Real-Time Compensation for Thermal Errors of the Milling Machine

Abstract

:1. Introduction

2. Thermal Model of a Machine Tool

2.1. Basic Theory

- Heat Conduction: heat can transfer from higher temperature to a lower one mainly by means of the solid medium, which can be described by following equation:where q is heat conduction, k is conduction factor of the medium, A is the area of contact surface, dX is the distance between the ends, and dT is the temperature difference between the ends.

- Heat convection: heat is delivered naturally from one side to another by affecting the volume and density of the media, which can be described by the following equation:where q is heat convection, h is convection factor, A is sectional area, and ΔT is temperature difference between the ends.

- Heat irradiation: Heat is delivered through electromagnetic wave, independent on any media, which can be described by following equation:where σ represents Stefan-Boltzmann constant, A is the radiating surface area, and T1 and T2 are the temperatures at two radiating surfaces.

2.2. Thermal Model

2.2.1. Theoretical model

2.2.2. Data-driven model

3. Experiment Approach

3.1. Experiment Setup

3.2. Initial Measurement

3.3. Measurement of Major Temperature Fields

3.4. Application of Compensation Module

- (1)

- Initial running of spindle for 48 h to ensure the measuring points on the machine tool, which can satisfy the desired temperature fields of thermal model.

- (2)

- Operating the spindle at 60% of full speed for 400 h—then, turning off the spindle and ensuring the x-y table and the spindle nose return to their initial positions.

- (3)

- Performing the test by running the spindle at 90% of full speed for 400 h, in the meantime, recording the displacements of the table on the x- and y-axes and spindle nose on the z-axis.

- (4)

- Activating the compensation module to remove the displacement error due to temperature rise.

4. Results and Discussions

4.1. Displacement Variation without Compensation

4.2. Displacement Variation with Compensation

4.3. Machining Test

5. Conclusions

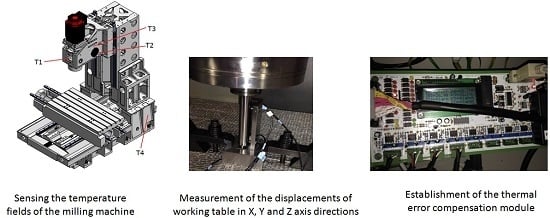

- Selection of the locations for sensing the temperature fields of the machine tool is very important for establishing the correct thermal model. We first used 14 temperature sensors to examine the real temperature fields around the machine, from which the four major sensing points were selected.

- Through the proposed thermal compensation system, the displacement variations on the x- and y-axes and the position error at the tool center can be controlled within 20 µm.

- Application of the thermal compensation system in milling operation examinations of the machined surface reveal that the surface accuracy can be controlled within −14 µm (minimum) and 1 µm (maximum) under the activation of the compensation system. Compared with the machined surface without thermal compensation, the overall efficiency is increased by 33%. The feasibility of the compensation system was successfully demonstrated in application in the milling operation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bryan, J.B. International status of thermal error research. CIRP Ann. Manuf. Technol. 1990, 39, 645–656. [Google Scholar] [CrossRef]

- Ferrreira, P.M.; Liu, C.R. A method for estimating and compensating quasistatic errors of machine tools. Trans. ASME J. Eng. Ind. 1993, 115, 149–159. [Google Scholar] [CrossRef]

- Yanga, H.; Ni, J. Dynamic neural network modelling for nonlinear, nonstationary machine tool thermally induced error. Int. J. Mach. Tools Manuf. 2005, 45, 455–465. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Liu, Q.W.; Han, J.L. Finite element analysis on thermal characteristic of the headstock of NC machine tool. Adv. Mater. Res. 2011, 291–294, 2302–2305. [Google Scholar] [CrossRef]

- Zhang, J.F.; Feng, P.F.; Wu, Z.J.; Yu, D.W.; Chen, C. Thermal structure design and analysis of a machine tool headstock. Mechanics 2013, 19, 478–485. [Google Scholar] [CrossRef]

- Donmez, M.A.; Hahn, M.H.; Soons, J.A. A novel cooling system to reduce thermally-induced errors of machine tools. CIRP Ann. Manuf. Technol. 2007, 56, 521–524. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Dumitrescu, M.; Ng, E.G.; Elbestawi, M.A. Effect of coolant strategy on tool performance, chip morphology and surface quality during high-speed machining of A356 aluminum alloy. Int. J. Mach. Tools Manuf. 2005, 45, 219–227. [Google Scholar] [CrossRef]

- Kodera, T.; Yokoyama, K.; Miyaguchi, K.; Nagai, Y.; Suzuki, T.; Masuda, M.; Yazawa, T. Real-time estimation of ball-screw thermal elongation based upon temperature distribution of ball-screw. JSME Int. J. Ser. C Mech. Syst. 2004, 47, 1175–1181. [Google Scholar] [CrossRef]

- Kim, S.K.; Cho, D.W. Real-time estimation of temperature distribution in a ballscrew system. Int. J. Mach. Tools Manuf. 1997, 37, 451–464. [Google Scholar] [CrossRef]

- Yuan, J.; Ni, J. The real-time error compensation technique for CNC machining systems. Mechatronics 1998, 8, 359–380. [Google Scholar] [CrossRef]

- El Ouafi, A.; Guillot, M.; Barka, N. An integrated modeling approach for ANN-based real-time thermal error compensation on a CNC turning center. Adv. Mater. Res. 2013, 664, 907–915. [Google Scholar] [CrossRef]

- Yang, J.; Yuan, J.; Ni, J. Thermal error mode analysis and robust modeling for error compensation on a CNC turning center. Int. J. Mach. Tools Manuf. 1999, 39, 1367–1381. [Google Scholar] [CrossRef]

- Donmez, M.A.; Blomquist, D.S.; Hocken, R.J.; Liu, C.R.; Barash, M.M. A general methodology for machine tool accuracy enhancement by error compensation. Precis. Eng. 1986, 8, 187–196. [Google Scholar] [CrossRef]

- Chen, J.S.; Yuan, J.; Ni, J.; Wu, S.M. Real-time compensation for time-variant volumetric errors on a machining center. Trans. ASME J. Eng. Ind. 1993, 115, 472–479. [Google Scholar] [CrossRef]

- Lo, C.H.; Yuan, J.; Ni, J. An application of real-time error compensation on a turning center. Int. J. Mach. Tools Manuf. 1995, 35, 1669–1682. [Google Scholar] [CrossRef]

- Lee, D.S.; Choi, J.Y.; Choi, D.H. ICA based thermal source extraction and thermal distortion compensation method for a machine tool. Int. J. Mach. Tools Manuf. 2003, 43, 589–597. [Google Scholar] [CrossRef]

- Postlethwaite, S.R.; Allen, J.P.; Ford, D.G. The use of thermal imaging, temperature and distortion models for machine tool thermal error reduction. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 1998, 212, 671–679. [Google Scholar] [CrossRef]

- Vanherck, P.; Dehaes, J.; Nuttin, M. Compensation of thermal deformation in machine tools with neural nets. Comput. Ind. 1997, 33, 119–125. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.H.; Yang, S.H. Thermal error modeling of a horizontal machining center usingfuzzy logic strategy. J. Manuf. Process. 2001, 3, 120–127. [Google Scholar] [CrossRef]

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S.; Myers, A. Application of GNNMCI(1, N) to environmental thermalerror modelling of CNC machine tools. In Proceedings of the 3rd International Conference on Advanced Manufacturing Engineering and Technologies, Stockholm, Sweden, 27–30 October 2013; pp. 253–262.

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S.; Myers, A. Comparative study of ANN and ANFIS prediction models for thermal error compensation on CNC machine tools. In Proceedings of the Laser Metrology and Machine Performance X: Lamdamap 10th International Conference, Buckinghamshire, UK, 20–21 March 2013; pp. 79–88.

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S. A novel approach for ANFIS modelling based on Grey system theory for thermal error compensation. In Proceedings of the 14th UK Workshop on Computational Intelligence (UKCI), Bradford, UK, 8–10 September 2014.

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S. A particle swarm optimisation-based Grey prediction model for thermal error compensation on CNC machine tools. In Proceedings of the Laser Metrology and Machine Performance XI: 11th International Conference and Exhibition on Laser Metrology, Machine Tool, CMM and Robotic Performance (Lamdamap), Huddersfield, UK, 17–18 March 2015.

- Horejš, O.; Mareš, M.; Novotný, L. Advanced modelling of thermally induced displacements and its implementation into standard CNC controller of horizontal milling center. Procedia CIRP 2012, 4, 67–72. [Google Scholar] [CrossRef]

- Chen, J.S.; Chiou, G. Quick testing and modeling of thermally-induced errors of CNC machine tools. Int. J. Mach. Tools Manuf. 1995, 35, 1063–1074. [Google Scholar] [CrossRef]

- Kurtoglu, A. The accuracy improvement of machine tools. Ann. CIRP 1990, 39, 417–419. [Google Scholar] [CrossRef]

- Hao, W.; Hongtao, Z.; Qianjian, G.; Xiushan, W.; Jianguo, Y. Thermal error optimization modeling and real-time compensation on a CNC turning center. J. Mater. Process. Technol. 2008, 207, 172–179. [Google Scholar] [CrossRef]

- Yang, S.; Yuan, J.; Ni, I. The improvement of thermal error modeling and compensation on machinetools by CMAC neural network. Int. J. Mach. Tools Manuf. 1996, 36, 527–537. [Google Scholar] [CrossRef]

- Vyroubal, J. Compensation of machine tool thermal deformation in spindle axis direction based on decomposition method. Precis. Eng. 2012, 36, 121–127. [Google Scholar] [CrossRef]

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S.; Myers, A. The application of ANFIS prediction models for thermal error compensation on CNC machine tools. Appl. Soft Comput. 2015, 27, 158–168. [Google Scholar] [CrossRef]

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S.; Myers, A. Thermal error modelling of machine tools based on ANFIS with fuzzy c-means clustering using a thermal imaging camera. Appl. Math. Model. 2015, 39, 1837–1852. [Google Scholar] [CrossRef]

| Temperature Sensor | Locations |

|---|---|

| T1 | Nearby rear bearings of spindle |

| T2 | Heat source of belt transmission in spindle head |

| T3 | Nearby spindle motor (directly) |

| T4 | Machine base, temperature of the environment |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.-C.; Chang, C.-J.; Hung, J.-P.; Lee, R.-M.; Wang, C.-C. Real-Time Compensation for Thermal Errors of the Milling Machine. Appl. Sci. 2016, 6, 101. https://doi.org/10.3390/app6040101

Chen T-C, Chang C-J, Hung J-P, Lee R-M, Wang C-C. Real-Time Compensation for Thermal Errors of the Milling Machine. Applied Sciences. 2016; 6(4):101. https://doi.org/10.3390/app6040101

Chicago/Turabian StyleChen, Tsung-Chia, Chia-Jung Chang, Jui-Pin Hung, Rong-Mao Lee, and Cheng-Chi Wang. 2016. "Real-Time Compensation for Thermal Errors of the Milling Machine" Applied Sciences 6, no. 4: 101. https://doi.org/10.3390/app6040101

APA StyleChen, T. -C., Chang, C. -J., Hung, J. -P., Lee, R. -M., & Wang, C. -C. (2016). Real-Time Compensation for Thermal Errors of the Milling Machine. Applied Sciences, 6(4), 101. https://doi.org/10.3390/app6040101