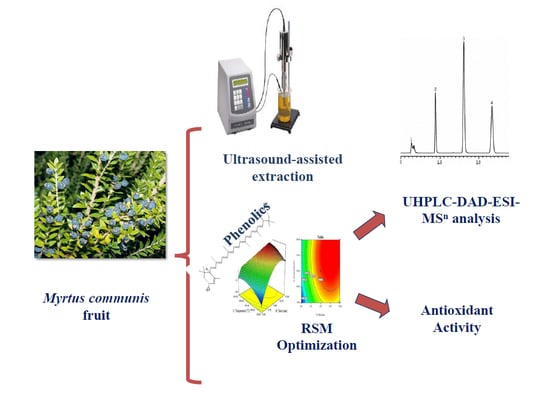

Optimization of Ultrasound-Assisted Extraction of Polyphenols from Myrtus communis L. Pericarp

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Extraction of Phenolic Compounds

2.2.1. Ultrasound Extraction

2.2.2. Microwave-Assisted Extraction

2.2.3. Conventional Solvent Extraction

2.3. Analytical Determinations

2.3.1. Total Phenolic and Flavonoid Contents

2.3.2. Total Monomeric Anthocyanins and Condensed Tannin Contents

2.3.3. Antioxidant Activity

2.4. Identification of Phenolic Compounds by UHPLC-DAD-ESI-MSn

2.5. Statistical Analysis

3. Results and Discussion

3.1. Optimization of UAE Conditions

3.1.1. Modeling and Fitting the Model Using RSM

10.588X1X4 + 15.196X2X3 − 7.198X2X4 − 6.580X3X4 − 1.526X12 − 11.561X22 − 0.888X32 −

17.876X42

3.1.2. Response Surface Analysis (RSA)

3.1.3. Validation and Verification of the Predictive Model

3.2. Comparison between UAE, MAE and CSE Methods

3.3. Identification of Phenolics by UHPLC-DAD-ESI-MSn Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nuvoli, F.; Spanu, D. Analisie prospettive economiche dell’utilizzazionze industriale del mirto. Riv. Ital. EPPOS 1996, 12, 231–236. [Google Scholar] [CrossRef]

- Sumbul, S.; Ahmad, M.A.; Asif, M.; Akhtar, M.; Saud, I. Physicochemical and phytochemical standardization of berries of Myrtus communis Linn. J. Pharm. Bioall. Sci. 2012, 4, 322–326. [Google Scholar] [CrossRef]

- Messaoud, C.; Boussaid, M. Myrtus communis berry color morphs: A comparative analysis of essential oils, fatty acids, phenolic compounds, and antioxidant activities. Chem. Biodivers. 2011, 8, 300–310. [Google Scholar] [CrossRef]

- Liu, R.H. Health benefits of fruit and vegetables are from additive and synergistic combinations of phytochemicals. Am. J. Clin. Nutr. 2003, 78, 517S–520S. [Google Scholar] [CrossRef]

- Dahmoune, F.; Boulekbache, L.; Moussi, K.; Aoun, O.; Spigno, G.; Madani, K. Valorization of Citrus limon residues for the recovery of antioxidants: Evaluation and optimization of microwave and ultrasound application to solvent extraction. Ind. Crops Prod. 2013, 50, 77–87. [Google Scholar] [CrossRef]

- Đorđević, T.; Antov, M. Ultrasound assisted extraction in aqueous two-phase system for the integrated extraction and separation of antioxidants from wheat chaff. Sep. Purif. Technol. 2017, 182, 52–58. [Google Scholar] [CrossRef]

- De Castro, M.D.L.; García-Ayuso, L.E. Soxhlet extraction of solid materials: An outdated technique with a promising innovative future. Anal. Chim. Acta 1998, 369, 1–10. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- Živković, J.; Šavikin, K.; Janković, T.; Ćujić, N.; Menković, N. Optimization of ultrasound-assisted extraction of polyphenolic compounds from pomegranate peel using response surface methodology. Sep. Purif. Technol. 2018, 194, 40–47. [Google Scholar] [CrossRef]

- Jacotet-Navarro, M.; Rombaut, N.; Deslis, S.; Fabiano-Tixier, A.-S.; Pierre, F.-X.; Bily, A.; Chemat, F. Towards a “dry” bio-refinery without solvents or added water using microwaves and ultrasound for total valorization of fruit and vegetable by-products. Green Chem. 2016, 18, 3106–3115. [Google Scholar] [CrossRef]

- Zu, G.; Zhang, R.; Yang, L.; Ma, C.; Zu, Y.; Wang, W.; Zhao, C. Ultrasound-assisted extraction of carnosic acid and rosmarinic acid using ionic liquid solution from Rosmarinus officinalis. Int. J. Mol. Sci. 2012, 13, 11027–11043. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.-L.; Yu, C.-H.; Chen, J.; Li, X.-X.; Wang, W.; Li, S.-Q. Ultrasonic-assisted extraction optimized by response surface methodology, chemical composition and antioxidant activity of polysaccharides from Tremella mesenterica. Carbohydr. Polym. 2011, 83, 217–224. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

- Montoro, P.; Tuberoso, C.I.G.; Piacente, S.; Perrone, A.; De Feo, V.; Cabras, P.; Pizza, C. Stability and antioxidant activity of polyphenols in extracts of Myrtus communis L. berries used for the preparation of myrtle liqueur. J. Pharm. Biomed. 2006, 41, 1614–1619. [Google Scholar] [CrossRef] [PubMed]

- Amensour, M.; Sendra, E.; Abrini, J.; Bouhdid, S.; Pérez-Alvarez, J.A.; Fernández-López, J. Total phenolic content and antioxidant activity of myrtle (Myrtus communis) extracts. Nat. Prod. Commun. 2009, 4, 819–824. [Google Scholar] [CrossRef] [PubMed]

- Tuberoso, C.I.G.; Rosa, A.; Bifulco, E.; Melis, M.P.; Atzeri, A.; Pirisi, F.M.; Dessì, M.A. Chemical composition and antioxidant activities of Myrtus communis L. berries extracts. Food Chem. 2010, 123, 1242–1251. [Google Scholar] [CrossRef]

- Jovanović, A.A.; Đorđević, V.B.; Zdunić, G.M.; Pljevljakušić, D.S.; Šavikin, K.P.; Gođevac, D.M.; Bugarski, B.M. Optimization of the extraction process of polyphenols from Thymus serpyllum L. herb using maceration, heat-and ultrasound-assisted techniques. Sep. Purif. Technol. 2017, 179, 369–380. [Google Scholar] [CrossRef]

- Bouaoudia-Madi, N.; Boulekbache-Makhlouf, L.; Kadri, N.; Dahmoune, F.; Remini, H.; Dairi, S.; Oukhmanou-Bensidhoum, S.; Madani, K. Phytochemical analysis of Myrtus communis plant: Conventional versus microwave assisted-extraction procedures. J. Complement. Integr. Med. 2017, 14. [Google Scholar] [CrossRef]

- Benmeziane, A.; Boulekbache-Makhlouf, L.; Mapelli-Brahm, P.; Khaled Khodja, N.; Remini, H.; Madani, K.; Meléndez-Martínez, A.J. Extraction of carotenoids from cantaloupe waste and determination of its mineral composition. Food Res. Int. 2018, 111, 391–398. [Google Scholar] [CrossRef]

- George, S.; Brat, P.; Alter, P.; Amiot, M.J. Rapid Determination of Polyphenols and Vitamin C in Plant-Derived Products. J. Agric. Food Chem. 2005, 53, 1370–1373. [Google Scholar] [CrossRef]

- Quettier-Deleu, C.; Gressier, B.; Vasseur, J.; Dine, T.; Brunet, C.; Luyckx, M.; Cazin, M.; Cazin, J.-C.; Bailleul, F.; Trotin, F. Phenolic compounds and antioxidant activities of buckwheat (Fagopyrum esculentum Moench) hulls and flour. J. Ethnopharmacol. 2000, 72, 35–42. [Google Scholar] [CrossRef]

- Cheok, C.Y.; China, N.L.; Yusof, Y.A.; Talib, R.A.; Law, C.L. Optimization of total monomeric anthocyanin (TMA) and total phenolic content (TPC) extractions from mangosteen (Garcinia mangostana Linn.) hull using ultrasonic treatments. Ind. Crops Prod. 2013, 50, 1–7. [Google Scholar] [CrossRef]

- Wannes, W.A.; Mhamdi, B.; Sriti, J.; Jemia, M.B.; Ouchikh, O.; Hamdaoui, G.; Kchouk, M.E.; Marzouk, B. Antioxidant activities of the essential oils and methanol extracts from myrtle (Myrtus communis var. italica L.) leaf, stem and flower. Food Chem. Toxicol. 2010, 48, 1362–1370. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Lu, Y.; Wei, D. Antioxidant activity of a flavonoid-rich extract of Hypericum perforatum L. in vitro. J. Agric. Food Chem. 2004, 52, 5032–5039. [Google Scholar] [CrossRef]

- Pereira, O.R.; Catarino, M.D.; Afonso, A.F.; Silva, A.M.S.; Cardoso, S.M. Salvia elegans, Salvia greggii and Salvia officinalis Decoctions: Antioxidant Activities and Inhibition of Carbohydrate and Lipid Metabolic Enzymes. Molecules 2018, 23, 3169. [Google Scholar] [CrossRef] [PubMed]

- Jacotet-Navarro, M.; Rombaut, N.; Fabiano-Tixier, A.-S.; Danguien, M.; Bily, A.; Chemat, F. Ultrasound versus microwave as green processes for extraction of rosmarinic, carnosic and ursolic acids from rosemary. Ultrason. Sonochem. 2015, 27, 102–109. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dahmoune, F.; Moussi, K.; Remini, H.; Belbahi, A.; Aoun, O.; Spigno, G.; Madani, K. Optimization of Ultrasound-Assisted Extraction of Phenolic Compounds from Citrus sinensis L. Peels using Response Surface Methodology. Chem. Eng. Trans. 2014, 37, 889–894. [Google Scholar] [CrossRef]

- Dahmoune, F.; Spigno, G.; Moussi, K.; Remini, H.; Cherbal, A.; Madani, K. Pistacia lentiscus leaves as a source of phenolic compounds: Microwave-assisted extraction optimized and compared with ultrasound-assisted and conventional solvent extraction. Ind. Crops Prod. 2014, 61, 31–40. [Google Scholar] [CrossRef]

- Ghafoor, K.; Choi, Y.H.; Jeon, J.Y.; Jo, I.H. Optimization of ultrasound-assisted extraction of phenolic compounds, antioxidants, and anthocyanins from grape (Vitis vinifera) seeds. J. Agric. Food Chem. 2009, 57, 4988–4994. [Google Scholar] [CrossRef] [PubMed]

- Wannes, W.A.; Marzouk, B. Differences between myrtle fruit parts (Myrtus communis var. italica) in phenolics and antioxidant contents. J. Food Biochem. 2013, 37, 585–594. [Google Scholar] [CrossRef]

- Pereira, P.; Cebola, M.-J.; Oliveira, M.C.; Bernardo-Gil, M.G. Supercritical fluid extraction vs conventional extraction of myrtle leaves and berries: Comparison of antioxidant activity and identification of bioactive compounds. J. Supercrit. Fluid 2016, 113, 1–9. [Google Scholar] [CrossRef]

- Romani, A.; Pinelli, P.; Mulinacci, N.; Vincieri, F.; Tattini, M. Identification and quantitation of polyphenols in leaves of Myrtus communis L. Chromatographia 1999, 49, 17–20. [Google Scholar] [CrossRef]

- Boldbaatar, D.; El-Seedi, H.R.; Findakly, M.; Jabri, S.; Javzan, B.; Choidash, B.; Göransson, U.; Hellman, B. Antigenotoxic and antioxidant effects of the Mongolian medicinal plant Leptopyrum fumarioides (L): An in vitro study. J. Ethnopharmacol. 2014, 155, 599–606. [Google Scholar] [CrossRef] [PubMed]

- Romani, A.; Coinu, R.; Carta, S.; Pinelli, P.; Galardi, C.; Vincieri, F.F.; Franconi, F. Evaluation of antioxidant effect of different extracts of Myrtus communis L. Free Radic. Res. 2004, 38, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Romani, A.; Campo, M.; Pinelli, P. HPLC/DAD/ESI-MS analyses and anti-radical activity of hydrolyzable tannins from different vegetal species. Food Chem. 2012, 130, 214–221. [Google Scholar] [CrossRef]

- Taamalli, A.; Iswaldi, I.; Arráez-Román, D.; Segura-Carretero, A.; Fernández-Gutiérrez, A.; Zarrouk, M. UPLC–QTOF/MS for a rapid characterisation of phenolic compounds from leaves of Myrtus communis L. Phytochem. Anal. 2014, 25, 89–96. [Google Scholar] [CrossRef] [PubMed]

- Hasdemir, B.; Yaşa, H.; Onar, H.Ç.; Yusufoğlu, A.S. Investigation of essential oil composition, polyphenol content, and antioxidant activity of Myrtus communis L. from Turkey. JOTCSA 2016, 3, 427–438. [Google Scholar] [CrossRef]

- Yoshimura, M.; Amakura, Y.; Tokuhara, M.; Yoshida, T. Polyphenolic compounds isolated from the leaves of Myrtus communis. J. Nat. Med. 2008, 62, 366–368. [Google Scholar] [CrossRef]

- Boulekbache-Makhlouf, L.; Medouni, L.; Medouni-Adrar, S.; Arkoub, L.; Madani, K. Effect of solvents extraction on phenolic content and antioxidant activity of the byproduct of eggplant. Ind. Crops Prod. 2013, 49, 668–674. [Google Scholar] [CrossRef]

- Saldanha, L.L.; Vilegas, W.; Dokkedal, A.L. Characterization of flavonoids and phenolic acids in Myrcia bella cambess. Using FIA-ESI-IT-MSn and HPLC-PAD-ESI-IT-MS combined with NMR. Molecules 2013, 18, 8402–8416. [Google Scholar] [CrossRef]

- Sobeh, M.; ElHawary, E.; Peixoto, H.; Labib, R.M.; Handoussa, H.; Swilam, N.; El-Khatib, A.H.; Sharapov, F.; Mohamed, T.; Krstin, S. Identification of phenolic secondary metabolites from Schotia brachypetala Sond. (Fabaceae) and demonstration of their antioxidant activities in Caenorhabditis elegans. PeerJ 2016, 4, e2404. [Google Scholar] [CrossRef] [PubMed]

- Cadahía, E.; Conde, E.; García-Vallejo, M.; Fernández de Simón, B. High pressure liquid chromatographic analysis of polyphenols in leaves of Eucalyptus camaldulensis, E. globulus and E. rudis: Proanthocyanidins, ellagitannins and flavonol glycosides. Phytochem. Anal. 1997, 8, 78–83. [Google Scholar] [CrossRef]

- Amakura, Y.; Yoshimura, M.; Sugimoto, N.; Yamazaki, T.; Yoshida, T. Marker constituents of the natural antioxidant Eucalyptus leaf extract for the evaluation of food additives. Biosci. Biotechnol. Biochem. 2009, 73, 1060–1065. [Google Scholar] [CrossRef]

- Okamura, H.; Mimura, A.; Niwano, M.; Takahara, Y.; Yasuda, H.; Yoshida, H. Two acylated flavonol glycosides from Eucalyptus rostrata. Phytochemistry 1993, 33, 512–514. [Google Scholar] [CrossRef]

- Cascaes, M.; Guilhon, G.; Andrade, E.; Zoghbi, M.; Santos, L. Constituents and pharmacological activities of Myrcia (Myrtaceae): A review of an aromatic and medicinal group of plants. Int. J. Mol. Sci. 2015, 16, 23881–23904. [Google Scholar] [CrossRef]

- Hussein, S.A.; Hashem, A.N.; Seliem, M.A.; Lindequist, U.; Nawwar, M.A. Polyoxygenated flavonoids from Eugenia edulis. Phytochemistry 2003, 64, 883–889. [Google Scholar] [CrossRef]

- Barboni, T.; Venturini, N.; Paolini, J.; Desjobert, J.-M.; Chiaramonti, N.; Costa, J. Characterisation of volatiles and polyphenols for quality assessment of alcoholic beverages prepared from Corsican Myrtus communis berries. Food Chem. 2010, 122, 1304–1312. [Google Scholar] [CrossRef]

- Bochi, V.C.; Godoy, H.T.; Giusti, M.M. Anthocyanin and other phenolic compounds in Ceylon gooseberry (Dovyalis hebecarpa) fruits. Food Chem. 2015, 176, 234–243. [Google Scholar] [CrossRef]

- Dias, T.; Bronze, M.R.; Houghton, P.J.; Mota-Filipe, H.; Paulo, A. The flavonoid-rich fraction of Coreopsis tinctoria promotes glucose tolerance regain through pancreatic function recovery in streptozotocin-induced glucose-intolerant rats. J. Ethnopharmacol. 2010, 132, 483–490. [Google Scholar] [CrossRef]

- Lopes-Lutz, D.; Dettmann, J.; Nimalaratne, C.; Schieber, A. Characterization and quantification of polyphenols in Amazon grape (Pourouma cecropiifolia Martius). Molecules 2010, 15, 8543–8552. [Google Scholar] [CrossRef]

- Scorrano, S.; Lazzoi, M.R.; Mergola, L.; Di Bello, M.P.; Del Sole, R.; Vasapollo, G. Anthocyanins Profile by Q-TOF LC/MS in Myrtus communis Berries from Salento Area. Food Anal. Methods 2017, 10, 2404–2411. [Google Scholar] [CrossRef]

- Romani, A.; Pinelli, P.; Galardi, C.; Mulinacci, N.; Tattini, M. Identification and quantification of galloyl derivatives, flavonoid glycosides and anthocyanins in leaves of Pistacia lentiscus L. Phytochem. Anal. 2002, 13, 79–86. [Google Scholar] [CrossRef] [PubMed]

- Abu-Reidah, I.M.; Ali-Shtayeh, M.S.; Jamous, R.M.; Arráez-Román, D.; Segura-Carretero, A. HPLC–DAD–ESI-MS/MS screening of bioactive components from Rhus coriaria L. (Sumac) fruits. Food Chem. 2015, 166, 179–191. [Google Scholar] [CrossRef] [PubMed]

| Run | X1-Ethanol (%, v/v) | X2-Irradiation Time (min) | X3-Amplitude (%) | X4-Solvent-to Solid Ratio (mL/g) | TPC Recovery (mg GAE/g DW) |

|---|---|---|---|---|---|

| 1 | 50 | 2.5 | 50 | 25 | 134.93 ± 11.37 |

| 2 | 70 | 10 | 70 | 30 | 195.24 ± 0.99 |

| 3 | 30 | 5 | 30 | 20 | 105.29 ± 11.72 |

| 4 | 70 | 5 | 30 | 30 | 221.73 ± 3.64 |

| 5 | 50 | 7.5 | 50 | 25 | 200.50 ± 12.82 |

| 6 | 50 | 7.5 | 50 | 15 | 78.90 ± 10.45 |

| 7 | 50 | 7.5 | 50 | 25 | 200.90 ± 28.02 |

| 8 | 50 | 7.5 | 50 | 25 | 200.10 ± 23.11 |

| 9 | 50 | 7.5 | 90 | 25 | 200.02 ± 13.23 |

| 10 | 70 | 10 | 30 | 30 | 214.07 ± 14.66 |

| 11 | 50 | 7.5 | 10 | 25 | 210.72 ± 2.70 |

| 12 | 50 | 7.5 | 50 | 25 | 210.21 ± 15.39 |

| 13 | 10 | 7.5 | 50 | 25 | 170.43 ± 9.38 |

| 14 | 30 | 10 | 70 | 20 | 159.56 ± 10.02 |

| 15 | 30 | 10 | 70 | 30 | 228.39 ± 12.96 |

| 16 | 50 | 7.5 | 50 | 25 | 203.34 ± 16.40 |

| 17 | 70 | 10 | 70 | 20 | 200.42 ± 14.47 |

| 18 | 70 | 10 | 30 | 20 | 185.51 ± 13.34 |

| 19 | 50 | 7.5 | 50 | 35 | 195.94 ± 12.80 |

| 20 | 50 | 12.5 | 50 | 25 | 190.43 ± 15.47 |

| 21 | 70 | 5 | 70 | 30 | 142.96 ± 9.60 |

| 22 | 30 | 10 | 30 | 20 | 118.92 ± 12.08 |

| 23 | 70 | 5 | 70 | 20 | 115.45 ± 16.12 |

| 24 | 30 | 5 | 30 | 30 | 219.12 ± 18.72 |

| 25 | 30 | 10 | 30 | 30 | 180.77 ± 9.38 |

| 26 | 70 | 5 | 30 | 20 | 161.68 ±9.42 |

| 27 | 30 | 5 | 70 | 30 | 179.22 ± 9.70 |

| 28 | 90 | 7.5 | 50 | 25 | 235.21 ±17.36 |

| 29 | 50 | 7.5 | 50 | 25 | 210.21 ± 16.60 |

| 30 | 30 | 5 | 70 | 20 | 111.38 ± 7.63 |

| Parameters | Estimated Coefficients | Standard Error | DF a | Sum of Squares | F Ratio b | Prob > F |

|---|---|---|---|---|---|---|

| Model | 14 | 46971.996 | 43.8356 | <0.0001 | ||

| Intercept | 205.032 | 3.912523 | 52.40 | <0.0001 | ||

| Linear | ||||||

| X1-Ethanol | 10.99875 | 1.736676 | 1 | 2903.340 | 37.9327 | <0.0001 |

| X2-Time | 14.04375 | 1.736676 | 1 | 4733.446 | 61.8434 | <0.0001 |

| X3-Amplitude | −3.994583 | 1.736676 | 1 | 382.961 | 5.0035 | 0.0421 |

| X4-Ratio | 27.390417 | 1.736676 | 1 | 18005.638 | 235.2474 | <0.0001 |

| Quadratic | ||||||

| X12 | −1.526438 | 1.717541 | 1 | 60.454 | 0.7898 | 0.3892 |

| X22 | −11.56144 | 1.717541 | 1 | 3468.113 | 45.3116 | <0.0001 |

| X32 | −0.888938 | 1.717541 | 1 | 20.503 | 0.2679 | 0.6128 |

| X42 | −17.87644 | 1.717541 | 1 | 8291.469 | 108.3279 | <0.0001 |

| Interaction | ||||||

| X1–X2 | 5.049375 | 2.187167 | 1 | 407.939 | 5.3298 | 0.0367 |

| X1–X3 | −11.46062 | 2.187167 | 1 | 2101.535 | 27.4570 | <0.0001 |

| X1–X4 | −12.58812 | 2.187167 | 1 | 2535.37 | 33.1252 | <0.0001 |

| X2–X3 | 15.196875 | 2.187167 | 1 | 3695.120 | 48.2775 | <0.0001 |

| X2–X4 | −7.198125 | 2.187167 | 1 | 829.008 | 10.8312 | 0.0054 |

| X3–X4 | −6.580625 | 2.187167 | 1 | 692.874 | 9.0525 | 0.0094 |

| Lack of fit | 10 | 94.0987 | 4.550 | 0.0911 | ||

| Pure error | 4 | |||||

| R2 | 0.9776 | |||||

| Adjusted R2 | 0.9553 | |||||

| C.V. % | 3.71%. | |||||

| RMSE | 8.7186 | |||||

| CorTotal c | 28 | 48043.545 |

| Method | EtOH (%) | Time (min) | US amp (w/power) | Liq:sol (mL/g) | TPC (mg GAE/g) | Flavonoids (mgQE/g) | Anthocyanin (mg/g) | Tannins (mg CE/g) | DPPH (%) | RP (Abs 700 nm) |

|---|---|---|---|---|---|---|---|---|---|---|

| UAE-OPT | 70 | 7.5 | 30 | 28 | 241.66 ± 12.77 a | 18.99 ± 1.31 a | 25.06 ± 0.36 a | 35.56 ± 0.36 a | 90.71 ± 0.23 a | 0.568 ± 0.002 b |

| MAE | 42 | 62 | 500 | 32 | 119.59 ± 8.40 b | 11.5 ± 0.01 b | 5.64 ± 0.06 c | 31.70 ± 1.00 b | 87.16 ± 0.28 b | 0.439 ± 0.006 b |

| CSE | 50 | 7200 | 50 | 76.40 ± 7.27 c | 6.95 ± 0.20 c | 6.96 ± 0.72 b | 30.70 ± 0.17 c | 88.03 ± 1.04 b | 0.429 ± 0.001 b | |

| BHA α-tocopherol | 26.98 ± 0.69 c 17.17 ± 0.4 d | 1.37 ± 0.03 a 0.53 ± 0.01 b |

| No. Peak | tR (min) | λmax (nm) | (m/z) | MSn Ions (m/z) | Probable Compound |

|---|---|---|---|---|---|

| 1 | 1.4 | 275 | 191 a | MS2[191]: 173, 127, 111, 93 | Quinic acid |

| 341 a | MS2[341]: 179 | Caffeoyl-O-hexoside | |||

| 2 | 1.9 | 276 | 331 | MS2[331]: 271, 169, 241, 211, 193, 125; MS3[271]: 211, 169 | Galloyl-O-hexoside |

| 3 | 2.1 | 273 | 343 | MS2[343]: 191, 169, 125 | Galloyl quinic acid (isomer 1) |

| 4 | 2.3 | 271 | 169 | MS2[169]: 125 | Gallic acid |

| 5 | 6.7 | 274 | 343 | MS2[343]: 191, 169, 125 | Galloyl quinic acid (isomer 2) |

| 6 | 7.6 | 276, 525 | 463 a,b | MS2[463]: 301, 300, 337,315 | Delphinidin-O-hexoside |

| 495 a | MS2[495]: 343, 325, 191, 169 | Digalloyl quinic acid | |||

| 483 a | MS2[483]: 271, 331, 313, 439, 193, 169; MS3[271]: 211, 169 | Digalloyl hexoside | |||

| 7 | 8.8 | 274, 525 | 477 b | MS2[477]: 315, 314 | Petunidin-O-hexoside |

| 8 | 9.7 | 274, 525 | 647 a,b | MS2[647]: 495, 477 | Petunidin-O-galloyl-hexoside derivative |

| 491 a,b | MS2[491]: 329 | Malvidin-O-hexoside | |||

| 9 | 10.3 | 265, 356 | 631 | MS2[631]: 479, 299, 317 | Myricetin-O-galloyl-hexoside |

| 10 | 11.0 | 260, 356 | 479 | MS2[479]: 316, 317 | Myricetin-O-hexoside (isomer 1) |

| 11 | 11.2 | 260, 356 | 479 | MS2[479]: 316, 317 | Myricetin-O- hexoside (isomer 2) |

| 12 | 11.4 | 265, 356 | 615 | MS2[615]: 463, 301; MS2[463]: 179, 151 | Quercetin O-hexoside- gallate |

| 13 | 11.8 | 263, 356 | 449 | MS2[449]: 316, 317 | Myricetin-O-pentoside |

| 14 | 12.1 | 261, 351 | 463 | MS2[463]: 316, 317 | Myricetin-O-deoxyhexoside (isomer 1) |

| 15 | 12.2 | 261, 351 | 463 | MS2[463]: 316, 317 | Myricetin-O-deoxyhexoside (isomer 2) |

| 16 | 12.9 | 265, 353 | 447 | MS2[447]: 285; MS3[285]: 267, 257, 241 | Kaempferol-O-hexoside |

| 17 | 13.4 | 257, 350 | 447 | MS2[447]: 301; MS3[301]: 179, 151 | Quercetin-O-eoxyhexoside |

| 18 | 14.5 | 265, 352 | 431 a | MS2[431]: 271; MS3[271]: 211, 169 | Galloyl derivative |

| 625 a | MS2[625]: 479, 317 | Myricetin-O-hexosyl-deoxyhexoside | |||

| 19 | 14.6 | 273, 350 | 569 | MS2[569]: 485, 317 | Myricetin-O-galloyl ester |

| 20 | 16.5 | 276 | 583 | MS2[583]: 271, 565, 313, 211, 331; MS3[271]: 211, 169 | Gallomyrtucommulone F |

| 21 | 16.8 | 276 | 567 | MS2[567]: 271, 313, 211, 169; MS3[271]: 211, 169 | Gallomyrtucommulone C |

| 22 | 17.6 | 276 | 467 | MS2[467]: 271, 313, 169, 211; MS3[271]: 211, 169 | Gallomyrtucommulone-type (isomer 1) |

| 23 | 17.8 | 276 | 467 | MS2[467]: 271, 313, 169, 211; MS3[271]: 211, 169 | Gallomyrtucommulone-type (isomer 2) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bouaoudia-Madi, N.; Boulekbache-Makhlouf, L.; Madani, K.; Silva, A.M.S.; Dairi, S.; Oukhmanou–Bensidhoum, S.; Cardoso, S.M. Optimization of Ultrasound-Assisted Extraction of Polyphenols from Myrtus communis L. Pericarp. Antioxidants 2019, 8, 205. https://doi.org/10.3390/antiox8070205

Bouaoudia-Madi N, Boulekbache-Makhlouf L, Madani K, Silva AMS, Dairi S, Oukhmanou–Bensidhoum S, Cardoso SM. Optimization of Ultrasound-Assisted Extraction of Polyphenols from Myrtus communis L. Pericarp. Antioxidants. 2019; 8(7):205. https://doi.org/10.3390/antiox8070205

Chicago/Turabian StyleBouaoudia-Madi, Nadia, Lila Boulekbache-Makhlouf, Khodir Madani, Artur M.S. Silva, Sofiane Dairi, Sonia Oukhmanou–Bensidhoum, and Susana M. Cardoso. 2019. "Optimization of Ultrasound-Assisted Extraction of Polyphenols from Myrtus communis L. Pericarp" Antioxidants 8, no. 7: 205. https://doi.org/10.3390/antiox8070205

APA StyleBouaoudia-Madi, N., Boulekbache-Makhlouf, L., Madani, K., Silva, A. M. S., Dairi, S., Oukhmanou–Bensidhoum, S., & Cardoso, S. M. (2019). Optimization of Ultrasound-Assisted Extraction of Polyphenols from Myrtus communis L. Pericarp. Antioxidants, 8(7), 205. https://doi.org/10.3390/antiox8070205