Dynamic Characterization of Cohesive Material Based on Wave Velocity Measurements

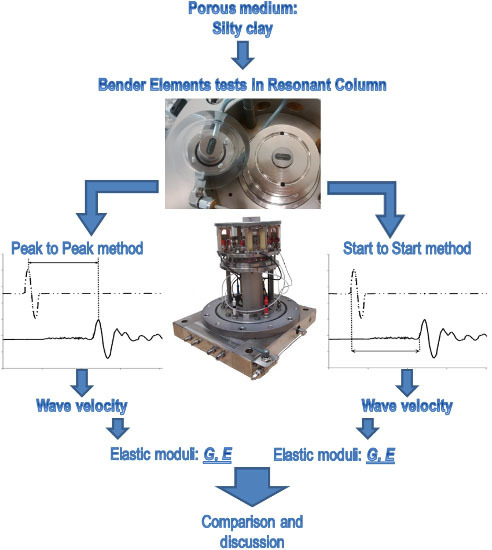

Abstract

:1. Introduction

2. Methods and Materials

2.1. Test Equipment

2.2. Methods of Interpretation of BE Results

2.3. Characterization of Test Material

| Parameter | Value |

|---|---|

| w (%) | 17.52 |

| wP (%) | 17.14 |

| wL (%) | 33.00 |

| IP (%) | 15.86 |

| IL (%) | 0.02 |

| IC (%) | 0.98 |

| ρ (kg/m3) | 2140 |

2.4. Test Setup and Procedure

3. Results and Discussion

3.1. Frequency Dependency

3.2. The Effect of Stress Level

| Mean Effective Stress | S-Wave Velocity | P-Wave Velocity | Average Ratio of Seismic Waves Velocities |

|---|---|---|---|

| p’ (kPa) | υS (m·s−1) | υP (m·s−1) | υP/υS (-) |

| 30 | 145–168 | 1518–1595 | 9.3 |

| 120 | 195–222 | 1469–1579 | 7.0 |

| 180 | 221–224 | 1508–1568 | 6.4 |

| 240 | 240–264 | 1522–1593 | 5.9 |

| 360 | 267–292 | 1486–1581 | 5.3 |

| 410 | 296–314 | 1435–1588 | 5.0 |

| Mean Effective Stress | S-Wave Velocity | P-Wave Velocity | Average Ratio of Seismic Waves Velocities |

|---|---|---|---|

| p’ (kPa) | υS (m·s−1) | υP (m·s−1) | υP/υS (-) |

| 180 | 224–260 | 1715–1759 | 6.8 |

| 240 | 252–284 | 1734–1779 | 6.3 |

| 360 | 281–319 | 1590–1609 | 4.7 |

| 410 | 301–336 | 1588–1645 | 4.9 |

| Mean Effective Stress | Average Dynamic Poisson’s Ratio |

|---|---|

| p’ (kPa) | νd (-) |

| 30 | 0.48 |

| 120 | 0.47 |

| 180 | 0.46 |

| 240 | 0.46 |

| 360 | 0.44 |

| 410 | 0.44 |

| Mean Effective Stress | Average Dynamic Poisson’s Ratio |

|---|---|

| p’ (kPa) | νd (-) |

| 180 | 0.47 |

| 240 | 0.46 |

| 360 | 0.44 |

| 410 | 0.44 |

3.3. Comparison of Results from Different Methods

3.4. The Effect of Unloading

4. Conclusions

- The data show that the input signal frequency, in particular frequencies, which are below the level of T = 0.1 ms, does not significantly affect the stiffness values obtained by both adopted identification methods. The decrease in frequency results in greater dependence on frequency.

- The best measurements of travel time for the tested soils were received at the frequencies of the input signal in the range of 50 to 20 kHz. In most of the considered cases, the greatest values of the dynamic parameters were obtained when the frequencies from this range were applied.

- Mean effective stress has a visible influence on the seismic wave velocities and on the elastic modulus of the examined soils.

- There are linear relationships between the mean effective stress and the small strain shear modulus and the small strain modulus of elasticity.

- The compression waves propagate through the analyzed clayey material with far larger velocities than in the case of shear waves; at certain pressure levels, these velocities can be even up to 10-times larger.

- The dynamic Poisson’s ratio for the tested cohesive soils is almost constant, being approximately equal to 0.46.

- The dynamic Poisson’s ratio linearly increases with the decrease of the shear modulus.

- Concerning the unloading process, it profitably affects the stiffness of silty clays. The dynamic properties rise in their values, from 8% to 16%, owing to unloading.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Salacak, M.; Pinar, S.B.S. Soil parameters which can be determined with seismic velocities. Jeofizik 2012, 16, 17–29. [Google Scholar]

- Youn, J.-U.; Choo, Y.-W.; Kim, D.-S. Measurement of small-strain shear modulus Gmax of dry and saturated sands by bender element, resonant column, and torsional shear tests. Can. Geotech. J. 2008, 45, 1426–1438. [Google Scholar] [CrossRef]

- Burland, J.B.; Longworth, T.I.; Moore, J.F.A. Study of ground and progressive failure caused by deep excavation in Oxford clay. Géotechnique 1977, 27, 557–591. [Google Scholar] [CrossRef]

- Oshaki, Y.; Iwasaki, R. On dynamic shear moduli and Poisson’s ratio of soil deposits. Soils Found. 1973, 13, 61–73. [Google Scholar]

- Sas, W.; Głuchowski, A.; Radziemska, M.; Dzięcioł, J.; Szymański, A. Environmental and Geotechnical Assessment of the Steel Slags as a Material for Road Structure. Materials 2015, 8, 4857–4875. [Google Scholar] [CrossRef]

- Yamashita, S.; Kawaguchi, T.; Nakata, Y.; Mikami, T.; Fujiwara, T.; Shibuya, S. Interpretation of international parallel test on the measurement of Gmax using bender elements. Soils Found. 2009, 49, 631–650. [Google Scholar] [CrossRef]

- Benz, T. Small-Strain Stiffness of Soils and Its Numerical Consequences; Universität Stuttgart: Stuttgart, Germany, 2007. [Google Scholar]

- Menzies, B. Near-surface site characterization by ground stiffness profiling using surface wave geophysics. In H. C. Verma Commemorative Volume; Indian Geotechnical Society: New Delhi, Indian, 2000; pp. 1–14. [Google Scholar]

- Leong, E.C.; Cahyadi, J.; Rahardjo, H. Measuring shear and compression wave velocities of soil using bender-extender elements. Can. Geotech. J. 2009, 46, 792–812. [Google Scholar] [CrossRef]

- Ha Giang, P.H.; van Impe, P.; van Impe, W.F.; Menge, P.; Haegeman, W. Effects of grain size distribution on the initial small strain shear modulus of calcareous sand. In Proceedings of the 16th ECSMGE Geotechnical Engineering for Infrastructure and Development, Edinburg, UK, 13–17 September 2015; pp. 3177–3182.

- Sas, W.; Gabryś, K.; Szymański, A. Laboratoryjne badanie sztywności gruntu według Eurokodu 7 [In Polish] Laboratory tests of soil stiffness by Eurocode 7. Acta Sci. Pol. Ser. Archit. 2013, 12, 39–50. [Google Scholar]

- Sas, W.; Gabryś, K.; Szymański, A. Comparison of resonant column and Bender elements tests on selected cohesive soil from Warsaw. Electron. J. Pol. Agric. Univ. EJPAU 2014, 17, #07. Available online: http://www.ejpau.media.pl/volume17/issue3/art-07.html (accessed on 23 July 2014). [Google Scholar]

- Lawrence, F.V. Propagation of Ultrasonic Waves through Sand; Research Report R63-08; Massachusetts Institute of Technology: Cambridge, MA, USA, 1963. [Google Scholar]

- Lawrence, F.V. Ultrasonic Shear Wave Velocity in Sand and Clay; Research Report R65-05; Massachusetts Institute of Technology: Cambridge, MA, USA, 1965. [Google Scholar]

- Shirley, D.J. An improved shear wave transducer. J. Acoust. Soc. Am. 1978, 63, 1643–1645. [Google Scholar] [CrossRef]

- Dyvik, R.; Madshus, C. Lab Measurement of Gmax Using Bender Elements; Norwegian Geotechnical Institute: Oslo, Norway, 1985; pp. 186–196. [Google Scholar]

- Styler, M.A.; Howie, J.A. Continuous Monitoring of Bender Element Shear Wave Velocities During Triaxial Testing. Geotech. Test. J. 2014, 37, 218–230. [Google Scholar] [CrossRef]

- Ferreira, C.; Martins, J.P.; Correia, A.G. Determination of the small-strain stiffness of hard soils by means of bender elements and accelerometers. In Proceedings of the 15th European Conference on Soil Mechanics and Geotechnical Engineering; Athens, Greece, 12–15 September 2013, Andreas, A., Michael, P., Christos, T., Eds.; IOS Press: Amsterdam, The Netherlands, 2011; Volume 1, pp. 179–184. [Google Scholar]

- Viggiani, G.; Atkinson, J.H. Interpretation of bender element tests. Géotechnique 1995, 45, 149–154. [Google Scholar] [CrossRef]

- Lee, J.S.; Santamarina, J.C. Bender elements: Performance and signal interpretation. J. Geotech. Geoenviron. Eng. ASCE 2005, 131, 1063–1070. [Google Scholar] [CrossRef]

- Leong, E.C.; Yeo, S.H.; Rahardjo, H. Measuring shear wave velocity using bender elements. Geotech. Test. J. 2005, 28, 488–498. [Google Scholar]

- Camacho-Tauta, J.F.; Cascante, G.; da Fonseca, A.V.; Santos, J.A. Time and frequency domain evaluation of bender element systems. Géotechnique 2015, 65, 548–562. [Google Scholar] [CrossRef]

- Sas, W.; Gabryś, K.; Szymański, A. Determination of Poisson’s ratio by means of resonant column tests. Electron. J. Pol. Agricu. Univ. EJPAU 2013, 16, #03. Available online: http://www.ejpau.media.pl/volume16/issue3/art-03.html (accessed on 20 August 2013). [Google Scholar]

- Sas, W.; Gabryś, K. Laboratory measurement of shear stiffness in resonant column apparatus. ACTA Sci. Pol. Ser. Arch. 2012, 11, 29–39. [Google Scholar]

- Gabryś, K.; Sas, W.; Soból, E. Small-strain dynamic characterization of clayey soil from Warsaw. ACTA Sci. Pol. Ser. Arch. 2015, 14, 55–65. [Google Scholar]

- GDS Instruments Ltd. Bender Elements. In The GDS Bender Elements System Hardware Handbook for Vertical and Horizontal Elements; GDS Instruments Ltd.: Hampshire, UK, 2005. [Google Scholar]

- Cheng, Z.; Leong, E.C. A Hybrid Bender Element-Ultrasonic System for Measurement of Wave Velocity in Soils. Geotech. Test. J. 2014, 37, 377–388. [Google Scholar] [CrossRef]

- Chan, C.M. Bender Element Test in Soil Specimens: Identifying the Shear Wave Arrival Time. EJGE 2010, 15, 1263–1276. [Google Scholar]

- Clayton, C.R.I.; Theron, M.; Best, A.I. The measurement of vertical shear-wave velocity using side-mounted bender elements in the triaxial apparatus. Géotechnique 2004, 54, 495–498. [Google Scholar] [CrossRef]

- Brocanelli, D.; Rinaldi, V. Measurement of low-strain material damping and wave velocity with bender elements in the frequency domain. Can. Geotech. J. 1998, 35, 1032–1040. [Google Scholar] [CrossRef]

- Arroyo, M.; Greening, P.; Wood, D.M. An estimate of uncertainty in current pulse test practice. Riv. Ital. Geotec. 2001, 37, 17–35. [Google Scholar]

- Mitaritonna, G.; Amorosi, A.; Cotecchia, F. Multidirectional bender element measurements in the triaxial cell: Equipment set-up and signal interpretation. Riv. Ital. Geotec. 2010, 1, 50–69. [Google Scholar]

- Jovičić, V.; Coop, M.R.; Simic, M. Objective criteria for determining Gmax from bender element tests. Géotechnique 1996, 46, 357–362. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. Geotechnical Investigations—Soil Classification—Part 2: Classification Rules; PN–EN ISO 14688-2:2004; Polish Committee for Standardization: Warsaw, Poland, 2004. (In Polish) [Google Scholar]

- Sas, W.; Gabryś, K.; Szymański, A. Effect of time on dynamic shear modulus of selected cohesive soil of one section of Express Way No S2 in Warsaw. Acta Geophys. 2015, 63, 398–413. [Google Scholar] [CrossRef]

- Head, K.H. Manual of Soil Laboratory Testing. Volume 3 Effective Stress Tests; J. Wiley & Sons Ltd.: New York, NY, USA, 1998. [Google Scholar]

- Viggiani, G. Panellist discussion: Recent advances in the interpretation of bender element tests. In Pre-Failure Deformation of Geomaterials; Satoru, S., Toshiyuki, M., Seiichi, M., Eds.; Balkema: Rotterdam, The Netherland, 1995; Volume 2, pp. 1099–1104. [Google Scholar]

- Brignoli, E.; Gotti, M.; Stokoe, K.H., II. Measurement of shear waves in laboratory specimens by means of piezoelectric transducers. ASTM Geotech. Test. J. 1996, 19, 384–397. [Google Scholar]

- Kawaguchi, T.; Mitachi, T.; Shibuya, S. Evaluation of shear wave travel time in laboratory bender element test. In Proceedings of 15th International Conference on Soil Mechanics and Geotechnical Engineering, Istambul, Turkey, 28–31 August 2001; Volume 1, pp. 155–158.

- Leong, E.C.; Yeo, S.H.; Rahardjo, H. Measuring Shear Wave Velocity Using Bender Elements. Geotech. Test. J. 2003. [Google Scholar] [CrossRef]

- Hasan, A.M.; Wheeler, S.J. Measuring travel time in bender/extender element tests. In Proceedings of the 16th ECSMGE Geotechnical Engineering for Infrastructure and Development, Edinburg, UK, 13–17 September 2015; pp. 3171–3176.

- Choo, H.; Larrahondo, J.; Burns, S.E. Coating Effects of Nano-Sized Particles onto Sand Surfaces: Small Strain Stiffness and Contact Mode of Iron Oxide-Coated Sands. J. Geotech. Geoenviron. Eng. 2015, 141, 04014077:1–04014077:10. [Google Scholar] [CrossRef]

- Lee, C.-J.; Hung, W.-Y.; Tsai, C.-H.; Chen, T.; Tu, Y.; Huang, C.-C. Shear wave velocity measurements and soil-pile system identifications in dynamic centrifuge tests. Bull. Earthq. Eng. 2014, 12, 717–734. [Google Scholar] [CrossRef]

- Fedrizzi, F.; Raviolo, P.L.; Vigano, A. Resonant column and cyclic torsional shear experiments on soils of the Trentino valleys. In Proceedings of the 16th ECSMGE Geotechnical Engineering for Infrastructure and Development, Edinburg, UK, 13–17 September 2015; pp. 3437–3442.

- Gabryś, K.; Szymański, A. Badania parametrów odkształceniowych gruntów spoistych w kolumnie rezonansowej [In Polish] Research of deformation parameters of cohesive soils in resonant column. Inżynieria Morska i Geotech. 2012, 4, 324–327. [Google Scholar]

- Amat, A.S. Elastic Stiffness Moduli of Huston Sand. Master’s Thesis, University of Bristol, Bristol, UK, 2007. [Google Scholar]

- Ali, H.; Mahbaz, S.B.; Cascante, G.; Garbinsky, M. Low strain measurement of shear modulus with resonant column and bender element tests—Frequency effects. In Proceedings of the GeoMontreal 2013: Geoscience for Sustainability, Montreal, QC, Canada, 29 September–3 October 2013.

- Das, B.M.; Ramana, G.V. Principles of Soil Dynamics, 2nd ed.United States of America: Stamford, CT, USA, 2011.

- Mavko, G. Parameters that Influence Seismic Velocity. Conceptual Overview of Rock and Fluid Factors that Impact Seismic Velocity and Impedance; Stanford Rock Physics Laboratory: Standford, CA, USA, 2009. [Google Scholar]

- Campanella, R.G.; Stewart, W.P. Seismic cone analysis using digital signal processing for dynamic site characterization. Can. Geotech. J. 1992, 29, 477–486. [Google Scholar] [CrossRef]

- Poisson’s ratio. Available online: http://www.engineeringtoolbox.com (accessed on 21 September 2015).

- Otsubo, M.; O’Sullivan, C.; Sim, W.W.; Ibraim, E. Quantitative assessment of the influence of surface roughness on soil stiffness. Géotechnique 2015, 65, 694–700. [Google Scholar] [CrossRef]

- Wichtmann, T.; Triantafyllidis, T. Stiffness and Damping of Clean Quartz Sand with Various Grain-Size Distribution Curves. J. Geotech. Geoenviron. Eng. 2014, 140, 06013003:1–06013003:4. [Google Scholar] [CrossRef]

- Qiu, T.; Huang, Y.; Guadalupe-Torres, Y.; Baxter, C.D.P.; Fox, P.J. Effective Soil Density for Small-Strain Shear Waves in Saturated Granular Materials. J. Geotech. Geoenviron. Eng. 2015, 141, 04015036:1–04015036:11. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Tsinopoulos, S.V.; Polyzos, D. An iterative effective medium approximation (IEMA) for wave dispersion and attenuation predictions in particulate composites, suspensions and emulsions. J. Acoust. Soc. Am. 2004, 116, 3443–3452. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sas, W.; Gabryś, K.; Soból, E.; Szymański, A. Dynamic Characterization of Cohesive Material Based on Wave Velocity Measurements. Appl. Sci. 2016, 6, 49. https://doi.org/10.3390/app6020049

Sas W, Gabryś K, Soból E, Szymański A. Dynamic Characterization of Cohesive Material Based on Wave Velocity Measurements. Applied Sciences. 2016; 6(2):49. https://doi.org/10.3390/app6020049

Chicago/Turabian StyleSas, Wojciech, Katarzyna Gabryś, Emil Soból, and Alojzy Szymański. 2016. "Dynamic Characterization of Cohesive Material Based on Wave Velocity Measurements" Applied Sciences 6, no. 2: 49. https://doi.org/10.3390/app6020049

APA StyleSas, W., Gabryś, K., Soból, E., & Szymański, A. (2016). Dynamic Characterization of Cohesive Material Based on Wave Velocity Measurements. Applied Sciences, 6(2), 49. https://doi.org/10.3390/app6020049