A SERS Study of Charge Transfer Process in Au Nanorod–MBA@Cu2O Assemblies: Effect of Length to Diameter Ratio of Au Nanorods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Sample Preparation

2.2.1. Preparation of Au NRs with Different L/Ds

2.2.2. Preparation of Au NR–MBA with Different L/Ds

2.2.3. Preparation of Au NR–MBA@Cu2O with Different L/Ds

2.3. Instruments

3. Results and Discussion

3.1. Characterization of Au NRs and Au NR–MBA@Cu2O with Different L/Ds

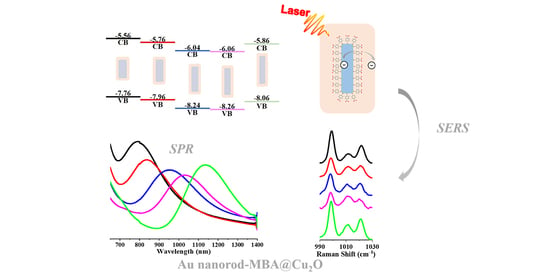

3.2. UV–VIS–NIR Characterization of Au NRs, Au NR–MBA, and Au NR–MBA@Cu2O Assemblies

3.3. SERS Spectra of MBA in Au NR–MBA and Au NR–MBA@Cu2O Assemblies

3.4. UPS of Au NR–MBA@Cu2O Assemblies with Different L/Ds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fleischmann, M.; Hendra, P.J.; McQuillan, A.J. Raman spectra of pyridine adsorbed at a silver electrode. Chem. Phys. Lett. 1974, 26, 163–166. [Google Scholar] [CrossRef]

- Shen, Z.D.; Wang, H.Y.; Yu, Q.; Li, Q.; Lu, X.M.; Kong, X.M. On-site separation and identification of polycyclic aromatic hydrocarbons from edible oil by TLC-SERS on diatomite photonic biosilica plate. Microchem. J. 2021, 160, 105672. [Google Scholar] [CrossRef]

- Ngo, H.T.; Wang, H.-N.; Fales, A.M.; Vo-Dinh, T. Label-Free DNA Biosensor Based on SERS Molecular Sentinel on Nanowave Chip. Anal. Chem. 2013, 85, 6378–6383. [Google Scholar] [CrossRef] [Green Version]

- Nie, X.M.; Chen, Z.Y.; Tian, Y.P.; Chen, S.; Qu, L.L.; Fan, M.B. Rapid detection of trace formaldehyde in food based on surface-enhanced Raman scattering coupled with assembled purge trap. Food Chem. 2021, 340, 127930. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, C.L.; Qin, L.X.; Kang, S.-Z.; Li, X.Q. A low-cost 3D core-shell nanocomposite as ultrasensitive and stable surface enhanced Raman spectroscopy substrate. Sens. Actuators B 2021, 327, 128907. [Google Scholar] [CrossRef]

- Bazzaoui, E.A.; Aubard, J.; Félidj, N.; Laurent, G.; Lévi, G. Ex situ and in situ SERS analyses of polybithiophene using roughened Ag and Cu electrodes and multilayer SERS-active systems. J. Raman Spectrosc. 2005, 36, 817–823. [Google Scholar] [CrossRef]

- Campion, A.; Kambhampati, P. Surface-enhanced Raman scattering. Chem. Soc. Rev. 1998, 27, 241–250. [Google Scholar] [CrossRef]

- Otto, A. The ‘chemical’ (electronic) contribution to surface-enhanced Raman scattering. J. Raman Spectrosc. 2005, 36, 497–509. [Google Scholar] [CrossRef]

- Das, R.S.; Agrawal, Y.K. Raman spectroscopy: Recent advancements, techniques and applications. Vib. Spectrosc. 2011, 57, 163–176. [Google Scholar] [CrossRef]

- Wustholz, K.L.; Henry, A.-I.; McMahon, J.M.; Freeman, R.G.; Valley, N.; Piotti, M.E.; Natan, M.J.; Schatz, G.C.; Duyne, R.P.V. Structure-Activity Relationships in Gold Nanoparticle Dimers and Trimers for Surface-Enhanced Raman Spectroscopy. J. Am. Chem. Soc. 2010, 132, 10903–10910. [Google Scholar] [CrossRef]

- Prinz, J.; Heck, C.; Ellerik, L.; Merk, V.; Bald, I. DNA origami based Au-Ag-core-shell nanoparticle dimers with single-molecule SERS sensitivity. Nanoscale 2016, 8, 5612–5620. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.T.; Herfort, D.; Jakobsen, H.J.; Skibsted, J. Site Preferences of Fluoride Guest Ions in the Calcium Silicate Phases of Portland Cement from Si-29{F-19} CP-REDOR NMR Spectroscopy. J. Am. Chem. Soc. 2009, 131, 14170. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Ozaki, Y.; Xu, Z.R.; Zhao, B. Effect of TiO2 on Altering Direction of Interfacial Charge Transfer in a TiO2-Ag-Mpy-FePc System by SERS. Angew. Chem. Int. Ed. 2019, 58, 8172–8176. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Zhu, L.; Ma, C.; Zhang, L.X.; Guo, L.; Liu, Y.W.; Ma, H.; Zhao, B. Plasmonic Molybdenum Tungsten Oxide Hybrid with Surface-Enhanced Raman Scattering Comparable to that of Noble Metals. ACS Appl. Mater. Interfaces 2020, 12, 19153–19160. [Google Scholar] [CrossRef] [PubMed]

- Ji, W.; Li, L.F.; Song, W.; Wang, X.N.; Zhao, B.; Ozaki, Y. Enhanced Raman Scattering by ZnO Superstructures: Synergistic Effect of Charge Transfer and Mie Resonances. Angew. Chem. Int. Ed. 2019, 58, 14452–14456. [Google Scholar] [CrossRef]

- Liu, Y.W.; Ma, H.; Han, X.X.; Zhao, B. Metal-semiconductor heterostructures for surface-enhanced Raman scattering: Synergistic contribution of plasmons and charge transfer. Mater. Horiz. 2021, 8, 370–382. [Google Scholar] [CrossRef]

- Gao, W.Q.; Liu, Q.; Zhang, S.; Yang, Y.Y.; Zhang, X.F.; Zhao, H.; Qin, W.; Zhou, W.J.; Wang, X.N.; Liu, H.; et al. Electromagnetic induction derived micro-electric potential in metal-semiconductor core-shell hybrid nanostructure enhancing charge separation for high performance photocatalysis. Nano Energy 2020, 71, 104624. [Google Scholar] [CrossRef]

- Wan, X.D.; Liu, J.; Wang, D.; Li, Y.M.; Wang, H.Z.; Pan, R.G.; Zhang, E.H.; Zhang, X.M.; Li, X.Y.; Zhang, J.T. From core-shell to yolk-shell: Keeping the intimately contacted interface for plasmonic metal@semiconductor nanorods toward enhanced near-infrared photoelectrochemical performance. Nano Res. 2020, 13, 1162–1170. [Google Scholar] [CrossRef]

- Lin, H.Y.; Chen, Y.F.; Wu, J.G.; Wang, D.I.; Chen, C.C. Carrier transfer induced photoluminescence change in metal-semiconductor core-shell nanostructures. Appl. Phys. Lett. 2006, 88, 161911. [Google Scholar] [CrossRef]

- Guo, H.X.; Su, X.P.; Su, Q.F.; Zhuang, W.; You, Z.J. Au-coated Fe3O4 core-shell nanohybrids with photothermal activity for point-of-care immunoassay for lipoprotein-associated phospholipase A2 on a digital near-infrared thermometer. Anal. Bioanal. Chem. 2021, 413, 235–244. [Google Scholar] [CrossRef] [PubMed]

- Lv, Y.P.; Duan, S.B.; Zhu, Y.C.; Yin, P.; Wang, R.M. Enhanced OER Performances of Au@NiCo2S4 Core-Shell Heterostructure. Nanomaterials 2020, 10, 611. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.L.; Deng, D.; Nguyen, M.T.; Rachel Chau, Y.-T.; Wen, C.-Y.; Yonezawa, T. Synthesis of Au@Cu2O Core-Shell Nanoparticles with Tunable Shell Thickness and Their Degradation Mechanism in Aqueous Solutions. Langmuir 2020, 36, 3386–3392. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.-Y.; Chang, S.-S.; Lee, C.-L.; Chris Wang, C.R. Gold Nanorods: Electrochemical Synthesis and Optical Properties. J. Phys. Chem. B 1997, 101, 6661–6664. [Google Scholar] [CrossRef]

- Huang, X.H.; Neretina, S.; El-Sayed, M.A. Gold nanorods: From synthesis and properties to biological and biomedical applications. Adv. Mater. 2009, 21, 4880–4910. [Google Scholar] [CrossRef]

- Nikoobakht, B.; El-Sayed, M.A. Preparation and Growth Mechanism of Gold Nanorods (NRs) Using Seed-Mediated Growth Method. Chem. Mater. 2003, 15, 1957–1962. [Google Scholar] [CrossRef]

- Kuo, C.-H.; Hua, T.-E.; Huang, M.H. Au Nanocrystal-Directed Growth of Au-Cu2O Core-Shell Heterostructures with Precise Morphological Control. J. Am. Chem. Soc. 2009, 131, 17871–17878. [Google Scholar] [CrossRef]

- Li, R.; Lv, H.; Zhang, X.; Liu, P.; Chen, L.; Cheng, J.; Zhao, B. Vibrational spectroscopy and density functional theory study of 4-mercaptobenzoic acid. Spectrochim. Acta Part A 2015, 148, 369–374. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yu, Z.; Ji, W.; Sui, H.M.; Cong, Q.; Wang, X.; Zhao, B. Charge-Transfer Effect on Surface-Enhanced Raman Scattering (SERS) in an Ordered Ag NPs/4-Mercaptobenzoic Acid/TiO2 System. J. Phys. Chem. C 2015, 119, 22439–22444. [Google Scholar] [CrossRef]

- Lombardi, J.R.; Birke, R.L. A Unified Approach to Surface-Enhanced Raman Spectroscopy. J. Phys. Chem. C 2008, 112, 5605–5617. [Google Scholar] [CrossRef]

- Lombardi, J.R.; Birke, R.L. A Unified View of Surface-Enhanced Raman Scattering. Acc. Chem. Res. 2009, 42, 734–742. [Google Scholar] [CrossRef] [Green Version]

| Wavenumber (cm−1) | Band Assignments | |

|---|---|---|

| Au NRs | Assemblies | |

| 998 | 999 | In-plane ring breathing, b2 |

| 1012 | 1012 | In-plane ring breathing + ν(CO), b2 |

| 1022 | 1022 | In-plane ring breathing, b2 |

| 1076 | 1075 | In-plane ring breathing + ν(C–S) |

| 1141 | C–H deformation modes v15, b2 | |

| 1178 | 1182 | C–H deformation modes v9, a1 |

| 1394 | ν(COO−) | |

| 1584 | 1586 | Totally symmetric ν(CC), a1 |

| 1710 | C=O stretching | |

| L/D | 1.96 | 2.26 | 2.78 | 3.02 | 3.49 | Pure Cu2O |

|---|---|---|---|---|---|---|

| CB (eV) | −5.56 | −5.76 | −6.04 | −6.06 | −5.86 | −5.7 |

| VB (eV) | −7.76 | −7.96 | −8.24 | −8.26 | −8.06 | −7.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, L.; Mao, Z.; Jin, S.; Zhu, L.; Zhao, J.; Zhao, B.; Jung, Y.M. A SERS Study of Charge Transfer Process in Au Nanorod–MBA@Cu2O Assemblies: Effect of Length to Diameter Ratio of Au Nanorods. Nanomaterials 2021, 11, 867. https://doi.org/10.3390/nano11040867

Guo L, Mao Z, Jin S, Zhu L, Zhao J, Zhao B, Jung YM. A SERS Study of Charge Transfer Process in Au Nanorod–MBA@Cu2O Assemblies: Effect of Length to Diameter Ratio of Au Nanorods. Nanomaterials. 2021; 11(4):867. https://doi.org/10.3390/nano11040867

Chicago/Turabian StyleGuo, Lin, Zhu Mao, Sila Jin, Lin Zhu, Junqi Zhao, Bing Zhao, and Young Mee Jung. 2021. "A SERS Study of Charge Transfer Process in Au Nanorod–MBA@Cu2O Assemblies: Effect of Length to Diameter Ratio of Au Nanorods" Nanomaterials 11, no. 4: 867. https://doi.org/10.3390/nano11040867

APA StyleGuo, L., Mao, Z., Jin, S., Zhu, L., Zhao, J., Zhao, B., & Jung, Y. M. (2021). A SERS Study of Charge Transfer Process in Au Nanorod–MBA@Cu2O Assemblies: Effect of Length to Diameter Ratio of Au Nanorods. Nanomaterials, 11(4), 867. https://doi.org/10.3390/nano11040867