Systolic Nanofabrication of Super-Resolved Photonics and Biomimetics

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

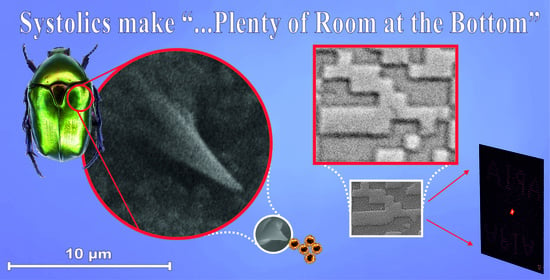

3.1. Systolic Downsizing

3.2. Photonic and Biomimetic Architectures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rho, J. Metasurfaces: Subwavelength nanostructure arrays for ultrathin flat optics and photonics. MRS Bull. 2020, 45, 180–187. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Lee, Y.; Han, M.; Sharma, B.K.; Chen, X.; Ahn, J.-H.; Rogers, J.A. Nanofabrication approaches for functional three-dimensional architectures. Nano Today 2020, 30, 100825. [Google Scholar] [CrossRef]

- Kistler, S.S. Coherent expanded aerogels. J. Phys. Chem. 1932, 36, 52–64. [Google Scholar] [CrossRef]

- Aegerter, M.A.; Leventis, N.; Koebel, M.M. (Eds.) Aerogels Handbook; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Akimov, Y.K. Fields of application of aerogels (Review). Instrum. Exp. Tech. 2003, 46, 287–299. [Google Scholar] [CrossRef]

- Vainos, N.A.; Karoutsos, V.; Mills, B.; Eason, R.W.; Prassas, M. Contractive scaling of 3-dimensional laser written microstructures via vitrification of silica aerogel monoliths. Opt. Mater. Express 2016, 6, 3814–3825. [Google Scholar] [CrossRef]

- Michaloudis, I.; Carroll, M.K.; Kupiec, S.; Cook, K.; Anderson, A.M. Facile method for surface etching of silica aerogel monoliths. J. Sol-Gel Sci. Technol. 2018, 87, 22–26. [Google Scholar] [CrossRef]

- Stanec, Α.Μ.; Anderson, A.M.; Avanessian, C.; Carroll, M.K. Analysis and characterization of etched silica aerogels. J. Sol-Gel Sci. Technol. 2020, 94, 406–415. [Google Scholar] [CrossRef]

- Michaloudis, I.; Dann, B. Aer( )sculpture: Inventing skies and micro-clouds into diaphanous sculptures made of the space technology nanomaterial silica aerogel. J. Sol-Gel Sci. Technol. 2017, 84, 535–542. [Google Scholar] [CrossRef]

- Kim, Y.; Baek, S.; Gupta, P. Air-like plasmonics with ultralow-refractive-index silica aerogels. Sci. Rep. 2019, 9, 2265. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.-M.; Xia, Y.; Schueller, O.J.A.; Qin, D.; Whitesides, G.M. Fabrication of microstructures using shrinkable polystyrene films. Sens. Actuators A Phys. 1998, 65, 209–217. [Google Scholar] [CrossRef]

- Juodkazis, S.; Yamasaki, K.; Matsuo, S.; Misawa, H. Glass transition-assisted microstructuring in polystyrene. Appl. Phys. Lett. 2004, 84, 514–516. [Google Scholar] [CrossRef]

- Balčytis, A.; Ryu, M.; Seniutinas, G.; Stoddart, P.R.; Al Mamun, M.A.; Morikawa, J.; Juodkazis, S. Nano-rescaling of gold films on polystyrene: Thermal management for SERS. Nanoscale 2017, 9, 690–695. [Google Scholar] [CrossRef] [PubMed]

- Moothanchery, M.; Naydenova, I.; Toal, V. Studies of shrinkage as a result of holographic recording in acrylamide-based photopolymer film. Appl. Phys. A 2011, 104, 899–902. [Google Scholar] [CrossRef] [Green Version]

- Santaniello, T.; Martello, F.; Tocchio, A.; Gassa, F.; Webb, P.; Milani, P.; Lenardi, C. Excimer laser micropatterning of freestanding thermo-responsive hydrogel layers for cells-on-chip applications. J. Micromech. Microeng. 2012, 22, 105033. [Google Scholar] [CrossRef]

- Le Goff, G.C.; Blum, L.J.; Marquette, C.A. Shrinking Hydrogel-DNA Spots Generates 3D Microdots Arrays: Shrinking Hydrogel-DNA Spots Generates 3D Microdots Arrays. Macromol. Biosci. 2013, 13, 227–233. [Google Scholar] [CrossRef]

- Cerda-Sumbarda, Y.D.; Domínguez-González, C.; Zizumbo-López, A.; Licea-Claverie, A. Thermoresponsive nanocomposite hydrogels with improved properties based on poly(N-vinylcaprolactam). Mater. Today Commun. 2020, 24, 101041. [Google Scholar] [CrossRef]

- Oran, D.; Rodriques, S.G.; Gao, R.; Asano, S.; Skylar-Scott, M.A.; Chen, F.; Tillberg, P.W.; Marblestone, A.H.; Boyden, E.S. 3D nanofabrication by volumetric deposition and controlled shrinkage of patterned scaffolds. Science 2018, 362, 1281–1285. [Google Scholar] [CrossRef] [Green Version]

- Xu, C.; Wu, Q.; L’Espérance, G.; Laberge Lebel, L.; Therriault, D. Environment-friendly and reusable ink for 3D printing of metallic structures. Mater. Des. 2018, 160, 262–269. [Google Scholar] [CrossRef]

- Bauer, J.; Schroer, A.; Schwaiger, R.; Kraft, O. Approaching theoretical strength in glassy carbon nanolattices. Nat. Mater. 2016, 15, 438–443. [Google Scholar]

- Gailevičius, D.; Padolskyte, V.; Mikoliunaite, L.; Sakirzanovas, S.; Juodkazis, S.; Malinauskas, M. Additive-manufacturing of 3D glass-ceramics down to nanoscale resolution. Nanoscale Horiz. 2019, 4, 647–651. [Google Scholar] [CrossRef]

- Papachristopoulou, K.; Karoutsos, V.; Papademetriou, A.; Vainos, N.A. Super-resolution fabrication of surface relief structures by contractive scaling of nanoporous monoliths. In Proceedings of the 45th International Conference on Micro & Nano Engineering, Rhodes, Greece, 23–26 September 2019. [Google Scholar]

- Teichner, S.J.; Nicolaon, G.A.; Vicarini, M.A.; Gardes, G.E.E. Inorganic oxide aerogels. Adv. Colloid Interface Sci. 1976, 5, 245–273. [Google Scholar] [CrossRef]

- Moner-Girona, M.; Roig, A.; Molins, E.; Libre, J. Sol-Gel Route to Direct Formation of Silica Aerogel Microparticles Using Supercritical Solvents. J. Sol-Gel Sci. Technol. 2003, 26, 645–649. [Google Scholar] [CrossRef]

- Wagh, P.B.; Ingale, S.V. Comparison of some physico-chemical properties of hydrophilic and hydrophobic silica aerogels. Ceram. Int. 2002, 28, 43–50. [Google Scholar] [CrossRef]

- Rao, A.P.; Rao, A.V.; Pajonk, G.M. Hydrophobic and physical properties of the ambient pressure dried silica aerogels with sodium silicate precursor using various surface modification agents. Appl. Surf. Sci. 2007, 253, 6032–6040. [Google Scholar] [CrossRef]

- Pajonk, G.M.; Rao, A.V.; Sawant, B.M.; Parvathy, N.N. Dependence of monolithicity and physical properties of TMOS silica aerogels on gel aging and drying conditions. J. Non-Cryst. Solids 1997, 209, 40–50. [Google Scholar] [CrossRef]

- Strøm, R.A.; Masmoudi, Y.; Rigacci, A.; Petermann, G.; Gullberg, L.; Chevalier, B.; Einarsrud, M.A. Strengthening and aging of wet silica gels for up-scaling of aerogel preparation. J. Sol-Gel Sci. Technol. 2007, 41, 291–298. [Google Scholar] [CrossRef]

- Vasileiou, M.; Mpatzaka, T.; Alexandropoulos, D.; Vainos, N.A. Biomimetic microstructures for photonic and fluidic synergies. Optofluid. Microfluid. Nanofluidics 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Prassas, M. Synthese Des Gels Du Systeme SiO2-Na2O et Des Gels Monolithiques De Silice. Étude De Leur Conversion En Verre. Th.D. Ingénieur, Université de Montpellier, Montpelier, France, 1981. [Google Scholar]

- Woignier, T.; Phallippou, J.; Prassas, M. Glasses from aerogels Part 1: The synthesis of monolithic silica aerogels. J. Mater. Sci. 1990, 25, 3111–3117. [Google Scholar]

- Woignier, T.; Phallippou, J.; Prassas, M. Glasses from aerogels Part 2: The aerogel-glass transformation. J. Mater. Sci. 1990, 25, 3118–3126. [Google Scholar] [CrossRef]

- Zarzycki, J.W.; Prassas, M.; Phalippou, J.E.H. Preparation of Monolithic Silica Aerogels, the Aerogels Thus Obtained and Their Use for the Preparation of Silica Glass Articles and of Heat-Insulating Materials. Patent US 4,432,956, 21 February 1984. [Google Scholar]

- Frenkel, J. Viscous flow of crystalline bodies under the action of surface tension. J. Phys. 1945, 9, 385–391. [Google Scholar]

- Scherer, G.W. Sintering of Low-Density Glasses: I. Theory. J. Am. Ceram. Soc. 1977, 60, 5–6. [Google Scholar] [CrossRef]

- Rabinovich, E.M. Preparation of glass by sintering. J. Mater. Sci. 1985, 20, 4259–4297. [Google Scholar] [CrossRef]

- Brinker, C.G.; Scherer, G.W. Sol-Gel Science; Academic Press: San Diego, CA, USA, 2013. [Google Scholar]

- Vainos, N.A. (Ed.) Laser Growth and Processing of Photonic Structures; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- Serrano, A.; de la Fuente, O.R.; García, M.A. Extended and localized surface plasmons in annealed Au films on glass substrates. J. Appl. Phys. 2010, 108, 074303. [Google Scholar] [CrossRef] [Green Version]

- Fabricius, J.C. Systema Entomologiae; Arkose Press: Flensburg/Leipzig, Germany, 1775. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papachristopoulou, K.; Vainos, N.A. Systolic Nanofabrication of Super-Resolved Photonics and Biomimetics. Nanomaterials 2020, 10, 2418. https://doi.org/10.3390/nano10122418

Papachristopoulou K, Vainos NA. Systolic Nanofabrication of Super-Resolved Photonics and Biomimetics. Nanomaterials. 2020; 10(12):2418. https://doi.org/10.3390/nano10122418

Chicago/Turabian StylePapachristopoulou, Konstantina, and Nikolaos A. Vainos. 2020. "Systolic Nanofabrication of Super-Resolved Photonics and Biomimetics" Nanomaterials 10, no. 12: 2418. https://doi.org/10.3390/nano10122418

APA StylePapachristopoulou, K., & Vainos, N. A. (2020). Systolic Nanofabrication of Super-Resolved Photonics and Biomimetics. Nanomaterials, 10(12), 2418. https://doi.org/10.3390/nano10122418