Formation of Nanospikes on AISI 420 Martensitic Stainless Steel under Gallium Ion Bombardment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Procedure of FIB Treatment of Martensitic, Austenitic and Ferritic Stainless Steel Plates

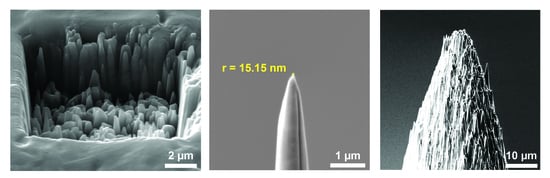

2.2. Procedure of Fabrication of Martensitic Stainless Steel Needle with Nanometer Sharpness

2.3. Procedure of Fabrication of Stainless Steel Microneedle with Nanospikes

3. Results

3.1. Nanospikes Formation on AISI 420 Martensitic Stainless Steels by FIB Treatment

3.2. Morphological Evolution of AISI 420 during FIB Treatment

3.3. Energy-Dispersive X-ray Spectroscopy (EDX) and X-ray Photoelectron Spectroscopy (XPS) Analysis of FIB Irradiated AISI 420 Stainless Steel Alloy with Gallium Ions

3.4. Effect from Variation of Incident Angle

3.5. Nanospiking Effect on Austenitic AISI 316, Ferritic AISI 430 and Martensitic AISI 431 during FIB Treatment

4. Discussion

5. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gupta, J.; Harper, J.M.E.; IV, J.M.; Blauner, P.G.; Smith, D.A. Focused ion beam imaging of grain growth in copper thin films. Appl. Phys. Lett. 1992, 61, 663–665. [Google Scholar] [CrossRef]

- Fujita, J.; Ishida, M.; Ichihashi, T.; Ochiai, Y.; Kaito, T.; Matsui, S. Growth of three-dimensional nano-structures using FIB-CVD and its mechanical properties. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2003, 206, 472–477. [Google Scholar] [CrossRef]

- Young, R.J. Micro-machining using a focused ion beam. Vacuum 1993, 44, 353–356. [Google Scholar] [CrossRef]

- Nagasaki, T.; Hirai, H.; Yoshino, M.; Yamada, T. Crystallographic orientation dependence of the sputtering yields of nickel and copper for 4-keV argon ions determined using polycrystalline targets. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 418, 34–40. [Google Scholar] [CrossRef]

- Lucille, A.; Giannuzzi, F.A.S. Introduction to Focused Ion Beams; Giannuzzi, L.A., Stevie, F.A., Eds.; Springer: Boston, MA, USA, 2005; ISBN 978-0-387-23116-7. [Google Scholar]

- Guu, Y.H.; Hocheng, H. Advanced Analysis of Nontraditional Machining; Hocheng, H., Tsai, H.Y., Eds.; Springer: New York, NY, USA, 2013; ISBN 978-1-4614-4053-6. [Google Scholar]

- Kempshall, B.W.; Schwarz, S.M.; Prenitzer, B.I.; Giannuzzi, L.A.; Irwin, R.B.; Stevie, F.A. Ion channeling effects on the focused ion beam milling of Cu. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2002, 19, 749. [Google Scholar] [CrossRef]

- Prenitzer, B.I.; Urbanik-Shannon, C.A.; Giannuzzi, L.A.; Brown, S.R.; Irwin, R.B.; Shofner, T.L.; Stevie, F.A. The Correlation between Ion Beam/Material Interactions and Practical FIB Specimen Preparation. Microsc. Microanal. 2003, 9, 216–236. [Google Scholar] [CrossRef] [Green Version]

- Ran, G.; Wu, S.; Liu, X.; Wu, J.; Li, N.; Zu, X.; Wang, L. The effect of crystal orientation on the behavior of a polycrystalline tungsten surface under focused Ga+ ion bombardment. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2012, 289, 39–42. [Google Scholar] [CrossRef]

- Wagner, A. X-ray mask repair with focused ion beams. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1990, 8, 1557. [Google Scholar] [CrossRef]

- Ran, G.; Liu, X.; Wu, J.; Li, N.; Zu, X.; Wang, L. In situ observation of surface morphology evolution in tungsten under focused Ga + ion irradiation. J. Nucl. Mater. 2012, 424, 146–152. [Google Scholar] [CrossRef]

- Ran, G.; Chen, N.; Qiang, R.; Wang, L.; Li, N.; Lian, J. Surface morphological evolution and nanoneedle formation of 18Cr-ODS steel by focused ion beam bombardment. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 356–357, 103–107. [Google Scholar] [CrossRef]

- Stewart, A.D.G.; Thompson, M.W. Microtopography of surfaces eroded by ion-bombardment. J. Mater. Sci. 1969, 4, 56–60. [Google Scholar] [CrossRef]

- Whitton, J.L.; Holck, O.; Carter, G.; Nobes, M.J. The crystallographic dependence of surface topographical features formed by energetic ion bombardment of copper. Nucl. Instrum. Methods 1980, 170, 371–375. [Google Scholar] [CrossRef]

- Whitton, J.L.; Tanović, L.; Williams, J.S. The production of regular pyramids on argon ion bombarded surfaces of copper crystals. Appl. Surf. Sci. 1978, 1, 408–413. [Google Scholar] [CrossRef]

- Auciello, O.; Kelly, R.; Iricibar, R. On the problem of the stability of pyramidal structures on bombarded copper surfaces. Radiat. Eff. 1979, 43, 37–42. [Google Scholar] [CrossRef]

- Kelly, R.; Auciello, O. On the origin of pyramids and cones on ion-bombarded copper surfaces. Surf. Sci. 1980, 100, 135–153. [Google Scholar] [CrossRef]

- Auciello, O. Critical Analysis on the Origin, Stability, Relative Sputtering Yield and Related Phenomena of Textured Surfaces Under Ion Bombardment. Radiat. Eff. 1982, 60, 1–26. [Google Scholar] [CrossRef]

- Cenev, Z.; Zhang, H.; Sariola, V.; Rahikkala, A.; Liu, D.; Santos, H.A.; Zhou, Q. Manipulating Superparamagnetic Microparticles with an Electromagnetic Needle. Adv. Mater. Technol. 2018, 3, 1700177. [Google Scholar] [CrossRef]

- Bionta, M.R.; Chalopin, B.; Champeaux, J.P.; Faure, S.; Masseboeuf, A.; Moretto-Capelle, P.; Chatel, B. Laser-induced electron emission from a tungsten nanotip: Identifying above threshold photoemission using energy-resolved laser power dependencies. J. Mod. Opt. 2014, 61, 833–838. [Google Scholar] [CrossRef]

- Bionta, M.R.; Chalopin, B.; Masseboeuf, A.; Chatel, B. First results on laser-induced field emission from a CNT-based nanotip. Ultramicroscopy 2015, 159, 152–155. [Google Scholar] [CrossRef]

- Slezak, B.R.; Lewandowski, C.W.; Hsu, J.F.; D’Urso, B. Cooling the motion of a silica microsphere in a magneto-gravitational trap in ultra-high vacuum. New J. Phys. 2018, 20, 063028. [Google Scholar] [CrossRef]

- Houlton, J.P.; Chen, M.L.; Brubaker, M.D.; Bertness, K.A.; Rogers, C.T. Axisymmetric scalable magneto-gravitational trap for diamagnetic particle levitation. Rev. Sci. Instrum. 2018, 89, 125107. [Google Scholar] [CrossRef] [PubMed]

- Baghjari, S.H.; AkbariMousavi, S.A.A. Experimental investigation on dissimilar pulsed Nd: YAG laser welding of AISI 420 stainless steel to kovar alloy. Mater. Des. 2014, 57, 128–134. [Google Scholar] [CrossRef]

- Khorram, A.; Davoodi Jamaloei, A.; Jafari, A.; Moradi, M. Nd:YAG laser surface hardening of AISI 431 stainless steel; mechanical and metallurgical investigation. Opt. Laser Technol. 2019, 119, 105617. [Google Scholar] [CrossRef]

- Long, Z.; Shetty, A.M.; Solomon, M.J.; Larson, R.G. Fundamentals of magnet-actuated droplet manipulation on an open hydrophobic surface. Lab Chip 2009, 9, 1567–1575. [Google Scholar] [CrossRef]

- Gao, N.; Geyer, F.; Pilat, D.W.; Wooh, S.; Vollmer, D.; Butt, H.J.; Berger, R. How drops start sliding over solid surfaces. Nat. Phys. 2018, 14, 191–196. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cenev, Z.; Bartenwerfer, M.; Klauser, W.; Jokinen, V.; Fatikow, S.; Zhou, Q. Formation of Nanospikes on AISI 420 Martensitic Stainless Steel under Gallium Ion Bombardment. Nanomaterials 2019, 9, 1492. https://doi.org/10.3390/nano9101492

Cenev Z, Bartenwerfer M, Klauser W, Jokinen V, Fatikow S, Zhou Q. Formation of Nanospikes on AISI 420 Martensitic Stainless Steel under Gallium Ion Bombardment. Nanomaterials. 2019; 9(10):1492. https://doi.org/10.3390/nano9101492

Chicago/Turabian StyleCenev, Zoran, Malte Bartenwerfer, Waldemar Klauser, Ville Jokinen, Sergej Fatikow, and Quan Zhou. 2019. "Formation of Nanospikes on AISI 420 Martensitic Stainless Steel under Gallium Ion Bombardment" Nanomaterials 9, no. 10: 1492. https://doi.org/10.3390/nano9101492

APA StyleCenev, Z., Bartenwerfer, M., Klauser, W., Jokinen, V., Fatikow, S., & Zhou, Q. (2019). Formation of Nanospikes on AISI 420 Martensitic Stainless Steel under Gallium Ion Bombardment. Nanomaterials, 9(10), 1492. https://doi.org/10.3390/nano9101492