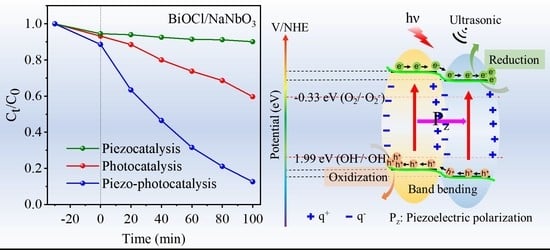

Synergistic Piezo-Photocatalysis of BiOCl/NaNbO3 Heterojunction Piezoelectric Composite for High-Efficient Organic Pollutant Degradation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Fabrication

2.1.1. Synthesis of NaNbO3

2.1.2. Synthesis of BiOCl

2.1.3. Synthesis of BiOCl/NaNbO3 Composites

2.2. Photocatalytic Performance Experiment

2.3. Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, L.; Yang, S.; Zhao, Y.; He, J.; Jiang, S.; Sun, C.; Song, S. Spontaneous polarization electric field briskly boosting charge separation and transfer for sustainable photocatalytic H2 bubble evolution. Appl. Catal. B 2021, 283, 119631. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wu, J.M. Effect of controlled oxygen vacancy on H2-production through the piezocatalysis and piezophototronics of ferroelectric R3C ZnSnO3 nanowires. Adv. Funct. Mater. 2019, 30, 1907619. [Google Scholar] [CrossRef]

- El-Bindary, A.A.; El-Marsafy, S.M.; El-Maddah, A.A. Enhancement of the photocatalytic activity of ZnO nanoparticles by silver doping for the degradation of AY99 contaminants. J. Mol. Struct. 2019, 1191, 76–84. [Google Scholar] [CrossRef]

- Kiwaan, H.A.; Atwee, T.M.; Azab, E.A.; El-Bindary, A.A. Efficient photocatalytic degradation of Acid Red 57 using synthesized ZnO nanowires. J. Chin. Chem. Soc. 2019, 66, 89–98. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Cai, J.; Wu, M.; Chen, J.; Zhao, W.; Tian, Y.; Ding, T.; Zhang, J.; Jiang, Z.; Li, X. Rational construction of oxygen vacancies onto tungsten trioxide to improve visible light photocatalytic water oxidation reaction. Appl. Catal. B 2018, 239, 398–407. [Google Scholar] [CrossRef]

- Ye, L.; Zan, L.; Tian, L.; Peng, T.; Zhang, J. The {001} facets-dependent high photoactivity of BiOCl nanosheets. Chem. Commun. 2011, 47, 6951–6953. [Google Scholar] [CrossRef]

- Li, Q.; Guan, Z.; Wu, D.; Zhao, X.; Bao, S.; Tian, B.; Zhang, J. Z-scheme BiOCl-Au-CdS heterostructure with enhanced sunlight-driven photocatalytic activity in degrading water dyes and antibiotics. ACS Sustain. Chem. Eng. 2017, 5, 6958–6968. [Google Scholar] [CrossRef]

- Li, T.B.; Chen, G.; Zhou, C.; Shen, Z.Y.; Jin, R.C.; Sun, J.X. New photocatalyst BiOCl/BiOI composites with highly enhanced visible light photocatalytic performances. Dalton Trans. 2011, 40, 6751–6758. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Lai, C.; Zeng, G.; Huang, D.; Cheng, M.; Wang, J.; Chen, F.; Zhou, C.; Xiong, W. BiOX (X=Cl, Br, I) photocatalytic nanomaterials: Applications for fuels and environmental management. Adv. Colloid Interface Sci. 2018, 254, 76–93. [Google Scholar] [CrossRef]

- Yuan, B.; Wu, J.; Qin, N.; Lin, E.; Bao, D. Enhanced piezocatalytic performance of (Ba,Sr)TiO3 nanowires to degrade organic pollutants. ACS Appl. Nano Mater. 2018, 1, 5119–5127. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, L.; Zhang, Y.; Sun, H. Significantly enhanced piezo-photocatalytic capability in BaTiO3 nanowires for degrading organic dye. J. Materiomics 2020, 6, 256–262. [Google Scholar] [CrossRef]

- Li, L.; Ma, Y.; Chen, G.; Wang, J.; Wang, C. Oxygen-vacancy-enhanced piezo-photocatalytic performance of AgNbO. Scr. Mater. 2022, 206, 114234. [Google Scholar] [CrossRef]

- Lei, H.; Zhang, H.; Zou, Y.; Dong, X.; Jia, Y.; Wang, F. Synergetic photocatalysis/piezocatalysis of bismuth oxybromide for degradation of organic pollutants. J. Alloys Compd. 2019, 809, 151840. [Google Scholar] [CrossRef]

- Zhou, X.; Wu, S.; Li, C.; Yan, F.; Bai, H.; Shen, B.; Zeng, H.; Zhai, J. Piezophototronic effect in enhancing charge carrier separation and transfer in ZnO/BaTiO3 heterostructures for high-efficiency catalytic oxidation. Nano Energy 2019, 66, 104127. [Google Scholar] [CrossRef]

- Singh, S.; Khare, N. Coupling of piezoelectric, semiconducting and photoexcitation properties in NaNbO3 nanostructures for controlling electrical transport: Realizing an efficient piezo-photoanode and piezo-photocatalyst. Nano Energy 2017, 38, 335–341. [Google Scholar] [CrossRef]

- Ma, J.; Jia, Y.; Chen, L.; Zheng, Y.; Wu, Z.; Luo, W.; Jiang, M.; Cui, X.; Li, Y. Dye wastewater treatment driven by cyclically heating/cooling the poled (K0.5Na0.5)NbO3 pyroelectric crystal catalyst. J. Clean. Prod. 2020, 276, 124218. [Google Scholar] [CrossRef]

- Zhang, A.; Liu, Z.; Geng, X.; Song, W.; Lu, J.; Xie, B.; Ke, S.; Shu, L. Ultrasonic vibration driven piezocatalytic activity of lead-free K0.5Na0.5NbO3 materials. Ceram. Int. 2019, 45, 22486–22492. [Google Scholar] [CrossRef]

- You, H.; Ma, X.; Wu, Z.; Fei, L.; Chen, X.; Yang, J.; Liu, Y.; Jia, Y.; Li, H.; Wang, F.; et al. Piezoelectrically/pyroelectrically-driven vibration/cold-hot energy harvesting for mechano-/pyro- bi-catalytic dye decomposition of NaNbO3 nanofibers. Nano Energy 2018, 52, 351–359. [Google Scholar] [CrossRef]

- Ismail, M.; Wu, Z.; Zhang, L.; Ma, J.; Jia, Y.; Hu, Y.; Wang, Y. High-efficient synergy of piezocatalysis and photocatalysis in bismuth oxychloride nanomaterial for dye decomposition. Chemosphere 2019, 228, 212–218. [Google Scholar] [CrossRef] [PubMed]

- Kamat, P.V. Photochemistry on Nonreactive and Reactive (Semiconductor) Surfaces. Chem. Rev. 1993, 93, 267–300. [Google Scholar] [CrossRef]

- Pan, J.; Liu, J.; Zuo, S.; Khan, U.A.; Yu, Y.; Li, B. Structure of Z-scheme CdS/CQDs/BiOCl heterojunction with enhanced photocatalytic activity for environmental pollutant elimination. Appl. Surf. Sci. 2018, 444, 177–186. [Google Scholar] [CrossRef]

- Liu, Q.; Chai, Y.; Zhang, L.; Ren, J.; Dai, W.L. Highly efficient Pt/NaNbO3 nanowire photocatalyst: Its morphology effect and application in water purification and H2 production. Appl. Catal. B 2017, 205, 505–513. [Google Scholar] [CrossRef]

- Yu, Z.; Zhan, B.; Ge, B.; Zhu, Y.; Dai, Y.; Zhou, G.; Yu, F.; Wang, P.; Huang, B.; Zhan, J. Synthesis of high efficient and stable plasmonic photocatalyst Ag/AgNbO3 with specific exposed crystal–facets and intimate heterogeneous interface via combustion route. Appl. Surf. Sci. 2019, 488, 485–493. [Google Scholar] [CrossRef]

- Liu, L.; Shi, D.; Knapp, M.; Ehrenberg, H.; Fang, L.; Chen, J. Large strain response based on relaxor–antiferroelectric coherence in Bi0.5Na0.5TiO3–SrTiO3–(K0.5Na0.5)NbO3 solid solutions. J. Appl. Phys. 2014, 116, 184104. [Google Scholar] [CrossRef]

- Zhu, M.; Li, S.; Zhang, H.; Gao, J.; Kwok, K.W.; Jia, Y.; Kong, L.B.; Zhou, W.; Peng, B. Diffused phase transition boosted dye degradation with Ba (ZrxTi1−x)O3 solid solutions through piezoelectric effect. Nano Energy 2021, 89, 106474. [Google Scholar] [CrossRef]

- Turchi, C.S.; Ollis, D.F. Photocatalytic degradation of organic water contaminants: Mechanisms involving hydroxyl radical attack. J. Catal. 1990, 122, 178–192. [Google Scholar] [CrossRef]

- Rajan, K.D.; Gotipamul, P.P.; Khanna, S.; Chidambaram, S.; Rathinam, M. Piezo-photocatalytic effect of NaNbO3 interconnected nanoparticles decorated CuBi2O4 nanocuboids. Mater. Lett. 2021, 296, 129902. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, G.; Sheng, C.; Zhang, F.; Fan, W. The effect of piezo-photocatalysis on enhancing the charge carrier separation in BaTiO3/KNbO3 heterostructure photocatalyst. Appl. Surf. Sci. 2021, 562, 150164. [Google Scholar] [CrossRef]

- Li, H.; Sang, Y.; Chang, S.; Huang, X.; Zhang, Y.; Yang, R.; Jiang, H.; Liu, H.; Wang, Z.L. Enhanced ferroelectric–nanocrystal–based hybrid photocatalysis by ultrasonic–wave–generated piezophototronic effect. Nano Lett. 2015, 15, 2372–2379. [Google Scholar] [CrossRef]

- Hu, C.; Huang, H.; Chen, F.; Zhang, Y.; Yu, H.; Ma, T. Coupling piezocatalysis and photocatalysis in Bi4NbO8X (X = Cl, Br) polar single crystals. Adv. Funct. Mater. 2019, 30, 1908168. [Google Scholar] [CrossRef]

- Sharma, M.; Halder, A.; Vaish, R. Effect of Ce on piezo/photocatalytic effects of Ba0.9Ca0.1CexTi1-xO3 ceramics for dye/pharmaceutical waste water treatment. Mater. Res. Bull. 2020, 122, 110647. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, Q.; Du, A. High piezo–photocatalytic efficiency of H2 production by CuS/ZnO nanostructure under solar and ultrasonic exposure. Mater. Lett. 2021, 294, 129752. [Google Scholar] [CrossRef]

- Yang, B.; Chen, H.; Yang, Y.; Wang, L.; Bian, J.; Liu, Q.; Lou, X. Insights into the tribo–/pyro–catalysis using Sr–doped BaTiO3 ferroelectric nanocrystals for efficient water remediation. Chem. Eng. J. 2021, 416, 128986. [Google Scholar] [CrossRef]

- Zhou, X.; Yan, F.; Wu, S.; Shen, B.; Zeng, H.; Zhai, J. Remarkable piezophoto coupling catalysis behavior of BiOX/BaTiO3 (X = Cl, Br, Cl0.166Br0.834) piezoelectric composites. Small 2020, 16, 2001573. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Cao, W.; Yao, J.; Liu, W.; Li, F.; Wang, C. Synergistic Piezo-Photocatalysis of BiOCl/NaNbO3 Heterojunction Piezoelectric Composite for High-Efficient Organic Pollutant Degradation. Nanomaterials 2022, 12, 353. https://doi.org/10.3390/nano12030353

Li L, Cao W, Yao J, Liu W, Li F, Wang C. Synergistic Piezo-Photocatalysis of BiOCl/NaNbO3 Heterojunction Piezoelectric Composite for High-Efficient Organic Pollutant Degradation. Nanomaterials. 2022; 12(3):353. https://doi.org/10.3390/nano12030353

Chicago/Turabian StyleLi, Li, Wenjun Cao, Jiahao Yao, Wei Liu, Feng Li, and Chunchang Wang. 2022. "Synergistic Piezo-Photocatalysis of BiOCl/NaNbO3 Heterojunction Piezoelectric Composite for High-Efficient Organic Pollutant Degradation" Nanomaterials 12, no. 3: 353. https://doi.org/10.3390/nano12030353

APA StyleLi, L., Cao, W., Yao, J., Liu, W., Li, F., & Wang, C. (2022). Synergistic Piezo-Photocatalysis of BiOCl/NaNbO3 Heterojunction Piezoelectric Composite for High-Efficient Organic Pollutant Degradation. Nanomaterials, 12(3), 353. https://doi.org/10.3390/nano12030353