Tuning Magnetic Entropy Change and Relative Cooling Power in La0.7Ca0.23Sr0.07MnO3 Electrospun Nanofibers

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Powder X-ray and Rietveld Refinement

3.2. High-Resolution Transmission and Scanning Electron Microscopy

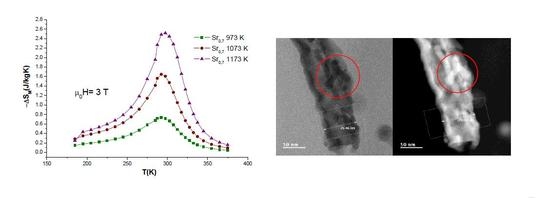

3.3. Magnetic Entropy Change

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Messaoui, I.; Kumaresavanji, M.; Riahi, K.; Cheikhrouhou Koubaa, W.; Koubaa, M.; Cheikhrouhou, A. Investigation on magnetic and magnetocaloric properties in the Pb-doped manganites La0.78CaPbxMnO3 (x = 0, 0.05 and 0.1). J. Alloys Compd. 2017, 693, 705–718. [Google Scholar] [CrossRef]

- Ben Rejeb, M.; Ben osman, C.; Regaieg, Y.; Marzouki-Ajmi, A.; Cheikhrouhou-Koubaa, W.; Ammar-Merah, S.; Cheikhrouhou, A.; Mhiri, T. A comparative study of La0.65Ca0.2(Na0.5K0.5)0.15MnO3 compound synthesized by solid-state and sol-gel process. J. Alloys Compd. 2017, 695, 2597–2604. [Google Scholar] [CrossRef]

- Khlifa, H.B.; M’nassri, R.; Tarhouni, S.; Regaieg, Y.; Cheikhrouhou-Koubaa, W.; Chniba-Boudjada, N.; Cheikhrouhou, A. Critical behavior and field dependence of magnetic entropy change in K-doped manganites Pr0.8Na0.2−xKxMnO3 (x= 0.10 and 0.15). J. Solid State Chem. 2018, 257, 9–18. [Google Scholar] [CrossRef]

- El-Moez, A.; Mohamed, A.; Hernando, B. Self-assembled impurity and its effect on magnetic and magnetocaloric properties of manganites. Ceram. Int. 2018, 44, 17044–17049. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, Y.; Cao, X.; Xue, Y.; Xu, D.; Jiang, L.; Su, W. Fabrication of polycrystalline lanthanum manganite (LaMnO3) nanofibers by electrospinning. Mater. Lett. 2008, 62, 470–472. [Google Scholar] [CrossRef]

- Hayat, K.; Rafiq, M.A.; Hasan, M.M. Synthesis and optimization of Barium manganate nanofibers by electrospinning. Ceram. Int. 2012, 38, 1441–1445. [Google Scholar] [CrossRef]

- Cao, Y.; Lin, B.; Sun, Y.; Yang, H.; Zhang, X. Structure, morphology and electrochemical properties of LaxSr1-xCo0.1Mn0.9O3-d perovskite nanofibers prepared by electrospinning method. J. Alloys Compd. 2015, 624, 31–39. [Google Scholar] [CrossRef]

- Li, L.; Liang, L.; Wu, H.; Zhu, X. One-Dimensional Perovskite Manganite Oxide Nanostructures: Recent Developments in Synthesis, Characterization, Transport properties, and Applications. Nanoscale Res. Lett. 2016, 11, 121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burrola-Gandara, L.A.; Sáenz-Hernández, R.J.; Santillán-Rodríguez, C.R.; Lardizabal-Gutierrez, D.; Pizá-Ruiz, P.; Elizalde-Galindo, J.T.; Matutes-Aquino, J.A. Spin-lattice coupling, Jahn-Teller effect and the influence of the measurement rate in La0.7Ca0.3−xSrxMnO3 manganites. AIP Adv. 2016, 6, 056219. [Google Scholar] [CrossRef] [Green Version]

- Thanh, T.D.; Linh, D.C.; Uyen Tuyen, N.T.; Phan, T.-L.; Yu, S.-C. Magnetic and magnetocaloric properties in Ba-doped La0.7Ca0.3MnO3 nanoparticles. J. Alloys Compd. 2015, 649, 981–987. [Google Scholar] [CrossRef]

- Juan, Z.; Gui, W. Magnetocaloric properties of (La0.67−xGdx)Sr0.33MnO3 polycrystalline nanoparticles. J. Magn. Magn. Mater. 2009, 321, 2977–2980. [Google Scholar] [CrossRef]

- Botello-Zubiate María, E.; Grijalva-Castillo María, C.; Soto-Parra, D.; Sáenz-Hernández Renee, J.; Santillán-Rodríguez, C.R.; Matutes-Aquino José, A. Preparation of La0.7Ca0.3−xSrxMnO3 Manganites by Four Synthesis Methods and Their Influence on the Magnetic Properties and Relative Cooling Power. Materials 2019, 12, 309. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burrola-Gandara, L.A.; Vazquez Zubiate, L.; Carrillo-Flores, D.M.; Elizalde-Galindo, J.T. Spin Glass Behavior in La0.7Ca0.23Sr0.07MnO3 Nanofibers Obtained by Electrospinning. J. Supercond. Novel Magn. 2019, 32, 2501. [Google Scholar] [CrossRef]

- Tola, P.S.; Kim, H.S.; Kim, D.H.; Phan, T.L.; Rhyee, J.S.; Shon, W.H.; Yang, D.S.; Manh, D.H.; Lee, B.W. Tunable magnetic properties and magnetocaloric effect of off-stoichiometric LaMnO3 nanoparticles. J. Phys. Chem. Solids 2017, 111, 219–228. [Google Scholar] [CrossRef]

- Khlifa, H.B.; Ayadi, F.; M’nassri, R.; Cheikhrouhou-Koubaa, W.; Schmerber, G.; Cheikhrouhou, A. Screening of the synthesis route on the structural, magnetic and magnetocaloric properties of La0.6Ca0.2Ba0.2MnO3 manganite: A comparison between solid-solid state process and a combination polyol process and Spark Plasma Sintering. J. Alloys Compd. 2017, 712, 451–459. [Google Scholar] [CrossRef]

- Iqbal, M.; Nasir Khan, M.; Arif Khan, A.; Zafar, N. Structural, magnetic, magnetocaloric and critical properties of La0.9Ba0.1MnO3 manganite. J. Alloys Compd. 2018, 769, 766–776. [Google Scholar] [CrossRef]

- Baaziz, H.; Tozri, A.; Dhahri, E.; Hlil, E.K. Magnetic properties of La0.67Sr0.33MnO3 tunable by particle size and dimensionality. Chem. Phys. Lett. 2018, 691, 355–359. [Google Scholar] [CrossRef]

- Tang, W.; Lu, W.J.; Luo, X.; Wang, B.S.; Zhu, X.B.; Song, W.H.; Yang, Z.R.; Sun, Y.P. Size-induced changes of structural, magnetic and magnetocaloric properties of La0.7Ca0.2Ba0.1MnO3. Physica B 2010, 405, 2733–2741. [Google Scholar] [CrossRef]

- Wang, G.F.; Li, L.R.; Zhao, Z.R.; Yu, X.Q.; Zhang, X.F. Structural and magnetocaloric effect of Ln0.67Sr0.33MnO3 (Ln= La, Pr and Nd) nanoparticles. Ceram. Int. 2014, 40, 16449–16454. [Google Scholar] [CrossRef]

- Pecharsky, V.K.; Gschneidner, K.A. Magnetocaloric effect from indirect measurements: Magnetization and heat capacity. J. Appl. Phys. 1999, 86, 565. [Google Scholar] [CrossRef]

- Burrola-Gándara, L.A.; Santillan-Rodriguez, C.R.; Rivera-Gomez, F.J.; Saenz-Hernandez, R.J.; Botello-Zubiate, M.E.; Matutes-Aquino, J.A. Comparison of the order of magnetic phase transitions in several magnetocaloric materials using the rescaled universal curve, Banerjee and mean field theory criteria. J. Appl. Phys. 2015, 117, 144. [Google Scholar] [CrossRef]

| a (Å) | b (Å) | c (Å) | Volume (Å) | Structure | |

|---|---|---|---|---|---|

| Sr0.07 (973 K) | 5.4540 (7) | 7.7096 (10) | 5.4992 (7) | 231.23 (5) | Orthorhombic |

| Sr0.07 (1073 K) | 5.4549 (7) | 7.7087 (10) | 5.4961 (7) | 231.11 (5) | Orthorhombic |

| Sr0.07 (1173 K) | 5.4582 (4) | 7.7111 (6) | 5.4915 (4) | 231.13 (3) | Orthorhombic |

| μ0H (T) | −∆SMmax (J/kgK) | δTFWHM (K) | RCP (J/kg) | |

|---|---|---|---|---|

| Sr0.07 (973 K) | 1 | 0.28 | 53.63 | 15 |

| 2 | 0.53 | 60.45 | 32 | |

| 3 | 0.74 | 66.24 | 49 | |

| Sr0.07 (1073 K) | 1 | 0.66 | 43.82 | 29 |

| 2 | 1.2 | 51.87 | 62 | |

| 3 | 1.65 | 58 | 96 | |

| Sr0.07 (1173 K) | 1 | 1 | 45.64 | 46 |

| 2 | 1.82 | 51.74 | 94 | |

| 3 | 2.51 | 56.82 | 143 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burrola Gándara, L.A.; Vázquez Zubiate, L.; Carrillo Flores, D.M.; Elizalde Galindo, J.T.; Ornelas, C.; Ramos, M. Tuning Magnetic Entropy Change and Relative Cooling Power in La0.7Ca0.23Sr0.07MnO3 Electrospun Nanofibers. Nanomaterials 2020, 10, 435. https://doi.org/10.3390/nano10030435

Burrola Gándara LA, Vázquez Zubiate L, Carrillo Flores DM, Elizalde Galindo JT, Ornelas C, Ramos M. Tuning Magnetic Entropy Change and Relative Cooling Power in La0.7Ca0.23Sr0.07MnO3 Electrospun Nanofibers. Nanomaterials. 2020; 10(3):435. https://doi.org/10.3390/nano10030435

Chicago/Turabian StyleBurrola Gándara, Luis Andrés, Lizeth Vázquez Zubiate, Diana M. Carrillo Flores, José T. Elizalde Galindo, Carlos Ornelas, and Manuel Ramos. 2020. "Tuning Magnetic Entropy Change and Relative Cooling Power in La0.7Ca0.23Sr0.07MnO3 Electrospun Nanofibers" Nanomaterials 10, no. 3: 435. https://doi.org/10.3390/nano10030435

APA StyleBurrola Gándara, L. A., Vázquez Zubiate, L., Carrillo Flores, D. M., Elizalde Galindo, J. T., Ornelas, C., & Ramos, M. (2020). Tuning Magnetic Entropy Change and Relative Cooling Power in La0.7Ca0.23Sr0.07MnO3 Electrospun Nanofibers. Nanomaterials, 10(3), 435. https://doi.org/10.3390/nano10030435