Open Source 3-D Printed Nutating Mixer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bill of Materials

2.2. Design

- (1)

- Base (Figure 2): The base of the equipment holds the 12 V 25 RPM DC geared motor, which is the main load bearing component of the equipment.

- (2)

- Bearing holder (Figure 3): The bearing holder is designed at a 20-degree tilt angle. A skateboard bearing is mounted on the top on a flat surface, which further holds the rod and the platform, hence enabling 3-D rotation of platform at 20 degrees.

- (3)

- Rod (Figure 4): The rod is mounted on the bearing holder and fits in the bore of the bearing, so that when the motor rotates, the rod rotates at 20 degrees with some offset. The slit hole in the rod is designed specifically for 20-degree angle and calculated based on the height of intersection of the rod with the center of the rotating shaft. It should be noted that the FreeCAD model can be adjusted for different angles, but if the mixer needs to be customized at a different angle, the slit hole position in the rod will change, respectively. 30% infill, with a lower layer height results in the mechanical strength needed for this component that has a relatively small cross-sectional area at the top. Polymer use could also be reduced by using a slicer capable of variable height infill settings.

- (4)

- Cover (Figure 5): The shell of the mixer is a functional component and is thus designed to fit on the base as well as hold the rotating rod exactly at the center of the slit hole position. Hence, the neck on the cover consists of a slit hole to accommodate a rubber (NinjaFlex slit), which passes through the cover and through the rotating rod such that it prevents the rod from rotating about its own axis. The height of the equipment is determined based on this slit height as it must be aligned with the rod slit hole after the assembly. Thus, again for customizing, the design of the cover will need to be modified in FreeCAD.

- (5)

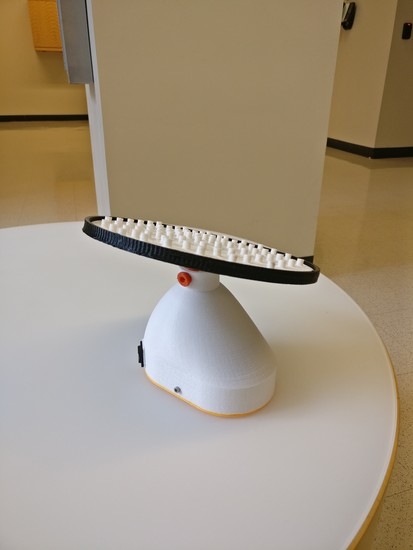

- Platform (Figure 6): The platform of the mixer is designed to provide a solid base for the dimpled mat, which is printed in flexible material to hold the test tubes. To reduce the amount of filament consumed, it is designed as a mesh, which is strong enough to hold the dimpled mat and the test tubes. The platform is attached to the rod with the M3 nuts and bolts.

- (6)

- Dimpled mat (Figure 7): The dimpled mat is built using NinjaFlex, which provides flexibility to hold test tubes of various sizes. The shown design can hold the test tubes with 13 mm, 16 mm, and 20 mm diameter. The design can be easily modified for any custom tube size (or assortment of tube sizes) by changing the location of the cylinders as per the requirement and test tube sizes. Finally, the diameter of the dimpled mat, as shown is 200 mm, and can be modified to a larger or smaller size to accommodate more samples or to save on equipment costs (as this is the most expensive 3-D printed component as shown in Table 1), respectively. Thus, the dimpled mat can be customized for any type of vessel include glass or plastic tubes, bottles, flasks, and microplates.

- (7)

- Slit (Figure 8): The flexible slit is built using NinjaFlex so that it not only holds the rod in place and prevents it from rotating about its own axis, but also acts as a damper to give smooth rotation to the mixer. This component needs to be added to the mixer after it is assembled.

2.3. Assembly and Testing

2.3.1. Procedure to Assemble the 3-D Printed Open Source Nutating Mixer

- (1)

- (2)

- Assemble the motor to the base, as shown in Figure 9. Use only two 6 mm M3 hex bolt screws to fit the motor to the base, as mentioned below. Adding the all 4 hex bolts restricts the movement of the bearing holder.Next, fit M3 nuts on all three blocks, as shown below. A little glue can be used to prevent slipping if necessary.

- (3)

- Fit the bearing holder to the motor shaft using 10 mm M3 hex bolt.

- (4)

- Fit the double pole double throw (DPDT) switch and DC barrel connector on the printed cover. Note: Do not solder it before assembling it to the cover.

- (5)

- Solder the DPDT switch to the barrel connector and the DC motor following the circuit shown in Figure 10.

- (6)

- Tighten the cover to the base using three 16 mm M3 hex screws. Make sure that the wires are out of the way of the bearing holder or else it might mess up when the bearing holder rotates.

- (7)

- Assemble the 3-D printed platform with the printed rod using M3 7 mm hex screws, as shown in Figure 11. Two screws should be enough for the assembly.

- (8)

- Important: Turn on the mixer using the adapter and make sure that the bearing holder is in parallel position to the base as shown in Figure 12. This step is important so that the rod and slit can be assembled with ease. It should be noted that if the bearing holder is not in this position while assembling the rod, the rod might break or it might not assemble properly.

- (9)

- Assemble the rod platform assembly to the cover such that the rod tip fits exactly at the center of the bearing bore.

- (10)

- Make sure that the rod fits properly in the bearing bore by aligning the slit hole of the cover with the rod hole, as shown in Figure 13.

- (11)

- Install the slit passing it through the cover and through the rod.

- (12)

- Place the dimpled mat on top of the cover. If required use some glue to fix it firmly to the platform.

2.3.2. Testing

3. Results

4. Discussion

4.1. Performance and Future Work

4.2. Cost Analysis

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper-Maximizing Customizability by Breeding the Means of Production. In Proceedings of the World Conference on Mass Customization and Personalization, Cambridge, MA, USA, 7–10 October 2007. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap-the Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Wohler, T. Wohlers Report 2016: 3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2016. [Google Scholar]

- Pearce, J. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs, 1st ed.; Elsevier: Waltham, MA, USA, 2014. [Google Scholar]

- Oh, J.; Hofer, R.; Fitch, W.T. An open source automatic feeder for animal experiments. HardwareX 2017, 1, 13–21. [Google Scholar] [CrossRef]

- McMunn, M.S. A time-sorting pitfall trap and temperature datalogger for the sampling of surface-active arthropods. HardwareX 2017, 1, 38–45. [Google Scholar] [CrossRef]

- Pocero, L.; Amaxilatis, D.; Mylonas, G.; Chatzigiannakis, I. Open source IoT meter devices for smart and energy-efficient school buildings. HardwareX 2017, 1, 54–67. [Google Scholar] [CrossRef]

- Jiang, J.; Claudel, C. A high performance, low power computational platform for complex sensing operations in smart cities. HardwareX 2017, 1, 22–37. [Google Scholar] [CrossRef]

- Baden, T.; Chagas, A.; Marzullo, T.; Prieto-Godino, L.; Euler, T. Open Laware: 3-D Printing Your Own Lab Equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar]

- Zhang, C.; Anzalone, N.C.; Faria, R.P.; Pearce, J.M. Open-source 3D-printable optics equipment. PLoS ONE 2013, 8, e59840. [Google Scholar] [CrossRef] [PubMed]

- Damase, T.R.; Stephens, D.; Spencer, A.; Allen, P.B. Open source and DIY hardware for DNA nanotechnology labs. J. Biol. Methods 2015, 2, e24. [Google Scholar] [CrossRef] [PubMed]

- Gwamuri, J.; Wittbrodt, B.; Anzalone, N.; Pearce, J. Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3-D-Printable Self-Adjustable Glasses. Chall. Sustain. 2014, 2, 30–40. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Laureto, J.; Tymrak, B.; Pearce, J. Distributed Manufacturing with 3-D Printing: A Case Study of Recreational Vehicle Solar Photovoltaic Mounting Systems. J. Frugal Innov. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Savonen, B.L.; Gershenson, J.K.; Pearce, J.M. Viability of distributed manufacturing of bicycle components with 3-D printing: CEN standardized polylactic acid pedal testing. J. Humanit. Eng. 2017, 5, 8–17. [Google Scholar]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Srai, J.S.; Kumar, M.; Graham, G.; Phillips, W.; Tooze, J.; Ford, S.; Beecher, P.; Raj, B.; Gregory, M.; Tiwari, M.K.; et al. Distributed manufacturing: Scope, challenges and opportunities. Int. J. Prod. Res. 2016, 54, 6917–6935. [Google Scholar] [CrossRef]

- Schausberger, S.E.; Kaltseis, R.; Drack, M.; Cakmak, U.D.; Major, Z.; Bauer, S. Cost-Efficient Open Source Desktop Size Radial Stretching System With Force Sensor. IEEE Access 2015, 3, 556–561. [Google Scholar] [CrossRef]

- Dhankani, K.; Pearce, J.M. Open Source Laboratory Sample Rotator Mixer and Shaker. HardwareX 2017, 1, 1–12. [Google Scholar] [CrossRef]

- Wijnen, B.; Anzalone, G.C.; Pearce, J.M. Open-source mobile water quality testing platform. J. Water Sanit. Hyg. Dev. 2014, 4, 532–537. [Google Scholar] [CrossRef]

- Wijnen, B.; Hunt, E.J.; Anzalone, G.C.; Pearce, J.M. Open-source syringe pump library. PLoS ONE 2014, 9, e107216. [Google Scholar] [CrossRef] [PubMed]

- Chiu, S.H.; Urban, P.L. Robotics-assisted mass spectrometry assay platform enabled by open-source electronics. Biosens. Bioelectron. 2015, 64, 260–268. [Google Scholar] [CrossRef] [PubMed]

- Gali, H. An Open-Source Automated Peptide Synthesizer Based on Arduino and Python. SLAS Technol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Harnett, C. Open source hardware for instrumentation and measurement. IEEE Instrum. Meas. Mag. 2011, 14. [Google Scholar] [CrossRef]

- Fobel, R.; Fobel, C.; Wheeler, A.R. DropBot: An open-source digital microfluidic control system with precise control of electrostatic driving force and instantaneous drop velocity measurement. Appl. Phys. Lett. 2013, 102, 193513. [Google Scholar] [CrossRef]

- Pearce, J.M.; Anzalone, N.C.; Heldt, C.L. Open-Source Wax RepRap 3-D Printer for Rapid Prototyping Paper-Based Microfluidics. J. Lab. Autom. 2016, 21, 510–516. [Google Scholar] [CrossRef] [PubMed]

- Chandra, H.; Allen, S.W.; Oberloier, S.W.; Bihari, N.; Gwamuri, J.; Pearce, J.M. Open-source automated mapping four-point probe. Materials 2017, 10, 110. [Google Scholar] [CrossRef] [PubMed]

- Wijnen, B.; Petersen, E.E.; Hunt, E.J.; Pearce, J.M. Free and open-source automated 3-D microscope. J. Microsc. 2016, 264, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Wijnen, B.; Pearce, J.M. Open-source 3-D platform for low-cost scientific instrument ecosystem. J. Lab. Autom. 2016, 21, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Coakley, M.; Hurt, D.E. 3D Printing in the Laboratory: Maximize Time and Funds with Customized and Open-Source Labware. J. Lab. Autom. 2016, 21, 489–495. [Google Scholar] [CrossRef] [PubMed]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014. [Google Scholar]

- PLA Filament from Amazon. Available online: https://www.amazon.com/3D-MARS-Printing-Filament-Dimensional (accessed on 29 August 2017).

- Ninja Flex Filament. Available online: https://www.lulzbot.com/store/filament/ninjaflex (accessed on 29 August 2017).

- Open Source 3-D Printed Nutating Mixer. Available online: https://osf.io/bqysc/ (accessed on 29 August 2017).

- Roller Skateboard Bearing. Available online: https://www.amazon.com/Jeremywell-608-2RS-Bearing-Rubber-Sealed (accessed on 29 August 2017).

- DC Power Jack Socket Female Mounting Connector. Available online: https://www.amazon.com/DC barrel jack (accessed on 29 August 2017).

- DPDT Switches. Available online: https://www.amazon.com/uxcell-Position-Rocker-Switch-Listed (accessed on 29 August 2017).

- DC Motor. Available online: https://www.amazon.com/gp/product/B01N1JQFYX/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1 (accessed on 29 August 2017).

- DC Adapter. Available online: https://www.amazon.com/ALED-LIGHT-Adapter-Regulated-Supply (accessed on 29 August 2017).

- FreeCAD. Available online: http://www.freecadweb.org/ (accessed on 29 August 2017).

- Cura. Available online: https://ultimaker.com/en/products/cura-software (accessed on 29 August 2017).

- Groenendyk, M.; Gallant, R. 3D printing and scanning at the Dalhousie University Libraries: A pilot project. Library Hi Tech 2013, 31, 34–41. [Google Scholar] [CrossRef]

- Merlo, D.F.; Ing, D.; Mazzoni, S. Gas Evolution during FDM 3D Printing and Health Impact. 3D Safety 2015. Available online: http://www.3dsafety.org/3dsafety/download/mf2015_eng.pdf (accessed on 29 August 2017).

- Anzalone, G.C.; Wijnen, B.; Pearce, J.M. Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer. Rapid Prototyp. J. 2015, 21, 506–519. [Google Scholar] [CrossRef]

- Wijnen, B.; Anzalone, G.C.; Haselhuhn, A.S.; Sanders, P.G.; Pearce, J.M. Free and open-source control software for 3-D motion and processing. J. Open Res. Softw. 2016, 4, e2. [Google Scholar] [CrossRef]

- Lulzbot Mini. Available online: https://www.lulzbot.com/store/printers/lulzbot-mini (accessed on 29 August 2017).

- Flexystruder Extruder. Available online: https://www.lulzbot.com/store/tool-heads/lulzbot-mini-flexystruder-tool-head-v2 (accessed on 29 August 2017).

- Labnet GyroMini S0500 3D Mixing Shaker with Dimpled Rubber Mat, 120 V. Available online: http://www.thomassci.com/Equipment/Ambient-Temperature-Shakers/_/GyroMini-Nutating-Mixer1?q=Nutating%20Mixer (accessed on 29 August 2017).

- Benchmark BlotBoy 3-Dimensional Rockers. Available online: https://www.amazon.com/Benchmark-BlotBoy-3-Dimensional-Rockers/dp/B01LVWMB31/ref=sr_1_fkmr0_2 (accessed on 29 August 2017).

- Benchmark Scientific MiniMixer 3-Dimensional Lab Shaker, with Autoclavable Dimpled Mat, 10.5″ Length × 7.5″ Width Platform. Available online: https://www.amazon.com/Benchmark-Scientific-MiniMixer-3-Dimensional-Autoclavable/dp/B003R7JZQI/ref=pd_sbs_328_3 (accessed on 29 August 2017).

- Boekel 201100 Mini Orbitron Variable Speed Nutator, 4 °C to 40 °C Temperature Range, 0.8 kg/1.8 lb. Capacity. Available online: https://www.amazon.com/Boekel-201100-Orbitron-Variable-Temperature/dp/B00C0ZFCAQ/ref=pd_sbs_328_5?encoding=UTF8&psc=1&refRID=ZV0GQ79TM55Z9P1H1C35 (accessed on 29 August 2017).

- Globe Nutating Mixer, 24 rpm, 10.5″ × 7.5″ Platform, 115 V. Available online: https://www.amazon.com/Nutating-Mixer-10-5-201c-7-5-201c-Platform/dp/B003T436A0 (accessed on 29 August 2017).

- Globe Scientific 522-230 Nutating Mixer II. Available online: https://www.amazon.com/Globe-Scientific-522-230-Nutating-Platform/dp/B01N7OKW0K/ref=sr_1_fkmr1_1 (accessed on 29 August 2017).

- Benchmark Mini BioMixer 3-D Shakers. Available online: https://www.amazon.com/Benchmark-Mini-BioMixer-3-Dimensional-Shakers/dp/B004SC3NFU/ref=sr_1_5 (accessed on 29 August 2017).

- Chemglass CLS-4029-100 3D Nutating Mixer Economical Shaker, 20 rpm Speed. Available online: https://www.amazon.com/Chemglass-CLS-4029-100-Nutating-Economical-Shaker/dp/B00DUGAFGK/ref=sr_1_1 (accessed on 29 August 2017).

- Schelly, C.; Anzalone, G.; Wijnen, B.; Pearce, J.M. Open-source 3-D printing technologies for education: Bringing additive manufacturing to the classroom. J. Vis. Lang. Comput. 2015, 28, 226–237. [Google Scholar] [CrossRef]

- Bailey, M.; Grieco, J.; Speights, A.; Weiss, R.G. 3D printing in the classroom and laboratory. J. Comput. Sci. Coll. 2015, 31, 183–184. [Google Scholar]

- Stacey, M. The FAB LAB network: A global platform for digital invention, education and entrepreneurship. Innovations 2014, 9, 221–238. [Google Scholar] [CrossRef]

- Fab Foundation. Fab Labs. Available online: http://www.fabfoundation.org/fab-labs/ (accessed on 9 September 2017).

- The Maker Map. Available online: http://themakermap.com/ (accessed on 9 September 2017).

- Hackerspaces. Available online: https://wiki.hackerspaces.org/ (accessed on 9 September 2017).

- Moorefield-Lang, H. 3-D printing in your libraries and classrooms. Knowl. Quest 2014, 43, 70–73. [Google Scholar]

- Make XYZ. Available online: https://www.makexyz.com/ (accessed on 9 September 2017).

| Sr. No. | Component | 3-D Printing Material | Quantity | Mass (g) | Cost (US$) |

|---|---|---|---|---|---|

| 1 | Rod | PLA | 1 | 7 | 0.15 |

| 2 | Bearing holder | PLA | 1 | 8 | 0.18 |

| 3 | Base | PLA | 1 | 60 | 1.32 |

| 4 | Cover | PLA | 1 | 126 | 2.77 |

| 5 | Platform | PLA | 1 | 76 | 1.67 |

| 6 | Dimpled Bed | Ninja Flex | 1 | 67 | 5.80 |

| 7 | Slit | Ninja Flex | 1 | 4 | 0.34 |

| Total Filament Cost | 12.23 | ||||

| Sr. No. | Component | Qty | Cost (US$) |

|---|---|---|---|

| 1 | Skateboard bearing [36] | 1 | 0.73 |

| 2 | DC barrel connector [37] | 1 | 1.00 |

| 3 | Switch DPDT [38] | 1 | 1.19 |

| 4 | 12 Volt DC Motor—25 RPM [39] | 1 | 13.95 |

| 5 | DC adapter [40] | 1 | 6.99 |

| 6 | M3 Fasteners (2 M3 7 mm, 2 6 mm, 3 M3 16 mm and 1 M3 10 mm and bolts) | 1 | <1.00 |

| Total Ordered Material Cost | 24.86 | ||

| Total Cost of Equipment (Table 1 and Table 2) | 37.09 | ||

| Commercial Proprietary Product | Cost (US$) | Cost Savings for OS Nutating Mixer (%) |

|---|---|---|

| Labnet GyroMini Nutating Mixer [49] | 291.65 | 87.3 |

| Benchmark BlotBoy 3-Dimensional Rockers [50] | 381.65 | 90.3 |

| Benchmark Scientific B3D1008 Mini [51] | 322.15 | 88.5 |

| Boekel 201100 Mini Orbitron [52] | 491.00 | 92.4 |

| Globe Nutating Mixer [53] | 443.03 | 91.6 |

| Globe Scientific 522-230 Nutating Mixer II [54] | 420.60 | 91.2 |

| Benchmark Mini BioMixer 3-D Shakers [55] | 313.65 | 88.2 |

| Chemglass CLS-4029-100 3D Nutating Mixer [56] | 325.00 | 88.6 |

| Average | 373.59 | 90.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trivedi, D.K.; Pearce, J.M. Open Source 3-D Printed Nutating Mixer. Appl. Sci. 2017, 7, 942. https://doi.org/10.3390/app7090942

Trivedi DK, Pearce JM. Open Source 3-D Printed Nutating Mixer. Applied Sciences. 2017; 7(9):942. https://doi.org/10.3390/app7090942

Chicago/Turabian StyleTrivedi, Dhwani K., and Joshua M. Pearce. 2017. "Open Source 3-D Printed Nutating Mixer" Applied Sciences 7, no. 9: 942. https://doi.org/10.3390/app7090942

APA StyleTrivedi, D. K., & Pearce, J. M. (2017). Open Source 3-D Printed Nutating Mixer. Applied Sciences, 7(9), 942. https://doi.org/10.3390/app7090942