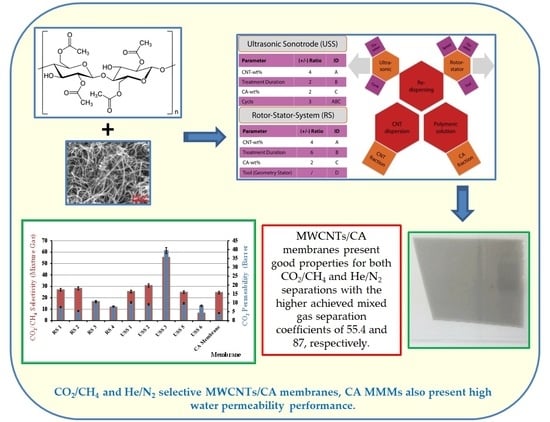

CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gudmundsson, J.S. Natural Gas Sweetening & Effect of Declining Pressure. In TPG4140 Project Report; NTNU: Trondheim, Norway, 2013. [Google Scholar]

- George, G.; Bhoria, N.; AlHallaq, S.; Abdala, A.; Mittal, V. Polymer membranes for acid gas removal from natural gas. Sep. Purif. Technol. 2016, 158, 333–356. [Google Scholar] [CrossRef]

- Shibata, T. Cellulose acetate in separation technology. Macromol. Symp. 2004, 208, 353–369. [Google Scholar] [CrossRef]

- Dunweg, G.; Lother, S.; Wolfgang, A. Dialysis Membrane Made of Cellulose Acetate. U.S. Patent 5,403,485, 4 April 1995. [Google Scholar]

- Hayama, M.; Yamamoto, K.; Kohori, F.; Sakai, K.J. How polysulfone dialysis membranes containing polyvinylpyrrolidone achieve excellent biocompatibility? Membr. Sci. 2004, 234, 41–49. [Google Scholar] [CrossRef]

- Qin, J.J.; Oo, M.H.; Cao, Y.M.; Lee, L.S. Development of a LCST membrane forming system for cellulose acetate ultrafiltration hollow fiber. Sep. Purif. Technol. 2005, 42, 291–295. [Google Scholar] [CrossRef]

- Zularisam, A.W.; Ismail, A.F.; Salim, M.R.; Sakinah, M.; Ozaki, H. The effects of natural organic matter (NOM) fractions on fouling characteristics and flux recovery of ultrafiltration membranes. Desalination 2007, 212, 191–208. [Google Scholar] [CrossRef]

- Shibutani, T.; Kitaura, T.; Ohmukai, Y.; Maruyama, T.; Nakatsuka, S.; Watabe, T.; Matsuyama, H. Membrane fouling properties of hollow fiber membranes prepared from cellulose acetate derivatives. J. Membr. Sci. 2011, 376, 102–109. [Google Scholar] [CrossRef]

- Favvas, E.P. Chapter, Nanomaterials and their Applicability as Membranes’ Fillers. In Innovations in Nanomaterials; Imran, A.B., Shapter, J., Eds.; Nova Science Publ.: New York, NY, USA, 2015; pp. 105–153. [Google Scholar]

- Ahmad, A.L.; Jawad, Z.A.; Low, S.C.; Zein, S.H.S. A cellulose acetate/multi-walled carbon nanotube mixed matrix membrane for CO2/N2 separation. J. Membr. Sci. 2014, 451, 55–66. [Google Scholar] [CrossRef]

- Mubashir, M.; Fong, Y.Y.; Leng, C.T.; Keong, L.K. Optimization of spinning parameters on the fabrication of NH2-MIL-53(Al)/cellulose acetate (CA) hollow fiber mixed matrix membrane for CO2. Sep. Purif. Technol. 2019, 215, 32–43. [Google Scholar] [CrossRef]

- Rashid, M.H.; Farrukh, S.; Javed, S.; Hussain, A.; Fan, X.; Ali, S.; Ayoub, M. Synthesis and gas permeation analysis of TiO2 nanotube-embedded cellulose acetate mixed matrix membranes. Chem. Pap. 2020, 74, 821–828. [Google Scholar] [CrossRef]

- Etemadi, H.; Yegani, R.; Seyfollahi, M. The effect of amino functionalized and polyethylene glycol grafted nanodiamond on anti-biofouling properties of cellulose acetate membrane in membrane bioreactor systems. Sep. Purif. Technol. 2017, 177, 350–362. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Macni, C.R.M.; Caparanga, A.R.; Huang, S.-H.; Tsai, H.-A.; Lee, K.-R.; Lai, J.-Y. Mitigating the fouling of mixed-matrix cellulose acetate membranes for oil-1 water separation through modification with polydopamine particles. Chem. Eng. Res. Des. 2020, 159, 195–204. [Google Scholar] [CrossRef]

- Zhao, Y.; Jung, B.T.; Ansaloni, L.; Ho, W.S.H. Multiwalled carbon nanotube mixed matrix membranes containing amines for high pressure CO2/H2 separation. J. Membr. Sci. 2014, 459, 233–243. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, M.; Liu, G.; Guan, K.; Jin, W. Size effects of graphene oxide on mixed matrix membranes for CO2 separation. AIChE 2016, 62, 2843–2852. [Google Scholar] [CrossRef]

- Dai, L.; Chang, D.W.; Baek, J.-B.; Lu, W. Carbon nanomaterials for advanced energy conversion and storage. Small 2012, 23, 1130–1166. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, D.; Sangwan, V.K.; Lauhon, L.J.; Marksa, T.J.; Hersam, M.C. Carbon nanomaterials for electronics, optoelectronics, photovoltaics, and sensing. Chem. Soc. Rev. 2013, 42, 2824–2860. [Google Scholar] [CrossRef] [Green Version]

- Mochalin, V.N.; Shenderova, O.; Ho, D.; Gogotsi, Y. The properties and applications of nanodiamonds. Nat. Nanotech. 2012, 7, 11–23. [Google Scholar] [CrossRef]

- Kim, J.; Van Der Bruggen, B. The use of nanoparticles in polymeric and ceramic membrane structures: Review of manufacturing procedures and performance improvement for water treatment. Environ. Pollut. 2010, 158, 2335–2349. [Google Scholar] [CrossRef]

- Karkhanechi, H.; Kazemian, H.; Nazockdast, H.; Mozdianfard, M.R.; Bidoki, S.M. Fabrication of Homogenous Polymer-Zeolite Nanocomposites as Mixed-Matrix Membranes for Gas Separation. Chem. Eng. Technol. 2012, 35, 885–892. [Google Scholar] [CrossRef]

- Favvas, E.P.; Stefanopoulos, K.L.; Nolan, J.W.; Papageorgiou, S.K.; Mitropoulos, A.C.; Lairez, D. Mixed Matrix Hollow Fiber Membranes with enhanced gas permeation properties. Sep. Purif. Technol. 2014, 132, 336–345. [Google Scholar] [CrossRef]

- Moore, T.T.; Mahajan, R.; Vu, D.Q.; Koros, W.J. Hybrid membrane materials comprising organic polymers with rigid dispersed phases. AICHE J. 2004, 50, 311–321. [Google Scholar] [CrossRef]

- Buonomenna, M.G.; Yave, W.; Golemme, G. Some approaches for high performance polymer based membranes for gas separation: Block copolymers, carbon molecular sieves and mixed matrix membranes. RSC Adv. 2012, 2, 10745–10773. [Google Scholar] [CrossRef]

- Zahid, M.; Rashid, A.; Akram, S.; Rehan, Z.A.; Razzaq, W. A Comprehensive Review on Polymeric Nano-Composite Membranes for Water Treatment. J. Membr. Sci. Technol. 2018, 8, 1000179. [Google Scholar] [CrossRef]

- Pereira, C.M.C.; Nóvoa, P.; Martins, M.; Forero, S.; Hepp, F. Characterization of carbon nanotube 3D-structures infused with low viscosity epoxy resin system. Compos. Struct. 2010, 92, 2252–2257. [Google Scholar] [CrossRef]

- Schweiss, R.; Steeb, M.; Wilde, P.M.; Schubert, T. Enhancement of proton exchange membrane fuel cell performance by doping microporous layers of gas diffusion layers with multiwall carbon nanotubes. J. Power Sources 2012, 220, 79–83. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. IUPAC Technical Report. Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar]

- Sapalidis, A.A.; Katsaros, F.K.; Steriotis, T.A.; Kanellopoulos, N.K. Properties of Poly(vinyl alcohol)—Bentonite Clay Nanocomposite Films in Relation to Polymer–Clay Interactions. J. Appl. Polym. Sci. 2012, 123, 1812–1821. [Google Scholar] [CrossRef]

- Jin, H.; Huang, Y.; Wang, X.; Yu, P.; Luo, Y. Preparation of modified cellulose acetate membranes using functionalized multi-walled carbon nanotubes for forward osmosis. Des. Water Treat. 2015, 57, 7166–7174. [Google Scholar] [CrossRef]

- Liao, Y.; Loh, C.-H.; Tian, M.; Wang, R.; Fane, A.G. Progress in electrospun polymeric nanofibrous membranes for water treatment: Fabrication, modification and applications. Prog. Polym. Sci. 2018, 77, 69–94. [Google Scholar] [CrossRef]

- O’Dwyer, M.J.; Maistros, G.M.; James, S.W.; Tatam, R.P.; Partridge, I.K. Relating the state of cure to the real-time internal strain development in a curing composite using in-fibre Bragg gratings and dielectric sensors. Meas. Sci. Technol. 1998, 9, 1153–1158. [Google Scholar] [CrossRef]

- Bekas, D.G.; Gkikas, G.; Maistros, G.M.; Paipetis, A.S. On the use of dielectric spectroscopy for the real time assessment of the dispersion of carbon nanotubes in epoxy. RSC Adv. 2016, 6, 78838–78845. [Google Scholar] [CrossRef]

- Dimou, A.-E.; Sakellariou, I.; Maistros, G.M.; Alexopoulos, N.D. Study of Reduced Graphene Oxide Dispersions via Electrical Impedance Spectroscopy. Procedia Struct. Integr. 2020, 28, 1679–1685. [Google Scholar] [CrossRef]

- Haussinger, P.; Glathaar, R.; Rhode, W.; Kick, H.; Benkmann, C.; Weber, J.; Wunschel, H.-J.; Stenke, V.; Leicht, E.; Stenger, H. Noble Gases. In Ullmann’s Encyclopedia of Industrial Chemistry; John Wiley and Sons: Hoboken, NJ, USA, 2011; pp. 392–448. [Google Scholar]

- Committee on the Impact of Selling the Federal Helium Reserve. The Impact of Selling the Federal Helium Reserve; National Academy Press: Washington, DC, USA, 2000. [Google Scholar]

- Scholes, C.A.; Ghosh, U.K. Review of Membranes for Helium Separation and Purification. Membranes 2017, 7, 9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Favvas, E.P.; Katsaros, F.K.; Papageorgiou, S.K.; Sapalidis, A.A.; Mitropoulos, A.C. A Review of the Latest Development of Polyimide based Membranes for CO2 Separations. React. Funct. Polym. 2017, 120, 104–130. [Google Scholar] [CrossRef]

- Scholes, C.A.; Tao, W.X.; Stevens, G.W.; Kentish, S.E. Sorption of methane, nitrogen, carbon dioxide and water in matrimid 5218. J. Appl. Polym. Sci. 2010, 117, 2284–2289. [Google Scholar] [CrossRef]

- Dong, G.; Lia, H.; Chen, V. Challenges and opportunities for mixed-matrix membranes for gas separation. J. Mater. Chem. A 2013, 1, 4610–4630. [Google Scholar] [CrossRef]

- Karousos, D.S.; Lei, L.; Lindbråthen, A.; Sapalidis, A.A.; Kouvelos, E.P.; He, X.; Favvas, E.P. Cellulose-based carbon hollow fiber membranes for high-pressure mixed gas separation of CO2/CH4 and CO2/N2. Sep. Purif. Technol. 2020, 253, 117473. [Google Scholar] [CrossRef]

- Gantzel, P.K.; Merten, U. Gas separations with high-flux cellulose acetate membranes. Ind. Eng. Chem. Process Des. Dev. 1970, 9, 331–332. [Google Scholar] [CrossRef]

- Syrtsova, D.A.; Kharitonov, A.P.; Teplyakov, V.V.; Koops, G.-H. Improving gas separation properties of polymeric membranes based on glassy polymers by gas phase fluorination. Desalination 2004, 163, 273–279. [Google Scholar] [CrossRef]

- Kim, S.; Pechar, T.W.; Marand, E. Poly(imide siloxane) and carbon nanotube mixed matrix membranes for gas separation. Desalination 2006, 192, 330–339. [Google Scholar] [CrossRef]

- Favvas, E.P.; Romanos, G.E.; Papageorgiou, S.K.; Katsaros, F.K.; Mitropoulos, A.C.; Kanellopoulos, N.K. A Methodology for the morphological and physicochemical characterisation of asymmetric carbon hollow fiber membranes. J. Membr. Sci. 2011, 375, 113–123. [Google Scholar] [CrossRef]

- Favvas, E.P.; Heliopoulos, N.S.; Papageorgiou, S.K.; Mitropoulos, A.C.; Kapantaidakis, G.C.; Kanellopoulos, N.K. Helium and hydrogen selective carbon hollow fiber membranes: The effect of pyrolysis isothermal time. Sep. Purif. Technol. 2015, 142, 176–181. [Google Scholar] [CrossRef]

- Sazali, N.; Salleh, W.N.W.; Ismail, A.F.; Ismail, N.H.; Aziz, F.; Yusof, N.; Hasbullah, H. Effect of stabilization temperature during pyrolysis process of P84 co-polyimide-based tubular carbon membrane for H2/N2 and He/N2 separations. IOP Conf. Ser. Mater. Sci. Eng. 2018, 342, 012027. [Google Scholar] [CrossRef]

- Sazali, N.; Salleh, W.N.W.; Ismail, A.F.; Kadirgama, K.; Othman, F.E.C. P84 Co-Polyimide Based-Tubular Carbon Membrane: Effect of Heating Rates on Helium Separations. Solid State Phenom. 2018, 280, 308–311. [Google Scholar] [CrossRef]

- Ma, X.; Li, Y.S.; Wei, X.; Kniep, J. Ultrathin Carbon Molecular Sieve Membrane for Propylene/Propane separation. AIChE 2016, 62, 491–499. [Google Scholar] [CrossRef]

- Nikolaeva, D.; Azcune, I.; Tanczyk, M.; Warmuzinski, K.; Jaschik, M.; Sandru, M.; Dahl, P.I.; Genua, A.; Loïs, S.; Sheridan, E.; et al. The performance of affordable and stable cellulose-based poly-ionic membranes in CO2/N2 and CO2/CH4 gas separation. J. Membr. Sci. 2018, 564, 552–561. [Google Scholar] [CrossRef]

- Vengatesan, M.; Wahab, M.A.; Kuppireddy, S.; Kakosimos, G.; Abdalla, O.; Favvas, E.; Reinalda, D.; Geuzebroek, F.; Abdala, A.; Karanikolos, G. Metal-Organic Framework—Based Mixed Matrix Membranes for Carbon Dioxide Separation: Recent Advances and Future Directions. Front. Chem. 2020, 8, 534. [Google Scholar]

- Kohl, A.L.; Nielsen, R.B. (Eds.) Chapter 2—Alkanolamines for hydrogen sulfide and carbon dioxide removal. In Gas Purification, 5th ed.; Gulf Professional Publishing: Houston, TX, USA, 1997; pp. 40–186. [Google Scholar]

- Luis, P.; Van Gerven, T.; Van der Bruggen, B. Recent developments in membrane-based technologies for CO2 capture. Prog. Energy Combus. Sci. 2012, 38, 419–448. [Google Scholar] [CrossRef]

- Adewole, J.K.; Ahmad, A.L.; Ismail, S.; Leo, C.P. Current challenges in membrane separation of CO2 from natural gas: A review. Int. J. Greenh. Gas Control 2013, 17, 46–65. [Google Scholar] [CrossRef]

- Baker, R.W. Future directions of membrane gas separation technology. Ind. Eng. Chem. Res. 2002, 41, 1393–1411. [Google Scholar] [CrossRef]

- Baker, R.W. Membrane gas-separation: Applications. In Membrane Operations: Innovative Separations and Transformations; Drioli, E., Giorno, L., Eds.; Wiley-VCH Verlag GmbH & CoKGaA: Weinheim, Germany, 2009. [Google Scholar]

- Bernardo, P.; Drioli, E.; Golemme, G. Membrane Gas Separation: A Review / State of the Art. Ind. Eng. Chem. Res. 2009, 48, 4638–4663. [Google Scholar] [CrossRef]

- Yeom, C.K.; Lee, S.H.; Lee, J.M. Study of Transport of Pure and Mixed CO2/N2 Gases through Polymeric Membranes. J. Appl. Polym. Sci. 1999, 78, 179–189. [Google Scholar] [CrossRef]

- Scholes, C.A.; Bacus, J.; Chen, G.Q.; Tao, W.X.; Li, G.; Qader, A.; Stevens, G.W.; Kentish, S.E. Pilot plant performance of rubbery polymeric membranes for carbon dioxide separation from syngas. J. Membr. Sci. 2012, 389, 470–477. [Google Scholar] [CrossRef]

- Favvas, E.P.; Figoli, A.; Castro-Munoz, R.; Fila, V.; He, X. Chapter 1st “Polymeric membrane materials for CO2 separations”. In Current Trends and Future Developments on (Bio-) Membranes, 1st ed.; Carbon Dioxide Separation/Capture by Using Membranes; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–50. ISBN 9780128136454. [Google Scholar]

- Achoundong, C.S.K.; Bhuwania, N.; Burgess, S.K.; Karvan, O.; Johnson, J.R.; Koros, W.J. Silane Modification of Cellulose Acetate Dense Films as Materials for Acid Gas Removal. Macromolecules 2013, 46, 5584–5594. [Google Scholar] [CrossRef]

- Yi, S.; Ghanem, B.; Liu, Y.; Pinnau, I.; Koros, W.J. Ultraselective glassy polymer membranes with unprecedented performance for energy-efficient sour gas separation. Sci. Adv. 2019, 5, eaaw5459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, H.; Yavari, M. Upper bound of polymeric membranes for mixed-gas CO2/CH4 separations. J. Membr. Sci. 2015, 475, 101–109. [Google Scholar] [CrossRef]

- Jeon, Y.-W.; Shin, M.-S. Separation of biogas using newly prepared cellulose acetate hollow fiber membranes. Energy Procedia 2017, 136, 219–224. [Google Scholar] [CrossRef]

- Pak, S.-H.; Jeon, Y.-W.; Shin, M.-S.; Koh, H.C. Preparation of Cellulose Acetate Hollow-Fiber Membranes for CO2/CH4 Separation. Environ. Eng. Sci. 2015, 33, 1–8. [Google Scholar]

- Mubashir, M.; Yeong, Y.F.; Lau, K.K.; Chew, T.L. Effect of spinning conditions on the fabrication of cellulose acetate hollow fiber membrane for CO2 separation from N2 and CH4. Polym. Test. 2019, 73, 1–11. [Google Scholar] [CrossRef]

- Mubashir, M.; Fong, Y.Y.; Leng, C.T.; Keong, L.K. Enhanced Gases Separation of Cellulose Acetate Membrane Using N-Methyl-1-2 Pyrrolidone as Fabrication Solvent. Int. J. Autom. Mech. Eng. 2018, 15, 4978–4986. [Google Scholar] [CrossRef]

- Salehi, A.A.; Ghannadi-Maragheh, M.; Torab-Mostaedi, M.; Torkaman, R.; Asadollahzadeh, M. A review on the water-energy nexus for drinking water production from humid air. Renew. Sust. Energy Rev. 2020, 120, 109627. [Google Scholar] [CrossRef]

- Antoniou, M.K.; Sapalidis, A.; Sideratou, Z. Functionalization of Carbon-Based Additives. In Membrane Desalination: From the Nanoscale to Real World Applications; Sapalidis, A.A., Ed.; CRC Press/Taylor and Francis Group: Abington, UK, 2021; pp. 91–123. ISBN 9780367030797. [Google Scholar]

- Yin, J.; Zhu, G.; Deng, B. Multi-walled carbon nanotubes (MWNTs)/polysulfone (PSU) mixed matrix hollow fiber membranes for enhanced water treatment. J. Membr. Sci. 2013, 437, 237–248. [Google Scholar] [CrossRef]

| Parameter | - | + |

|---|---|---|

| Treatment duration (min) | 5 | 30 |

| Revolution speed (min−1) | 2000 | 6000 |

| Tool (geometry stator) | Emulsor screen (ES) | General purpose disintegrating head (MUSS) |

| MWCNTs weight concentration (%) * | 0.5 | 2 |

| CA weight concentration (%) | 5 | 10 |

| Parameter | - | + |

|---|---|---|

| Treatment duration (min) | 2.5 | 5 |

| Cycle (%) | 30 | 100 |

| MWCNTs weight concentration (%) * | 0.5 | 2 |

| CA weight concentration (%) | 5 | 10 |

| Parameter | Value |

|---|---|

| Roll gap (µm) | 10 |

| Revolution speed (min−1) | 450 |

| Roll temperature (°C) | 24 |

| MWCNTs weight concentration (%) * | 0.5–2 |

| CA weight concentration (%) | 10 |

| Samples Prepared by Rotor-Stator System | |||||

| Sample | Method | CA Concentration (%) | MWCNTs Concentration (%) | Revolution Speed (min−1) | Duration (min) |

| RS1 | RS (ES) | 10 | 0.5 | 6000 | 30 |

| RS2 | RS (MUSS) | 10 | 2.0 | 6000 | 30 |

| RS3 | RS (MUSS) | 5 | 0.5 | 6000 | 30 |

| RS4 | RS (ES) | 5 | 2.0 | 6000 | 30 |

| RS5 | RS (MUSS) | 5 | 0.5 | 2000 | 5 |

| Samples Prepared by Ultrasonification | |||||

| Sample | Method | CA Concentration (%) | MWCNTs Concentration (%) | Cycle (%) | Duration (min) |

| USS1 | USS | 5.0 | 0.5 | 100 | 2.5 |

| USS2 | USS | 10.0 | 0.5 | 30 | 2.5 |

| USS3 | USS | 10.0 | 2.0 | 30 | 5 |

| USS4 | USS | 10.0 | 2.0 | 100 | 2.5 |

| USS5 | USS | 5.0 | 2.0 | 100 | 5 |

| USS6 | USS | 10.0 | 0.5 | 100 | 5 |

| USS7 | USS | 10.0 | 2.0 | 100 | 2.5 |

| Sample | Water Permeability (L/(h·m2·bar)) | Water Permeability Decrease (%) |

|---|---|---|

| CA-Membrane | 109 | -- |

| RS1 | 36 | 67 |

| RS2 | 38 | 65 |

| USS1 | 23 | 79 |

| USS2 | 27 | 75 |

| USS3 | 12 | 89 |

| USS6 | 19 | 83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esser, T.; Wolf, T.; Schubert, T.; Benra, J.; Forero, S.; Maistros, G.; Barbe, S.; Theodorakopoulos, G.V.; Karousos, D.S.; Sapalidis, A.A.; et al. CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method. Nanomaterials 2021, 11, 280. https://doi.org/10.3390/nano11020280

Esser T, Wolf T, Schubert T, Benra J, Forero S, Maistros G, Barbe S, Theodorakopoulos GV, Karousos DS, Sapalidis AA, et al. CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method. Nanomaterials. 2021; 11(2):280. https://doi.org/10.3390/nano11020280

Chicago/Turabian StyleEsser, Tobias, Tobias Wolf, Tim Schubert, Jan Benra, Stefan Forero, George Maistros, Stéphan Barbe, George V. Theodorakopoulos, Dionysios S. Karousos, Andreas A. Sapalidis, and et al. 2021. "CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method" Nanomaterials 11, no. 2: 280. https://doi.org/10.3390/nano11020280

APA StyleEsser, T., Wolf, T., Schubert, T., Benra, J., Forero, S., Maistros, G., Barbe, S., Theodorakopoulos, G. V., Karousos, D. S., Sapalidis, A. A., & Favvas, E. P. (2021). CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method. Nanomaterials, 11(2), 280. https://doi.org/10.3390/nano11020280