3.2.1. Micro-/Nanofibrillated Celluloses-Starch-Based Coating

When comparing the printing quality of mechanically and enzymatically produced MFCs,

Figure 3A reveals that GA was increased by roughly 7% from that of starch-coated papers, when the proportion of both MFCs was 16% of the total solids concentration in respective formulations. An additional increase in m-MFC and e-MFC concentrations up to 32% improved the GA by 9.3% and 6.8%, respectively, whilst an increase up to 48% increased the GA by 13.1% and 7.3%, respectively.

Paper coated with m-MFC showed more hydrophilic surfaces than those of e-MFC coatings, as indicated by the static contact angle in

Table 6. Therefore, ink holdout properties were particularly enhanced by m-MFC [

8]. Although more research is still necessary to fully understand the effects of mechanical stress and endoglucanase-mediated hydrolysis on cellulose, it is generally accepted that the latter targets the amorphous regions [

26,

27]. Mechanical stress tends to break polymer chains at the middle and to increase their reactivity [

28], besides disrupting the structure of the fiber, and thus the higher hydrophilicity that m-MFC produced could be explained by the more severe loss of supramolecular order during the pre-treatment [

29].

In the case of NFC-based coatings,

Figure 3A reveals that the GA was increased by 9.6 and 11.5% using 16% t-NFC and c-NFC, respectively, also compared to the starch-coated papers. Compared to MFCs, NFCs formulations showed higher GA at lower concentrations. However, there was no substantial improvement when increasing the concentration of these NFCs. Higher concentrations of NFCs, on the other hand, increased PT values, given that the sorption of water-based carrier solvents increases with increasing charge density [

30].

Table 6 also shows that the smoothness of M/NFC-coated papers was comparable to that of starch-coated papers. Out of all M/NFCs, paper coated with e-MFC showed the highest smoothness. Likewise, ITCB improved by 11.1, 8.9 and 5.6% when employing 16, 32 and 48% of e-MFC, respectively, whereas other M/NFCs showed no improvement in ITCB (

Figure 3C).

Paper sheets coated with M/NFC and starch displayed similar air permeance as those coated with starch alone, hinting that the latter acted as host polymer. The permeance of the uncoated sheets was only slightly greater, 11.3 ± 0.4. Perhaps due to the low coat weight (1.7–2.9 g m

−2), coatings did not attain high air resistance. However, this was probably convenient for certain printing properties, since the most permeable coating formulation, e-MFC/starch, also improved the PT by 8.6, 15.2, 16.8% using 16, 32, and 48% of e-MFC, respectively, whereas other M/NFCs demonstrated no improvement in PT (

Figure 3D).

Figure 3B shows that the highest increase of 14.3% in the optical density of black was obtained with 16% m-MFC-coated papers. An additional increase in m-MFC concentration did not improve the OD (black). At the same time, e-MFC showed no improvement in OD (black) at any used concentration. However, in the case of NFC coatings, 32% t-NFC or c-NFC increased the OD (black) by 12.9 and 6.5%, respectively.

As shown in

Table 6, the presence of OBA in formulation with both MFCs and t-NFC coating formulations improved the whiteness of coated papers; however, the presence of c-NFC drastically lowered it. It also decreased as the concentration of c-NFC increased. Similar findings were also reported in our prior investigation with the use of cationic starch ether in the coating formulation, as whiteness was reduced with the addition of said cationic starch [

19].

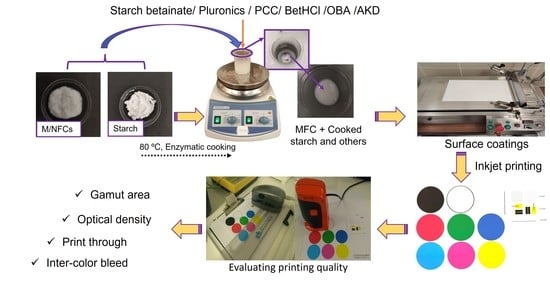

3.2.2. MFCs/Starch, Starch Betainate (SB), Pluronics and PCC-Based Coatings

For the combined coatings, a MFC concentration of 16% was selected because of their suitable rheology for coatings and the desirable paper properties attained, as discussed before.

Figure 4 shows the printing properties of papers coated using formulations containing starch, m-MFC, e-MFC, SB, Pluronics and PCC. Two coatings for comparison purposes are also presented: native starch and starch with 16% MFCs as can be observed in

Figure 4.

In

Figure 4A,B, the GA improved by 6.6% and 6.8% with 16% m-MFC and e-MFC, respectively. Furthermore, SB and Pluronics-P123 (8% of each) increased the GA by 13.3% (m-MFC) and 13.8% (e-MFC) in combination.

GA was improved by 16.5% (with m-MFC) and 13.1% (with e-MFC) with the addition of 8% of PCC. The highest increase in the GA was noticed when 16% of each component was used in the coating formulations: 19.2% for m-MFC and 17.7% for e-MFC. Likewise,

Figure 4A,B show that OD (black) was also improved by 11.1, 8.9, 8.6 and 13.3% using m-MFC, m-MFC/SB (8%)/P123 (8%), m-MFC/SB (8%)/P123 (8%)/PCC (8%), m-MFC/SB (16%)/P123 (16%)/PCC (16%), respectively. In case of e-MFC coatings, the OD (black) changed by −2.6, 4.3, 5.1 and 10.3%.

Contrary to the GA and OD, PT demonstrated no improvement upon the addition of SB or P123 in m-MFC-based formulations and as observed from

Figure 4C,D. Besides, the addition of PCC lowered the penetration of ink pigments as also detected elsewhere [

15] and resulted in lower values of this property. PT improved by 18.2% with 16% of each component, along with m-MFC, whereas ITCB increased by up to 12.8%. This ITCB variation is explained by the fact that cationic sizing reduces the ink feathering due to the electrostatic adsorption of anionic dyes, resulting in quick fixation of ink particles onto the paper surface and preventing their migration [

31]. Regarding e-MFC coatings, PT improved with the addition of these e-MFCs; SB, P123 and PCC (8% of each) showed the highest improvement in PT, 12.2%. ITCB followed the same trend as PT, but the highest increase, 19.7%, was achieved using SB and P123 (8% each, in combination with e-MFC).

3.2.3. NFCs/Starch, Starch Betainate (SB), Pluronics and PCC-Based Coatings

Similarly to MFCs coatings, a NFC proportion of 16% was chosen;

Figure 5 shows the printing properties of paper coated using formulations containing starch, t-NFC, c-NFC, SB, P123 and PCC.

Figure 5 additionally presented two coatings for comparison purposes: native starch and 16% NFCs/starch. In

Figure 5A,B, GA improved by 9.6% and 11.5% with 16% t-NFC or c-NFC, respectively. Furthermore, SB and P123 (8% of each) increased the GA by 11.6% (t-NFC) and 16.8% (c-NFC) in combination.

GA was improved by 15% (with t-NFC) and 17% (with c-NFC) after an additional 8% of PCC was added. The highest increase in the GA was noticed when 16% of each component was used in the coating formulations, which was 20.3% (t-NFC) and 17.2% (c-NFC). Likewise,

Figure 5A,B show that OD (black) was also improved by 1.2, 1.7, 8.3 and 9.9% using t-NFC, t-NFC/SB (8%)/P123 (8%), t-NFC/SB (8%)/P123 (8%)/PCC (8%) and t-NFC/SB (16%)/P123 (16%)/PCC (16%), respectively, and it was 0.2, 4.8, 7.4 and 11.6% (following the same sequence) in the case of c-NFC coatings.

Contrary to the GA and OD, as observed from

Figure 5C,D, PT improved by 12.6 and 4.2% using 16% of t-NFC and c-NFC, respectively. However, the further addition of SB, P123 and PCC demonstrated no improvements for both NFC-based formulations. Nonetheless, ITCB improved with the addition of these components and demonstrated a maximum improvement of 18.4% using SB and P123 (8% of each) for t-NFC coatings. Regarding c-NFC coatings, a highest increase of 10.8% was achieved in ITCB using SB, P123 and PCC (16% each, in combination with c-NFC).

Table 6 and

Table 7 shows that the whiteness of coated papers was reduced with the use of c-NFCs because of their positively charged, electron-withdrawing quaternary ammonium groups, as they quenched the OBA which used to improve the whiteness of papers. This OBA is a sulfonated derivative of stilbene, and thus the interaction between its negatively-charged functional groups and quaternary ammonium groups may induce aggregation and/or electron transfer-mediated quenching. The whiteness was not affected with the use of other M/NFCs, SB or P123.

3.2.4. Coating Formulations with BetHCl

In order to reduce the cost of coating formulations, instead of cationizing the starch, BetHCl was directly added to the rest of the components of the coating suspension. These experiments also implied a lower concentration of P123 (5%) and higher total solids concentration (10%, w/w).

As shown in

Figure 6A, the addition of 16% of BetHCl improved the GA by 17.8%, whereas it increased by 21.3% in combination with PCC (16%), and by 22.4% with P123 (besides BetHCl). The combination of all these components improved the GA by 24.4%. The further addition of m-MFC (16%), along with the aforementioned agents, improved the GA by 36.1%, the highest increase among all the formulations in this study. Likewise, GA improved by 31.0%, 35.5% and 26.1% with the use of e-MFC, t-NFC and c-NFC (16%), respectively.

Similar to the GA, as shown in

Table 8, gamut volume (GV) also improved by 25% with the addition of 16% BetHCl in compared to the reference formulation. In the further addition of 16% PCC along with the BetHCl in the formulation, there was an increase in the GV from 132 × 10

3 to 168 × 10

3, which corresponds to an increase of 27%, compared to the reference formulation. With the addition of 5% P123 along with the BetHCl, GV increased by 31%. When 16% PCC and 5% P123 were added along with the BetHCl in the formulation, it showed an increase of 34%.

The addition of m-MFC (in presence of PCC, P123 and BetHCl) resulted in an increase in GV from 132 × 103 to 202 × 103, which corresponds to an increase of 53%, compared to the reference formulation. The formulations, which correspond to incorporations of e-MFC, t-NFC and c-NFC showed increases in GV values from 132 (reference formulation) to 188, 198 and 183, corresponding to increments of 42%, 50% and 39%, respectively. Thus, as observed for the GA, there was also an increase in GV values with the addition of BetHCl, and comparable or even higher increments in gamut volume by including components such as PCC, P123 and M/NFCs.

Figure 6A also represents the OD (black) of BetHCl-coated papers. A 16% addition of BetHCl improved the OD by 13.7%, whereas it increased only by 10.3% with the BetHCl/PCC (16%) system, and by 14.5% when P123 (5%) was used in combination with BetHCl. Together, the three of them improved the OD (black) by 13.7%. Therefore, it may be concluded that PCC exerts either a negative influence or no significant influence on OD. By the further addition of m-MFC (16%), OD (black) improved by 24%, which was once again the highest improvement out of all the formulations that are reported herein. OD (black) increased by 14.5%, 20.8% and 20.2% with the use of e-MFC, t-NFC and c-NFC, respectively.

As shown in the

Figure 6B, PT decreased by 33% (desired) with the addition of 16% of BetHCl. Moreover, with the addition of PCC and P123, PT decreased by 24 and 28%, respectively in combination of BetHCl. It was decreased by 18% with both PCC and P123, in a formulation with BetHCl. Similarly, it was decreased by 15, 18, 8 and 7% with m-MFC, e-MFC, t-NFC and c-NFC, respectively, in combination with BetHCl, PCC and P123. Thus, the highest improvement was observed with the use of BetHCl alone in the formulation with starch, OBA and AKD.

It was also shown in the

Figure 6B that the ITCB improved by 23% with the addition of 16% of BetHCl in the coating formulation. Additionally, ITCB improved with 22 and 21% with the addition of PCC and P123, respectively, in the presence of BetHCl in the formulations. The presence of both PCC and P123 in a formulation improved the ITCB by 24% in combination with BetHCl. A highest improvement of 26% was observed with m-MFC in combination with BetHCl, PCC and P123, however, it was 17, 13 and 17% with the e-MFC, t-NFC and c-NFC, respectively.

Similar to SB coatings,

Table 8 shows that the whiteness improved with the use of BetHCl; thus, these was no quenching of OBA in presence of these cationic substances in the coating formulations. Additionally, it increased by 3.7% with the used of BetHCl, PCC and P123 in the coating formulation. The presence of MFCs retained the whiteness, however, it substantially reduced with the use of c-NFC in the coating formulation. The

Table 8 also represents the variations in Bendtsen roughness and Gurley air permeance, as also expected, without any significant impact.