1D Piezoelectric Material Based Nanogenerators: Methods, Materials and Property Optimization

Abstract

:1. Introduction

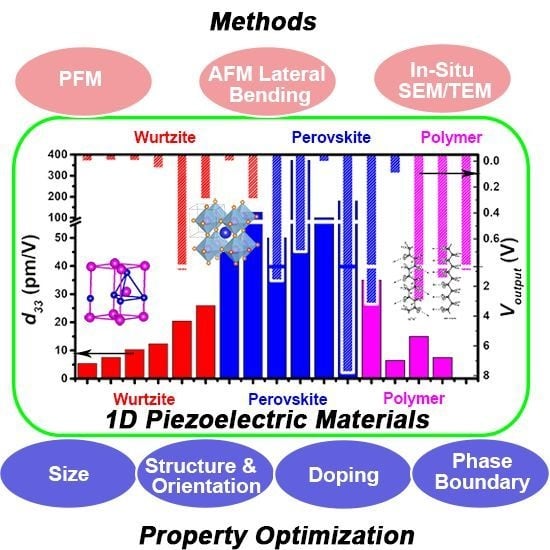

2. Characterization Methods of Piezoelectricity in One-Dimensional (1D) Nanomaterials

2.1. Piezoresponse Force Microscopy Method: Piezoelectric Coefficient Measurement of Single Nanowire (NW)

2.2. Atomic Force Microscopy Lateral Bending: Performance Evaluation of Single NW-Based Nanogenerators (NGs)

2.3. In-Situ Scanning/Transmission Electron Microscopy Method: Microstructural Dependenct Performance of NW Based-NG

3. 1D Piezoelectric Materials

3.1. Wurtzite or Zinc Blend Structured NWs

3.2. Perovskite NWs/Nanofibers/Nanorods/Microbelts

3.3. 1D Polymers NWs/Nanofibers

4. Performance Optimization

4.1. Size Effect of Piezoelectric NWs

4.2. Crystal Structure and Orientation Dependent Piezoelectric Properties of NWs

4.3. Influence of Doping on NW-Based NGs

4.4. Influence of Phase Bounday on the Piezoelectric Properties of NWs

5. Application of 1D Piezoelectric Materials

6. Summary and Future Perspectives

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, Y.; Wang, S.; Liu, H.; Peng, L.M. Carbon nanotube-based three-dimensional monolithic optoelectronic integrated system. Nat. Commun. 2017, 8, 15649. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Wei, X.; Gao, S.; Chen, Q.; Peng, L. Tunable graphene micro-emitters with fast temporal response and controllable electron emission. Nat. Commun. 2016, 7, 11513. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Zhang, Z.; Liang, S.; Pei, T.; Wang, S.; Li, Y.; Zhou, W.; Liu, J.; Peng, L.M. CMOS-based carbon nanotube pass-transistor logic integrated circuits. Nat. Commun. 2012, 3, 677. [Google Scholar] [CrossRef] [PubMed]

- Shang, Y.; Hua, C.; Xu, W.; Hu, X.; Wang, Y.; Zhou, Y.; Zhang, Y.; Li, X.; Cao, A. Meter-long spiral carbon nanotube fibers show ultrauniformity and flexibility. Nano Lett. 2016, 16, 1768–1775. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Gu, G.Q.; Han, C.B.; Lu, C.X.; He, C.; Jiang, T.; Gao, Z.L.; Li, C.J.; Wang, Z.L. Triboelectric nanogenerator enhanced nanofiber air filters for efficient particulate matter removal. ACS Nano 2017, 11, 6211–6217. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wen, Z.; Guo, H.; Wu, C.; He, X.; Lin, L.; Cao, X.; Wang, Z.L. Fully packaged blue energy harvester by hybridizing a rolling triboelectric nanogenerator and an electromagnetic generator. ACS Nano 2016, 10, 11369–11376. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Guo, H.; He, X.; Liu, G.; Xi, Y.; Shi, H.; Hu, C. Enhancing performance of triboelectric nanogenerator by filling high dielectric nanoparticles into sponge PDMS film. ACS Appl. Mater. Interfaces 2016, 8, 736–744. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Wang, S.; Lin, L.; Jing, Q.; Lin, Z.-H.; Niu, S.; Wu, Z.; Wang, Z.L. Rotary triboelectric nanogenerator based on a hybridized mechanism for harvesting wind energy. ACS Nano 2013, 7, 7119–7125. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Geng, D.; Liang, E.; Wang, X. Single-electrode triboelectric nanogenerator for scavenging friction energy from rolling tires. Nano Energy 2015, 15, 227–234. [Google Scholar] [CrossRef]

- Mao, Y.; Zhang, N.; Tang, Y.; Wang, M.; Chao, M.; Liang, E. A paper triboelectric nanogenerator for self-powered electronic systems. Nanoscale 2017, 9, 14499–14505. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Guo, W.; Pradel, K.C.; Zhu, G.; Zhou, Y.; Zhang, Y.; Hu, Y.; Lin, L.; Wang, Z.L. Pyroelectric nanogenerators for harvesting thermoelectric energy. Nano Lett. 2012, 12, 2833–2838. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Jung, J.H.; Yun, B.K.; Zhang, F.; Pradel, K.C.; Guo, W.; Wang, Z.L. Flexible pyroelectric nanogenerators using a composite structure of lead-free KnbO3 nanowires. Adv. Mater. 2012, 24, 5357–5362. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Pradel, K.C.; Jing, Q.; Wu, J.M.; Zhang, F.; Zhou, Y.; Zhang, Y.; Wang, Z.L. Thermoelectric nanogenerators based on single Sb-doped ZnO micro/nanobelts. ACS Nano 2012, 6, 6984–6989. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Wang, S.; Yeh, M.H.; Pan, C.; Lin, L.; Yu, R.; Zhang, Y.; Zheng, L.; Jiao, Z.; Wang, Z.L. A streaming potential/current-based microfluidic direct current generator for self-powered nanosystems. Adv. Mater. 2015, 27, 6482–6487. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Liang, D.; Gao, X.P.A.; Alexander, J.I.D. Sensing and energy harvesting of fluidic flow by InAs nanowires. Nano Lett. 2013, 13, 3953–3957. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Hoyt, J.L.; Nayfeh, H.M.; Eguchi, S.; Aberg, I.; Xia, G.; Drake, T.; Fitzgerald, E.A.; Antoniadis, D.A. Strained silicon MOSFET technology. In Proceedings of the International Electron Devices Meeting, San Francisco, CA, USA, 8–11 December 2002; pp. 23–26. [Google Scholar]

- Greil, J.; Lugstein, A.; Zeiner, C.; Strasser, G.; Bertagnolli, E. Tuning the electro-optical properties of germanium nanowires by tensile strain. Nano Lett. 2012, 12, 6230–6234. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Guo, X.; Wang, W.; Zhang, Y.; Xu, S.; Lien, D.H.; Wang, Z.L. Enhancing sensitivity of a single ZnO micro/nanowire photodetector by piezo-phototronic effect. ACS Nano 2010, 4, 6285–6291. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-F.; Song, J.; Ding, Y.; Lu, S.-Y.; Wang, Z.L. Piezoelectric nanogenerator using CdS nanowires. Appl. Phys. Lett. 2008, 92, 022105. [Google Scholar] [CrossRef]

- Huang, C.T.; Song, J.; Tsai, C.M.; Lee, W.F.; Lien, D.H.; Gao, Z.; Hao, Y.; Chen, L.J.; Wang, Z.L. Single-InN-nanowire nanogenerator with upto 1 V output voltage. Adv. Mater. 2010, 22, 4008–4013. [Google Scholar] [CrossRef] [PubMed]

- Minary-Jolandan, M.; Bernal, R.A.; Kuljanishvili, I.; Parpoil, V.; Espinosa, H.D. Individual GaN nanowires exhibit strong piezoelectricity in 3D. Nano Lett. 2012, 12, 970–976. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wei, X.; Xu, T.; Pan, D.; Zhao, J.H.; Chen, Q. Remarkable and crystal-structure-dependent piezoelectric and piezoresistive effects of InAs Nanowires. Adv. Mater. 2015, 27, 2852–2858. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Lee, M.; Ding, L.; Liu, J.; Wang, Z.L. Piezopotential gated nanowire-nanotube hybrid field-effect transistor. Nano Lett. 2010, 10, 3084–3089. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Wei, Y.; Wang, Z.L. Strain-gated piezotronic logic nanodevices. Adv. Mater. 2010, 22, 4711–4715. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.; Niu, S.; Ding, Y.; Dong, L.; Yu, R.; Liu, Y.; Zhu, G.; Wang, Z.L. Enhanced Cu2S/CdS coaxial nanowire solar cells by piezo-phototronic effect. Nano Lett. 2012, 12, 3302–3307. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Wang, W.; Xu, S.; Wang, Z.L. Enhancing light emission of ZnO microwire-based diodes by piezo-phototronic effect. Nano Lett. 2011, 11, 4012–4017. [Google Scholar] [CrossRef] [PubMed]

- Pan, D.; Fu, M.; Yu, X.; Wang, X.; Zhu, L.; Nie, S.; Wang, S.; Chen, Q.; Xiong, P.; von Molnár, S. Controlled synthesis of phase-pure InAs nanowires on Si(111) by diminishing the diameter to 10 nm. Nano Lett. 2014, 14, 1214–1220. [Google Scholar] [CrossRef] [PubMed]

- Kuykendall, T.; Ulrich, P.; Aloni, S.; Yang, P. Complete composition tunability of InGaN nanowires using a combinatorial approach. Nat. Mater. 2007, 6, 951–956. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qian, F.; Xiang, J.; Lieber, C.M. Nanowire electronic and optoelectronic devices. Mater. Today 2006, 9, 18–27. [Google Scholar] [CrossRef]

- Feng, X.L.; He, R.; Yang, P.; Roukes, M.L. Very high frequency silicon nanowire electromechanical resonators. Nano Lett. 2007, 7, 1953–1959. [Google Scholar] [CrossRef]

- Mathew, J.P.; Patel, R.; Borah, A.; Maliakkal, C.B.; Abhilash, T.S.; Deshmukh, M.M. Nanoscale electromechanics to measure thermal conductivity, expansion, and interfacial losses. Nano Lett. 2015, 15, 7621–7626. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.M.; Pan, W.Y.; Cross, L.E. Laser interferometer for the study of piezoelectric and electrostrictive strains. J. Appl. Phys. 1988, 63, 2492–2496. [Google Scholar] [CrossRef]

- Berlincourt, D.A.; Kulscsar, F. Electromechanical properties of BaTiO3 compositions showing substantial shifts in phase transition points. J. Acoust. Soc. Am. 1952, 24, 709–713. [Google Scholar] [CrossRef]

- Zhao, M.-H.; Wang, Z.L.; Mao, S.X. Piezoelectric characterization of individual zinc oxide nanobelt probed by piezoresponse force microscope. Nano Lett. 2004, 4, 587–590. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, J.; Yang, Y.; Wang, Y.; Wu, Y.; He, H.; Wei, X.; Ye, Z.; Zeng, H.; Cong, H. Piezoelectric properties of rhombic LiNbO3 nanowires. RSC Adv. 2012, 2, 7380–7383. [Google Scholar] [CrossRef]

- Varghese, J.; Barth, S.; Keeney, L.; Whatmore, R.W.; Holmes, J.D. Nanoscale ferroelectric and piezoelectric properties of Sb2S3 nanowire arrays. Nano Lett. 2012, 12, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Poirier, G.; Yao, N. Fabrication and piezoelectric property of PMN-PT nanofibers. Nano Energy 2012, 1, 602–607. [Google Scholar] [CrossRef]

- Ghasemian, M.B.; Lin, Q.; Adabifiroozjaei, E.; Wang, F.; Chu, D.; Wang, D. Morphology control and large piezoresponse of hydrothermally synthesized lead-free piezoelectric (Bi0.5Na0.5)TiO3 nanofibres. RSC Adv. 2017, 7, 15020–15026. [Google Scholar] [CrossRef]

- Zhou, Z.; Tang, H.; Sodano, H.A. Vertically aligned arrays of BaTiO3 nanowires. ACS Appl. Mater. Interfaces 2013, 5, 11894–11899. [Google Scholar] [CrossRef] [PubMed]

- Minary-Jolandan, M.; Bernal, R.A.; Espinosa, H.D. Strong piezoelectricity in individual GaN nanowires. MRS Commun. 2011, 1, 45–48. [Google Scholar] [CrossRef]

- Bowland, C.; Zhou, Z.; Sodano, H.A. Multifunctional barium titanate coated carbon fibers. Adv. Funct. Mater. 2014, 24, 6303–6308. [Google Scholar] [CrossRef]

- Christman, J.A.; Woolcott, R.R., Jr.; Kingon, A.I.; Nemanich, R.J. Piezoelectric measurements with atomic force microscopy. Appl. Phys. Lett. 1998, 73, 3851–3853. [Google Scholar] [CrossRef]

- Alekseev, P.A.; Sharov, V.A.; Geydt, P.; Dunaevskiy, M.S.; Lysak, V.V.; Cirlin, G.E.; Reznik, R.R.; Khrebtov, A.I.; Soshnikov, I.P.; Lähderanta, E. Piezoelectric current generation in wurtzite GaAs nanowires. Phys. Status Solidi Rapid Res. Lett. 2017, 12, 1700358. [Google Scholar] [CrossRef]

- Wang, X.; Song, J.; Zhang, F.; He, C.; Hu, Z.; Wang, Z. Electricity generation based on one-dimensional group-III nitride nanomaterials. Adv. Mater. 2010, 22, 2155–2158. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-Y.; Zhu, G.; Yu, J.-W.; Song, J.; Cheng, K.-Y.; Peng, L.-H.; Chou, L.-J.; Wang, Z.L. Gallium nitride nanowire based nanogenerators and light-emitting diodes. ACS Nano 2012, 6, 5687–5692. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wei, X.L.; Xu, T.T.; Ning, Z.Y.; Shu, J.P.; Wang, X.Y.; Pan, D.; Zhao, J.H.; Yang, T.; Chen, Q. Mechanical properties of individual InAs nanowires studied by tensile tests. Appl. Phys. Lett. 2014, 104, 103110. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Wen, M.; Hacopian, E.; Chen, W.; Gong, Y.; Zhang, J.; Li, B.; Zhou, W.; Ajayan, P.M. Brittle fracture of 2D MoSe2. Adv. Mater. 2017, 29, 1604201. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sun, M.; Shan, C.; Chen, Q.; Wei, X. Mechanical properties of 2D materials studied by in situ microscopy techniques. Adv. Mater. Interfaces 2018, 5, 1701246. [Google Scholar] [CrossRef]

- Ning, Z.Y.; Fu, M.Q.; Shi, T.W.; Guo, Y.; Wei, X.L.; Gao, S.; Chen, Q. In situ multiproperty measurements of individual nanomaterials in SEM and correlation with their atomic structures. Nanotechnology 2014, 25, 275703. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xiao, D.; Zheng, H.; Wei, X.; Wang, X.; Gu, L.; Hu, Y.-S.; Yang, T.; Chen, Q. Ultrafast and reversible electrochemical lithiation of InAs nanowires observed by in-situ transmission electron microscopy. Nano Energy 2016, 20, 194–201. [Google Scholar] [CrossRef]

- Wei, X.; Chen, Q.; Peng, L.; Cui, R.; Li, Y. Tensile loading of double-walled and triple-walled carbon nanotubes and their mechanical properties. J. Phys. Chem. C 2009, 113, 17002–17005. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, J.; Suryavanshi, A.P.; Yum, K.; Yu, M.-F. Voltage generation from individual BaTiO3 nanowires under periodic tensile mechanical load. Nano Lett. 2007, 7, 2966–2969. [Google Scholar] [CrossRef] [PubMed]

- Perez Garza, H.H.; Kievit, E.W.; Schneider, G.F.; Staufer, U. Controlled, reversible, and nondestructive generation of uniaxial extreme strains (>10%) in graphene. Nano Lett. 2014, 14, 4107–4113. [Google Scholar] [CrossRef] [PubMed]

- Zheng, K.; Zhang, Z.; Hu, Y.; Chen, P.; Lu, W.; Drennan, J.; Han, X.; Zou, J. Orientation dependence of electromechanical characteristics of defect-free InAs nanowires. Nano Lett. 2016, 16, 1787–1793. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Wang, L.; Tian, X.; Xu, Z.; Wang, W.; Bai, X.; Wang, E. The piezotronic effect of zinc oxide nanowires studied by in situ TEM. Adv. Mater. 2012, 24, 4676–4682. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L. Piezopotential gated nanowire devices: Piezotronics and piezo-phototronics. Nano Today 2010, 5, 540–552. [Google Scholar] [CrossRef]

- Wang, Z.L. Progress in piezotronics and piezo-phototronics. Adv. Mater. 2012, 24, 4632–4646. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.-J.; Shi, Z.-F.; Shan, C.-X.; Shen, D.-Z. ZnO-based deep-ultraviolet light-emitting devices. Chin. Phys. B 2017, 26, 047703. [Google Scholar] [CrossRef]

- Shi, Z.F.; Xu, T.T.; Wu, D.; Zhang, Y.T.; Zhang, B.L.; Tian, Y.T.; Li, X.J.; Du, G.T. Semi-transparent all-oxide ultraviolet light-emitting diodes based on ZnO/NiO-core/shell nanowires. Nanoscale 2016, 8, 9997–10003. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.-Y.; Song, J.; Lu, M.-P.; Lee, L.-J.; Wang, Z.L. ZnO-ZnS heterojunction and ZnS nanowire arrays for electricity generation. ACS Nano 2009, 3, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Hou, T.-C.; Yang, Y.; Lin, Z.-H.; Ding, Y.; Park, C.; Pradel, K.C.; Chen, L.-J.; Wang, Z.L. Nanogenerator based on zinc blende CdTe micro/nanowires. Nano Energy 2013, 2, 387–393. [Google Scholar] [CrossRef]

- Jamond, N.; Chretien, P.; Houze, F.; Lu, L.; Largeau, L.; Maugain, O.; Travers, L.; Harmand, J.C.; Glas, F.; Lefeuvre, E. Piezo-generator integrating a vertical array of GaN nanowires. Nanotechnology 2016, 27, 325403. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Li, Y.; Zhang, Y.; Chen, Y.; Li, X.; Wu, D.; Xu, T.; Shan, C.; Du, G. High-efficiency and air-stable perovskite quantum dots light-emitting diodes with an all-inorganic heterostructure. Nano Lett. 2017, 17, 313–321. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Xu, S.; Yao, N.; Shi, Y. 1.6 V nanogenerator for mechanical energy harvesting using PZT nanofibers. Nano Lett. 2010, 10, 2133–2137. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Hansen, B.J.; Wang, Z.L. Piezoelectric-nanowire-enabled power source for driving wireless microelectronics. Nat. Commun. 2010, 1, 93. [Google Scholar] [CrossRef] [PubMed]

- Moorthy, B.; Baek, C.; Wang, J.E.; Jeong, C.K.; Moon, S.; Park, K.-I.; Kim, D.K. Piezoelectric energy harvesting from a PMN-PT single nanowire. RSC Adv. 2017, 7, 260–265. [Google Scholar] [CrossRef]

- Xu, S.; Poirier, G.; Yao, N. PMN-PT nanowires with a very high piezoelectric constant. Nano Lett. 2012, 12, 2238–2242. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Yeh, Y.W.; Poirier, G.; McAlpine, M.C.; Register, R.A.; Yao, N. Flexible piezoelectric PMN-PT nanowire-based nanocomposite and device. Nano Lett. 2013, 13, 2393–2398. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.H.; Lee, M.; Hong, J.-I.; Ding, Y.; Chen, C.-Y.; Chou, L.-J.; Wang, Z.L. Lead-free NaNbO3 nanowires for a high output piezoelectric nanogenerator. ACS Nano 2011, 5, 10041–10046. [Google Scholar] [CrossRef] [PubMed]

- Rorvik, P.M.; Grande, T.; Einarsrud, M.A. One-dimensional nanostructures of ferroelectric perovskites. Adv. Mater. 2011, 23, 4007–4034. [Google Scholar] [CrossRef] [PubMed]

- Yun, B.K.; Park, Y.K.; Lee, M.; Lee, N.; Jo, W.; Lee, S.; Jung, J.H. Leed-free LiNbO3 nanowire-based nanocomposite for piezoelectric power generation. Nanoscale Res. Lett. 2014, 9, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.M.; Xu, C.; Zhang, Y.; Wang, Z.L. Leed-free nanogenerator made from single ZnSnO3 microbelt. ACS Nano 2012, 6, 4335–4340. [Google Scholar] [CrossRef] [PubMed]

- Kang, P.G.; Yun, B.K.; Sung, K.D.; Lee, T.K.; Lee, M.; Lee, N.; Oh, S.H.; Jo, W.; Seog, H.J.; Ahn, C.W. Piezoelectric power generation of vertically aligned lead-free (K,Na)NbO3 nanorod arrays. RSC Adv. 2014, 4, 29799–29805. [Google Scholar] [CrossRef]

- Lovinger, A.J. Ferroelectric polymers. Science 1983, 220, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Gu, Q.; Ding, G.; Tong, F.; Hu, Z.; Jonas, A.M. Confinement induced preferential orientation of crystals and enhancement of properties in ferroelectric polymer nanowires. ACS Macro Lett. 2013, 2, 535–538. [Google Scholar] [CrossRef]

- Liew, W.H.; Mirshekarloo, M.S.; Chen, S.; Yao, K.; Tay, F.E. Nanoconfinement induced crystal orientation and large piezoelectric coefficient in vertically aligned P(VDF-TrFE) nanotube array. Sci. Rep. 2015, 5, 9790. [Google Scholar] [CrossRef] [PubMed]

- Cauda, V.; Canavese, G.; Stassi, S. Nanostructured piezoelectric polymers. J. Appl. Polym. Sci. 2015, 132, 41667. [Google Scholar] [CrossRef]

- Cauda, V.; Torre, B.; Falqui, A.; Canavese, G.; Stassi, S.; Bein, T.; Pizzi, M. Confinement in oriented mesopores induces piezoelectric behavior of polymeric nanowires. Chem. Mater. 2012, 24, 4215–4221. [Google Scholar] [CrossRef]

- Cauda, V.; Stassi, S.; Bejtka, K.; Canavese, G. Nanoconfinement: An effective way to enhance PVDF piezoelectric properties. ACS Appl. Mater. Interfaces 2013, 5, 6430–6437. [Google Scholar] [CrossRef] [PubMed]

- Whiter, R.A.; Narayan, V.; Kar-Narayan, S. A scalable nanogenerator based on self-poled piezoelectric polymer nanowires with high energy conversion efficiency. Adv. Energy Mater. 2014, 4, 1400519. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1633. [Google Scholar] [CrossRef] [PubMed]

- Persano, L.; Dagdeviren, C.; Maruccio, C.; De Lorenzis, L.; Pisignano, D. Cooperativity in the enhanced piezoelectric response of polymer nanowires. Adv. Mater. 2014, 26, 7574–7580. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Z.; Wingert, M.C.; Strzalka, J.; Wang, H.H.; Sun, T.; Wang, J.; Chen, R.; Jiang, Z. Structure-induced enhancement of thermal conductivities in electrospun polymer nanofibers. Nanoscale 2014, 6, 8283–8291. [Google Scholar] [CrossRef] [PubMed]

- Datta, A.; Choi, Y.S.; Chalmers, E.; Ou, C.; Kar-Narayan, S. Piezoelectric nylon-11 nanowire arrays grown by template wetting for vibrational energy harvesting applications. Adv. Funct. Mater. 2017, 27, 1604262. [Google Scholar] [CrossRef]

- Berlincourt, D.; Jaffe, H.; Shiozawa, L.R. Electroelastic properties of the sulfides, selenides, and tellurides of Zinc and Cadmium. Phys. Rev. 1963, 129, 1009–1017. [Google Scholar] [CrossRef]

- Bernardini, F.; Fiorentini, V. First-principles calculation of the piezoelectric tensor d of III–V nitrides. Appl. Phys. Lett. 2002, 80, 4145–4147. [Google Scholar] [CrossRef]

- Steinhausen, R.; Hauke, T.; Beige, H.; Watzka, W.; Lange, U.; Sporn, D.; Gebhardt, S.; Schonecker, A. Properties of fine scale piezoelectric PZT fibers with different Zr content. J. Eur. Ceram. Soc. 2001, 21, 1459–1462. [Google Scholar] [CrossRef]

- He, M.-R.; Shi, Y.; Zhou, W.; Chen, J.W.; Yan, Y.J.; Zhu, J. Diameter dependence of modulus in zinc oxide nanowires and the effect of loading mode: In situ experiments and universal core-shell approach. Appl. Phys. Lett. 2009, 95, 091912. [Google Scholar] [CrossRef]

- Fu, M.; Pan, D.; Yang, Y.; Shi, T.; Zhang, Z.; Zhao, J.; Xu, H.Q.; Chen, Q. Electrical characteristics of field-effect transistors based on indium arsenide nanowire thinner than 10 nm. Appl. Phys. Lett. 2014, 105, 143101. [Google Scholar] [CrossRef]

- Chen, C.Q.; Shi, Y.; Zhang, Y.S.; Zhu, J.; Yan, Y.J. Size dependence of Young’s modulus in ZnO nanowires. Phys. Rev. Lett. 2006, 96, 075505. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, C.; Chowdhury, R.; Adhikari, S. Size- and temperature-dependent piezoelectric properties of gallium nitride nanowires. Scr. Mater. 2013, 68, 627–630. [Google Scholar] [CrossRef]

- Agrawal, R.; Espinosa, H.D. Giant piezoelectric size effects in zinc oxide and gallium nitride nanowires. A first principles investigation. Nano Lett. 2011, 11, 786–790. [Google Scholar] [CrossRef] [PubMed]

- Riaz, M.; Song, J.; Nur, O.; Wang, Z.L.; Willander, M. Study of the piezoelectric power generation of ZnO nanowire arrays grown by different methods. Adv. Funct. Mater. 2011, 21, 628–633. [Google Scholar] [CrossRef]

- Zhang, Y.; Hong, J.; Liu, B.; Fang, D. Strain effect on ferroelectric behaviors of BaTiO3 nanowires: A molecular dynamics study. Nanotechnology 2010, 21, 015701. [Google Scholar] [CrossRef] [PubMed]

- Ma, W. Surface tension and Curie temperature in ferroelectric nanowires and nanodots. Appl. Phys. A 2009, 96, 915–920. [Google Scholar] [CrossRef]

- Hong, J.; Fang, D. Size-dependent ferroelectric behaviors of BaTiO3 nanowires. Appl. Phys. Lett. 2008, 92, 012906. [Google Scholar] [CrossRef]

- Hong, J.; Fang, D. Systematic study of the ferroelectric properties of Pb(Zr0.5Ti0.5)O3 nanowires. J. Appl. Phys. 2008, 104, 064118. [Google Scholar] [CrossRef]

- Spanier, J.E.; Kolpak, A.M.; Urban, J.J.; Grinberg, I.; Ouyang, L.; Yun, W.S.; Rappe, A.M.; Park, H. Ferroelectric phase transition in individual single-crystalline BaTiO3 Nanowires. Nano Lett. 2006, 6, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Nonnenmann, S.S.; Leaffer, O.D.; Gallo, E.M.; Coster, M.T.; Spanier, J.E. Finite curvature-mediated ferroelectricity. Nano Lett. 2010, 10, 542–546. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.; Wang, X.; Shi, X.; Ran, X. The induction of poly(vinylidene fluoride) electroactive phase by modified anodic aluminum oxide template nanopore surface. RSC Adv. 2015, 5, 87429–87436. [Google Scholar] [CrossRef]

- Boxberg, F.; Sondergaard, N.; Xu, H.Q. Photovoltaics with piezoelectric core-shell nanowires. Nano Lett. 2010, 10, 1108–1112. [Google Scholar] [CrossRef] [PubMed]

- Boxberg, F.; Sondergaard, N.; Xu, H.Q. Elastic and piezoelectric properties of zincblende and wurtzite crystalline nanowire heterostructures. Adv. Mater. 2012, 24, 4692–4706. [Google Scholar] [CrossRef] [PubMed]

- Thelander, C.; Caroff, P.; Plissard, S.; Dey, A.W.; Dick, K.A. Effects of crystal phase mixing on the electrical properties of InAs nanowires. Nano Lett. 2011, 11, 2424–2429. [Google Scholar] [CrossRef] [PubMed]

- Wallentin, J.; Ek, M.; Wallenberg, L.R.; Samuelson, L.; Borgstrom, M.T. Electron trapping in InP nanowire FETs with stacking faults. Nano Lett. 2012, 12, 151–155. [Google Scholar] [CrossRef] [PubMed]

- Shimamura, K.; Yuan, Z.; Shimojo, F.; Nakano, A. Effects of twins on the electronic properties of GaAs. Appl. Phys. Lett. 2013, 103, 022105. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, C.; Liu, J.; Xiong, J.; Liu, J.; Zhang, K.; Liu, Y.; Peng, M.; Yu, A.; Zhang, A. Lattice strain induced remarkable enhancement in piezoelectric performance of ZnO-based flexible nanogenerators. ACS Appl. Mater. Interfaces 2016, 8, 1381–1387. [Google Scholar] [CrossRef] [PubMed]

- Dai, G.; Zou, H.; Wang, X.; Zhou, Y.; Wang, P.; Ding, Y.; Zhang, Y.; Yang, J.; Wang, Z.L. Piezo-phototronic effect enhanced responsivity of photon sensor based on composition-tunable ternary CdSxSe1−x nanowires. ACS Photonics 2017, 4, 2495–2503. [Google Scholar] [CrossRef]

- Wang, C.H.; Liao, W.S.; Ku, N.J.; Li, Y.C.; Chen, Y.C.; Tu, L.W.; Liu, C.P. Effects of free carriers on piezoelectric nanogenerators and piezotronic devices made of GaN nanowire arrays. Small 2014, 10, 4718–4725. [Google Scholar] [CrossRef] [PubMed]

- Pradel, K.C.; Wu, W.; Zhou, Y.; Wen, X.; Ding, Y.; Wang, Z.L. Piezotronic effect in solution-grown p-type ZnO nanowires and films. Nano Lett. 2013, 13, 2647–2653. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Fei, P.; Song, J.; Wang, X.; Lao, C.; Tummala, R.; Wang, Z.L. Carrier density and schottky barrier on the performance of DC nanogenrator. Nano Lett. 2008, 8, 328–332. [Google Scholar] [CrossRef] [PubMed]

- Sohn, J.I.; Cha, S.N.; Song, B.G.; Lee, S.; Kim, S.M.; Ku, J.; Kim, H.J.; Park, Y.J.; Choi, B.L.; Wang, Z.L. Engineering of efficiency limiting free carriers and an interfacial energy barrier for an enhancing piezoelectric generation. Energy Environ. Sci. 2013, 6, 97–104. [Google Scholar] [CrossRef]

- Liu, C.; Yu, A.; Peng, M.; Song, M.; Liu, W.; Zhang, Y.; Zhai, J. Improvement in the piezoelectric performance of a ZnO nanogenerator by a combination of chemical doping and interfacial modification. J. Phys. Chem. C 2016, 120, 6971–6977. [Google Scholar] [CrossRef]

- Shin, S.-H.; Lee, M.H.; Jung, J.-Y.; Seol, J.H.; Nah, J. Piezoelectric performance enhancement of ZnO flexible nanogenerator by a CuO–ZnO p–n junction formation. J. Mater. Chem. C 2013, 1, 8103–8107. [Google Scholar] [CrossRef]

- Yin, B.; Qiu, Y.; Zhang, H.; Lei, J.; Chang, Y.; Ji, J.; Luo, Y.; Zhao, Y.; Hu, L. Piezoelectric performance enhancement of ZnO flexible nanogenerator by a NiO–ZnO p–n junction formation. Nano Energy 2015, 14, 95–101. [Google Scholar] [CrossRef]

- Guo, R.; Cross, L.E.; Park, S.-E.; Noheda, B.; Cox, D.E.; Shirane, G. Origin of the high piezoelectric response in PbZr1-xTixO3. Phys. Rev. Lett. 2000, 84, 5423–5426. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Cohen, R.E. Polarization rotation mechanism for ultrahigh electromechanical response in single-crystal piezoelectrics. Nature 2000, 403, 281–283. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wu, J.; Xiao, D.; Zhu, J.; Cheng, X.; Zheng, T.; Zhang, B.; Lou, X.; Wang, X. Giant piezoelectricity in potassium-sodium niobate lead-free ceramics. J. Am. Chem. Soc. 2014, 136, 2905–2910. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Zhang, J.; Yao, W.; Lu, C.; Zhang, S. Domain configuration and thermal stability of (K0.48Na0.52)(Nb0.96Sb0.04)O3–Bi0.50(Na0.82K0.18)0.50ZrO3 piezoceramics with high d33 coefficient. ACS Appl. Mater. Interfaces 2016, 8, 7257–7265. [Google Scholar] [CrossRef] [PubMed]

- Rubio-Marcos, F.; Lopez-Juarez, R.; Rojas-Hernandez, R.E.; del Campo, A.; Razo-Perez, N.; Fernandez, J.F. Lead-free piezoceramics: Revealing the role of the rhombohedral-tetragonal phase coexistence in enhancement of the piezoelectric properties. ACS Appl. Mater. Interfaces 2015, 7, 23080–23088. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Wang, W.; Ke, H.; Rao, J.; Jia, D.; Zhou, Y. Synthesis, piezoelectric property and domain behaviour of the vertically aligned K1−xNaxNbO3 nanowire with a morphotropic phase boundary. J. Mater. Chem. C 2017, 5, 747–753. [Google Scholar] [CrossRef]

- Joung, M.-R.; Seo, I.-T.; Kim, J.-S.; Xu, H.; Han, G.; Kang, M.-G.; Kang, C.-Y.; Yoon, S.-J.; Nahm, S. Structural dependence of the piezoelectric properties of KNbO3 nanowires synthesized by the hydrothermal method. Acta Mater. 2013, 61, 3703–3708. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, X.; He, Y.; Hu, Y.; Gu, H.; Wang, Y. Piezoelectric nanowires in energy harvesting applications. Adv. Mater. Sci. Eng. 2015, 2015, 165631. [Google Scholar] [CrossRef]

- Zi, Y.; Wang, Z.L. Nanogenerators: An emerging technology towards nanoenergy. APL Mater. 2017, 5, 074103. [Google Scholar] [CrossRef]

- Briscoe, J.; Dunn, S. Piezoelectric nanogenerators—A review of nanostructured piezoelectric energy harvesters. Nano Energy 2015, 14, 15–29. [Google Scholar] [CrossRef]

- Fei, P.; Yeh, P.-H.; Zhou, J.; Xu, S.; Gao, Y.; Song, J.; Gu, Y.; Huang, Y.; Wang, Z.L. Piezoelectric potential gated field-effect transistor based on a free-standing ZnO Wire. Nano Lett. 2009, 9, 3435–3439. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhou, J.; Song, J.; Liu, J.; Xu, N.; Wang, Z.L. Piezoelectric field effect transistor and nanoforce sensor based on a single ZnO nanowire. Nano Lett. 2006, 6, 2768–2772. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.-S.; Hong, W.-K.; Jo, G.; Maeng, J.; Kim, T.-W.; Song, S.; Lee, T. Piezoelectric effect on the electronic transport characteristics of ZnO nanowire field-effect transistors on bent flexible substrates. Adv. Mater. 2008, 20, 4557–4562. [Google Scholar] [CrossRef]

- Chen, L.; Xue, F.; Li, X.; Huang, X.; Wang, L.; Kou, J.; Wang, Z.L. Strain-gated field effect transistor of a MoS2–ZnO 2D–1D hybrid structure. ACS Nano 2016, 10, 1546–1551. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, Z.L. Theory of piezo-phototronics for light-emitting diodes. Adv. Mater. 2012, 24, 4712–4718. [Google Scholar] [CrossRef] [PubMed]

- Bao, R.; Wang, C.; Dong, L.; Yu, R.; Zhao, K.; Wang, Z.L.; Pan, C. Flexible and controllable piezo-phototronic pressure mapping sensor matrix by ZnO NW/p-Polymer LED Array. Adv. Funct. Mater. 2015, 25, 2884–2891. [Google Scholar] [CrossRef]

- Yang, X.; Dong, L.; Shan, C.; Sun, J.; Zhang, N.; Wang, S.; Jiang, M.; Li, B.; Xie, X.; Shen, D. Piezophototronic-effect-enhanced electrically pumped lasing. Adv. Mater. 2017, 29, 1602832. [Google Scholar] [CrossRef] [PubMed]

- Rai, S.C.; Wang, K.; Chen, J.; Marmon, J.K.; Bhatt, M.; Wozny, S.; Zhang, Y.; Zhou, W. Enhanced broad band photodetection through piezo-phototronic effect in CdSe/ZnTe core/shell nanowire array. Adv. Electron. Mater. 2015, 1, 1400050. [Google Scholar] [CrossRef]

- Liu, X.; Yang, X.; Gao, G.; Yang, Z.; Liu, H.; Li, Q.; Lou, Z.; Shen, G.; Liao, L.; Pan, C.; et al. Enhancing photoresponsivity of self-aligned MoS2 field-effect transistors by piezo-phototronic effect from GaN nanowires. ACS Nano 2016, 10, 7451–7457. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Wang, L.; Xue, F.; Chen, L.; Fu, J.; Feng, X.; Li, T.; Wang, Z.L. Piezo-phototronic effect enhanced flexible solar cells based on n-ZnO/p-SnS core-shell nanowire array. Adv. Sci. 2017, 4, 1600185. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Wang, L.; Pan, C.; Chen, L.; Xue, F.; Chen, B.; Yang, L.; Su, L.; Wang, Z.L. Enhancing the efficiency of silicon-based solar cells by the piezo-phototronic effect. ACS Nano 2017, 11, 1894–1900. [Google Scholar] [CrossRef] [PubMed]

- Gu, L.; Cui, N.; Cheng, L.; Xu, Q.; Bai, S.; Yuan, M.; Wu, W.; Liu, J.; Zhao, Y.; Ma, F. Flexible fiber nanogenerator with 209 V output voltage directly powers a light-emitting diode. Nano Lett. 2013, 13, 91–94. [Google Scholar] [CrossRef] [PubMed]

- Lin, P.; Yan, X.; Zhang, Z.; Shen, Y.; Zhao, Y.; Bai, Z.; Zhang, Y. Self-powered UV photosensor based on PEDOT:PSS/ZnO micro/nanowire with strain-modulated photoresponse. ACS Appl. Mater. Interfaces 2013, 5, 3671–3676. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Hu, L.; Fang, X. Energy harvesting for nanostructured self-powered photodetectors. Adv. Funct. Mater. 2014, 24, 2591–2610. [Google Scholar] [CrossRef]

| Structure | Materials | d33 (pm/V) | References |

|---|---|---|---|

| WZ structure | ZnO | 14.3–26.7 (Nanobelt) | [36] |

| GaN | 12.4 (NW) | [23] | |

| GaAs | 26 (NW) | [45] | |

| CdS | 10.32 (Bulk) | [87] | |

| InN | 7.6 (Calculation) | [88] | |

| AlN | 5.4 (Calculation) | [88] | |

| Perovskite | PZT | 127 (Fiber) | [89] |

| PMN–PT | 50 (Nanofiber) | [39] | |

| 373 (NW) | [69] | ||

| LiNbO3 | 100 (NW) | [37] | |

| (K,Na)NbO3 | 180 (Nanorod) | [75] | |

| BaTiO3 | 45 (NW) | [54] | |

| Polymer | P(VDF–TrFe) | ~35 (NW) | [78,82] |

| 25–45 (NW) | [77] | ||

| PVDF | 6.5 (NW) | [81] | |

| ~10–20 (NW) | [80] | ||

| Nylon–11 | 3–12 (Films, d31) | [86] |

| Structure | Materials | Voutput (mV) | D (nm) | L (μm) | References | Forms of NGs |

|---|---|---|---|---|---|---|

| WZ | ZnO | ~6–9 (NW) | ~20–40 | 0.2–0.5 | [5] | AFM lateral bending: Single NW |

| ZnS | 2 (NW) | ~100 | ~2 | [62] | ||

| CdS | ~–3 (NW) | ~100 | >1 | [21] | ||

| InN | 60 (Nanocone) ~–1000 (NW) | ~200–400 25–100 | ~1 ~5 | [46] [22] | ||

| GaN | –300 (NW) 7 (Nanorod) | ~50 ~500 | ~3–4 ~5 | [47] [46] | ||

| CdTe | ~300 (MW) | 1000–2000 | 100–800 | [63] | Lateral packed single NW NG | |

| Perovskite | PZT | 1630 (Nanofibers) 700 (NWs) | 60 ~500 | 500 ~5 | [66] [67] | PDMS packed lateral PZT nanofibers Vertical PZT NW arrays |

| PMN–PT | 9 (NW) 7800 (NWs) | ~500 ~200–1000 | ~5 ~5–10 | [68] [70] | Lateral packed single NW NG NWs-PDMS composite | |

| NaNbO3 | 3200 (NWs) | ~200 | ~10 | [71] | NWs-PDMS composite | |

| ZnSnO3 | 100 (Nanobelt) | 100 | 1000 | [74] | Lateral packed single nanobelt NG | |

| Polymer | P(VDF–TrFe) | 3000 (NWs) 1500 (Nanofibers) | ~200 ~200 | ~60 | [82] [83] | Vertical NW arrays Highly aligned nanofiber arrays |

| Nylon–11 | 1000 (NWs) | ~200 | ~40-50 | [86] | Vertical NW arrays |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Sun, M.; Wei, X.; Shan, C.; Chen, Q. 1D Piezoelectric Material Based Nanogenerators: Methods, Materials and Property Optimization. Nanomaterials 2018, 8, 188. https://doi.org/10.3390/nano8040188

Li X, Sun M, Wei X, Shan C, Chen Q. 1D Piezoelectric Material Based Nanogenerators: Methods, Materials and Property Optimization. Nanomaterials. 2018; 8(4):188. https://doi.org/10.3390/nano8040188

Chicago/Turabian StyleLi, Xing, Mei Sun, Xianlong Wei, Chongxin Shan, and Qing Chen. 2018. "1D Piezoelectric Material Based Nanogenerators: Methods, Materials and Property Optimization" Nanomaterials 8, no. 4: 188. https://doi.org/10.3390/nano8040188

APA StyleLi, X., Sun, M., Wei, X., Shan, C., & Chen, Q. (2018). 1D Piezoelectric Material Based Nanogenerators: Methods, Materials and Property Optimization. Nanomaterials, 8(4), 188. https://doi.org/10.3390/nano8040188