Enhanced Thermoelectric Performance of Cu2Se via Nanostructure and Compositional Gradient

Abstract

:1. Introduction

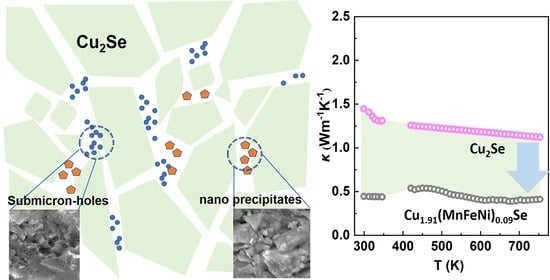

2. Materials and Methods

3. Results and Discussion

3.1. Effects of Compositional Gradient on the Thermoelectric (TE) Performance of Cu2Se

3.2. Effects of Nanostructure on the TE Performance of Cu2Se

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ming, H.; Zhu, C.; Qin, X. Improved figure of merit of Cu2SnSe3 via band structure modification and energy-dependent carrier scattering. ACS Appl. Mater. Interfaces 2020, 12, 19693–19700. [Google Scholar] [CrossRef]

- Gurukrishna, K.; Rao, A.; Jiang, Z.Z.; Kuo, Y.K. Enhancement of thermoelectric performance by tuning selenium content in the Cu2SnSe3 compound. Intermetallics 2020, 122, 106803. [Google Scholar] [CrossRef]

- Kim, H.; Kihoi, S.K.; Lee, H.S. Point defects control in non-stoichiometric CuInTe2 compounds and its corresponding effects on the microstructure and thermoelectric properties. J. Alloy. Compd. 2021, 869, 159381. [Google Scholar] [CrossRef]

- Wang, C.; Ma, Q.; Xue, H.; Wang, Q.; Luo, P.; Yang, J.; Zhang, W.; Luo, J. Tetrahedral distortion and thermoelectric performance of the Ag-substituted CuInTe2 chalcopyrite compound. ACS Appl. Energ. Mater. 2020, 3, 11015–11023. [Google Scholar] [CrossRef]

- Fan, F.J.; Xiu, Y. Large-scale colloidal synthesis of non-stoichiometric Cu2ZnSnSe4 nanocrystals for thermoelectric applications. Adv. Mater. 2012, 24, 6158–6163. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, H.; Nolas, G.S. Synthesis and thermoelectric properties of Cu excess Cu2ZnSnSe4. Phys. Status. Solidi-R. 2014, 8, 61–64. [Google Scholar] [CrossRef]

- Li, J.M.; Li, D.; Song, C.J.; Wang, L.; Xin, H.X.; Zhang, J.; Qin, X. Realized high power factor and thermoelectric performance in Cu3SbSe4. Intermetallics 2019, 109, 68–73. [Google Scholar] [CrossRef]

- Liu, Y.; Gregorio, G.; Ortega, S. Solution-based synthesis and processing of Sn and Bi-doped Cu3SbSe4 nanocrystals, nanomaterials and ring-shaped thermoelectric generators. J. Mater. Chem. A 2017, 5, 2592–2602. [Google Scholar] [CrossRef] [Green Version]

- Cahill, D.G.; Watson, S.K.; Pohl, R.O. Lower limit to the thermal conductivity of disordered crystals. Phys. Rev. B 1992, 46, 6131–6140. [Google Scholar] [CrossRef]

- Zou, T.H.; Qin, X.Y.; Li, D. Enhanced thermoelectric performance of β-Zn4Sb3 based composites incorporated with large proportion of nanophase Cu3SbSe4. J. Alloy. Compd. 2014, 588, 568–572. [Google Scholar] [CrossRef]

- Lu, X.F.; Zhang, Q.H.; Liao, J.C.; Chen, H.; Fan, Y.; Xing, J.; Gu, S.; Huang, J.; Ma, J.; Wang, J.; et al. High-efficiency Thermoelectric Power Generation Enabled by Homogeneous Incorporation of MXene in (Bi,Sb)2Te3 Matrix. Adv. Energy. Mater. 2019, 10, 1902986. [Google Scholar] [CrossRef]

- Wang, W.Y.; Wang, Y.P.; Bo, L.; Zhao, D.G. Enhanced thermoelectric properties of Cu3SbSe4 via compositing with nano-SnTe. J. Alloy. Compd. 2021, 878, 160358. [Google Scholar] [CrossRef]

- Bo, L.; Wang, Y.P.; Wang, W.Y.; Zhao, D.G. Grain size and compositional gradient dependence of thermoelectric performance for Cu3−xNixSbSe4 Materials. Results Phys. 2021, 26, 104337. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Zhou, Z.X.; Dylla, M. Realizing high-performance thermoelectric power generation through grain boundary engineering of skutterudite-based nanocomposites. Nano Energy 2017, 41, 501–510. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Ai, X.; Wang, L.J. Improved Thermoelectric Performance of Silver Nanoparticles-Dispersed Bi2Te3 Composites Deriving from Hierarchical Two-Phased Heterostructure. Adv. Funct. Mater. 2014, 25, 966–976. [Google Scholar] [CrossRef]

- Cai, J.; Yang, J.; Liu, G.; Wang, H.; Shi, F.; Tan, X.; Jiang, J. Ultralow thermal conductivity and improved zT of CuInTe2 by high-entropy structure design. Mater. Today Phys. 2021, 18, 100394. [Google Scholar] [CrossRef]

- Li, X.Y.; Li, D.; Xin, H.X.; Zhang, J.; Song, C.J.; Qin, X.Y. Effects of bismuth doping on the thermoelectric properties of Cu3SbSe4 at moderate temperatures. J. Alloy. Compd. 2013, 561, 105–108. [Google Scholar] [CrossRef]

- Wang, T.; Wang, H.C.; Su, W.B.; Zhai, J.; Yakovleva, G.; Wang, X.; Chen, T.; Romanenko, A.; Wang, C. Simultaneous enhancement of thermoelectric and mechanical performance for SnTe by nano SiC compositing. J. Mater. Chem. C 2020, 8, 7393–7400. [Google Scholar] [CrossRef]

- Zhou, X.; Yan, Y.; Lu, X.; Zhu, H.; Han, X.; Chen, G.; Ren, Z. Dopant-induced electron localization drives CO2 reduction to C2 hydrocarbons. Nat. Chem. 2018, 10, 974–980. [Google Scholar] [CrossRef]

- Feng, B.; Xie, J.; Cao, G.; Zhu, T.; Zhao, X. Enhanced thermoelectric properties of p-type CoSb3/graphene nanocomposite. J. Mater. Chem. A 2013, 1, 13111–13119. [Google Scholar] [CrossRef]

- Zhao, L.; Yang, J.; Zou, Y.; Hu, Y.J.; Liu, G.; Shao, H.; Zhang, X.; Shi, Z.; Hussain, S.; Qiao, G. Tuning Ag content to achieve high thermoelectric properties of Bi-doped p-type Cu3SbSe4-based materials. J. Alloy. Compd. 2021, 872, 159659. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, J.; Jiang, Q.; Fu, L.; Xiao, Y.; Luo, Y.; Zhou, Z. Improvement of thermoelectric properties of Cu3SbSe4 compound by In doping. Mater. Design. 2016, 98, 150–154. [Google Scholar] [CrossRef]

- Alam, H.; Ramakrishna, S. A review on the enhancement of figure of merit from bulk to nano-thermoelectric materials. Nano Energy 2013, 2, 190–212. [Google Scholar] [CrossRef]

- Yu, B.; Zhang, Q.; Wang, H. Thermoelectric property studies on thallium-doped lead telluride prepared by ball milling and hot pressing. J. Appl. Phys. 2010, 108, 16104. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Zhang, Y.; Zhang, T.; Zuo, Y.; Xiao, K.; Arbiol, J.; Llorca, J.; Liu, Y.; Cabot, A. Enhanced Thermoelectric Performance of n-Type Bi2Se3 Nanosheets through Sn Doping. Nanomaterials 2021, 11, 1827. [Google Scholar] [CrossRef]

- Baláž, P.; Guilmeau, E.; Achimovičová, M.; Baláž, M.; Daneu, N.; Dobrozhan, O.; Kaňuchová, M. Bismuth Doping in Nanostructured Tetrahedrite: Scalable Synthesis and Thermoelectric Performance. Nanomaterials 2021, 11, 1386. [Google Scholar] [CrossRef]

- Heinz, S.; Angel, E.C.; Trapp, M.; Kleebe, H.-J.; Jakob, G. Phonon Bridge Effect in Superlattices of Thermoelectric TiNiSn/HfNiSn with Controlled Interface Intermixing. Nanomaterials 2020, 10, 1239. [Google Scholar] [CrossRef]

- Deng, Y.P.; Wang, K.; Du, J.; Wu, H. From Dislocation to Nano-Precipitation: Evolution to Low Thermal Conductivity and High Thermoelectric Performance in n-Type PbTe. Adv. Funct. Mater. 2020, 30, 2005479. [Google Scholar] [CrossRef]

- Jiang, B.B.; Yu, Y.; Chen, H.; Cui, J.; Liu, X.; Xie, L.; He, J. Entropy engineering promotes thermoelectric performance in p-type chalcogenides. Nat. Commun. 2021, 12, 3234. [Google Scholar]

- Liu, H.; Chen, L.D. Ultrahigh Thermoelectric Performance by Electron and Phonon Critical Scattering in Cu2Se1−xIx. Adv. Mater. 2013, 25, 6607–6612. [Google Scholar] [CrossRef] [Green Version]

- Stephen, D. Enhanced stability and thermoelectric figure-of-merit in copper selenide by lithium doping. Mater. Today. Phys. 2017, 1, 7–13. [Google Scholar]

- Chen, X.; He, Y.; Lu, P.; Fu, Z.; Xu, F.; Yao, H.; Zhang, L.; Shi, X.; Chen, L. Multiple nanostructures in high performance Cu2S0.5Te0.5 thermoelectric materials. Ceram. Int. 2017, 43, 7866–7869. [Google Scholar]

- Peng, P.; Gong, Z.N.; Liu, F.S.; Huang, M.J.; Ao, W.Q.; Li, J.Q. Structure and thermoelectric performance of β-Cu2Se doped with Fe, Ni, Mn, In, Zn or Sm. Intermetallics 2016, 75, 72–78. [Google Scholar] [CrossRef]

- Jiang, F. Thermoelectric Properties of p-Type Polycrystalline Bi0.8Sb0.8In0.4Se3. Appl. Phys. Lett. 2021, 118, 193903. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.G.; Han, G.; Hong, M.; Zou, Y.; Zou, J. High-performance thermoelectric Cu2Se nanoplates through nanostructure engineering. Nano Energy 2015, 16, 367–374. [Google Scholar] [CrossRef]

- Bailey, T.; Si, H.; Xie, H.; Olvera, A.; Poudeu, P.; Tang, X. Enhanced zT and attempts to chemically stabilize Cu2Se via Sn doping. J. Mater. Chem. A 2017, 4, 17225. [Google Scholar] [CrossRef]

- Hu, Q.; Zheng, Z.; Zhang, Y. Remarkably high thermoelectric performance of Cu2−xLixSe bulks with nanopores. J. Mater. Chem. A 2018, 6, 23417. [Google Scholar] [CrossRef]

- Nunna, R.; Qiu, P.; Yin, M.; Chen, H.; Hanus, R.; Song, Q.; Zhang, T.; Chou, M.-Y.; Agne, M.T.; He, J.; et al. Ultrahigh thermoelectric performance in Cu2Se-based hybrid materials with highly dispersed molecular CNTs. Energ. Environ. Sci. 2017, 10, 1928–1935. [Google Scholar] [CrossRef]

- Wang, J.; Liu, B.; Miao, N.; Zhou, J.; Sun, Z. I-doped Cu2Se nanocrystals for high-performance thermoelectric applications. J. Alloy. Compd. 2019, 772, 366–370. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, K.; Wei, T.; Qiu, P.; Chen, L.; Shi, X. Cu2Se-based Liquid-like Thermoelectric Materials: Looking Back and Stepping Forward. Energy Environ. Sci. 2020, 13, 3307–3329. [Google Scholar] [CrossRef]

- Geng, Z.; Shi, D.; Shi, L.; Li, Y.; Snyder, G.; Lam, K. Conventional Sintered Cu2−xSe Thermoelectric Material. J. Mater. 2019, 5, 626–633. [Google Scholar]

- Shi, D.; Geng, Z.; Shi, L.; Li, Y.; Lam, K. Thermal stability study of Cu1.97Se superionic thermoelectric material. J. Mater. Chem. C 2020, 8, 10221. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.G.; Han, G.; Hong, M.; Zou, J. Impacts of Cu deficiency on the thermoelectric properties of Cu2−xSe nanoplates. Acta Materialia 2016, 113, 140–146. [Google Scholar] [CrossRef]

- Zhao, X.; Ning, S.; Qi, N.; Li, Y.; Dong, Y.; Zhang, H.; Liu, J.; Ye, B.; Chen, Z. Synergetic optimization of electrical and thermal transport properties by Cu vacancies and nanopores in Cu2Se. ACS Appl. Energ. Mater. 2021, 13, 58936–58948. [Google Scholar] [CrossRef]

- Liu, W.; Shi, X.; Hong, M.; Yang, L.; Moshwan, R.; Chen, Z.G.; Zou, J. Ag doping induced abnormal lattice thermal conductivity in Cu2Se. J. Mater. Chem. C 2018, 6, 13225–13231. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bo, L.; Li, F.; Hou, Y.; Zuo, M.; Zhao, D. Enhanced Thermoelectric Performance of Cu2Se via Nanostructure and Compositional Gradient. Nanomaterials 2022, 12, 640. https://doi.org/10.3390/nano12040640

Bo L, Li F, Hou Y, Zuo M, Zhao D. Enhanced Thermoelectric Performance of Cu2Se via Nanostructure and Compositional Gradient. Nanomaterials. 2022; 12(4):640. https://doi.org/10.3390/nano12040640

Chicago/Turabian StyleBo, Lin, Fujin Li, Yangbo Hou, Min Zuo, and Degang Zhao. 2022. "Enhanced Thermoelectric Performance of Cu2Se via Nanostructure and Compositional Gradient" Nanomaterials 12, no. 4: 640. https://doi.org/10.3390/nano12040640

APA StyleBo, L., Li, F., Hou, Y., Zuo, M., & Zhao, D. (2022). Enhanced Thermoelectric Performance of Cu2Se via Nanostructure and Compositional Gradient. Nanomaterials, 12(4), 640. https://doi.org/10.3390/nano12040640