BIM-LEAN as a Methodology to Save Execution Costs in Building Construction—An Experience under the Spanish Framework

Abstract

:1. Introduction

2. Current Approaches to Optimize the Efficiency of Construction Projects

2.1. Last Planner System

2.2. Building Information Modelling Paradigm

2.3. Synergies between the BIM and LEAN Paradigms

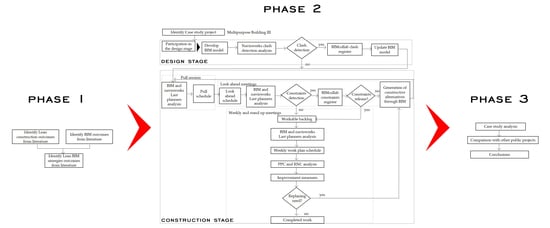

3. Research Approach

4. Construction Management of a Public Building

Bim and Lean Synergies in the Construction Work of the Multipurpose Building III

5. Comparative Analysis, Research Findings and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Love, P.E.; Wang, X.; Sing, C.; Tiong, R.L.K. Determining the probability of project cost overruns. J. Constr. Eng. Manag. 2013, 139, 321–330. [Google Scholar] [CrossRef]

- Plebankiewicz, E. Model of predicting cost overrun in construction projects. Sustainability 2018, 10, 4387. [Google Scholar] [CrossRef] [Green Version]

- KPMG. 2015 Global Construction Project Owner’s Survey; KPMG International: Amstelveen, The Netherlands, 2015. [Google Scholar]

- Andújar-Montoya, M.V.; Gilart-Iglesias, A.; Montoyo, D.M.J. A construction management framework for mass customisation in traditional construction. Sustainability 2015, 7, 5182–5210. [Google Scholar] [CrossRef] [Green Version]

- Alshawi, M.; Ingirige, B. Web-enabled project management: An emerging paradigm in construction. Autom. Constr. 2003, 12, 349–364. [Google Scholar] [CrossRef]

- Aziz, R.F.; Hafez, S.M. Applying lean thinking in construction and performance improvement. Alex. Eng. J. 2013, 52, 679–695. [Google Scholar] [CrossRef] [Green Version]

- Love, P.E.D.; Edwards, D.W. Forensic project management: The underlying causes of rework in construction projects. Civ. Eng. Environ. Syst. 2004, 21, 207–228. [Google Scholar] [CrossRef]

- Love, P.E. Influence of project type and procurement method on rework costs in building construction projects. J. Constr. Eng. Manag. 2002, 128, 18–29. [Google Scholar] [CrossRef] [Green Version]

- Akinci, B.; Boukamp, F.; Gordon, C.; Huber, D.; Lyons, C.; Park, K. A formalism for utilization of sensor systems and integrated project models for active construction quality control. Autom. Constr. 2006, 15, 124–138. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.H.; Thomas, S.R.; Haas, C.T.; Caldas, C.H. Measuring the impact of rework on construction cost performance. J. Constr. Eng. Manag. 2009, 135, 187–198. [Google Scholar] [CrossRef]

- Josephson, P.E.; Hammarlund, Y. The causes and costs of defects in construction: A study of seven building projects. Autom. Constr. 1999, 8, 681–687. [Google Scholar] [CrossRef]

- Andújar-Montoya, M.D. Integral Construction Management Model for Mass Customisation in Residential Building. An Approach Based on BPM; Sciences and Urbanism Department, University of Alicante Polytechnic School, University of Alicante: Alicante, Spain, 2015. [Google Scholar]

- Andújar-Montoya, M.D.; Marcos-Jorquera, D.; Garca-Botella, F.; Gilart-Iglesias, V. A Context-Driven Model for the Flat Roofs Construction Process through Sensing Systems, Internet-of-Things and Last Planner System. Sensors 2017, 17, 1691. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choo, H.J.I.D.; Tommelein, I.D. Requirements and barriers to adoption of last planner computer tools. In Proceedings of the 9th Annual Conference of the International Group for Lean Construction, Singapore, 6–8 August 2001; pp. 6–8. [Google Scholar]

- Abdelhamid, T.S.; Everett, J.G. Physical demands of construction work: A source of workflow unreliability. In Proceedings of the 10th Conference of International Group for Lean Construction IGLC-10, Gramado, Brazil, 6–8 August 2002; Federal University of Rio Grande de Sul: Porto Alegre, Brazil, 2002. [Google Scholar]

- Calveras, A.; Ganuza, J.J.; Hauk, E. Reckless bidding in public projects. An analysis of Spanish regulation. J. Public Econ. 2002, 135–153. [Google Scholar]

- Porwal, A.; Hewage, K.N. Building Information Modeling (BIM) partnering framework for public construction projects. Autom. Constr. 2013, 31, 204–214. [Google Scholar] [CrossRef]

- Galiano-Garrigós, A.; Andújar-Montoya, M.D. Building Information Modelling in Operations of Maintenance at the University of Alicante. Int. J. Sustain. Dev. Plan. 2017, 13, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Koskela, L. Application of the New Production Philosophy to Construction; Technical Report; Center for Integrated Facility Engineering, Department of Civil Engineering: Stanford, CA, USA, 1992. [Google Scholar]

- Koskela, L. Lean Production in Construction; University of Huddersfield: Huddersfield, UK, 1997. [Google Scholar]

- Koskela, L. Management of production in construction: A theoretical view. In Proceedings of the 7th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 26–28 July 1999. [Google Scholar]

- Koskela, L.; Howell, G. The theory of project management: Explanation to novel methods. In Proceedings of the 10th Annual Conference of the International Group for Lean Construction, Gramado, Brazil, 6–8 August 2002. [Google Scholar]

- Koskela, G.; Howell, E.; Pikas, B.; Dave, B. If CPM is so bad, why have we been using it so long? In Proceedings of the 22th International Group for Lean Construction Conference, Oslo, Norway, 25–27 June 2014. [Google Scholar]

- Santos, A.; Powell, J. Potential of poka-yoke devices to reduce variability in construction. In Proceedings of the 7th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 26–28 July 1999. [Google Scholar]

- Alzraiee, H.; Zayed, T.; Moselhi, O. Dynamic planning of construction activities using hybrid simulation. Autom. Constr. 2015, 49, 176–192. [Google Scholar] [CrossRef]

- Ballard, G.; Howell, G. An update on last planner. In Proceedings of the 11th Annual Conference of the International Group for Lean Construction (IGLC-11), Blacksburg, VA, USA, 22–24 July 2003. [Google Scholar]

- Ballard, H.G. The Last Planner System of Production Control. Ph.D. Thesis, The University of Birmingham, Birmingham, UK, 2000. [Google Scholar]

- Tommelein, I.D.; Ballard, G. Look-Ahead Planning: Screening and Pulling; University of California: Berkeley, CA, USA, 1997. [Google Scholar]

- Muñoz, S. Standardize to Meet New Market Challenges; BuildingSMART Spanish Chapter; BuildingSMART: Hertfordshire, UK, 2016. [Google Scholar]

- Azhar, S.; Nadeem, A.; Mok, J.Y.N.; Leung, B.H.Y. Building Information Modeling (BIM): A new paradigm for visual interactive modeling and simulation for construction projects. In Proceedings of the First International Conference on Construction in Developing Countries, Karachi, Pakistan, 4–5 August 2008. [Google Scholar]

- Succar, B. Building information modelling framework: A research and delivery foundation for industry stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Azhar, S.; Khalfan, M.; Maqsood, T. Building information modeling (BIM): Now and beyond. Australas. J. Constr. Econ. Build. 2012, 12, 15. [Google Scholar]

- Bryde, D.; Broquetas, M.; Volm, J.M.; Jung, Y.; Joo, M. Building information modelling (BIM) framework for practical implementation. Autom. Constr. 2011, 20, 126–133. [Google Scholar]

- Miettinen, R.; Paavola, S. Beyond the BIM utopia: Approaches to the development and implementation of building information modeling. Autom. Constr. 2014, 43, 84–91. [Google Scholar] [CrossRef]

- Khanzode, A.; Fischer, M.; Reed, D. Benefits and lessons learned of implementing building virtual design and construction (VDC) technologies for coordination of mechanical, electrical, and plumbing (MEP) systems on a large healthcare project. J. Inf. Technol. Constr. (ITcon) 2008, 13, 324–342. [Google Scholar]

- Azhar, S. Building information modeling (BIM): Trends, benefits, risks, and challenges for the AEC industry. ASCE 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Bernstein, H.M. The Business Value of BIM in North America; McGraw Hill: New York, NY, USA, 2012. [Google Scholar]

- Zhang, X.; Azhar, S.; Nadeem, A.; Khalfan, M. Using Building Information Modelling to achieve Lean principles by improving efficiency of work teams. Int. J. Constr. Manag. 2018, 18, 293–300. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of building information modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Chen, S.M.; Chen, P.H.; Chang, L.M. A framework for an automated and integrated project scheduling and management system. Autom. Constr. 2013, 35, 89–110. [Google Scholar] [CrossRef]

- Hardin, B.; Mccool, D. BIM and Construction Management: Proven Tools, Methods, and Workflows; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Dave, B.; Koskela, L.; Kiviniemi, A.; Owen, R.L.; Fazenda, P.T. Implementing Lean in Construction: Lean Construction and BIM; CIRIA: London, UK, 2013. [Google Scholar]

- Mollasalehi, S.; Fleming, A.; Talebi, S.; Underwood, J. Development of an Experimental Waste Framework based on BIM/Lean concept in construction design. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 19 July 2016. [Google Scholar]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of lean and building information modeling in construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef] [Green Version]

- Hattab, R.A.; Hamzeh, F. Using social network theory and simulation to compare traditional versus BIM-lean practice for design error management. Autom. Constr. 2015, 52, 59–69. [Google Scholar] [CrossRef]

- Clemente, J.; Cachadinha, N. Bim-Lean synergies in the management on mep works in public facilities of intensive use—A case study. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 751–759. [Google Scholar]

- Nascimento, D.L.D.M.; Quelhas, O.L.G.; Meiriño, M.J.; Caiado, R.G.G.; Barbosa, S.D.; Ivson, P. Facility Management using digital Obeya Room by integrating BIM-Lean approaches-an empirical study. J. Civ. Eng. Manag. 2018, 24, 581–591. [Google Scholar] [CrossRef]

- Andújar-Montoya, M.D.; Galiano-Garrigós, A.; Rizo-Maestre, C.; Echarri-Iribarren, V. Bim and lean construction interactions: A state-of-the-art review. In Building Information Modelling (BIM) in Design, Construction and Operations III; WIT Press: Chilworth, UK, 2019; Volume 1, pp. 1–13. [Google Scholar]

- Tauriainen, M.; Marttinen, P.; Dave, B.; Koskela, L. The Effects of BIM and Lean Construction on Design Management Practices. Procedia Eng. 2016, 164, 567–574. [Google Scholar] [CrossRef]

- Bhatla, A.; Leite, F. Integration Framework of BIM with the Last Planner System TM. In Proceedings of the 20th Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Koseoglu, O.; Sakin, M.; Arayici, Y. Exploring the BIM and lean synergies in the Istanbul Grand Airport construction project. Eng. Constr. Archit. Manag. 2018, 25. [Google Scholar] [CrossRef]

- Mahalingam, A.; Yadav, A.K.; Varaprasad, J. Investigating the role of lean practices in enabling BIM adoption: Evidence from two Indian cases. J. Constr. Eng. Manag. 2015, 141, 05015006. [Google Scholar] [CrossRef]

- Garrido, M.C.; Mendes, R.; Scheer, S.; Campestrini, T.F. Using BIM for Last Planner System: Case studies in Brazil. In Proceedings of the 2015 International Workshop on Computing in Civil Engineering, Austin, TX, USA, 21–23 June 2015. [Google Scholar]

- Toledo, M.; Olivares, K.; Gonzlez, V. Exploration of a Lean-BIM planning framework: A Last Planner System and BIM-based case study. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 19 July 2016. [Google Scholar]

- Golafshani, N. Understanding reliability and validity in qualitative research. Qual. Rep. 2003, 8, 597–606. [Google Scholar]

- Chen, L.; Luo, H. A BIM-based construction quality management model and its applications. Autom. Constr. 2014, 46, 64–73. [Google Scholar] [CrossRef]

- Barlish, K.; Sullivan, K. How to measure the benefits of BIM - A case study approach. Autom. Constr. 2012, 24, 149–159. [Google Scholar] [CrossRef] [Green Version]

- Kassem, M.; Kelly, G.; Dawood, N.; Serginson, M.; Lockley, S. BIM in facilities management applications: A case study of a large university complex. Built Environ. Proj. Asset Manag. 2015, 5, 261–277. [Google Scholar] [CrossRef] [Green Version]

- Merschbrock, C.; Munkvold, B.E. Effective digital collaboration in the construction industry—A case study of BIM deployment in a hospital construction project. Comput. Ind. 2015, 73, 1–7. [Google Scholar] [CrossRef]

| Id | Constraints | Detection Date | Construction Date | Time Ahead | Quantified Delays Avoided | Quantified Economic Savings | Quality Issues |

|---|---|---|---|---|---|---|---|

| ID_01 | Interference of the slab of one of the stairs with a window in the modern building | Design stage | Week 16 | 68 weeks ahead | 4 weeks | 4,760.00 | Demolition of stairs and rework |

| ID_02 | Intersection of the sunshades with rainwater downpipes | Design stage | Week 29 | 81 weeks ahead | 2 weeks | 7425.60 | Remove and modify parasols and rework |

| ID_03 | Conflict of heights of the false ceiling by the edge beams, the air conditioning ducts and the height of the windows | Design stage + LAM 09 in Week 05 | Week 09 | 61 weeks ahead and 4 weeks ahead | 1 week | 13,923.00 | Remove ducts, modify windows and rework |

| ID_04 | Conflict with the layout of the air conditioning ducts in the computer room with the luminaires and other ducts | Design stage + LAM 09 in Week 05 | Week 09 | 61 weeks ahead and 4 weeks ahead | 1 week | 2,915.50 | Modify ducts and rework |

| ID_05 | Crossings in the corridors between the different facilities located in the false ceilings | Design stage + LAM 09 in Week 05 | Week 09 | 61 weeks ahead and 4 weeks ahead | 1 week | 4,331.60 | Relocate facilities |

| ID_06 | Optimization of the modulation of the large format porcelain (Large Format Ceramic) as interior facing in the baseboards of the corridors of the entire building | Initial meeting. | Week 10 | 20 weeks ahead | No quantify-cation in time | No economic quantifica-tion | Worst aesthetic. |

| ID_07 | Space for air conditioning machines on one of the toilets of the old building and its form of access | LAM 10 in Week 06 | Week 10 | 4 weeks ahead | 2 weeks | 13,090.00 | Ceiling modification and disassembly machines. Reworks |

| ID_08 | False ceilings and suspended elements bolt in concrete beams instead of in the ceramic vaults in the modern building | LAM 13 in Week 09 | Week 13 | 65 weeks ahead | 2 weeks | 5,355.00 | Future Maintenance Issues |

| ID_09 | Location of the machines on the roof and design of the layout of the ducts and pipes for servicing it | LAM 26 in Week 22 | Week 26 | 4 weeks ahead | 3 weeks | 11,186.00 | Mount and disassemble ducts. Reworks. Difficulties for future maintenance |

| ID_10 | Slope options in the underneath slab of the yard and the level of access in the classrooms of the north façade | LAM 31 in Week 27 | Week 31 | 4 weeks ahead | 2 weeks | 23,205.00 | Water entry into the classrooms. Future modification of slope formation throughout the yard |

| Code | Budget (€) | Built Area (m) | Ratio (€/m) | Type of Building | Type of Intervention | Budget Deviation (€) | Deviation Percentage | HVAC Deviation (€) | HVAC Percentage | HVAC Complexity |

|---|---|---|---|---|---|---|---|---|---|---|

| B 01 | 4,011,967.81 | 4789.00 | 837.75 | E | E | 798,774.68 | 0.199 | 649,410.31 | 0.81 | High |

| B 02 | 812,260.89 | 818.61 | 992.24 | R | RV | 48,426.50 | 0.060 | 22,536.00 | 0.47 | Low |

| B 03 | 709,634.97 | 450.14 | 1576.48 | E | NB | 49,674.45 | 0.070 | 7202.79 | 0.145 | High |

| B 04 | 1,535,474.41 | 1150.50 | 1334.61 | DCC | NB | 146,301.19 | 0.095 | 24,871.20 | 0.17 | High |

| B 05 | 2,024,745.66 | 1333.86 | 1517.96 | DCC | NB | 184,251.86 | 0.091 | 24,874.00 | 0.14 | High |

| B 06 | 2,054,406.45 | 3060.37 | 671.29 | M | NB | 165,688.93 | 0.081 | 10,352.64 | 0.06 | Low |

| B 07 | 1,106,439.84 | 773.63 | 1430.19 | R | NB | 95,401.00 | 0.086 | 21,744.00 | 0.23 | Low |

| B 08 | 1,655,635.83 | 1376.99 | 1202.36 | DCC | NB | 162,252.31 | 0.098 | 19,656.23 | 0.12 | High |

| B 09 | 932,029.58 | 1238.67 | 752.44 | DCC | RV | 83,267.25 | 0.089 | 12,490.09 | 0.15 | High |

| CS | 1,912,332.00 | 2438.80 | 784.13 | E | E | 24,942.17 | 0.013 | 13,671.09 | 0.50 | High |

| Chapter | Company | Budget (€) | Deviation (€) | Deviation (%) |

|---|---|---|---|---|

| Demolition | Subcontractor 1 | 59,804.53 | ||

| Excavation | Subcontractor 2 | 2431.81 | ||

| Foundation | Subcontractor 3 | 4205.83 | ||

| Structure | Subcontractor 3 | 35,740.46 | ||

| Brickwork | Subcontractor 1 | 90,377.95 | 2079.14 | 11% |

| Coating | Subcontractor 4 and Subcontractor 5 | 95,343.37 | ||

| Roof | Subcontractor 6 | 17,356.01 | 1483.29 | 8% |

| Façade | Subcontractor 7 | 119,098.81 | ||

| Floor | Subcontractor 5 | 168,592.54 | ||

| Wood Carpentry | Subcontractor 8 | 52,150.80 | ||

| Metal carpentry | Subcontractor 9 | 147,177.68 | ||

| Locksmithing | Subcontractor 9 | 29,575.63 | ||

| Stained glass windows | Subcontractor 9 | 30,795.13 | ||

| Painting | Subcontractor 10 | 33,713.71 | ||

| Several | Main construction company | 11,708.16 | ||

| Furniture | Subcontractor 11 | 22,280.61 | ||

| Urbanization | Subcontractor 1 | 88,726.48 | ||

| Total Architecture | 1,009,079.50 | |||

| Previous | 23,695.27 | |||

| CT | Subcontractor 12 | 83,976.33 | ||

| Electricity | Subcontractor 12 | 271,807.68 | 6440.92 | 34% |

| Plumbing | Subcontractor 13 | 19,211.36 | ||

| Sanitary drainage | Subcontractor 13 | 19,408.97 | 138.48 | 1% |

| Fire | Subcontractor 13 | 28,470.60 | ||

| Voice and data | Subcontractor 12 | 51,156.81 | 1129.26 | 6% |

| PA system | Subcontractor 12 | 10,388.71 | ||

| HVAC | Subcontractor 13 | 337,340.20 | 13,671.09 | 71% |

| Total Facilities | 845,455.93 | |||

| Control | 20,303.43 | |||

| Quality | 6392.34 | |||

| Residues | 6066.92 | |||

| Health and safety | 25,033.87 | |||

| TOTAL | 1,912,332.00 | 24,942.18 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andújar-Montoya, M.D.; Galiano-Garrigós, A.; Echarri-Iribarren, V.; Rizo-Maestre, C. BIM-LEAN as a Methodology to Save Execution Costs in Building Construction—An Experience under the Spanish Framework. Appl. Sci. 2020, 10, 1913. https://doi.org/10.3390/app10061913

Andújar-Montoya MD, Galiano-Garrigós A, Echarri-Iribarren V, Rizo-Maestre C. BIM-LEAN as a Methodology to Save Execution Costs in Building Construction—An Experience under the Spanish Framework. Applied Sciences. 2020; 10(6):1913. https://doi.org/10.3390/app10061913

Chicago/Turabian StyleAndújar-Montoya, María Dolores, Antonio Galiano-Garrigós, Víctor Echarri-Iribarren, and Carlos Rizo-Maestre. 2020. "BIM-LEAN as a Methodology to Save Execution Costs in Building Construction—An Experience under the Spanish Framework" Applied Sciences 10, no. 6: 1913. https://doi.org/10.3390/app10061913

APA StyleAndújar-Montoya, M. D., Galiano-Garrigós, A., Echarri-Iribarren, V., & Rizo-Maestre, C. (2020). BIM-LEAN as a Methodology to Save Execution Costs in Building Construction—An Experience under the Spanish Framework. Applied Sciences, 10(6), 1913. https://doi.org/10.3390/app10061913