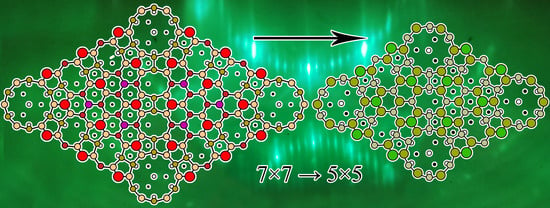

Peculiarities of the 7 × 7 to 5 × 5 Superstructure Transition during Epitaxial Growth of Germanium on Silicon (111) Surface

Abstract

:1. Background

2. Experimental Details

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lawrie, W.I.L.; Eenink, H.G.J.; Hendrickx, N.W.; Boter, J.M.; Petit, L.; Amitonov, S.V.; Lodari, M.; Paquelet Wuetz, B.; Volk, C.; Philips, S.G.J.; et al. Veldhorst Quantum dot arrays in silicon and germanium. Appl. Phys. Lett. 2020, 116, 080501. [Google Scholar] [CrossRef] [Green Version]

- Izhnin, I.I.; Fitsych, O.I.; Voitsekhovskii, A.V.; Kokhanenko, A.P.; Lozovoy, K.A.; Dirko, V.V. Nanostructures with Ge–Si quantum dots for infrared photodetectors. Opto-Electron. Rev. 2018, 26, 195–200. [Google Scholar] [CrossRef]

- Wu, J.; Chen, S.; Seeds, A.; Liu, H. Quantum dot optoelectronic devices: Lasers, photodetectors and solar cells. J. Phys. D: Appl. Phys. 2015, 48, 363001. [Google Scholar] [CrossRef]

- Hendrickx, N.W.; Franke, D.P.; Sammak, A.; Kouwenhoven, M.; Sabbagh, D.; Yeoh, L.; Li, R.; Tagliaferri, M.L.V.; Virgilio, M.; Capellini, G.; et al. Gate-controlled quantum dots and superconductivity in planar germanium. Nat. Commun. 2018, 9, 2835. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Izhnin, I.I.; Kurbanov, K.R.; Lozovoy, K.A.; Kokhanenko, A.P.; Dirko, V.V.; Voitsekhovskii, A.V. Epitaxial fabrication of 2D materials of group IV elements. Appl. Nanosci. 2020, 10, 4375–4383. [Google Scholar] [CrossRef]

- Schröter, M.; Rosenbaum, T.; Chevalier, P.; Heinemann, B.; Voinigescu, S.P.; Preisler, E.; Böck, J.; Mukherjee, A. SiGe HBT technology: Future trends and TCAD-based. Proc. IEEE. 2017, 105, 1068–1086. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Izhnin, I.I.; Kokhanenko, A.P.; Dirko, V.V.; Vinarskiy, V.P.; Voitsekhovskii, A.V.; Fitsych, O.I.; Akimenko, N.Y. Single-element 2D materials beyond graphene: Methods of epitaxial synthesis. Nanomaterials 2022, 12, 2221. [Google Scholar] [CrossRef] [PubMed]

- Bukharaev, A.A.; Zvezdin, A.K.; Pyatakov, A.P.; Fetisov, Y.K. Straintronics: A new trend in micro- and nanoelectronics and materials science. Physics 2018, 61, 1175–1212. [Google Scholar] [CrossRef]

- Assali, S.; Albani, M.; Bergamaschini, R.; Verheijen, M.A.; Li, A.; Kölling, S.; Gagliano, L.; Bakkers, E.P.; Miglio, L. Strain engineering in Ge/GeSn core/shell nanowires. Appl. Phys. Lett. 2019, 115, 113102. [Google Scholar] [CrossRef] [Green Version]

- Timofeev, V.A.; Nikiforov, A.I.; Tuktamyshev, A.R.; Mashanov, V.I.; Loshkarev, I.D.; Bloshkin, A.A.; Gutakovskii, A.K. Pseudomorphic GeSiSn, SiSn and Ge layers in strained heterostructures. Semicond. Sci. Technol. 2018, 29, 154002. [Google Scholar] [CrossRef]

- Voigtlander, B. Fundamental processes in Si/Si and Ge/Si epitaxy studied by scanning tunneling microscopy during growth. Surf. Sci. Rep. 2001, 43, 127–254. [Google Scholar] [CrossRef]

- Aqua, J.N.; Berbezier, I.; Favre, L.; Frisch, T.; Ronda, A. Growth and self-organization of SiGe nanostructures. Phys. Rep. 2013, 522, 59–189. [Google Scholar] [CrossRef]

- Ichimiya, A.; Cohen, P.I.; Cohen, P.I. Reflection High-Energy Electron Diffraction; Cambridge University Press: Cambridge, UK, 2004; 349p. [Google Scholar]

- Berrie, C.L.; Leone, S.R. Observation of monolayer and bilayer period RHEED oscillations during epitaxial growth of Ge on Ge (1 0 0). J. Cryst. Growth 2000, 216, 159–170. [Google Scholar] [CrossRef]

- Fukutani, K.; Daimon, H.D.H.; Ino, S.I.S. Reflection high-energy electron diffraction study of the growth of Ge on the Ge(111). Jpn. J. Appl. Phys. 1992, 31, 3429–3435. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Korotaev, A.G.; Kokhanenko, A.P.; Dirko, V.V.; Voitsekhovskii, A.V. Kinetics of epitaxial formation of nanostructures by Frank–van der Merwe, Volmer–Weber and Stranski–Krastanow growth modes. Surf. Coat. Technol. 2020, 384, 125289. [Google Scholar] [CrossRef]

- Nikiforov, A.I.; Timofeev, V.A.; Teys, S.A.; Gutakovsky, A.K.; Pchelyakov, O.P. Initial stage growth of GexSi1-x layers and Ge quantum dot formation on GexSi1-x surface by MBE. Nanoscale Res. Lett. 2012, 7, 561. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Storozhevykh, M.S.; Arapkina, L.V.; Yuryev, V.A. Evidence for kinetic limitations as a controlling factor of Ge pyramid formation: A study of structural features of Ge/Si(001) wetting layer formed by Ge deposition at room temperature followed by annealing at 600 °C. Nanoscale Res. Lett. 2015, 10, 295. [Google Scholar] [CrossRef] [Green Version]

- Talochkin, A.B.; Shklyaev, A.A.; Mashanov, V.I. Super-dense array of Ge quantum dots grown on Si(100) by low-temperature molecular beam epitaxy. J. Appl. Phys. 2014, 115, 144306. [Google Scholar] [CrossRef]

- Zhang, J.J.; Rastelli, A.; Schmidt, O.G.; Scopece, D.; Miglio, L.; Montalenti, F. Montalenti Self-organized evolution of Ge/Si(001) into intersecting bundles of horizontal nanowires during annealing. Appl. Phys. Lett. 2013, 103, 083109. [Google Scholar]

- Teys, S.A.; Talochkin, A.B.; Olshanetsky, B.Z. Formation of Ge nanoislands before the completion of a wetting layer in the Ge/Si(111) system. J. Cryst. Growth 2009, 311, 3898–3903. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Kokhanenko, A.P.; Dirko, V.V.; Akimenko, N.Y.; Voitsekhovskii, A.V. Evolution of epitaxial quantum dots formed by Volmer−Weber growth mechanism. Cryst. Growth Des. 2019, 19, 7015–7021. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Zhou, Y.; Smith, R.; Lloyd, A.; Kokhanenko, A.P.; Dirko, V.V.; Akimenko, N.Y.; Grigoryev, D.V.; Voitsekhovskii, A.V. Thickness-dependent surface energy and formation of epitaxial quantum dots. Thin Solid Film. 2020, 713, 138363. [Google Scholar] [CrossRef]

- Dirko, V.V.; Lozovoy, K.A.; Kokhanenko, A.P.; Voitsekhovskii, A.V. Thickness-dependent elastic strain in Stranski–Krastanow growth. Phys. Chem. Chem. Phys. 2020, 22, 19318–19325. [Google Scholar] [CrossRef]

- Dirko, V.V.; Lozovoy, K.A.; Kokhanenko, A.P.; Voitsekhovskii, A.V. High-resolution RHEED analysis of dynamics of low-temperature superstructure transitions in Ge/Si(001) epitaxial system. Nanotechnology 2022, 33, 115603. [Google Scholar] [CrossRef] [PubMed]

- Takayanagi, K.; Tanishiro, Y.; Takahashi, S.; Takahashi, M. Structure analysis of Si(111)-7 × 7 reconstructed surface by transmission electron diffraction. Surf. Sci. 1985, 164, 367–392. [Google Scholar] [CrossRef]

- Shklyaev, A.A.; Shibata, M.; Ichikawa, M. Ge islands on Si(111) at coverages near the transition from two-dimensional to three-dimensional growth. Surf. Sci. 1998, 416, 192–199. [Google Scholar] [CrossRef]

- Grimm, A.; Fissel, A.; Bugiel, E.; Wietler, T.F. In situ observation of low temperature growth of Ge on Si(111) by reflection high energy electron diffraction. Appl. Surf. Sci. 2016, 370, 40–48. [Google Scholar] [CrossRef]

- Filimonov, S.; Cherepanov, V.; Hervieu, Y.; Voigtlander, B. Multistage nucleation of two-dimensional Si islands on Si(111)-7 × 7 during MBE growth: STM experiments and extended rate-equation model. Phys. Rev. B 2007, 76, 035428. [Google Scholar] [CrossRef] [Green Version]

- Paul, N.; Filimonov, S.; Cherepanov, V.; Cakmak, M.; Voightlander, B. Identification of Ge/Si intermixing processes at the Bi/Ge/Si(111) surface. Phys. Rev. Lett. 2007, 98, 166104. [Google Scholar] [CrossRef] [Green Version]

- Teys, S.A. Different growth mechanisms of Ge by Stranski–Krastanow on Si (111) and (001) surfaces: An STM study. Appl. Surf. Sci. 2017, 392, 1017–1025. [Google Scholar] [CrossRef]

- Lozovoy, K.; Kokhanenko, A.; Voitsekhovskii, A. Comparative analysis of germanium-silicon quantum dots formation on Si(100), Si(111) and Sn/Si(100) surfaces. Nanotechnology 2018, 29, 054002. [Google Scholar] [CrossRef] [PubMed]

- MacLeod, J.M.; Psiachos, D.; Stott, M.J.; McLean, A.B. Indium clusters on the Ge (5 × 5) wetting layer of Si(111)–7 × 7. Phys. Rev. J. B 2006, 73, 241306. [Google Scholar] [CrossRef]

- Yoshida, R.; Tosaka, A.; Shigeta, Y. Surface morphology and structure of Ge layer on Si(111) after solid phase epitaxy. Surf. Sci. 2018, 671, 43–50. [Google Scholar] [CrossRef]

- Rogilo, D.I.; Fedina, L.I.; Kosolobov, S.S.; Latyshev, A.V. On the role of mobile nanoclusters in 2D island nucleation on Si(111)-(7 × 7) surface. Surf. Sci. 2018, 667, 1–7. [Google Scholar] [CrossRef]

- Zhachuk, R.; Teys, S.; Coutinho, J. Strain-induced structure transformations on Si(111) and Ge(111) surfaces: A combined density-functional and scanning tunneling microscopy study. J. Chem. Phys. 2013, 138, 224702. [Google Scholar] [CrossRef] [Green Version]

- Maeda, T.; Jevasuwan, W.; Hattori, H.; Uchida, N.; Miura, S.; Tanaka, M.; Santos, N.D.M.; Vantomme, A.; Locquet, J.-P.; Lieten, R.R. Ultrathin GeSn p-channel MOSFETs grown directly on Si(111) substrate using solid phase epitaxy. Jpn. J. Appl. Phys. 2015, 54, 04DA07. [Google Scholar] [CrossRef]

- Han, G.; Wang, Y.; Liu, Y.; Zhang, C.; Feng, Q.; Liu, M.; Zhao, S.; Cheng, B.; Zhang, J.; Hao, Y. GeSn quantum well p-channel tunneling FETs Fabricated on Si(001) and (111) With Improved Subthreshold Swing. IEEE Electron Device Lett. 2016, 37, 701–704. [Google Scholar] [CrossRef]

- Pokharia, R.S.; Khiangte, K.R.; Rathore, J.S.; Schmidt, J.; Osten, H.J.; Laha, A.; Mahapatra, S. Metal semiconductor metal photodiodes based on all-epitaxial Ge-on-insulator-on- Si(111), grown by molecular beam epitaxy. In SPIE Proceedings: Optical Components and Materials XVI; SPIE: Bellingham, WA, USA, 2019; Volume 10914, p. 1091417. [Google Scholar]

- Shklyaev, A.; Bolotov, L.; Poborchii, V.; Tada, T. Properties of three-dimensional structures prepared by Ge dewetting from Si(111) at high temperatures. J. Appl. Phys. 2015, 117, 205303. [Google Scholar] [CrossRef]

- Alam, M.M.; Hoshi, Y.; Sawano, K. Structural properties of compressive strained Ge channels fabricated on Si (111) and Si (100). Semicond. Sci. Technol. 2018, 33, 124008. [Google Scholar] [CrossRef]

- Benediktovich, A.; Zhylik, A.; Ulyanenkova, T.; Myronov, M.; Ulyanenkov, A. Characterization of dislocations in germanium layers grown on (011)- and (111)-oriented silicon by coplanar and noncoplanar X-ray diffraction. J. Appl. Crystallogr. 2015, 48, 655–665. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; Li, Y.; Chen, Y. Si/Ge (111) Semicoherent Interfaces: Responses to an In-Plane Shear and Interactions with Lattice Dislocations. Phys. Status Solidi B 2020, 257, 2000274. [Google Scholar] [CrossRef]

- Miao, Y.-H.; Hu, H.-Y.; Song, J.-J.; Xuan, R.-X.; Zhang, H.-M. Effects of rapid thermal annealing on crystallinity and Sn surface segregation of Ge1-𝑥Sn𝑥 films on Si (100) and Si (111). Chin. Phys. B 2017, 26, 127306. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Sun, H.; You, J.; Miao, Y.; Dong, Z.; Liu, T.; Jiang, Z.; Hu, H. Nanoscale growth of a Sn-guided SiGeSn alloy on Si (111) substrates by molecular beam epitaxy. Nanoscale Adv. 2021, 3, 997. [Google Scholar] [CrossRef] [PubMed]

- Mamiyev, Z.; Pfnur, H. View on Si(111)-(5 × 2)-Au with plasmon spectroscopy. Phys. Rev. B 2020, 102, 075438. [Google Scholar] [CrossRef]

- Olyanich, D.A.; Utas, T.V.; Bondarenko, L.V.; Tupchaya, A.Y.; Gruznev, D.V.; Mihalyuk, A.N.; Zotov, A.V.; Saranin, A.A. Structural and electronic effects of adsorbed Bi on the metallic atomic chains in Au/Si(111)5 × 2. Appl. Surf. Sci. 2021, 558, 149859. [Google Scholar] [CrossRef]

- Tao, M.-L.; Tu, Y.-B.; Sun, K.; Wang, Y.-L.; Xie, Z.-B.; Liu, L.; Shi, M.-X.; Wang, J.-Z. Gallenene epitaxially grown on Si(1 1 1). 2D Mater. 2018, 5, 035009. [Google Scholar] [CrossRef]

- Charles, M.; Kanyandekwe, J.; Bos, S.; Baines, Y.; Morvan, E.; Torres, A.; Templier, F.; Plissonnier, M. Epitaxy of GaN on Si (111) for Power Electronics, RF and LEDs. ECS Trans. 2018, 86, 233–247. [Google Scholar] [CrossRef]

- Bansal, A.; Martin, N.C.; Wang, K.; Redwing, J.M. GaN Heteroepitaxy on Strain-Engineered (111) Si/Si1-xGex. J. Electron. Mater. 2019, 48, 3355–3362. [Google Scholar] [CrossRef]

- Monzur-Ul-Akhir, A.A.M.; Mori, M.; Maezawa, K. An investigation of the crystalline nature for GaSb films on Si(111) at varied growth temperature and growth rate. Jpn. J. Appl. Phys. 2019, 58, SII17. [Google Scholar] [CrossRef]

- Zhu, F.; Chen, W.; Xu, Y.; Gao, C.-L.; Guan, D.-D.; Liu, C.-H.; Qian, D.; Zhang, S.-C.; Jia, J.-F. Epitaxial growth of two-dimensional stanene. Nat. Mater. 2015, 14, 1020–1025. [Google Scholar] [CrossRef]

- Qin, J.; Qiu, G.; Jian, J.; Zhou, H.; Yang, L.; Charnas, A.; Zemlyanov, D.Y.; Xu, C.-Y.; Xu, X.; Wu, W.; et al. Controlled Growth of a Large-Size 2D Selenium Nanosheet and Its Electronic and Optoelectronic Applications. ACS Nano 2017, 11, 10222–10229. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, T.; Takayama, A.; Hobara, R.; Gruznev, D.V.; Zotov, A.V.; Saranin, A.A.; Hasegawa, S. Superconducting single-atomic-layer Tl-Pb compounds on Ge(111) and Si (111) surfaces. Appl. Surf. Sci. 2019, 479, 679–684. [Google Scholar] [CrossRef]

- Gruznev, D.V.; Bondarenko, L.V.; Tupchaya, A.Y.; Mihalyuk, A.N.; Eremeev, S.V.; Zotov, A.V.; Saranin, A.A. Thallene: Graphene-like honeycomb lattice of Tl atoms frozen on single-layer NiSi2. 2D Mater. 2020, 7, 045026. [Google Scholar] [CrossRef]

- Mihalyuk, A.N.; Vekovshinin, Y.E.; Bondarenko, L.V.; Tupchaya, A.Y.; Utas, T.V.; Gruznev, D.V.; Eremeev, S.V.; Zotov, A.V.; Saranin, A.A. Insights Into the Electronic Properties of PbBi Atomic Layers on Ge(111) and Si(111) Surfaces. Front. Mater. 2022, 9, 882008. [Google Scholar] [CrossRef]

- Lozovoy, K.A.; Dirko, V.V.; Vinarskiy, V.P.; Kokhanenko, A.P.; Voitsekhovskii, A.V.; Akimenko, N.Y. Two-dimensional materials of group IVA: Latest advances in epitaxial methods of growth. Russ. Phys. J. 2022, 64, 1583–1591. [Google Scholar] [CrossRef]

- Ponomarenko, V.P.; Popov, V.S.; Popov, S.V.; Chepurnov, E.L. Photo- and Nanoelectronics Based on Two-Dimensional Materials. Part I. Two-Dimensional Materials: Properties and Synthesis. J. Commun. Technol. Electron. 2020, 65, 1062–1104. [Google Scholar] [CrossRef]

- Isa, F.; Pezzoli, F.; Isella, G.; Meduna, M.; Falub, C.V.; Muller, E.; Kreiliger, T.; Taboada, A.G.; von Kanel, H.; Miglio, L. Three-dimensional Ge/SiGe multiple quantum wells deposited on Si(001) and Si (111) patterned substrates. Semicond. Sci. Technol. 2015, 30, 105001. [Google Scholar] [CrossRef]

- Genath, H.; Norberg, J.; Wolpensinger, B.; Osten, H.J. Investigation of the temperature stability of germanium-rich SiGe layers on Si(111) substrates. Thin Solid Film. 2022, 763, 139561. [Google Scholar] [CrossRef]

- Ichikawa, T.; Ino, S. Rheed study on the Ge/Si(111) and Si/Ge(111) systems: Reaction of Ge with the Si(111)(7 × 7) surface. Surf. Sci. 1984, 136, 267–284. [Google Scholar] [CrossRef]

- Ishii, C.; Shigeta, Y. Structural changes due to reannealing of Ge thin films prepared by solid phase epitaxial growth on Si (111) surface. Thin Solid Film. 2020, 709, 138007. [Google Scholar] [CrossRef]

- Vinarskiy, V.P.; Kokhanenko, A.P.; Lozovoy, K.A. Modelling of epitaxial growth of two-dimensional film. J. Phys. Conf. Ser. 2021, 2140, 012001. [Google Scholar] [CrossRef]

- Zhou, Y.; Lloyd, A.; Smith, R.; Lozovoy, K.A.; Voitsekhovskii, A.V.; Kokhanenko, A.P. Molecular dynamics simulations of the growth of Ge on Si. Surf. Sci. 2020, 696, 121594. [Google Scholar] [CrossRef]

- Kashammer, P.; Borgardt, N.I.; Seibt, M.; Sinno, T. Quantitative assessment of molecular dynamics-grown amorphous silicon and germanium films on silicon (111). Surf. Sci. 2016, 651, 100–104. [Google Scholar] [CrossRef]

- Izhnin, I.I.; Lozovoy, K.A.; Kokhanenko, A.P.; Khomyakova, K.I.; Douhan, R.M.H.; Dirko, V.V.; Voitsekhovskii, A.V.; Fitsych, O.I.; Akimenko, N.Y. Single-photon avalanche diode detectors based on group IV materials. Appl. Nanosci. 2022, 12, 253–263. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dirko, V.V.; Lozovoy, K.A.; Kokhanenko, A.P.; Kukenov, O.I.; Korotaev, A.G.; Voitsekhovskii, A.V. Peculiarities of the 7 × 7 to 5 × 5 Superstructure Transition during Epitaxial Growth of Germanium on Silicon (111) Surface. Nanomaterials 2023, 13, 231. https://doi.org/10.3390/nano13020231

Dirko VV, Lozovoy KA, Kokhanenko AP, Kukenov OI, Korotaev AG, Voitsekhovskii AV. Peculiarities of the 7 × 7 to 5 × 5 Superstructure Transition during Epitaxial Growth of Germanium on Silicon (111) Surface. Nanomaterials. 2023; 13(2):231. https://doi.org/10.3390/nano13020231

Chicago/Turabian StyleDirko, Vladimir V., Kirill A. Lozovoy, Andrey P. Kokhanenko, Olzhas I. Kukenov, Alexander G. Korotaev, and Alexander V. Voitsekhovskii. 2023. "Peculiarities of the 7 × 7 to 5 × 5 Superstructure Transition during Epitaxial Growth of Germanium on Silicon (111) Surface" Nanomaterials 13, no. 2: 231. https://doi.org/10.3390/nano13020231

APA StyleDirko, V. V., Lozovoy, K. A., Kokhanenko, A. P., Kukenov, O. I., Korotaev, A. G., & Voitsekhovskii, A. V. (2023). Peculiarities of the 7 × 7 to 5 × 5 Superstructure Transition during Epitaxial Growth of Germanium on Silicon (111) Surface. Nanomaterials, 13(2), 231. https://doi.org/10.3390/nano13020231