Superhydrophobic Surfaces Created by Elastic Instability of PDMS

Abstract

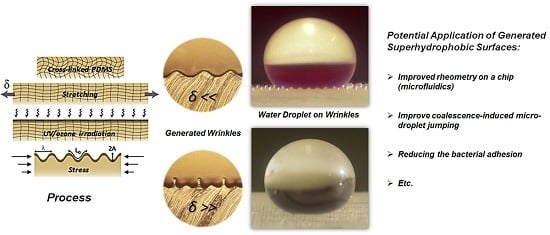

:1. Introduction

2. Materials and Methods

2.1. Preparation of Base Material

2.2. Method for Fabricating Micro-Wrinkling Pattern

2.3. Replication of Structured Surface

3. Results and Discussion

4. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| PDMS | poly-dimethylsiloxane |

| UV | Ultra Violet |

| SEM | Scanning Electron Microscope |

References

- Öner, D.; McCarthy, T.J. Ultrahydrophobic surfaces. Effets of topography length scales on wettability. Langmuir 2000, 16, 7777–7782. [Google Scholar] [CrossRef]

- Bico, J.; Marzolin, C.; Quéré, D. Pearl drops. Europhys. Lett. 1999, 47, 220–226. [Google Scholar] [CrossRef]

- Ditsche-Kuru, P.; Schneider, E.; Melskotte, J.-E.; Brede, M.; Leder, A.; Barthlott, W. Superhydrophobic surfaces of the water bug Notonecta glauca: A model for friction reduction and air retention. Beilstein J. Nanotechnol. 2011, 2, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Cerman, Z.; Striffler, B.F.; Barthlott, W. Dry in the water: The superhydrophobic water fern Salvinia—A model for biomimetic surfaces. In Functional Surfaces in Biology: Little Structures with Big Effects; Gorb, S.N., Ed.; Springer: Dordrecht, The Netherlands, 2009; Volume 1, pp. 97–111. [Google Scholar]

- McHale, G.; Newton, M.I.; Shirtcliffe, N.J. Immersed superhydrophobic surfaces: Gas exchange, slip and drag reduction properties. Soft Matter 2010, 6, 714–719. [Google Scholar] [CrossRef]

- Awada, H.; Grignard, B.; Jérôme, C.; Vaillant, A.; de Coninck, J.; Nysten, B.; Jonas, A.M. Correlation between Superhydrophobicity and the Power Spectral Density of Randomly Rough Surfaces. Langmuir 2010, 26, 17798–17803. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.; Seo, J.; Han, H.; Kang, S.; Kim, H.; Lee, T. Bio-Inspired Extreme Wetting Surfaces for Biomedical Applications. Materials 2016, 9, 116. [Google Scholar] [CrossRef]

- Bowden, N.; Huck, W.; Paul, K.; Whitesides, G.M. The Controlled Formation of Ordered, Sinusoidal Structures by Plasma Oxidation of an Elastomeric Polymer. Appl. Phys. Lett. 1999, 75, 2557–2559. [Google Scholar] [CrossRef]

- Park, J.; Hammond, P. Polyelectrolyte multilayer formation on neutral hydrophobic surfaces. Macromolecules 2005, 38, 10542–10550. [Google Scholar] [CrossRef]

- Roucoules, V.; Ponche, A.; Geissler, A. Changes in silicon elastomeric surface properties under stretching induced by three surface treatments. Langmuir 2007, 23, 13136–13145. [Google Scholar] [CrossRef] [PubMed]

- Brassard, J.-D.; Sarkar, D.; Perron, J. Fluorine Based Superhydrophobic Coatings. Appl. Sci. 2012, 2, 453–464. [Google Scholar] [CrossRef]

- Graubner, V.; Jordan, R.; Nuyken, O.; Schnyder, B.; Lippert, T.; Kotz, R.; Wokaun, A. Photochemical modification of cross-linked poly(dimethylsiloxane) by irradiation at 172 nm. Macromolecules 2004, 37, 5936–5943. [Google Scholar] [CrossRef]

- Lin, P.-C.; Yang, S. Mechanically switchable wetting on wrinkled elastomers with dual-scale roughness. Soft Matter 2009, 5, 1011–1018. [Google Scholar] [CrossRef]

- Cerda, E.; Ravi-Chandar, K.; Mahadevan, L. Thin films: Wrinkling of an elastic sheet under tension. Nature 2000, 419, 579–580. [Google Scholar] [CrossRef] [PubMed]

- Pipe, C.; McKinley, G.H. Microfluidic rheometry. Mech. Res. Commun. 2009, 36, 110–120. [Google Scholar] [CrossRef]

- Galindo-Rosales, J.; Alves, A.; Oliveira, N. Microdevices for extensional rheometry of low viscosity elastic liquids: A review. Microfluid. Nanofluid. 2013, 14, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Haward, J. Microfluidic extensional rheometry using stagnation point flow. Biomicrofluidics 2016, 10, 043401. [Google Scholar] [CrossRef] [PubMed]

- Broboana, D.; Tanase, O.N.; Balan, C. Influence of patterned surface in the rheometry of simple and complex fluids. J. Non-Newton. Fluid Mech. 2015, 222, 151–162. [Google Scholar] [CrossRef]

- Roman, S.V.; Dimitrios, V.P. Review of Fluid Slip over Superhydrophobic Surfaces and Its Dependence on the Contact Angle. Ind. Eng. Chem. Res. 2008, 47, 2455–2477. [Google Scholar]

- Song, D.; Daniello, R.; Rothstein, J. Drag reduction using superhydrophobic sanded Teflon surfaces. Exp. Fluids 2014, 55, 1783. [Google Scholar] [CrossRef]

- Farokhirad, S.; Morris, J.; Lee, T. Coalescence-induced jumping of droplet: Inertia and viscosity effects. Phys. Fluids 2016, 27, 102102. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Levänen, E. Superhydrophobic surfaces for the reduction of bacterial adhesion. RSC Adv. 2013, 3, 12003–12020. [Google Scholar] [CrossRef]

- Brau, F.; Vandeparre, H.; Sabbah, A.; Poulard, C.; Boudaoud, A.; Damman, P. Multiple-length-scale elastic instability mimics parametric resonance of nonlinear oscillators. Nat. Phys. 2011, 7, 56–60. [Google Scholar] [CrossRef]

- Efimenko, K.; Rackaitis, M.; Manias, E.; Vaziri, A.; Mahadevan, L.; Genzer, J. Nested self-similar wrinkling patterns in skins. Nat. Mater. 2005, 4, 293–297. [Google Scholar] [CrossRef] [PubMed]

- Genzer, J.; Efimenko, K. Recent developments in superhydrophobic surfaces and their relevance to marine fouling: A review. Biofouling 2006, 22, 339–360. [Google Scholar] [CrossRef] [PubMed]

- Stafford, C.; Harrison, C.; Beers, K.; Karim, A.; Amis, E.; Vanlandingham, M.; Kim, H.; Volksen, W.; Miller, R.; Simonyi, E. A buckling-based metrology for measuring the elastic moduli of polymeric thin films. Nat. Mater. 2004, 3, 545–550. [Google Scholar] [CrossRef] [PubMed]

- Vandeparre, H.; Damman, P. Wrinkling of Stimuloresponsive Surfaces: Mechanical Instability Coupled to Diffusion. Phys. Rev. Lett. 2008, 101, 124301. [Google Scholar] [CrossRef] [PubMed]

- Kolaric, B.; Vandeparre, H.; Desprez, S.; Vallée, R.; Damman, P. In situ tuning the optical properties of a cavity by wrinkling. Appl. Phys. Lett. 2010, 96, 043119. [Google Scholar] [CrossRef]

- Odijk, T. Microfibrillar buckling within fibers under compression. J. Chem. Phys. 1998, 108, 6923–6928. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surface to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Wenzel, R.N. Surface roughness and contact angle. Phys. Colloid Chem. 1949, 53, 1466–1467. [Google Scholar] [CrossRef]

- Cassie, A.B.; Baxter, S. Large Contact Angles of Plant and Animal Surfaces. Nature 1945, 155, 21–22. [Google Scholar] [CrossRef]

- Cassie, A.B. Contact angles. Discuss. Faraday Soc. 1948, 3, 11–14. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabbah, A.; Youssef, A.; Damman, P. Superhydrophobic Surfaces Created by Elastic Instability of PDMS. Appl. Sci. 2016, 6, 152. https://doi.org/10.3390/app6050152

Sabbah A, Youssef A, Damman P. Superhydrophobic Surfaces Created by Elastic Instability of PDMS. Applied Sciences. 2016; 6(5):152. https://doi.org/10.3390/app6050152

Chicago/Turabian StyleSabbah, Abbas, Ayman Youssef, and Pascal Damman. 2016. "Superhydrophobic Surfaces Created by Elastic Instability of PDMS" Applied Sciences 6, no. 5: 152. https://doi.org/10.3390/app6050152

APA StyleSabbah, A., Youssef, A., & Damman, P. (2016). Superhydrophobic Surfaces Created by Elastic Instability of PDMS. Applied Sciences, 6(5), 152. https://doi.org/10.3390/app6050152