipulation of Rumen Fermentation and Methane Production. Sci. Rep. 2016, 6, 32321. [Google Scholar] [CrossRef]

- Kumar, C.S.; Ganesan, P.; Suresh, P.V.; Bhaskar, N. Seaweeds as a source of nutritionally beneficial compounds—A review. J. Food Sci. Technol. 2008, 45, 1–13. [Google Scholar]

- Makkar, H.P.S.; Tran, G.; Heuz, V.; Giger-Reverdin, S.; Lessire, M.; Lebas, F.; Ankers, P. Seaweeds for livestock diets: A review. Anim. Feed Sci. Technol. 2016, 212, 1–17. [Google Scholar] [CrossRef]

- Holdt, S.L.; Kraan, S. Bioactive compounds in seaweed: Functional food applications and legislation. J. Appl. Phycol. 2011, 23, 543–597. [Google Scholar] [CrossRef]

- Ford, L.; Theodoridou, K.; Sheldrake, G.N.; Walsh, P.J. A critical review of analytical methods used for the chemical characterisation and quantification of phlorotannin compounds in brown seaweeds. Phytochem. Anal. 2019, 30, 587–599. [Google Scholar] [CrossRef]

- Catarino, M.D.; Silva, A.M.S.; Cardoso, S.M. Fucaceae: A source of bioactive phlorotannins. Int. J. Mol. Sci. 2017, 18, 1327. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Xu, Z.; Bach, S.J.; McAllister, T.A. Effects of phlorotannins from Ascophyllum nodosum (brown seaweed) on in vitro ruminal digestion of mixed forage or barley grain. Anim. Feed Sci. Technol. 2008, 145, 375–395. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Z.; Bach, S.J.; McAllister, T.A. Sensitivity of Escherichia coli to seaweed (Ascophyllum nodosum) phlorotannins and terrestrial tannins. Asian-Aust. J. Anim. Sci. 2009, 22, 238–245. [Google Scholar] [CrossRef]

- Schiener, P.; Black, K.D.; Stanley, M.S.; Green, D.H. The seasonal variation in the chemical composition of the kelp species Laminaria digitata, Laminaria hyperborea, Saccharina latissima and Alaria esculenta. J. Appl. Phycol. 2014, 27, 363–373. [Google Scholar] [CrossRef]

- Marinho, G.S.; Holdt, S.L.; Angelidaki, I. Seasonal variations in the amino acid profile and protein nutritional value of Saccharina latissima cultivated in a commercial IMTA system. J. Appl. Phycol. 2015, 27, 1991–2000. [Google Scholar] [CrossRef]

- Milledge, J.J.; Harvey, P.J. Ensilage and anaerobic digestion of Sargassum muticum. J. Appl. Phycol. 2016, 28, 3021–3030. [Google Scholar] [CrossRef]

- Bruton, T.; Lyons, H.; Lerat, Y.; Stanley, M.; Rasmussen, M.B. A Review of the Potential of Marine Algae as a Source of Biofuel in Ireland; Sustainable Energy Ireland: Dublin, Ireland, 2009; pp. 1–88. [Google Scholar]

- Pahlow, G.; Muck, R.E.; Driehuis, F.; Oude Elferink, S.J.W.H.; Spoelstra, S.F. Microbiology of ensiling. In Silage Science and Technology; Buxton, D.R., Muck, R.E., Harrison, J.H., Eds.; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Madison, WI, USA, 2003; pp. 31–93. [Google Scholar]

- Cabrita, A.R.J.; Maia, M.R.G.; Sousa-Pinto, I.; Fonseca, A.J.M. Ensilage of seaweeds from an integrated multi-trophic aquaculture system. Algal Res. 2017, 24, 290–298. [Google Scholar] [CrossRef]

- Herrmann, C.; FitzGerald, J.; O’Shea, R.; Xia, A.; O’Kiely, P.; Murphy, J.D. Ensiling of seaweed for a seaweed biofuel industry. Bioresour. Technol. 2015, 196, 301–313. [Google Scholar] [CrossRef]

- Williams, A.G.; Withers, S.; Sutherland, A.D. The potential of bacteria isolated from ruminal contents of seaweed-eating North Ronaldsay sheep to hydrolyse seaweed components and produce methane by anaerobic digestion in vitro. Microb. Biotechnol. 2013, 6, 45–52. [Google Scholar] [CrossRef]

- Moen, E.; Horn, S.; Østgaard, K. Biological degradation of Ascophyllum nodosum. J. Appl. Phycol. 1997, 9, 347–357. [Google Scholar] [CrossRef]

- Addah, W.; Baah, J.; Groenewegen, P.; Okine, E.K.; McAllister, T.A. Comparison of the fermentation characteristics, aerobic stability and nutritive value of barley and corn silages ensiled with or without a mixed bacterial inoculant. Can. J. Anim. Sci. 2011, 91, 133–146. [Google Scholar] [CrossRef]

- Olsson, J.; Malmhäll-Bah, E.; Albers, E. Ensiling of Saccharina latissima and Laminaria digitata with organic acid additives. In Proceedings of the Nordic Seaweed Conference, Grenå, Denmark, 12–13 October 2016. [Google Scholar]

- Wout, R.; Greenwell, H.; Davies, D.; Theodorou, M. Methods of Ensiling Algae, Ensiled Algae and Uses of Ensiled Algae. Google Patents WO2013045931, 2013. [Google Scholar]

- AOAC. Official Methods of Analysis, Association of Analytical Chemists, 15th ed.; AOAC: Washington, DC, USA, 2000; pp. 141–144. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Mertens, D.R. Gravimetric determination of amylase-treated neutral detergent fiber in feeds with refluxing in beakers or crucibles: Collaborative study. J. AOAC Int. 2002, 85, 1217–1240. [Google Scholar]

- Robertson, J.B.; Van Soest, P.J. The detergent system of analysis and its application to human foods. In The Analysis of Dietary Fiber in Food; James, W.P.T., Theander, O., Eds.; Marcel Dekker: New York, NY, USA, 1981. [Google Scholar]

- Angell, A.R.; Mata, L.; de Nys, R.; Paul, N.A. The protein content of seaweeds: A universal nitrogen-to-protein conversion factor of five. J. Appl. Phycol. 2016, 28, 511–524. [Google Scholar] [CrossRef]

- McDonald, P.; Henderson, A.R. Determination of water-soluble carbohydrates in grass. J. Agric. Food Chem. 1964, 15, 395–398. [Google Scholar] [CrossRef]

- Li, Y.; Fu, X.; Duan, D.; Liu, X.; Xu, J.; Gao, X. Extraction and Identification of Phlorotannins from the Brown Alga, Sargassum fusiforme (Harvey) Setchell. Mar. Drugs 2017, 15, 49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Holden, L.A. Comparison of methods of in vitro dry matter digestibility for ten feeds. J Dairy Sci. 1999, 82, 1791–1794. [Google Scholar] [CrossRef]

- Ford, L.; Stratakos, A.C.; Theodoridou, K.; Dick, J.T.A.; Sheldrake, G.N.; Linton, M.; Corcionivoschi, N.; Walsh, P.J. Polyphenols from Brown Seaweeds as a Potential Antimicrobial Agent in Animal Feeds. ACS Omega 2020, 5, 9093–9103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Woolford, M.K.; Pahlow, G. The silage fermentation. In Microbiology of Fermented Foods, 2nd ed.; Wood, B.J.B., Ed.; Blackie Academic & Professional: London, UK, 1998; Volume 1, pp. 73–102. [Google Scholar]

- Piltz, J.W.; Kaiser, A.G. Principles of silage preservation. In Successful Silage; Kaiser, A.G., Piltz, J.W., Burns, H.M., Neil, W.G., Eds.; Dairy Australia and New South Wales Department of Primary Industries: Orange, NSW, Australia, 2004; pp. 25–56. [Google Scholar]

- McDonald, P.; Henderson, A.R.; Herson, S.J.E. The Biochemistry of Silage, 2nd ed.; Chalcombe Publications, Marlow: Bucks, UK, 1991; p. 340. [Google Scholar]

- Connan, S.; Goulard, F.; Stiger, V.; Deslandes, E.; Gall, E.A. Interspecific and temporal variation in phlorotannin levels in an assemblage of brown algae. Bot. Mar. 2004, 47, 410–416. [Google Scholar] [CrossRef]

- Pavia, H.; Toth, G.B. Influence of light and nitrogen on the phlorotannin content of the brown seaweeds Ascophyllum nodosum and Fucus vesiculosus. Hydrobiologia 2000, 440, 299–305. [Google Scholar] [CrossRef]

- Parys, S.; Kehraus, S.; Pete, R.; Küpper, F.C.; Glombitza, K.W.; König, G.M. Seasonal variation of polyphenolics in Ascophyllum nodosum (Phaeophyceae). Eur. J. Phycol. 2009, 44, 331–338. [Google Scholar] [CrossRef]

- Koivikko, R.; Eränen, J.K.; Loponen, J.; Jormalainen, V. Variation of phlorotannins among three populations of Fucus vesiculosus as revealed by HPLC and colorimetric quantification. J. Chem. Ecol. 2008, 34, 57–64. [Google Scholar] [CrossRef]

- Henderson, A.R.; McDonald, P. The effect of a range of commercial inoculants on the biochemical changes during the ensilage of grass in laboratory studies. Res. Dev. Agric. 1984, 3, 167–171. [Google Scholar]

- Sandbakken, I.S.; Sæther, M.; Funderud, J.; Aasen, I.M. Acid preservation of Saccharina latissima for application as a carbon source for fermentation to biofuels and chemicals. J. Appl. Phycol. 2018, 30, 3581–3588. [Google Scholar] [CrossRef]

- Oladosu, Y.; Rafii, M.Y.; Abdullah, N.; Magaji, U.; Hussin, G.; Ramli, A.; Miah, G. Fermentation Quality and Additives: A Case of Rice Straw Silage. Biomed Res. Int. 2016, 1–14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Borreani, G.; Tabacco, E.; Schmidt, R.J.; Holmes, B.J.; Muck, R.E. Silage review: Factors affecting dry matter and quality losses in silages. J. Dairy Sci. 2018, 101, 3952–3979. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Davies, D.R.; Merry, R.J.; Williams, A.P.; Bakewell, E.L.; Leemans, D.K.; Tweed, J.K.S. Proteolysis during Ensilage of Forages Varying in Soluble Sugar Content. J. Dairy Sci. 1998, 81, 444–453. [Google Scholar] [CrossRef]

- Adams, J.M.M.; Ross, A.B.; Anastasakis, K.; Hodgson, E.M.; Gallagher, J.A.; Jones, J.M.; Donnison, I.S. Seasonal variation in the chemical composition of the bioenergy feedstock Laminaria digitata for thermochemical conversion. Bioresour. Technol. 2011, 102, 226–234. [Google Scholar] [CrossRef]

- Gallo, A.; Bertuzzi, T.; Giuberti, G.; Moschini, M.; Bruschi, S.; Cerioli, C.; Masoero, F. New assessment based on the use of principal factor analysis to investigate corn silage quality from nutritional traits, fermentation end products and mycotoxins. J. Sci. Food Agric. 2016, 96, 437–448. [Google Scholar] [CrossRef]

- Zhou, X.; Ouyang, Z.; Zhang, X.; Wei, Y.; Tang, S.; Ma, Z.; Tan, Z.; Zhu, N.; Teklebrhan, T.; Han, X. Sweet corn stalk treated with saccharomyces cerevisiae alone or in combination with lactobacillus plantarum: Nutritional composition, fermentation traits and aerobic stability. Animals 2019, 9, 598. [Google Scholar] [CrossRef] [Green Version]

- Rook, A.J.; Dhanoa, M.S.; Gill, M. Prediction of the voluntary intake of grass silages by beef cattle. 2. Principal component and ridge regression analyses. Anim. Prod. 1990, 50, 439–454. [Google Scholar] [CrossRef]

- Uchida, M.; Miyoshi, T. Algal fermentation-The seed for a new fermentation industry of foods and related products. JARQ 2013, 47, 53–63. [Google Scholar] [CrossRef] [Green Version]

- Wekre, M.E.; Kåsin, K.; Underhaug, J.; Holmelid, B.; Jordheim, M. Quantification of Polyphenols in Seaweeds: A Case Study of Ulva intestinalis. Antioxidants 2019, 8, 612. [Google Scholar] [CrossRef] [Green Version]

- Peng, K.; Huang, Q.; Xu, Z.; McAllister, T.A.; Acharya, S.; Mueller-Harvey, I.; Drake, C.; Cao, J.; Huang, Y.; Sun, Y.; et al. Characterization of condensed tannins from purple prairie clover (Dalea purpurea Vent.) conserved as either freeze-dried forage, sun-cured hay or silage. Molecules 2018, 23, 586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nascimento, T.V.C.; Bezerra, L.R.; Menezes, D.R.; Lucena, A.R.F.; Queiroz, M.A.A.; Trajano, J.S.; Oliveira, R.L. Condensed tannin-amended cassava silage: Fermentation characteristics, degradation kinetics and in-vitro gas production with rumen liquor. J. Agric. Sci. 2018, 156, 83–91. [Google Scholar] [CrossRef]

- Ometto, F.; Steinhovden, K.B.; Kuci, H.; Lunnbäck, J.; Berg, A.; Karlsson, A.; Handå, A.; Wollan, H.; Ejlertsson, J. Seasonal variation of elements composition and biomethane in brown macroalgae. Biomass Bioenergy 2018, 109, 31–38. [Google Scholar] [CrossRef]

- Rupérez, P. Mineral content of edible marine seaweeds. Food Chem. 2002, 79, 23–26. [Google Scholar] [CrossRef]

- Cabrita, A.R.J.; Maia, M.R.G.; Oliveira, H.M.; Sousa-Pinto, I.; Almeida, A.A.; Pinto, E.; Fonseca, A.J.M. Tracing seaweeds as mineral sources for farm-animals. J. Appl. Phycol. 2016, 28, 3135–3150. [Google Scholar] [CrossRef]

- European Commission. Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed. Off. J. Eur. Un. L. 2002, 140, 10. [Google Scholar]

- Antaya, N.T.; Soder, K.J.; Kraft, J.; Whitehouse, N.L.; Guindon, N.E.; Erickson, P.S.; Conroy, A.B.; Brito, A.F. Incremental amounts of Ascophyllum nodosum meal do not improve animal performance but do increase milk iodine output in early lactation dairy cows fed high-forage diets. J. Dairy Sci. 2015, 98, 1991–2004. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Greenwood, Y.; Orpin, C.G.; Paterson, I.W. Digestibility of seaweeds in Orkney sheep. J. Physiol. 1983, 343, 120. [Google Scholar]

- Sharma, S.; Neves, L.; Funderud, J.; Mydland, L.T.; Øverland, M.; Horn, S.J. Seasonal and depth variations in the chemical composition of cultivated Saccharina latissima. Algal Res. 2018, 32, 107–112. [Google Scholar] [CrossRef]

- Uchida, M.; Amakasu, H.; Satoh, Y.; Murata, M. Combinations of lactic acid bacteria and yeast suitable for preparation of marine silage. Fish. Sci. 2004, 70, 507–517. [Google Scholar] [CrossRef]

- Urano, N.; Hirai, H.; Ishida, M.; Kimura, S. Characterization of ethanol-producing marine yeasts isolated from coastal water. Fish. Sci. 1998, 64, 633–637. [Google Scholar] [CrossRef] [Green Version]

- Randby, A.T.; Selmer-Olsen, I.; Baevre, L. Effect of ethanol in feed on milk flavor and chemical composition. J. Dairy Sci. 1999, 82, 420–428. [Google Scholar] [CrossRef]

| Chemical Profile | FVu | FVi | SLu | SLi | SEM | p | ||

|---|---|---|---|---|---|---|---|---|

| Species | Inoculant | Species * Inoculant | ||||||

| DM (g/kg FW) | 229.2 | 226.6 | 205.1 | 202.2 | 4.46 | <0.001 | 0.773 | 0.974 |

| CP | 44.8 a,b | 45.0 a | 41.1 b | 45.7 a | 0.94 | 0.130 | 0.009 | 0.029 |

| Ash | 144.4 | 136.8 | 156.2 | 151.0 | 5.06 | 0.046 | 0.524 | 0.828 |

| WSC | 38.5 c | 41.9 c | 63.6 b | 75.2 a | 2.86 | <0.001 | 0.025 | 0.170 |

| aNDF | 247.6 | 236.4 | 86.4 | 86.4 | 10.5 | <0.001 | 0.676 | 0.538 |

| ADF | 133.3 | 126.4 | 59.8 | 46.4 | 4.96 | <0.001 | 0.476 | 0.242 |

| ADL | 80.4 | 83.4 | 13.4 | 13.4 | 4.66 | <0.001 | 0.647 | 0.516 |

| TPC | 21.7 a | 15.1 b | 1.5 c | 1.3 c | 1.33 | <0.001 | 0.024 | 0.043 |

| IVTDMD (%) | 68.1 b | 67.4 b | 94.7 a | 94.2 a | 1.63 | <0.001 | 0.931 | 0.967 |

| Fermentation profile | FVu | FVi | SLu | SLi | SEM | p | ||

|---|---|---|---|---|---|---|---|---|

| Species | Inoculant | Species * Inoculant | ||||||

| pH | 4.9 | 5.0 | 3.9 | 3.9 | 0.09 | <0.001 | 0.928 | 0.846 |

| Lactic Acid | 2.8 | 2.5 | 56.6 | 54.9 | 1.65 | <0.001 | 0.767 | 0.751 |

| Acetic Acid | 2.5 | 3.1 | 3.9 | 3.7 | 0.42 | 0.024 | 0.600 | 0.382 |

| L:A | 0.9 | 0.6 | 14.7 | 15.1 | 1.05 | <0.001 | 0.946 | 0.789 |

| Propionic Acid | ND | ND | 0.3 | ND | 0.10 | 0.159 | 0.143 | 0.158 |

| n-Butyric Acid | ND | ND | ND | ND | - | ns | ns | ns |

| i-Valeric Acid | ND | ND | ND | ND | - | ns | ns | ns |

| Ethanol | 4.0 | 6.1 | 18.1 | 13.9 | 2.33 | <0.001 | 0.388 | 0.196 |

| Propanol | ND | ND | ND | ND | - | ns | ns | ns |

| Ammonia N (g/kg CP) | 56.8 | 50.0 | 61.2 | 64.9 | 10.01 | 0.348 | 0.862 | 0.606 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campbell, M.; Ortuño, J.; Ford, L.; Davies, D.R.; Koidis, A.; Walsh, P.J.; Theodoridou, K. The Effect of Ensiling on the Nutritional Composition and Fermentation Characteristics of Brown Seaweeds as a Ruminant Feed Ingredient. Animals 2020, 10, 1019. https://doi.org/10.3390/ani10061019

Campbell M, Ortuño J, Ford L, Davies DR, Koidis A, Walsh PJ, Theodoridou K. The Effect of Ensiling on the Nutritional Composition and Fermentation Characteristics of Brown Seaweeds as a Ruminant Feed Ingredient. Animals. 2020; 10(6):1019. https://doi.org/10.3390/ani10061019

Chicago/Turabian StyleCampbell, Mairead, Jordi Ortuño, Lauren Ford, David R. Davies, Anastasios Koidis, Pamela J. Walsh, and Katerina Theodoridou. 2020. "The Effect of Ensiling on the Nutritional Composition and Fermentation Characteristics of Brown Seaweeds as a Ruminant Feed Ingredient" Animals 10, no. 6: 1019. https://doi.org/10.3390/ani10061019

APA StyleCampbell, M., Ortuño, J., Ford, L., Davies, D. R., Koidis, A., Walsh, P. J., & Theodoridou, K. (2020). The Effect of Ensiling on the Nutritional Composition and Fermentation Characteristics of Brown Seaweeds as a Ruminant Feed Ingredient. Animals, 10(6), 1019. https://doi.org/10.3390/ani10061019