3.1. Analysis of the Harvesting Process

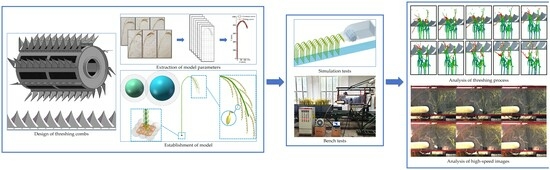

To explore the interactive effects and threshing mechanism of the preharvest threshing device on rice during the harvesting process, a simulation test was conducted with the working parameters set at a rotation speed of 300 r/min, a forward velocity of 1.1 m/s, and a threshing height of 795 mm. In this section, this set of simulation tests was used to analyze the position change and earhead state of the rice plant during the threshing process. The entire process of rice from contact with machinery to completion of harvesting could be divided into four stages: (a) pressing stage, (b) feeding stage, (c) threshing stage, and (d) extraction stage, as depicted in

Figure 7a. During the pressing stage, the upright entire-plant rice came into contact with the crop gathering nose of the device and began to be bent downward. Due to the flexible nature of rice and its fixed root system, the speed and deflection of the rice increased progressively from the root to the earhead. As the rice moved towards the end of the crop gathering nose, both the deformation and the accumulated elastic potential energy reached their maximum values. After escaping the pressing from the crop gathering nose, the rice plants rebounded towards the direction of the threshing cylinder and fed themselves into the rotating cylinder area. This stage was defined as the feeding stage. Subsequently, the rice began to interact with the rotating combs on the cylinder, marking the beginning of the threshing stage. The earheads that hung low to the ground due to their own weight were lifted upward by the clockwise rotation of the combs, and the previously accumulated elastic potential energy was partially released. The rice earheads began to sweep rapidly towards the combs in an extended posture, sliding along the curved edge towards the base of the combs. From a functional and structural perspective, the two sides of the combs can be divided into the offset flattening zone and the sliding-cut threshing zone as depicted in

Figure 1b in

Section 2.1. During the process of sliding towards the base of the combs in the offset flattening zone, the rice plants were subjected to a lateral displacement perpendicular to the flattening plane, leading to a tilting motion towards the sliding-cut threshing zone of the combs. Under the combined influence of the device’s forward movement and the high-speed rotation of the threshing cylinder, the rice plants initiated their sliding cut along the edge of the sliding-cut threshing zone. This process occurred repeatedly during the period when rice came into contact with the combs, detaching a significant quantity of rice grains, earheads carrying rice grains, and a small fraction of other rice components from the stems of the rice plants. This stage was defined as the threshing stage, as illustrated in

Figure 7b. Finally, the rice plants gradually withdrew from the rotation area, and the threshing materials during the operation were continuously thrown backwards under the combined action of the speed imparted by the rotating cylinder and their own inertia. This stage was defined as the extraction stage.

The interaction between rice and the comb during the threshing process is observed from above and in front of the threshing cylinder. From the top view, the sliding-cut motion of rice on the comb’s curved edge can be seen as the cylinder rotates. From a frontal view, the continuous compression of the rice from stem to earhead by the offset flattening zone structure, causing a shift towards the sliding-cut threshing zone, is observable, as shown in

Figure 8a.

To further observe the interaction details between the rice and the comb, structures other than the comb were hidden for a clearer view of rice movement under the influence of a single row of combs. The time interval from 0.814 s to 0.832 s was selected to analyze the interaction details between the rice and the combs during operation. From the top view of the cylinder, as shown in

Figure 8b, at 0.814 s, the rice was about to contact the combs. At this moment, the movement of the rice earheads divided into two scenarios: some approached the sliding-cut zone of the comb, while others neared the offset flattening zone. From 0.814 s to 0.822 s, as the cylinder rotated, the rice near the sliding-cut zone began to undergo sliding-cuts, while other grains started offset displacement after contact, leaning towards the sliding-cut zone. By 0.822 s, all the rice earheads were offset into the sliding-cut zone. From 0.822 s to 0.828 s, the earheads sliding cut along the contour of the combs in the sliding-cut zone, where numerous rice grains and branches were seen to slide off the plant. From 0.828 s to 0.832 s, the earheads began to disengage from the combs they initially contacted and approached another row below, repeating the described threshing process. Throughout the operation, the rice earheads continuously moved along the contours of the combs. According to the velocity nephogram, the rice’s speed was high and constantly changing during the threshing process, consistent with sliding-cut characteristics. This also caused the lower rice stems to swing back and forth along the cylinder’s axial direction with variable speed. This motion was beneficial for further enhancing the sliding-cut efficiency of the combs [

31]. Based on visual analysis of the above simulation, it could be concluded that throughout the entire process of the harvesting each functional zone of the combs was effectively performing its designated function, achieving a favorable bias displacement and sliding-cut effect on the rice.

3.2. Analysis of Sliding-Cut Rules

For the purpose of investigating the influence of various working parameters on the sliding-cut effect of combs on rice, the duration of contact between the rice and the combs was defined as ‘contact time’. The time period from contact to complete separation between combs and a row of rice was selected as the duration of the contact time. Utilizing the working parameters of the device as test factors, we conducted single-factor simulation tests, with the average velocity of rice grains during the threshing process and the amount of broken bonds (acquired by postprocessing the simulation results) as test indicators. The variation of rice grain velocity with time can reflect the movement of rice grains during threshing. The amount of broken bonds with rice grains (the bonds between rice grains and rice rachis, denoted as BWG) can reflect the direct cutting of grains by combs, while the amount of broken bonds with impurities (the bonds between the stem, substem, and rice rachis, denoted as BWI) indicates the degree of impurity dispersion and the overall trend of the impurity rate during the threshing process. The sum of these two values effectively represents the sliding-cut efficiency of the combs.

We define the number of times the combs hit the rice per unit distance as K, and the mathematical expression is shown in Equation (7). It is evident that this indicator correlates with the rotation speed n (r/min) and forward velocity v (m/s). When other factors remain constant, the faster the cylinder rotates, the more times the combs hit the rice, and the shorter the time the combs are in contact with the rice at one time.

Firstly, an analysis of the rotation speed was conducted. As depicted in

Figure 9a, an increase in the rotation speed correlated with a gradual rise in the number of velocity wave peaks for rice grains, whereas the velocity wave height decreased. It showed that during the operation process, the frequency of the sliding-cut of rice by the combs gradually increased, while the single sliding-cut time gradually decreased. Simultaneously, the overall velocity of the grains increased with the increase in the rotation speed, indicating that the average velocity of grains rises with an increase in rotation speed during the sliding-cut process. A high speed and small fluctuation in the sliding-cut could more effectively separate grains from the stems of rice plants [

23]. The analysis of sliding-cut effectiveness was conducted based on the amount of broken bonds, as illustrated in

Figure 9b. With the elevation of the rotation speed, there was a gradual increase in the amount of broken bonds for both the rice grains and other rice components. This implied an improvement in sliding-cut effectiveness as the rotation speed increased. In conditions of a high rotation speed, the frequent yet short duration sliding cut mentioned above could effectively separate the rice grains from the rice stems, which resulted in a more efficient reduction in the residual loss attributed to incomplete threshing.

When the threshing height was considered as the test variable, it can be observed from

Figure 10a that as the threshing height increased, the velocity of grains continuously increased. This was attributed to the expanded contact area between the combs and the rice plants when the threshing height was low, resulting in an increased workload during the threshing process. Under the same cylinder rotation speed, the combs contacted more materials, resulting in a lower average sliding-cut velocity of the rice grains. With an excessively high threshing height, the contact between the combs and materials was relatively reduced, and the duration of the single sliding-cut actions shortened. As shown in

Figure 10a, the velocity peaks were lower and the frequency was uncertain. From the perspective of the amount of broken bonds, under the working condition of an excessive threshing height, the amount of broken bonds of rice grains was significantly lower than that of other conditions, while the amount of broken bonds of rice grains at other height levels was relatively uniform. This indicated that an unreasonable threshing height could have an adverse impact on the effectiveness of the sliding cuts by the combs.

When the forward velocity was taken as a test variable,

Figure 11a indicates that the contact time between the combs and rice plants was inversely proportional to the device’s forward velocity. As the forward velocity increased, the velocity peaks on the graph became higher and more densely distributed, indicating a greater fluctuation in the velocity of rice grains during the sliding-cut process and a shorter duration of a single sliding cut, resulting in unsatisfactory sliding-cut effectiveness. Conversely, as the forward velocity decreased, the contact time between the combs and rice increased, resulting in smoother velocity variations during the sliding-cut process, which contributed to an enhancement in sliding-cut effectiveness [

32]. The results in

Figure 11a,b verified each other. The amount of broken bonds gradually decreased with the increase of the forward velocity, which indicated that the higher the forward velocity, the worse the sliding-cut effectiveness was, while the other working parameters remained constant.

3.3. Single-Factor Bench Test

For the purposes of investigating the impact patterns of the experimental results and the various working parameters on harvest quality, a high-speed imaging device was applied to acquire images of the detailed characteristics at a frame rate of 500 fps during the harvesting process for auxiliary analysis.

- (1)

Results of the single-factor bench test

With an invariable forward velocity and threshing height, the rice grain loss rate exhibited a tendency of initially decreasing and subsequently increasing with the increase in the rotation speed. At a rotation speed of 600 r/min, the grain loss rate reached its minimum value at 3.24%, with decreases of 4.84% (300 r/min), 0.14% (400 r/min), 1.33% (500 r/min), and 2.37% (700 r/min) relative to other levels. Additionally, the impurity rate of the threshing material showed a pattern of initially decreasing followed by an increase. When the rotation speed was 500 r/min, the impurity rate of the threshing material achieved its minimum at 5.49%, indicating reductions of 3.83% (300 r/min), 1.39% (400 r/min), 0.11% (600 r/min), and 0.99% (700 r/min) compared to other levels.

With the rotation speed and threshing height held constant, the grain loss rate exhibited a tendency to decrease initially and then increase as the forward velocity increased. When the device’s forward velocity reached 0.9 m/s, the grain loss rate attained its minimum value (4.44%). In comparison to the other levels, it decreased by 0.47% (0.7 m/s), 0.13% (1.1 m/s), 0.7% (1.3 m/s), and 1.15% (1.5 m/s). The impurity rate exhibited a tendency to start with a decrease and then transition to an increase. At the time when the device’s forward velocity attained 0.9 m/s, the impurity rate reached its minimum value (5.33%). In comparison to the other levels, it decreased by 0.88% (0.7 m/s), 0.16% (1.1 m/s), 0.94% (1.3 m/s), and 1.62% (1.5 m/s).

When the forward velocity and rotation speed remained unchanged, as the threshing height increased, the grain loss rate exhibited an initial decrease, followed by an increase. When the threshing height was 795 r/min, the grain loss rate reached its minimum value at 4.31%. Compared to other levels, it decreased by 0.57% (770 mm), 0.26% (820 mm), 0.56% (845 mm), and 1.36% (870 mm). The impurity rate demonstrated a pattern of initially decreasing and subsequently increasing. When the threshing height was 795 r/min, the impurity rate reached its minimum value of 5.42%. Relative to other levels, it decreased by 1.23% (770 mm), 0.07% (820 mm), 0.36% (845 mm), and 0.91% (870 mm). The indicator data obtained from the bench tests are depicted in

Figure 12.

- (2)

Discussion of the single-factor bench test

In the bench test, by conducting high-speed filming of the test process, we identified five typical detail characteristics of threshing materials that significantly affected the harvest quality. The schematic diagram for better comprehension of these features is illustrated in

Figure 13a, while the attributes captured through the high-speed imaging device are depicted in

Figure 13b. In conjunction with the experimental results, an analysis was conducted on the impact patterns and effect of the test factors on the harvesting quality.

The sliding-cut effect of the combs was less effective at lower rotation speeds. Some grains were unable to be threshed, and at the same time, larger-sized impurities were difficult to cut, leading to entanglement on the combs (Characteristic A). After several rotations, these impurities were thrown into the collection box (Characteristic B). Consequently, both the grain loss rate and impurity rate were at relatively high values under this condition. When the rotation speed increased, the sliding-cut effectiveness gradually improved and the residual loss began to decrease. At the same time, the impurities were also cut more discretely, making them less likely to become entangled, and the impurity rate also began to gradually decrease. As the cylinder rotation speed increased further, a portion of the rice that was not completely fed into the header was threshed but failed to move backward; instead, it splashed forward, resulting in splash loss (Characteristic C), which contributed to an additional increase in the grain loss rate. The impurities became more discrete, with a reduction in both mass and volume, which enabled them to attain sufficient velocity to be thrown into the collection box during the transportation process. As a result, the impurity rate rebounded.

As the forward speed increased, the accumulated elastic potential energy and deflection of the rice plants became greater before the feeding stage. The excessive elastic potential energy caused the rice to rapidly fall towards the cylinder during the feeding stage, preventing part of the rice from being fully sliding cut, resulting in an increase in the residual loss (Characteristic D). The large deflection also prevented some rice from fully entering the working area of the combs during the harvesting process, resulting in increased splash loss (Characteristic C). Therefore, there was a positive correlation between the loss rate and forward velocity. The sliding-cut effectiveness of the combs deteriorated with the increase in the forward velocity, making it difficult for the impurities to be thrown into the collection box; so, the impurity rate began to gradually decrease. However, as the forward velocity further increased, the sliding-cut effectiveness decreased and the deflection of the rice increased. The impurities that could not be cut began to wrap around the cylinder (Characteristic A) and were thrown into the collection box (Characteristic B), causing the impurity rate to increase again.

The grain loss rate exhibited an initial decrease, followed by an increase, as the threshing height increased. This was because, when the threshing height was low, more impurities would be cut off from the stems by the combs. As a larger mass and volume of impurities were thrown backwards, they would generate a barrier behind the cylinder (Characteristic B), obstructing the transfer of grains to the collection box, resulting in return loss (Characteristic E). With the increase in the threshing height, the rice obstructed from collection gradually decreased, resulting in a gradual decline in the grain loss rate and a corresponding decrease in the impurity rate. However, when the threshing height was excessively high, some rice earheads could not enter the reasonable working range of the combs, resulting in residual loss (Characteristic D) and causing an escalation in rice grain loss rate. Since the impact force of the cylinder rotation remained constant, there was less material in contact with the threshing cylinder, resulting in a higher impact force on the rice components. This caused more nongrain components to be cut off from the rice, causing the impurity rate to rise again.

3.4. Multi-Factor Optimization Bench Test

A three-factor, five-level response surface optimization experiment was undertaken, with the rotation speed, forward velocity, and threshing height as the test factors and the grain loss rate and impurity rate as the test indicators. Analysis of the experiment results was conducted by Design-Expert 13 software (2020, StatEase, Inc., Minneapolis, MN, USA) (

Table 2). The regression model demonstrated high significance, and the lack of significant mismatch suggested the accuracy and effectiveness of the established model. By fitting the values of the regression terms that had a significant impact on the model, Equation (8) was derived.

Based on the F-values obtained in the analysis of variance for each test factor, the factors influencing the grain loss rate followed this sequence:

>

>

>

>

>

>

>

>

, and the sequence of factors affecting the impurity rate was as follows:

>

>

>

>

>

>

>

>

. For the purpose of visually depicting the influence of each experiment factor and interactions on the experiment indicators, a response surface graph is plotted (

Figure 14).

It was evident that there were significant interactions between the forward velocity and rotation speed, the threshing height and rotation speed, and the threshing height and forward velocity in their influence on the grain loss rate. When the forward velocity interacted with the rotation speed, as the forward velocity increased, the grain loss rate exhibited an initial decrease, followed by a subsequent increase; with the increase in rotation speed, the rice grain loss rate initially decreased and then increased. When the threshing height interacted with the rotation speed, as the threshing height increased, the grain loss rate initially decreased and then increased; the grain loss rate demonstrated an initial decrease followed by an increase as the rotation speed increased. When the threshing height interacted with the forward velocity, as the threshing height increased, the loss rate initially showed a decline and then rose again; and with the increase in forward velocity, the grain loss rate initially decreased and then increased.

There were significant interactions between the forward velocity and rotation speed, the threshing height and rotation speed, and the threshing height and forward velocity in their influence on impurity rate. When the forward velocity interacted with the rotation speed, as the forward velocity increased, the impurity rate rose initially and then declined; as the rotation speed increased, the impurity rate initially rose and then declined. When the threshing height interacted with the rotation speed, as the threshing height increased, the impurity rate rose and then declined; as the rotation speed increased, the impurity rate rose initially and then declined. When the threshing height interacted with the forward velocity, as the threshing height increased, the impurity rate declined initially and then rose; and when the forward velocity increased, the impurity rate declined initially and then rose.

The optimization solution was implemented to explore the optimal combination of working parameters for each test factor within the feasible range of design parameters. The goal was to minimize both the grain loss rate and impurity rate. The objective function and the range of working parameters are shown in Equation (9).

Utilizing Design Expert-13 software (2020, StatEase, Inc., Minneapolis, MN, USA), the optimization solution was implemented. The result revealed that when the rotation speed was 615.668 r/min, the forward velocity was 0.913 m/s, and the threshing height was 791.613 mm, the grain loss rate was 1.942%, and the impurity rate was 4.095%. The best working parameter combination of the preharvest threshing device was obtained through the optimization solution.

According to the optimization result, a bench verification test was conducted to validate the accuracy of the solution under the condition of the optimal working parameter combination. The result of the verification test revealed that when the rotation speed was 616 r/min, the forward velocity was 0.91 m/s, and the threshing height was 792 mm, the grain loss rate was 1.997%, and the impurity rate was 4.073%. The relative error compared to the model’s estimation was relatively small. Compared with the performance of the original combs in our previous research, both the residual loss and the falling loss were much lower than the original plane combs [

16].

This study designed an offset sliding-cut comb and, based on an innovatively constructed discrete element model of rice plants during the harvesting period, explored the sliding-cut interaction mechanism between the combs and rice plants in the threshing process. It investigated the effects of different operational parameters on the threshing quality, effectively addressing the issue of excessive harvesting losses in preharvest threshing combine harvesters. This provides a theoretical foundation and data support for the innovative design and further development of preharvest threshing device combs. The test results revealed that rotation speed, forward velocity, and threshing height all have a significant impact on the harvest quality. Furthermore, through targeted optimization design, the offset sliding-cut combs, compared to the original plane combs, reduced residual loss by 23%. Since the falling loss accounts for a high proportion of the grain loss, reducing the falling loss to improve harvest quality is one of the issues that needs to be solved urgently in subsequent research.

The discrete element model of rice developed for the harvesting period effectively represents characteristics such as drooping earheads and field planting density. However, the issue of uniform orientation in the simulation requires improvement in future research, alongside studies aimed at creating a more broadly representative rice model. The simulation tests conducted in this study primarily analyzed the threshing process of rice. Due to factors like airflow affecting the throwing process, DEM simulations cannot fully replicate this phase. Future research will explore the throwing process and its impact on the operation quality using CFD-DEM coupled simulations. Additionally, since the rice harvesting period is prolonged and factors like the moisture content and maturity level change during this time, affecting the harvest quality, further studies will investigate the influence of varying the moisture content on the harvest quality.

Additionally, the designed components have not been integrated and configured into the preharvest threshing harvester. Therefore, the working parameter combination obtained in this study has not been validated in field tests. Due to the continuous vibration of the harvester during actual field operations, the strong vibrations complicate the interaction between the machine and rice plants, preventing the attainment of the most ideal working conditions and adversely affecting the quality of the harvesting. Consequently, further field harvesting tests will be conducted to validate the harvest quality on various terrains. Future research will also involve further exploration of related agricultural implements.