Failure Mechanism of Multilayer Ceramic Capacitors under Transient High Impact

Abstract

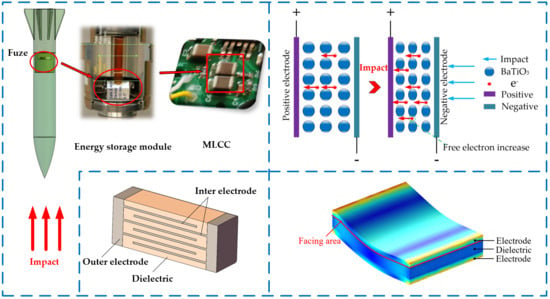

:1. Introduction

2. Experimental Study on MLCC Parameter Fluctuation Failure

2.1. Structure and Principle of an MLCC

2.2. MLCC High-Impact Test System

2.3. Transient Variation of Capacitance

2.4. Transient Change of the Leakage Current

3. Modeling of MLCC Parameter Fluctuation Failure

3.1. Modeling of Capacitance Fluctuation Based on Electrode Deformation

3.2. Modeling of Leakage Current Fluctuation Based on the Piezoresistive Effect

3.2.1. Piezoresistive Model of Ceramics

3.2.2. Theoretical Model of Equivalent Circuit for Multilayer Ceramic Capacitor

4. Conclusions

- (1)

- Under high-g impact acceleration, in the MLCC occurs the phenomenon of parameter drift, in which the capacitance value becomes larger and the leakage current increases. Besides, the larger the rated capacitance and withstand voltage of the MLCC, the greater the capacitance change and leakage current drift. With impact acceleration of no more than 9000 g, the influence on the capacity and leakage current are reversible.

- (2)

- The facing area deformation is the dominant factor in the transient change of the capacity value. A mechanical model based on the facing area is established to calculate the capacity change. The numerical calculation results are consistent with the experimental results, and the relationship between the impact and capacity changes can be described semi-quantitatively.

- (3)

- The piezoresistive effect of the ceramic dielectric is the dominant factor in leakage current variation. The insulation resistance begins to decrease when the threshold pressure exceeds 2.7 MPa. With increasing pressure, the insulation impedance of the ceramic dielectric decreases continuously, and when the pressure reaches 18.1 MPa, the resistance drops gradually. By combining the P-R model and the equivalent circuit model, the relationship between the leakage current and impact acceleration can be simulated, which is an approximately exponentially increasing relationship.

- (4)

- The sudden increase in the leakage current of the ceramic capacitor causes the energy storage loss of the MLCC, which makes the detonator energy of the fuze insufficient. The design of the fuze’s energy-storage capacitor must consider the leakage current during the impact and increase the design margin to ensure the reliability of the fuze.

Author Contributions

Funding

Conflicts of Interest

References

- He, Z. Basic Theory and Application of Smart Fuze Design, 2nd ed.; Beijing Institute of Technology Press: Beijing, China, 2019; pp. 183–237. [Google Scholar]

- He, Z. Fuze and environment. J. Detect. Control 2019, 41, 1–5. [Google Scholar]

- Zhang, H.; Dai, K.; Yin, Q. Ammunition Reliability Against the Harsh Environments During the Launch of an Electromagnetic Gun: A Review. IEEE Access 2019, 7, 45322–45339. [Google Scholar] [CrossRef]

- Dai, K.; Wang, X.; Niu, S.; Yi, F.; Yin, Y.; Chen, L.; Zhang, Y.; You, Z. Simulation and structure optimization of triboelectric nanogenerators considering the effects of parasitic capacitance. Nano Res. 2016, 10, 157–171. [Google Scholar] [CrossRef]

- Archangelo, K.; Guilardi, L.; Campanelli, D.; Valandro, L.F.; Borges, A. Fatigue failure load and finite element analysis of multilayer ceramic restorations. Dent. Mater. 2019, 35, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Nagayoshi, M.; Matsubara, K.; Fujikawa, N. Analyses of microstructure at degraded local area in Ni-multilayer ceramic capacitors under highly accelerated life test. Jpn. J. Appl. Phys. 2020, 59, SPPC01. [Google Scholar] [CrossRef]

- Kalaiselvan, C.; Rao, L.B. Accelerated life testing of nano ceramic capacitors and capacitor test boards using non-parametric method. Measurement 2016, 88, 58–65. [Google Scholar] [CrossRef]

- Lall, P.; Dornala, K.; Suhling, J. Effect of Dielectric Material on the Reliability of 3640 MLCC Capacitors under High-G Shock Loads. In Proceedings of the 2019 18th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Las Vegas, NV, USA, 28–31 May 2019; pp. 1037–1046. [Google Scholar]

- Lall, P.; Dornala, K.; Deep, J. Measurement and Prediction of Interface Crack Growth at the PCB-Epoxy Interfaces Under High-G Mechanical Shock. In Proceedings of the 2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 29 May–1 June 2018; pp. 1097–1105. [Google Scholar]

- Lall, P.; Dornala, K.; Lowe, R. Survivability Assessment of Electronics Subjected to Mechanical Shock Up to 25,000g. In Proceedings of the 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Las Vegas, NV, USA, 31 May–3 June 2016; pp. 507–518. [Google Scholar]

- Lall, P.; Patel, K.; Lowe, R. Modeling and reliability characterization of area-array electronics subjected to high-g mechanical shock up to 50,000 g. In Proceedings of the 2012 IEEE 62nd Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2012; pp. 1194–1204. [Google Scholar]

- Klaus, P.; Rainer, W.; Klaus, F. Finite-Element Analysis of Ceramic Multilayer Capacitors: Modeling and Electrical Impedance Spectroscopy for a Nondestructive Failure Test. J. Am. Ceram. Soc. 2000, 83, 1153–1159. [Google Scholar]

- Pyo, L.S.; Weon, K.K. Analysis for deformation behavior of multilayer ceramic capacitor based on multiscale homogenization approach. J. Mech. Sci. Technol. 2018, 32, 2577–2585. [Google Scholar]

- Xuhui, Z.; Kuahai, Y.; Hongyu, X.; Bin, L.; Xingguo, K. Failure analysis of multilayer ceramic capacitor structure under high G impact load. Electron. Compon. Mater. 2016, 35, 28–31. [Google Scholar]

- Ronghua, H.; Ya, Z.; Bo, L.; Yunluan, H.; Pan, G. Parameter variation and failure analysis of military capacitance under high overload. Reliab. Environ. Test Electron. Prod. 2010, 28, 24–26. [Google Scholar]

- Keren, D.; Xiaofeng, W.; Yin, Y.; Hao, C.; Zheng, Y. Voltage Fluctuation in a Supercapacitor during a High-g Impact. Sci. Rep. 2016, 6, 38794. [Google Scholar]

- Changlong, L.; Shiqiao, G.; Shaohua, N.; Haipeng, L. Parameter variation of solid tantalum capacitor under high shock. Explos. Shock 2018, 38, 419–425. [Google Scholar]

- Kim, J.H.; Jeong, H.C. Ceramic Electronic Component and Method of Manufacturing the Same. 2013. Available online: https://www.freepatentsonline.com/y2013/0049532.html (accessed on 26 November 2020).

- Chazono, H. Structure-Property Relationship in Ni-MLCC: Composition & Microstructure. IEICE Tech. Rep. Compon. Parts Mater. 2002, 102, 7–12. [Google Scholar]

- Mattes, B.L. Secondary Piezoresistivity in Oxygen Deficient BaTiO3 Single Crystals. J. Appl. Phys. 1963, 34, 682–685. [Google Scholar] [CrossRef]

- Guojun, S. Material Mechanics; Shanghai Jiaotong University Press: Shanghai, China, 2006; pp. 220–323. [Google Scholar]

- Hong, K.; Lee, T.H.; Suh, J.M. Perspectives and challenges in multilayer ceramic capacitors for next generation electronics. J. Mater. Chem. C 2019, 7, 9782–9802. [Google Scholar] [CrossRef]

- Kim, M.G. Equivalent-Circuit Model for High-Capacitance MLCC Based on Transmission-Line Theory. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 1012–1020. [Google Scholar] [CrossRef]

| Capacitor Type | δ (µm) | N | h (µm) | l (µm) | b (µm) | S (mm2) |

|---|---|---|---|---|---|---|

| “J”CT41G-1210-X5R-16V-22µF | 3.11 | 501 | 1.31 | 2945 | 2059 | 5.34 |

| “J”CT41G-1210-X5R-25V-22µF | 2.91 | 379 | 1.81 | 3165 | 2161 | 5.99 |

| “J”CT41G-1210-X5R-16V-47µF | 1.79 | 462 | 1.96 | 3238 | 2184 | 6.22 |

| “J”CT41G-1210-X5R-25V-47µF | 2.57 | 570 | 1.76 | 3364 | 2369 | 7.05 |

| Capacitor Type | Capacitance Variation/µF | |||

|---|---|---|---|---|

| 5026 g | 5608 g | 6305 g | 8297 g | |

| “J”CT41G-1210-X5R-16V-22µF | 0.022 | 0.030 | 0.106 | 0.146 |

| “J”CT41G-1210-X5R-25V-22µF | 0.027 | 0.033 | 0.109 | 0.151 |

| “J”CT41G-1210-X5R-16V-47µF | 0.031 | 0.056 | 0.122 | 0.174 |

| “J”CT41G-1210-X5R-25V-47µF | 0.037 | 0.060 | 0.127 | 0.181 |

| Capacitor Model | Capacitance Variation/µF | |||

|---|---|---|---|---|

| 5026 g | 5608 g | 6305 g | 8297 g | |

| “J”CT41G-1210-X5R-16V-22µF | 0.011 | 0.028 | 0.082 | 0.129 |

| “J”CT41G-1210-X5R-25V-22µF | 0.017 | 0.033 | 0.091 | 0.141 |

| “J”CT41G-1210-X5R-16V-47µF | 0.029 | 0.054 | 0.112 | 0.164 |

| “J”CT41G-1210-X5R-25V-47µF | 0.038 | 0.059 | 0.123 | 0.175 |

| R0 | A1 | T1 | M1 | A2 | T2 | M2 |

|---|---|---|---|---|---|---|

| 457 MΩ | −248 | −18.9 | 11.9 | −204 | 2.34 | 2.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, D.; Dai, K.; Zhang, J.; Yang, B.; Zhang, H.; Ma, S. Failure Mechanism of Multilayer Ceramic Capacitors under Transient High Impact. Appl. Sci. 2020, 10, 8435. https://doi.org/10.3390/app10238435

Yu D, Dai K, Zhang J, Yang B, Zhang H, Ma S. Failure Mechanism of Multilayer Ceramic Capacitors under Transient High Impact. Applied Sciences. 2020; 10(23):8435. https://doi.org/10.3390/app10238435

Chicago/Turabian StyleYu, Da, Keren Dai, Jinming Zhang, Benqiang Yang, He Zhang, and Shaojie Ma. 2020. "Failure Mechanism of Multilayer Ceramic Capacitors under Transient High Impact" Applied Sciences 10, no. 23: 8435. https://doi.org/10.3390/app10238435

APA StyleYu, D., Dai, K., Zhang, J., Yang, B., Zhang, H., & Ma, S. (2020). Failure Mechanism of Multilayer Ceramic Capacitors under Transient High Impact. Applied Sciences, 10(23), 8435. https://doi.org/10.3390/app10238435