The Influence of the Mechanical Compliance of a Substrate on the Morphology of Nanoporous Gold Thin Films

Abstract

:1. Introduction

2. Experimental

2.1. Chemicals/Materials

2.2. Sample Preparation

2.3. Post-Dealloying Characterization

2.4. Simulations

2.5. Statistical Analysis

3. Results

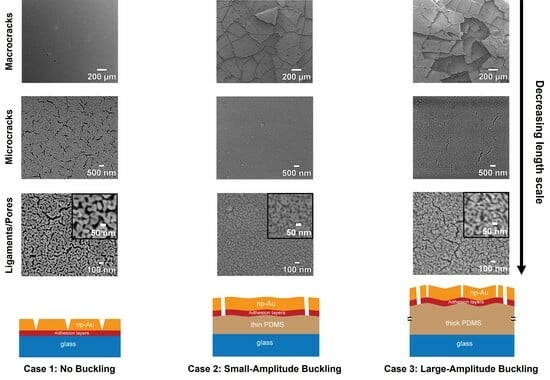

3.1. Macroscopic Cracks

3.2. Microscopic Cracks

3.3. Ligaments and Pores

3.4. Finite Element Simulations

4. Discussion

4.1. Main Effects

4.1.1. More Macroscopic Cracking in np-Au/PDMS Compared to np-Au/Glass

4.1.2. More Microscopic Cracks in np-Au/Glass Compared to np-Au/PDMS

4.1.3. Larger Ligament and Pore Sizes in np-Au/Glass Compared to np-Au/PDMS

4.2. Secondary Effects

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ding, Y.; Chen, M. Nanoporous Metals for Catalytic and Optical Applications. MRS Bull. 2009, 34, 569–576. [Google Scholar] [CrossRef]

- Juarez, T.; Biener, J.; Weissmüller, J.; Hodge, A.M. Nanoporous Metals with Structural Hierarchy: A Review. Adv. Eng. Mater. 2017, 19, 1700389. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.M. Nanoporous metals: Fabrication strategies and advanced electrochemical applications in catalysis, sensing and energy systems. Chem. Soc. Rev. 2012, 41, 7016. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Kisslinger, K.; Huang, X.; Bai, J.; Liu, X.; Lin, C.-H.; Yu, L.-C.; Lu, M.; Tong, X.; Zhong, H.; et al. Design nanoporous metal thin films via solid state interfacial dealloying. Nanoscale 2021, 13, 17725–17736. [Google Scholar] [CrossRef] [PubMed]

- Detsi, E.; van de Schootbrugge, M.; Punzhin, S.; Onck, P.R.; De Hosson, J.T.M. On tuning the morphology of nanoporous gold. Scr. Mater. 2011, 64, 319–322. [Google Scholar] [CrossRef]

- Qiu, H.-J.; Peng, L.; Li, X.; Xu, H.T.; Wang, Y. Using corrosion to fabricate various nanoporous metal structures. Corros. Sci. 2015, 92, 16–31. [Google Scholar] [CrossRef]

- McCue, I.; Benn, E.; Gaskey, B.; Erlebacher, J. Dealloying and Dealloyed Materials. Annu. Rev. Mater. Res. 2016, 46, 263–286. [Google Scholar] [CrossRef]

- Erlebacher, J.; Aziz, M.J.; Karma, A.; Dimitrov, N.; Sieradzki, K. Evolution of nanoporosity in dealloying. Nature 2001, 410, 450–453. [Google Scholar] [CrossRef] [PubMed]

- Chen-Wiegart, Y.K.; Wang, S.; McNulty, I.; Dunand, D.C. Effect of Ag–Au composition and acid concentration on dealloying front velocity and cracking during nanoporous gold formation. Acta Mater. 2013, 61, 5561–5570. [Google Scholar] [CrossRef]

- Weissmüller, J.; Newman, R.C.; Jin, H.-J.; Hodge, A.M.; Kysar, J.W. Nanoporous Metals by Alloy Corrosion: Formation and Mechanical Properties. MRS Bull. 2009, 34, 577–586. [Google Scholar] [CrossRef]

- Hu, K.; Ziehmer, M.; Wang, K.; Lilleodden, E.T. Nanoporous gold: 3D structural analyses of representative volumes and their implications on scaling relations of mechanical behaviour. Philos. Mag. 2016, 96, 3322–3335. [Google Scholar] [CrossRef]

- Rout, S.; Qi, Z.; Biener, M.M.; Courtwright, D.; Adrien, J.C.; Mills, E.; Shahabuddin, M.; Noginova, N.; Noginov, M.A. Nanoporous gold nanoleaf as tunable metamaterial. Sci. Rep. 2021, 11, 1795. [Google Scholar] [CrossRef] [PubMed]

- Hakamada, M.; Kato, N.; Mabuchi, M. Electrical resistivity of nanoporous gold modified with thiol self-assembled monolayers. Appl. Surf. Sci. 2016, 387, 1088–1092. [Google Scholar] [CrossRef]

- Fujita, T.; Okada, H.; Koyama, K.; Watanabe, K.; Maekawa, S.; Chen, M.W. Unusually small electrical resistance of three-dimensional nanoporous gold in external magnetic fields. Phys. Rev. Lett. 2008, 101, 166601. [Google Scholar] [CrossRef] [PubMed]

- Dorofeeva, T.S.; Seker, E. In situ electrical modulation and monitoring of nanoporous gold morphology. Nanoscale 2016, 8, 19551–19556. [Google Scholar] [CrossRef] [PubMed]

- Zandersons, B.; Lührs, L.; Li, Y.; Weissmüller, J. On factors defining the mechanical behavior of nanoporous gold. Acta Mater. 2021, 215, 116979. [Google Scholar] [CrossRef]

- Li, J.; Tian, C.; Hong, W.; Duan, S.; Zhang, Y.; Wu, W.; Hu, G.; Xia, R. Shock responses of nanoporous gold subjected to dynamic loadings: Energy absorption. Int. J. Mech. Sci. 2021, 192, 106191. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Tian, C.; Zhou, H.; Hu, G.; Xia, R. Structurally ordered nanoporous Pt–Co alloys with enhanced mechanical behaviors in tension. Microporous Mesoporous Mater. 2020, 295, 109955. [Google Scholar] [CrossRef]

- Matharu, Z.; Daggumati, P.; Wang, L.; Dorofeeva, T.S.; Li, Z.; Seker, E. Nanoporous-Gold-Based Electrode Morphology Libraries for Investigating Structure–Property Relationships in Nucleic Acid Based Electrochemical Biosensors. ACS Appl. Mater. Interfaces 2017, 9, 12959–12966. [Google Scholar] [CrossRef] [PubMed]

- Patel, J.; Radhakrishnan, L.; Zhao, B.; Uppalapati, B.; Daniels, R.C.; Ward, K.R.; Collinson, M.M. Electrochemical Properties of Nanostructured Porous Gold Electrodes in Biofouling Solutions. Anal. Chem. 2013, 85, 11610–11618. [Google Scholar] [CrossRef] [PubMed]

- Shulga, O.V.; Zhou, D.; Demchenko, A.V.; Stine, K.J. Detection of free prostate specific antigen (fPSA) on a nanoporous gold platform. Analyst 2008, 133, 319–322. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Si, P.; Magner, E. An overview of dealloyed nanoporous gold in bioelectrochemistry. Bioelectrochemistry 2016, 109, 117–126. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Markmann, J.; Weissmüller, J.; Mameka, N. Nanoporous gold-polypyrrole hybrid electrochemical actuators with tunable elasticity. Acta Mater. 2021, 212, 116852. [Google Scholar] [CrossRef]

- Xue, Y.; Markmann, J.; Duan, H.; Weissmüller, J.; Huber, P. Switchable imbibition in nanoporous gold. Nat. Commun. 2014, 5, 4237. [Google Scholar] [CrossRef]

- Detsi, E.; Onck, P.; De Hosson, J.T.M. Metallic muscles at work: High rate actuation in nanoporous gold/polyaniline composites. ACS Nano 2013, 7, 4299–4306. [Google Scholar] [CrossRef] [PubMed]

- Wittstock, A.; Wichmann, A.; Biener, J.; Bäumer, M. Nanoporous gold: A new gold catalyst with tunable properties. Faraday Discuss. 2011, 152, 87–98. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-I.; Kim, S.-W.; Jung, K.; Kim, J.-B.; Jang, J.-H. Ideal nanoporous gold based supercapacitors with theoretical capacitance and high energy/power density. Nano Energy 2016, 24, 17–24. [Google Scholar] [CrossRef]

- Chapman, C.A.R.; Wang, L.; Chen, H.; Garrison, J.; Lein, P.J.; Seker, E. Nanoporous Gold Biointerfaces: Modifying Nanostructure to Control Neural Cell Coverage and Enhance Electrophysiological Recording Performance. Adv. Funct. Mater. 2017, 27, 1604631. [Google Scholar] [CrossRef] [PubMed]

- Şeker, E.; Shih, W.-C.; Stine, K.J. Nanoporous metals by alloy corrosion: Bioanalytical and biomedical applications. MRS Bull. 2018, 43, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Daggumati, P.; Kurtulus, O.; Chapman, C.A.R.; Dimlioglu, D.; Seker, E. Microfabrication of Nanoporous Gold Patterns for Cell-material Interaction Studies. J. Vis. Exp. 2013, 77, e50678. [Google Scholar] [CrossRef] [PubMed]

- Engwall, A.M.; Rao, Z.; Chason, E. Origins of residual stress in thin films: Interaction between microstructure and growth kinetics. Mater. Des. 2016, 110, 616–623. [Google Scholar] [CrossRef]

- Thornton, J.A.; Hoffman, D.W. Stress-related effects in thin films. Thin Solid Films 1989, 171, 5–31. [Google Scholar] [CrossRef]

- Vlassak, J.J. Channel cracking in thin films on substrates of finite thickness. Int. J. Fract. 2003, 119, 299–323. [Google Scholar] [CrossRef]

- Beuth, J.L. Cracking of thin bonded films in residual tension. Int. J. Solids Struct. 1992, 29, 1657–1675. [Google Scholar] [CrossRef]

- Ye, T.; Suo, Z.; Evans, A.G. Thin film cracking and the roles of substrate and interface. Int. J. Solids Struct. 1992, 29, 2639–2648. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, J.Y.; Liu, G.; Zhang, P.; Cheng, P.M.; Li, J.; Zhang, G.J.; Sun, J. Buckling behaviors and adhesion energy of nanostructured Cu/X (X = Nb, Zr) multilayer films on a compliant substrate. Acta Mater. 2013, 61, 7889–7903. [Google Scholar] [CrossRef]

- Yu, S.; Ma, L.; He, L.; Ni, Y. Hierarchical crack patterns of metal films sputter deposited on soft elastic substrates. Phys. Rev. E 2019, 100, 052804. [Google Scholar] [CrossRef]

- Ibru, T.; Kalaitzidou, K.; Baldwin, J.K.; Antoniou, A. Stress-induced surface instabilities and defects in thin films sputter deposited on compliant substrates. Soft Matter 2017, 13, 4035–4046. [Google Scholar] [CrossRef] [PubMed]

- Seker, E.; Gaskins, J.T.; Bart-Smith, H.; Zhu, J.; Reed, M.L.; Zangari, G.; Kelly, R.; Begley, M.R. The effects of post-fabrication annealing on the mechanical properties of freestanding nanoporous gold structures. Acta Mater. 2007, 55, 4593–4602. [Google Scholar] [CrossRef]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics toward Wearable Sensing. Acc. Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Wagner, S.; Lacour, S.P.; Jones, J.; Hsu, P.I.; Sturm, J.C.; Li, T.; Suo, Z. Electronic skin: Architecture and components. Phys. E Low-Dimens. Syst. Nanostruct. 2004, 25, 326–334. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 978-0-12-385972-3. [Google Scholar]

- Seghir, R.; Arscott, S. Extended PDMS stiffness range for flexible systems. Sens. Actuators Phys. 2015, 230, 33–39. [Google Scholar] [CrossRef]

- Hérault, Q.; Gozhyk, I.; Balestrieri, M.; Montigaud, H.; Grachev, S.; Lazzari, R. Kinetics and mechanisms of stress relaxation in sputtered silver thin films. Acta Mater. 2021, 221, 117385. [Google Scholar] [CrossRef]

- Ross, R.B. Metallic Materials Specification Handbook; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 978-1-4615-3482-2. [Google Scholar]

- Karunaratne, M.S.A.; Kyaw, S.; Jones, A.; Morrell, R.; Thomson, R.C. Modelling the coefficient of thermal expansion in Ni-based superalloys and bond coatings. J. Mater. Sci. 2016, 51, 4213–4226. [Google Scholar] [CrossRef]

- Hosseinian, E.; Gupta, S.; Pierron, O.N.; Legros, M. Size effects on intergranular crack growth mechanisms in ultrathin nanocrystalline gold free-standing films. Acta Mater. 2018, 143, 77–87. [Google Scholar] [CrossRef]

- Douville, N.J.; Li, Z.; Takayama, S.; Thouless, M.D. Fracture of metal coated elastomers. Soft Matter 2011, 7, 6493. [Google Scholar] [CrossRef]

- Thouless, M.D.; Li, Z.; Douville, N.J.; Takayama, S. Periodic cracking of films supported on compliant substrates. J. Mech. Phys. Solids 2011, 59, 1927–1937. [Google Scholar] [CrossRef] [PubMed]

- Seker, E.; Reed, M.; Begley, M. A thermal treatment approach to reduce microscale void formation in blanket nanoporous gold films. Scr. Mater. 2009, 60, 435–438. [Google Scholar] [CrossRef]

- Parida, S.; Kramer, D.; Volkert, C.A.; Rösner, H.; Erlebacher, J.; Weissmüller, J. Volume Change during the Formation of Nanoporous Gold by Dealloying. Phys. Rev. Lett. 2006, 97, 035504. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Balk, T.J. Evolution of Structure, Composition, and Stress in Nanoporous Gold Thin Films with Grain-Boundary Cracks. Metall. Mater. Trans. A 2008, 39, 2656–2665. [Google Scholar] [CrossRef]

- Li, W.-C.; Balk, T.J. Effects of substrate curvature on dealloying of nanoporous thin films. Scr. Mater. 2009, 61, 1125–1128. [Google Scholar] [CrossRef]

- Raja, J.; Muralikrishnan, B.; Fu, S. Recent advances in separation of roughness, waviness and form. Precis. Eng. 2002, 26, 222–235. [Google Scholar] [CrossRef]

- Zeng, Q.; Qin, Y.; Chang, W.; Luo, X. Correlating and evaluating the functionality-related properties with surface texture parameters and specific characteristics of machined components. Int. J. Mech. Sci. 2018, 149, 62–72. [Google Scholar] [CrossRef]

- Biener, J.; Hodge, A.M.; Hayes, J.R.; Volkert, C.A.; Zepeda-Ruiz, L.A.; Hamza, A.V.; Abraham, F.F. Size Effects on the Mechanical Behavior of Nanoporous Au. Nano Lett. 2006, 6, 2379–2382. [Google Scholar] [CrossRef] [PubMed]

- Seker, E.; Gaskins, J.T.; Bart-Smith, H.; Zhu, J.; Reed, M.L.; Zangari, G.; Kelly, R.; Begley, M.R. The effects of annealing prior to dealloying on the mechanical properties of nanoporous gold microbeams. Acta Mater. 2008, 56, 324–332. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahriar, S.; Somayajula, K.; Winkeljohn, C.; Mason, J.K.; Seker, E. The Influence of the Mechanical Compliance of a Substrate on the Morphology of Nanoporous Gold Thin Films. Nanomaterials 2024, 14, 758. https://doi.org/10.3390/nano14090758

Shahriar S, Somayajula K, Winkeljohn C, Mason JK, Seker E. The Influence of the Mechanical Compliance of a Substrate on the Morphology of Nanoporous Gold Thin Films. Nanomaterials. 2024; 14(9):758. https://doi.org/10.3390/nano14090758

Chicago/Turabian StyleShahriar, Sadi, Kavya Somayajula, Conner Winkeljohn, Jeremy K. Mason, and Erkin Seker. 2024. "The Influence of the Mechanical Compliance of a Substrate on the Morphology of Nanoporous Gold Thin Films" Nanomaterials 14, no. 9: 758. https://doi.org/10.3390/nano14090758

APA StyleShahriar, S., Somayajula, K., Winkeljohn, C., Mason, J. K., & Seker, E. (2024). The Influence of the Mechanical Compliance of a Substrate on the Morphology of Nanoporous Gold Thin Films. Nanomaterials, 14(9), 758. https://doi.org/10.3390/nano14090758