The Effect of Cellulose Nanofibres on Dewatering during Wet-Forming and the Mechanical Properties of Thermoformed Specimens Made of Thermomechanical and Kraft Pulps

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pulp Fibre Characterization

2.3. Sheets

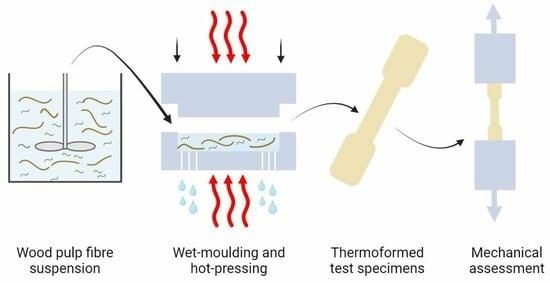

2.4. Thermoformed Test Specimens

2.5. Mechanical Testing of Sheets and Dogbone Specimens

3. Results and Discussion

3.1. Fibre Characteristics

3.2. Thermopressed Sheet Samples

3.3. Assessment of Moulded Dogbone Test Specimens

3.4. Demonstrators

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brodin, M.; Vallejos, M.; Opedal, M.T.; Area, M.C.; Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Clean. Prod. 2017, 162, 646–664. [Google Scholar] [CrossRef]

- López-Ibáñez, S.; Beiras, R. Is a compostable plastic biodegradable in the sea? A rapid standard protocol to test mineralization in marine conditions. Sci. Total Environ. 2022, 831, 154860. [Google Scholar] [CrossRef] [PubMed]

- Sixta, H. Introduction. In Handbook of Pulp; Wiley: Hoboken, NJ, USA, 2006; pp. 2–19. [Google Scholar]

- Ghose, A.; Chinga-Carrasco, G. Environmental aspects of Norwegian production of pulp fibres and printing paper. J. Clean. Prod. 2013, 57, 293–301. [Google Scholar] [CrossRef]

- Hart, P.W. Production of high yield bleached hardwood kraft pulp: Breaking the kraft pulp yield barrier. TAPPI J. 2011, 10, 37–41. [Google Scholar] [CrossRef]

- Syverud, K.; Stenius, P. Strength and barrier properties of MFC films. Cellulose 2009, 16, 75–85. [Google Scholar] [CrossRef]

- Nakagaito, A.N.; Fujimura, A.; Sakai, T.; Hama, Y.; Yano, H. Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process. Compos. Sci. Technol. 2009, 69, 1293–1297. [Google Scholar] [CrossRef]

- Eriksen, Ø.; Syverud, K.; Gregersen, Ø. The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord. Pulp Pap. Res. J. 2008, 23, 299–304. [Google Scholar] [CrossRef]

- Taipale, T.; Österberg, M.; Nykänen, A.; Ruokolainen, J.; Laine, J. Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 2010, 17, 1005–1020. [Google Scholar] [CrossRef]

- Sjöstrand, B.; Deshpande, R.; Thyrel, M.; Henriksson, G. Dewatering properties of pulps made from different parts of a Norway spruce (Picea abies). Nord. Pulp Pap. Res. J. 2022, 37, 702–711. [Google Scholar] [CrossRef]

- Winter, A.; Gindl-Altmutter, W.; Mandlez, D.; Bauer, W.; Eckhart, R.; Leitner, J.; Veigel, S. Reinforcement effect of pulp fines and microfibrillated cellulose in highly densified binderless paperboards. J. Clean. Prod. 2021, 281, 125258. [Google Scholar] [CrossRef]

- Hii, C.; Gregersen, Ø.W.; Chinga-Carrasco, G.; Eriksen, Ø. The effect of MFC on the pressability and paper properties of TMP and GCC based sheets. Nord. Pulp Pap. Res. J. 2012, 27, 388–396. [Google Scholar] [CrossRef]

- Keyes, F.E. Method of Molding Pulp Articles. US424003A, 25 March 1890. [Google Scholar]

- Keyes, M.L. Apparatus for Making Pulp Articles. US740023A, 29 September 1903. [Google Scholar]

- Reme, P.A.; Johnsen, P.O.; Helle, T. Assessment of fibretransverse dimensions using SEM and image analysis. J. Pulp Pap. Sci. 2002, 28, 122–128. [Google Scholar]

- ISO 5269-1; Pulps—Preparing of Laboratory Sheets for Physical Testing—Part 1: Conventional Sheet-Former Method. International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 187; Paper, Board and Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. International Organization for Standardization: Geneva, Switzerland, 1990.

- ISO 534; Paper and Board—Determination of Thickness, Density and Specific Volume. International Organization for Standardization: Geneva, Switzerland, 2011.

- Reme, P.A.; Helle, T. Fibre characteristics of some mechanical pulp grades. Nord. Pulp Pap. Res. J. 1998, 13, 263–268. [Google Scholar] [CrossRef]

- Kure, K.-A.; Dahlqvist, G.; Helle, T. Morphological characteristics of TMP fibres as affected by the rotational speed of the refiner. Nord. Pulp Pap. Res. J. 1999, 14, 105–110. [Google Scholar] [CrossRef]

- Esteves, C.V.; Sevastyanova, O.; Östlund, S.; Brännvall, E. Differences and similarities between kraft and oxygen delignification of softwood fibers: Effects on mechanical properties. Cellulose 2021, 28, 3775–3788. [Google Scholar] [CrossRef]

- Sirviö, J.; Nurminen, I. Systematic changes in paper properties caused by fines. Pulp Pap. Can. Ont. 2004, 105, 39–42. [Google Scholar]

- Negro, C.; Pettersson, G.; Mattsson, A.; Nyström, S.; Sanchez-Salvador, J.L.; Blanco, A.; Engstrand, P. Synergies between Fibrillated Nanocellulose and Hot-Pressing of Papers Obtained from High-Yield Pulp. Nanomaterials 2023, 13, 1931. [Google Scholar] [CrossRef] [PubMed]

- Ruwoldt, J.; Tanase Opedal, M. Green materials from added-lignin thermoformed pulps. Ind. Crops Prod. 2022, 185, 115102. [Google Scholar] [CrossRef]

- Zeng, X.; Vishtal, A.; Retulainen, E.; Sivonen, E.; Fu, S. The elongation potential of paper—How should fibres be deformed to make paper extensible? BioResources 2013, 8, 472–486. [Google Scholar] [CrossRef]

- Designerdata. Thermo Plastics. Available online: https://designerdata.nl/materials/plastics/thermo-plastics (accessed on 1 August 2023).

- NatureWorks. Ingeo Biopolymer 4043D Technical Data Sheet. Available online: https://www.natureworksllc.com/ (accessed on 1 August 2023).

- Nanri, Y.; Uesaka, T. Dimensional stability of mechanical pulps—Drying shrinkage and hygroexpansivity. Tappi J. 1993, 76, 62–66. [Google Scholar]

- Klayya, S.; Tawichai, N.; Intatha, U.; Zhang, H.; Bilotti, E.; Soykeabkaew, N. Sustainable nanocomposite coating for moulded pulp with enhanced barrier properties for food packaging applications. Polym. Int. 2023, 72, 323–332. [Google Scholar] [CrossRef]

- Lang, C.V.; Jung, J.; Wang, T.; Zhao, Y. Investigation of mechanisms and approaches for improving hydrophobicity of molded pulp biocomposites produced from apple pomace. Food Bioprod. Process. 2022, 133, 1–15. [Google Scholar] [CrossRef]

- Chi, K.; He, J.; Lin, W.-S.; Bokhari, S.M.Q.; Catchmark, J.M. Electrostatically Complexed Natural Polysaccharides as Aqueous Barrier Coatings for Sustainable and Recyclable Fiber-Based Packaging. ACS Appl. Mater. Interfaces 2023, 15, 12248–12260. [Google Scholar] [CrossRef] [PubMed]

- Hussain, K.A.; Romanova, S.; Okur, I.; Zhang, D.; Kuebler, J.; Huang, X.; Wang, B.; Fernandez-Ballester, L.; Lu, Y.; Schubert, M.; et al. Assessing the Release of Microplastics and Nanoplastics from Plastic Containers and Reusable Food Pouches: Implications for Human Health. Environ. Sci. Technol. 2023, 57, 9782–9792. [Google Scholar] [CrossRef] [PubMed]

- General Information Brief Concerning the Regulation of Materials and Articles Intended to Come into Contact with Food. Regulation (EC) No. 1935/2004. 2004.

- Bradley, E.L.; Stratton, J.S.; Leak, J.; Lister, L.; Castle, L. Printing ink compounds in foods: UK survey results. Food Addit. Contam. Part B Surveill. 2013, 6, 73–83. [Google Scholar] [CrossRef] [PubMed]

- Wrona, M.; Román, A.; Song, X.-C.; Nerín, C.; Dreolin, N.; Goshawk, J.; Asensio, E. Ultra-high performance liquid chromatography coupled to ion mobility quadrupole time-of-flight mass spectrometry for the identification of non-volatile compounds migrating from ‘natural’ dishes. J. Chromatogr. A 2023, 1691, 463836. [Google Scholar] [CrossRef]

| Length (mm) | Width (mm) | Fibril Area (%) | Fibril Perimeter (%) | Fines (%) | |

|---|---|---|---|---|---|

| TMP | 1.46 ± 0.02 | 32.8 ± 0.0 | 10.4 ± 0.6 | 33.3 ± 1.3 | 42.5 ± 0.0 |

| Kraft | 2.08 ± 0.02 | 29.0 ± 0.1 | 2.1 ± 0.2 | 7.2 ± 0.3 | 25 ± 1 |

| CNF | 0.70 ± 0.02 | 25.7 ± 0.5 | 23.0 ± 0.0 | 56.8 ± 0.5 | 61.3 ± 0 |

| Pulp Fibres | Young’s Modulus (GPa) | Tensile Strength (MPa) | Elongation (%) | Density (g/cm3) |

|---|---|---|---|---|

| TMP | 1.2 ± 0.04 | 49.3 ± 2.5 | 5.6 ± 0.3 | 0.76 |

| Kraft | 0.6 ± 0.06 | 49.2 ± 4.8 | 8.6 ± 0.9 | 0.74 |

| Plastic materials | ||||

| PET | 2.95 | 55 | 100 | 1.38 |

| HDPE | 1.0 | 26 | 590 | 0.94–0.97 |

| LDPE | 0.3 | 10 | 625 | 0.91–0.94 |

| PP | 1.3 | 34 | 450 | 0.90–0.92 |

| PLA | 3.6 | 60 | 6 | 1.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jacobsen, E.U.; Følkner, S.P.; Blindheim, J.; Molteberg, D.; Steinert, M.; Chinga-Carrasco, G. The Effect of Cellulose Nanofibres on Dewatering during Wet-Forming and the Mechanical Properties of Thermoformed Specimens Made of Thermomechanical and Kraft Pulps. Nanomaterials 2023, 13, 2511. https://doi.org/10.3390/nano13182511

Jacobsen EU, Følkner SP, Blindheim J, Molteberg D, Steinert M, Chinga-Carrasco G. The Effect of Cellulose Nanofibres on Dewatering during Wet-Forming and the Mechanical Properties of Thermoformed Specimens Made of Thermomechanical and Kraft Pulps. Nanomaterials. 2023; 13(18):2511. https://doi.org/10.3390/nano13182511

Chicago/Turabian StyleJacobsen, Eirik Ulsaker, Simen Prang Følkner, Jørgen Blindheim, Dag Molteberg, Martin Steinert, and Gary Chinga-Carrasco. 2023. "The Effect of Cellulose Nanofibres on Dewatering during Wet-Forming and the Mechanical Properties of Thermoformed Specimens Made of Thermomechanical and Kraft Pulps" Nanomaterials 13, no. 18: 2511. https://doi.org/10.3390/nano13182511

APA StyleJacobsen, E. U., Følkner, S. P., Blindheim, J., Molteberg, D., Steinert, M., & Chinga-Carrasco, G. (2023). The Effect of Cellulose Nanofibres on Dewatering during Wet-Forming and the Mechanical Properties of Thermoformed Specimens Made of Thermomechanical and Kraft Pulps. Nanomaterials, 13(18), 2511. https://doi.org/10.3390/nano13182511