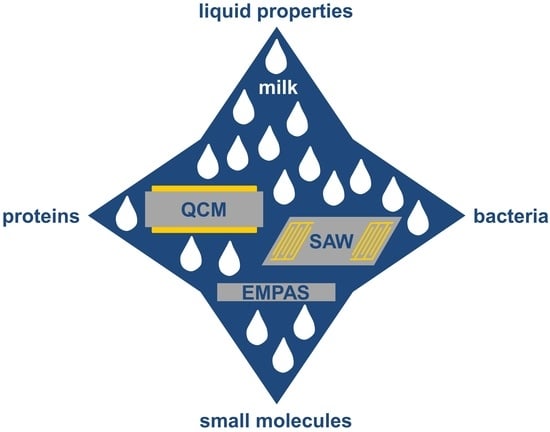

Bulk and Surface Acoustic Wave Biosensors for Milk Analysis †

Abstract

:1. Introduction

2. Acoustic Wave Biosensors for Measurements in Milk Samples

2.1. Bulk and Surface Acoustic Wave Sensor Devices for Use in Liquid Applications

2.2. Measuring with BAW and SAW Sensors

2.3. Testing Milk Samples with BAW and SAW Biosensors

2.3.1. Capture Molecules

2.3.2. Biosensor Test Formats

2.3.3. Dealing with the Milk Sample Matrix

3. Application of BAW and SAW Sensors and Biosensors in Milk Measurements

3.1. Coagulation Monitoring—Measurements of Physical Liquid Parameters

3.2. Determination of Fat Content

3.3. Detection of Proteins in Milk

3.4. Detection of Low-Molecular-Weight Compounds in Milk

3.5. Determination of Bacteria in Milk

3.6. BAW and SAW Biosensor Performance Compared with Standard Methods

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Töpel, A. Chemie und Physik der Milch, 4th ed.; B. Behr’s Verlag: Hamburg, Germany, 2016. [Google Scholar]

- Nielsen, S.S. Food Analysis, 5th ed.; Springer International Publishing AG: Cham, Switzerland, 2021. [Google Scholar]

- Smirnova, A.; Konoplev, G.; Mukhin, N.; Stepanova, O.; Steinmann, U. Milk as a complex multiphase polydisperse system: Approaches for the quantitative and qualitative analysis. J. Compos. Sci. 2020, 4, 151. [Google Scholar] [CrossRef]

- Kunes, R.; Bartos, P.; Iwasaka, G.K.; Lang, A.; Hankovec, T.; Smutny, L.; Cerny, P.; Poborska, A.; Smetana, P.; Kriz, P.; et al. In-line technologies for the analysis of important milk parameters during the milking process: A review. Agriculture 2021, 11, 239. [Google Scholar] [CrossRef]

- Hebling e Tavares, J.P.; da Silva Medeiros, M.L.; Barbin, D.F. Near-infrared techniques for fraud detection in dairy products: A review. J. Food Sci. 2022, 87, 1943–1960. [Google Scholar] [CrossRef] [PubMed]

- Motshakeri, M.; Sharma, M.; Phillips, A.R.J.; Kilmartin, P.A. Electrochemical methods for the analysis of milk. J. Agric. Food Chem. 2022, 70, 2427–2449. [Google Scholar] [CrossRef] [PubMed]

- Farag, M.A.; Tanios, M.; AlKarimy, S.; Ibrahim, H.; Guirguis, H.A. Biosensing approaches to detect potential milk contaminants: A comprehensive review. Food Addit. Contam. Part A Chem. 2021, 38, 1169–1192. [Google Scholar] [CrossRef]

- Wang, R.N.; Wang, L.L.; Yan, J.; Luan, D.L.; Sun, T.; Wu, J.K.; Bian, X.J. Rapid, sensitive and label-free detection of pathogenic bacteria using a bacteria-imprinted conducting polymer film-based electrochemical sensor. Talanta 2021, 226, 122135. [Google Scholar] [CrossRef]

- Conzuelo, F.; Gamella, M.; Campuzano, S.; Pinacho, D.G.; Reviejo, A.J.; Marco, M.P.; Pingarrón, J.M. Disposable and integrated amperometric immunosensor for direct determination of sulfonamide antibiotics in milk. Biosens. Bioelectron. 2012, 36, 81–88. [Google Scholar] [CrossRef]

- Rau, S.; Hilbig, U.; Gauglitz, G. Label-free optical biosensor for detection and quantification of the non-steroidal anti-inflammatory drug diclofenac in milk without any sample pretreatment. Anal. Bioanal. Chem. 2014, 406, 3377–3386. [Google Scholar] [CrossRef]

- Indyk, H.E.; Chetikam, S.; Gill, B.D.; Wood, J.E.; Woollard, D.C. Development and application of an optical biosensor immunoassay for aflatoxin M-1 in bovine milk. Food Anal. Methods 2019, 12, 2630–2637. [Google Scholar] [CrossRef]

- Crosson, C.; Rossi, C. Quartz crystal microbalance immunosensor for the quantification of immunoglobulin G in bovine milk. Biosens. Bioelectron. 2013, 42, 453–459. [Google Scholar] [CrossRef]

- Gruhl, F.J.; Länge, K. Surface acoustic wave (SAW) biosensor for rapid and label-free detection of penicillin G in milk. Food Anal. Methods 2014, 7, 430–437. [Google Scholar] [CrossRef]

- Cole, M.; Sehra, G.; Gardner, J.W.; Varadan, V.K. Development of smart tongue devices for measurement of liquid properties. IEEE Sens. J. 2004, 4, 543–550. [Google Scholar] [CrossRef]

- Gruhl, F.J.; Rapp, B.E.; Länge, K. Biosensors for diagnostic applications. Adv. Biochem. Eng. Biotechnol. 2013, 133, 115–148. [Google Scholar] [PubMed]

- Puiu, M.; Bala, C. Microfluidics-integrated biosensing platforms as emergency tools for on-site field detection of foodborne pathogens. Trac. Trends Anal. Chem. 2020, 125, 115831. [Google Scholar] [CrossRef]

- Hohmann, S.; Kögel, S.; Brunner, Y.; Schmieg, B.; Ewald, C.; Kirschhöfer, F.; Brenner-Weiß, G.; Länge, K. Surface acoustic wave (SAW) resonators for monitoring conditioning film formation. Sensors 2015, 15, 11873–11888. [Google Scholar] [CrossRef] [PubMed]

- Mujahid, A.; Afzal, A.; Dickert, F.L. An overview of high frequency acoustic sensors-QCMs, SAWs and FBARs-chemical and biochemical applications. Sensors 2019, 19, 4395. [Google Scholar] [CrossRef]

- Länge, K. Bulk and surface acoustic wave sensor arrays for multi-analyte detection: A review. Sensors 2019, 19, 5382. [Google Scholar] [CrossRef]

- Rocha-Gaso, M.I.; March-Iborra, C.; Montoya-Baides, A.; Arnau-Vives, A. Surface generated acoustic wave biosensors for the detection of pathogens: A review. Sensors 2009, 9, 5740–5769. [Google Scholar] [CrossRef]

- Alder, J.F.; McCallum, J.J. Piezoelectric crystals for mass and chemical measurements—A review. Analyst 1983, 108, 1169–1189. [Google Scholar] [CrossRef]

- Electronic Notes. Quartz Crystal Resonator Timeline & History. Available online: https://www.electronics-notes.com/articles/history/electronic-components/quartz-crystal-resonator-timeline-history.php (accessed on 15 July 2022).

- White, R.M.; Voltmer, F.W. Direct piezoelectric coupling to surface elastic waves. Appl. Phys. Lett. 1965, 7, 314–316. [Google Scholar] [CrossRef]

- Morgan, D.P. History of SAW devices. In Proceedings of the IEEE International Frequency Control Symposium, Pasadena, CA, USA, 27–29 May 1998. [Google Scholar]

- Länge, K.; Rapp, B.E.; Rapp, M. Surface acoustic wave biosensors: A review. Anal. Bioanal. Chem. 2008, 391, 1509–1519. [Google Scholar] [CrossRef]

- Sauerbrey, G. Verwendung von Schwingquarzen zur Wägung dünner Schichten und zur Mikrowägung. Z. Phys. 1959, 155, 206–222. [Google Scholar] [CrossRef]

- Songkhla, S.N.; Nakamoto, T. Overview of quartz crystal microbalance behavior analysis and measurement. Chemosensors 2021, 9, 350. [Google Scholar] [CrossRef]

- King, W.H. Piezoelectric sorption detector. Anal. Chem. 1964, 36, 1735–1739. [Google Scholar] [CrossRef]

- Shons, A.; Najarian, J.; Dorman, F. An immunospecific microbalance. J. Biomed. Mater. Res. 1972, 6, 565–570. [Google Scholar] [CrossRef] [PubMed]

- O’Sullivan, C.K.; Vaughan, R.; Guilbault, G.G. Piezoelectric immunosensors—Theory and applications. Anal. Lett. 1999, 32, 2353–2377. [Google Scholar] [CrossRef]

- Wohltjen, H.; Dessy, R. Surface acoustic wave probes for chemical analysis II. Gas chromatography detector. Anal. Chem. 1979, 51, 1465–1470. [Google Scholar] [CrossRef]

- Cheeke, J.D.N. Fundamentals and Applications of Ultrasonic Waves, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Tuantranont, A.; Wisitsora-at, A.; Sritongkham, P.; Jaruwongrungsee, K. A review of monolithic multichannel quartz crystal microbalance: A review. Anal. Chim. Acta 2011, 687, 114–128. [Google Scholar] [CrossRef]

- Dizon, M.; Tatarko, M.; Hianik, T. Advances in analysis of milk proteases activity at surfaces and in a volume by acoustic methods. Sensors 2020, 20, 5594. [Google Scholar] [CrossRef]

- Thompson, M.; Ballantyne, S.M.; Cheran, L.E.; Stevenson, A.C.; Lowe, C.R. Electromagnetic excitation of high frequency acoustic waves and detection in the liquid phase. Analyst 2003, 128, 1048–1055. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, J.K.; Flewitt, A.J.; Cai, Z.Q.; Zhao, X.B. Film bulk acoustic resonators (FBARs) as biosensors: A review. Biosens. Bioelectron. 2018, 116, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.Q.; Luo, J.K.; Nguyen, N.T.; Walton, A.J.; Flewitt, A.J.; Zu, X.T.; Li, Y.; McHale, G.; Matthews, A.; Iborra, E.; et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 2017, 89, 31–91. [Google Scholar] [CrossRef]

- Mandal, D.; Banerjee, S. Surface acoustic wave (SAW) sensors: Physics, materials, and applications. Sensors 2022, 22, 820. [Google Scholar] [CrossRef]

- McHale, G.; Newton, M.I.; Banerjee, M.K.; Cowen, J.A. Acoustic wave-liquid interactions. Mater. Sci. Eng. C-Biomim. Supramol. Syst. 2000, 12, 17–22. [Google Scholar] [CrossRef]

- McHale, G.; Lucklum, R.; Newton, M.I.; Cowen, J.A. Influence of viscoelasticity and interfacial slip on acoustic wave sensors. J. Appl. Phys. 2000, 88, 7304–7312. [Google Scholar] [CrossRef]

- Weiss, M.; Welsch, W.; Von Schickfus, M.; Hunklinger, S. Viscoelastic behavior of antibody films on a shear horizontal acoustic surface wave sensor. Anal. Chem. 1998, 70, 2881–2887. [Google Scholar] [CrossRef] [PubMed]

- Länge, K.; Rapp, M. Influence of intermediate hydrogel layer and amount of binding sites on the signal response of surface acoustic wave biosensors. Sens. Actuators B Chem. 2009, 142, 39–43. [Google Scholar] [CrossRef]

- Nomura, T.; Saitoh, A.; Horikoshi, Y. Measurement of acoustic properties of liquid using liquid flow SH-SAW sensor system. Sens. Actuators B Chem. 2001, 76, 69–73. [Google Scholar] [CrossRef]

- Mensah-Brown, A.K.; Wenzel, M.J.; Josse, F.J.; Yaz, E.E. Near real-time monitoring of organophosphate pesticides in the aqueous-phase using SH-SAW sensors including estimation-based signal analysis. IEEE Sens. J. 2009, 9, 1817–1824. [Google Scholar] [CrossRef]

- Hossenlopp, J.M. Applications of acoustic wave devices for sensing in liquid environments. Appl. Spectrosc. Rev. 2006, 41, 151–164. [Google Scholar] [CrossRef]

- Voglhuber-Brunnmaier, T.; Jakoby, B. Electromechanical resonators for sensing fluid density and viscosity—A review. Meas. Sci. Technol. 2022, 33, 12001. [Google Scholar] [CrossRef]

- Rodahl, M.; Höök, F.; Kasemo, B. QCM operation in liquids: An explanation of measured variations in frequency and Q factor with liquid conductivity. Anal. Chem. 1996, 68, 2219–2227. [Google Scholar] [CrossRef] [PubMed]

- Hunt, W.D.; Stubbs, D.D.; Lee, S.H. Time-dependent signatures of acoustic wave biosensors. Proc. IEEE 2003, 91, 890–901. [Google Scholar] [CrossRef]

- Kustanovic, K.; Yantchev, V.; Doosti, B.A.; Gözen, I.; Jesorka, A. A microfluidics-integrated impedance/surface acoustic resonance tandem sensor. Sens. Bio-Sens. Res. 2019, 25, 100291. [Google Scholar] [CrossRef]

- Conroy, P.J.; Hearty, S.; Leonard, P.; O’Kennedy, R.J. Antibody production, design and use for biosensor-based applications. Semin. Cell Dev. Biol. 2009, 20, 10–26. [Google Scholar] [CrossRef]

- Sharma, S.; Byrne, H.; O’Kennedy, R.J. Antibodies and antibody-derived analytical biosensors. Essays Biochem. 2016, 60, 9–18. [Google Scholar]

- Crivianu-Gaita, V.; Thompson, M. Aptamers, antibody scFv, and antibody Fab’ fragments: An overview and comparison of three of the most versatile biosensor biorecognition elements. Biosens. Bioelectron. 2016, 85, 32–45. [Google Scholar] [CrossRef]

- Toh, S.Y.; Citartan, M.; Gopinath, S.C.B.; Tang, T.H. Aptamers as a replacement for antibodies in enzyme-linked immunosorbent assay. Biosens. Bioelectron. 2015, 64, 392–403. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, H.G.; Yin, J.Q.; Guo, Q.; Zhang, Y.H.; Sun, X.; Guo, Y.M.; Yang, Q.Q.; Li, F.L.; Zhang, Y.Y. Recent Advances and Future Prospects of Aptamer-based Biosensors in Food Safety Analysis. Int. J. Electrochem. Sci. 2022, 17, 22019. [Google Scholar] [CrossRef]

- Jolly, P.; Estrela, P.; Ladomery, M. Oligonucleotide-based systems: DNA, microRNAs, DNA/RNA aptamers. Essays Biochem. 2016, 60, 27–35. [Google Scholar]

- Lowdon, J.W.; Diliën, H.; Singla, P.; Peeters, M.; Cleij, T.J.; van Grinsven, B.; Eersels, K. MIPs for commercial application in low-cost sensors and assays—An overview of the current status quo. Sens. Actuators B Chem. 2020, 325, 128973. [Google Scholar] [CrossRef] [PubMed]

- Ali, G.K.; Omer, K.M. Molecular imprinted polymer combined with aptamer (MIP-aptamer) as a hybrid dual recognition element for bio(chemical) sensing applications. Review. Talanta 2022, 236, 122878. [Google Scholar] [CrossRef] [PubMed]

- Ermolaeva, T.; Kalmykova, E. Capabilities of piezoelectric immunosensors for detecting infections and for early clinical diagnostics. In Advances in Immunoassay Technology, 1st ed.; Chiu, N.H.L., Christopulos, T.K., Eds.; Intech: Rijeka, Croatia, 2012; pp. 81–108. [Google Scholar]

- Pan, B.; Blake, D.A. Recombinant antibodies and non-antibody scaffolds for immunoassays. In Advances in Immunoassay Technology, 1st ed.; Chiu, N.H.L., Christopulos, T.K., Eds.; Intech: Rijeka, Croatia, 2012; pp. 3–22. [Google Scholar]

- Crowther, J.R. The ELISA Guidebook, 1st ed.; Humana Press: Totowa, NJ, USA, 2001. [Google Scholar]

- Lichtenberg, J.Y.; Ling, Y.; Kim, S. Non-specific adsorption reduction methods in biosensing. Sensors 2019, 19, 2488. [Google Scholar] [CrossRef] [PubMed]

- Sheikh, S.; Yang, D.Y.; Blaszykowski, C.; Thompson, M. Single ether group in a glycol-based ultra-thin layer prevents surface fouling from undiluted serum. Chem. Commun. 2012, 48, 1305–1307. [Google Scholar] [CrossRef]

- Dacres, H.; Wang, J.; Anderson, A.; Trowell, S.C. A rapid and sensitive biosensor for measuring plasmin activity in milk. Sens. Actuators B Chem. 2019, 301, 127141. [Google Scholar] [CrossRef]

- Post, A.E.; Arnold, B.; Weiss, J.; Hinrichs, J. Effect of temperature and pH on the solubility of caseins: Environmental influences on the dissociation of alpha(S)- and beta-casein. J. Dairy Sci. 2012, 95, 1603–1616. [Google Scholar] [CrossRef]

- Huellemeier, H.A.; Eren, N.M.; Ortega-Anaya, J.; Jimenez-Flores, R.; Heldman, D.R. Application of quartz crystal microbalance with dissipation (QCM-D) to study low-temperature adsorption and fouling of milk fractions on stainless steel. Chem. Eng. Sci. 2022, 247, 117004. [Google Scholar] [CrossRef]

- Qie, Z.W.; Huang, Z.W.; Gao, Z.C.; Meng, W.; Zhu, Y.H.; Xiao, R.; Wang, S.Q. Pretreatment-integration for milk protein removal and device-facilitated immunochromatographic assay for 17 items. Sci Rep 2019, 9, 11630. [Google Scholar] [CrossRef]

- Brignon, G.; Chtourou, A.; Ribadeaudumas, B. Contamination of human whole casein by whey proteins—Quantitative aspects. Lait 1984, 64, 537–543. [Google Scholar] [CrossRef]

- Kudryashov, E.D.; Hunt, N.T.; Arikainen, E.O.; Buckin, V.A. Monitoring of acidified milk gel formation by ultrasonic shear wave measurements. High-frequency viscoelastic moduli of milk and acidified milk gel. J. Dairy Sci. 2001, 84, 375–388. [Google Scholar] [CrossRef]

- Pais, V.F.; Veríssimo, M.I.S.; Oliveira, J.A.B.P.; Gomes, M.T.S.R. Using acoustic wave sensors to follow milk coagulation and to separate the cheeses according to the milk. Sens. Actuators B Chem. 2015, 207, 1121–1128. [Google Scholar] [CrossRef]

- Sengenuity (a Division of Vectron International). ViSmartTM Low Shear Bolt Viscosity Sensor Manual, Revision A, Revision Date: 19 May 2009. Available online: https://archive-resources.coleparmer.com/Manual_pdfs/98946-00%20-01%20Manual_A.pdf (accessed on 10 June 2022).

- Sengenuity (a Division of Vectron International). ViSmartTM Low Shear Bolt Viscosity Sensor VS-2000, VS-2500, VS-2600 Series Datasheet, Rev. 06/02/2014. Available online: https://www.electronicsdatasheets.com/download/53f5f6a1e34e24ae51d9838d.pdf?format=pdf (accessed on 10 June 2022).

- Electronica. Vectron International Announces ViSmart(R) Viscosity Sensor for Aqueous and Solvent Based Ink Measurement and Control. 2012. Available online: https://www.businesswire.com/news/home/20121113007513/en/Vectron-International-Announces-ViSmart%C2%AE-Viscosity-Sensor-for-Aqueous-and-Solvent-Based-Ink-Measurement-and-Control (accessed on 10 June 2022).

- Fritze, H. High-temperature bulk acoustic wave sensors. Meas. Sci. Technol. 2011, 22, 012002. [Google Scholar] [CrossRef]

- Pu, Y.Y.; O’Shea, N.; Hogan, S.A.; Tobin, J.T. Assessment of a solid-state bulk acoustic wave sensor to measure viscosity of Newtonian and Non-Newtonian fluids under static and flow conditions. J. Food Eng. 2020, 277, 109917. [Google Scholar] [CrossRef]

- Xu, G.Y.; Pu, Y.Y.; Hogan, S.A.; Kennedy, D.; O’Donnell, C.; O’Shea, N. Potential of bulk acoustic wave (BAW) process analytical technology to monitor acid-induced skim milk coagulation. Measurement 2022, 188, 110599. [Google Scholar] [CrossRef]

- Schöck, N.; Weber, T.; Länge, K. Surface acoustic wave resonators for milk analysis. Eng. Proc. 2022, accepted. [Google Scholar]

- Manganiello, L.; Ríos, A.; Valcárcel, M.; Ligero, A.; Tena, T. Automatic determination of fat in milk by use of a flow injection system with a piezoelectric detector. Anal. Chim. Acta 2000, 406, 309–315. [Google Scholar] [CrossRef]

- Manganiello, L.; Ríos, A.; Valcárcel, M. Automatic microgravimetric determination of fats in milk products by use of supercritical fluid extraction with on-line piezoelectric detection. J. Chromatogr. A 2000, 874, 265–274. [Google Scholar] [CrossRef]

- Guo, J.P.; Fang, G.Z.; Wang, S.; Wang, J.P. Quartz crystal microbalance sensor based on 11-mercaptoundecanoic acid self-assembly and amidated nano-titanium film for selective and ultrafast detection of phosphoproteins in food. Food Chem. 2021, 344, 128656. [Google Scholar] [CrossRef]

- Poturnayova, A.; Karpisova, I.; Castillo, G.; Mező, G.; Kocsis, L.; Csámpai, A.; Keresztes, Z.; Hianik, T. Detection of plasmin based on specific peptide substrate using acoustic transducer. Sens. Actuators B Chem. 2016, 223, 591–598. [Google Scholar] [CrossRef]

- Poturnayova, A.; Szabo, K.; Tatarko, M.; Hucker, A.; Kocsis, R.; Hianik, T. Determination of plasmin in milk using QCM and ELISA methods. Food Control 2021, 123, 107774. [Google Scholar] [CrossRef]

- Salmain, M.; Ghasemi, M.; Boujday, S.; Pradier, C.M. Elaboration of a reusable immunosensor for the detection of staphylococcal enterotoxin A (SEA) in milk with a quartz crystal microbalance. Sens. Actuators B Chem. 2012, 173, 148–156. [Google Scholar] [CrossRef]

- Karaseva, N.; Ermolaeva, T. A regenerable piezoelectric immunosensor on the basis of electropolymerized polypyrrole for highly selective detection of staphylococcal enterotoxin A in foodstuffs. Microchim. Acta 2015, 182, 1329–1335. [Google Scholar] [CrossRef]

- Liu, N.; Li, X.L.; Ma, X.H.; Ou, G.R.; Gao, Z.X. Rapid and multiple detections of staphylococcal enterotoxins by two-dimensional molecularly imprinted film-coated QCM sensor. Sens. Actuators B Chem. 2014, 191, 326–331. [Google Scholar] [CrossRef]

- Lin, H.C.; Tsai, W.C. Piezoelectric crystal immunosensor for the detection of staphylococcal enterotoxin B. Biosens. Bioelectron. 2003, 18, 1479–1483. [Google Scholar] [CrossRef]

- Ebarvia, B.S.; Ubando, I.E.; Sevilla, F.B. Biomimetic piezoelectric quartz crystal sensor with chloramphenicol-imprinted polymer sensing layer. Talanta 2015, 144, 1260–1265. [Google Scholar] [CrossRef]

- Shinko, E.I.; Farafonova, O.V.; Shanin, I.A.; Eremin, S.A.; Ermolaeva, T.N. Determination of the fluoroquinolones levofloxacin and ciprofloxacin by a piezoelectric immunosensor modified with multiwalled carbon nanotubes (MWCNTs). Anal. Lett. 2022, 55, 1164–1177. [Google Scholar] [CrossRef]

- Liu, N.; Han, J.G.; Liu, Z.; Qu, L.J.; Gao, Z.X. Rapid detection of endosulfan by a molecularly imprinted polymer microsphere modified quartz crystal microbalance. Anal. Methods 2013, 5, 4442–4447. [Google Scholar] [CrossRef]

- Pan, M.F.; Gu, Y.; Zhang, M.Y.; Wang, J.P.; Yun, Y.G.; Wang, S. Reproducible molecularly imprinted QCM sensor for accurate, stable, and sensitive detection of enrofloxacin residue in animal-derived foods. Food Anal. Methods 2018, 11, 495–503. [Google Scholar] [CrossRef]

- Gültekin, A.; Celep, G.K.; Say, R. Gadolinium chelate monomer based memories onto QCM electrodes for folic acid detection in commercial follow-on baby milk. J. Food Meas. Charact. 2018, 12, 2892–2898. [Google Scholar] [CrossRef]

- Zeilinger, M.; Sussitz, H.; Cuypers, W.; Jungmann, C.; Lieberzeit, P. Mass-sensitive sensing of melamine in dairy products with molecularly imprinted polymers: Matrix challenges. Sensors 2019, 19, 2366. [Google Scholar] [CrossRef]

- Cömert, S.C.; Özgür, E.; Uzun, L.; Odabașı, M. The creation of selective imprinted cavities on quartz crystal microbalance electrode for the detection of melamine in milk sample. Food Chem. 2022, 372, 131254. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.L.; He, Y.; Wang, Y.N.; Wang, S.; Wang, J.P. Hollow molecularly imprinted polymer based quartz crystal microbalance sensor for rapid detection of methimazole in food samples. Food Chem. 2020, 309, 125787. [Google Scholar] [CrossRef] [PubMed]

- Yola, M.L.; Uzun, L.; Özaltın, N.; Denizli, A. Development of molecular imprinted nanosensor for determination of tobramycin in pharmaceuticals and foods. Talanta 2014, 120, 318–324. [Google Scholar] [CrossRef] [PubMed]

- Karaseva, N.A.; Ermolaeva, T.N. Piezoelectric immunosensors for the detection of individual antibiotics and the total content of penicillin antibiotics in foodstuffs. Talanta 2014, 120, 312–317. [Google Scholar] [CrossRef]

- Karaseva, N.A.; Ermolaeva, T.N. A piezoelectric immunosensor for chloramphenicol detection in food. Talanta 2012, 93, 44–48. [Google Scholar] [CrossRef]

- Liu, S.M.; Liu, X.Y.; Pan, Q.W.; Dai, Z.H.; Pan, M.F.; Wang, S. A portable, label-free, reproducible quartz crystal microbalance immunochip for the detection of zearalenone in food samples. Biosensors 2021, 11, 53. [Google Scholar] [CrossRef]

- Liu, X.Y.; Hu, Y.W.; Sheng, X.; Peng, Y.; Bai, J.L.; Lv, Q.J.; Jia, H.; Jiang, H.C.; Gao, Z.X. Rapid high-throughput detection of diethylstilbestrol by using the arrayed langasite crystal microbalance combined with gold nanoparticles through competitive immunoassay. Sens. Actuators B Chem. 2017, 247, 245–253. [Google Scholar] [CrossRef]

- Jin, X.Y.; Jin, X.F.; Chen, L.G.; Jiang, J.H.; Shen, G.L.; Yu, R.Q. Piezoelectric immunosensor with gold nanoparticles enhanced competitive immunoreaction technique for quantification of aflatoxin B-1. Biosens. Bioelectron. 2009, 24, 2580–2585. [Google Scholar] [CrossRef]

- Jin, X.F.; Jin, X.Y.; Liu, X.P.; Chen, L.G.; Jiang, J.H.; Shen, G.L.; Yu, R.Q. Biocatalyzed deposition amplification for detection of aflatoxin B-1 based on quartz crystal microbalance. Anal. Chim. Acta 2009, 645, 92–97. [Google Scholar] [CrossRef]

- Netherlands Chamber of Commerce and Trade. Antibioticsfinder. Available online: https://www.antibioticsfinder.com/antibioticsfinder (accessed on 10 June 2022).

- Codex Alimentarius Commission; Food and Agriculture Organization of the United Nations; World Health Organization. International Food Standards. Available online: https://www.fao.org/fao-who-codexalimentarius/codex-texts/dbs/en/ (accessed on 10 June 2022).

- Boison, J. Analysis of antithyroid drug residues in food animals. Bioanalysis 2012, 4, 2067–2083. [Google Scholar] [CrossRef]

- Food and Drug Administration. Bad Bug Book, Foodborne Pathogenic Microorganisms and Natural Toxins, 2nd ed.2012. Available online: https://www.fda.gov/media/83271/download (accessed on 22 June 2022).

- Pohanka, M. Current trends in the biosensors for biological warfare agents assay. Materials 2019, 12, 2303. [Google Scholar] [CrossRef] [PubMed]

- Szalontai, H.; Adányi, N.; Kiss, A. Development of piezoelectric immunosensor for the detection of probiotic bacteria. Anal. Lett. 2012, 45, 1214–1229. [Google Scholar] [CrossRef]

- Institute of Medicine (US) and National Research Council (US) Committee on the Review of the Use of Scientific Criteria and Performance Standards for Safe Food. Scientific Criteria to Ensure Safe Food; National Academies Press: Washington, DC, USA, 2003. [Google Scholar]

- Plata, M.R.; Contento, A.M.; Ríos, A. Simplified determination of bacterial contamination by Escherichia coli using a flow injection system with piezoelectric detection. Microchim. Acta 2011, 172, 447–454. [Google Scholar] [CrossRef]

- Han, H.C.; Chang, Y.R.; Hsu, W.L.; Chen, C.Y. Application of parylene-coated quartz crystal microbalance for on-line real-time detection of microbial populations. Biosens. Bioelectron. 2009, 24, 1543–1549. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.; Park, I.S. Application of a flow-type antibody sensor to the detection of Escherichia coli in various foods. Biosens. Bioelectron. 2003, 18, 1101–1107. [Google Scholar] [CrossRef]

- Pohanka, M.; Skládal, P. Piezoelectric immunosensor for the direct and rapid detection of Francisella tularensis. Folia Microbiol. 2007, 52, 325–330. [Google Scholar] [CrossRef] [PubMed]

- Park, I.S.; Kim, W.Y.; Kim, N. Operational characteristics of an antibody-immobilized QCM system detecting Salmonella spp. Biosens. Bioelectron. 2000, 15, 167–172. [Google Scholar] [CrossRef]

- Minunni, M.; Mascini, M.; Carter, R.M.; Jacobs, M.B.; Lubrano, G.J.; Guilbault, G.G. A quartz crystal microbalance displacement assay for Listeria monocytogenes. Anal. Chim. Acta 1996, 325, 169–174. [Google Scholar] [CrossRef]

- Hou, K.J.; Zhao, P.S.; Chen, Y.R.; Li, G.P.; Lin, Y.; Chen, D.J.; Zhu, D.; Wu, Z.Z.; Lian, D.C.; Huang, X.J.; et al. Rapid detection of Bifidobacterium bifidum in feces sample by highly sensitive quartz crystal microbalance immunosensor. Front. Chem. 2020, 8, 548. [Google Scholar] [CrossRef]

- Spagnolo, S.; de la Franier, B.; Davoudian, K.; Hianik, T.; Thompson, M. Detection of E. coli bacteria in milk by an acoustic wave aptasensor with an anti-fouling coating. Sensors 2022, 22, 1853. [Google Scholar] [CrossRef]

- Bayramoglu, G.; Ozalp, V.C.; Oztekin, M.; Arica, M.Y. Rapid and label-free detection of Brucella melitensis in milk and milk products using an aptasensor. Talanta 2019, 200, 263–271. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.Q.; Wang, J.F.; Qiu, Z.G.; Jin, M.; Wang, X.W.; Chen, Z.L.; Li, J.W.; Cao, F.H. QCM immunosensor detection of Escherichia coli O157:H7 based on beacon immunomagnetic nanoparticles and catalytic growth of colloidal gold. Biosens. Bioelectron. 2011, 26, 3376–3381. [Google Scholar] [CrossRef] [PubMed]

- Bonaiuto, E.; Magro, M.; Fasolato, L.; Novelli, E.; Shams, S.; Piccirillo, A.; Bakhshi, B.; Moghadam, T.T.; Baratella, D.; Vianello, F. Versatile nano-platform for tailored immuno-magnetic carriers. Anal. Bioanal. Chem. 2018, 410, 7575–7589. [Google Scholar] [CrossRef]

- Ozalp, V.C.; Bayramoglu, G.; Erdem, Z.; Arica, M.Y. Pathogen detection in complex samples by quartz crystal microbalance sensor coupled to aptamer functionalized core-shell type magnetic separation. Anal. Chim. Acta 2015, 853, 533–540. [Google Scholar] [CrossRef]

- Chen, S.H.; Wu, V.C.H.; Chuang, Y.C.; Lin, C.S. Using oligonucleotide-functionalized Au nanoparticles to rapidly detect foodborne pathogens on a piezoelectric biosensor. J. Microbiol. Methods 2008, 73, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Papadakis, G.; Murasova, P.; Hamiot, A.; Tsougeni, K.; Kaprou, G.; Eck, M.; Rabus, D.; Bilkova, Z.; Dupuy, B.; Jobst, G.; et al. Micro-nano-bio acoustic system for the detection of foodborne pathogens in real samples. Biosens. Bioelectron. 2018, 111, 52–58. [Google Scholar] [CrossRef]

- Tsougeni, K.; Kaprou, G.; Loukas, C.M.; Papadakis, G.; Hamiot, A.; Eck, M.; Rabus, D.; Kokkoris, G.; Chatzandroulis, S.; Papadopoulos, V.; et al. Lab-on-Chip platform and protocol for rapid foodborne pathogen detection comprising on-chip cell capture, lysis, DNA amplification and surface-acoustic-wave detection. Sens. Actuators B Chem. 2020, 320, 128345. [Google Scholar] [CrossRef]

- Sakhraoui, H.E.E.; Mazouz, Z.; Attia, G.; Fourati, N.; Zerrouki, C.; Maouche, N.; Othmane, A.; Yaakoubi, N.; Kalfat, R.; Madani, A.; et al. Design of L-cysteine and acrylic acid imprinted polypyrrole sensors for picomolar detection of lead ions in simple and real media. IEEE Sens. J. 2020, 20, 4147–4155. [Google Scholar] [CrossRef]

- Fertier, L.; Rolland, M.; Thami, T.; Persin, M.; Zimmermann, C.; Lachaud, J.L.; Rebière, D.; Déjous, C.; Bêche, E.; Cretin, M. Synthesis and grafting of a thiourea-based chelating agent on SH-SAW transducers for the preparation of thin films sensitive to heavy metals. Mater. Sci. Eng. C-Biomim. Supramol. Syst. 2009, 29, 823–830. [Google Scholar] [CrossRef]

- Gammoudi, I.; Blanc, L.; Moroté, F.; Grauby-Heywang, C.; Boissière, C.; Kalfat, R.; Rebière, D.; Cohen-Bouhacina, T.; Dejous, C. High sensitive mesoporous TiO2-coated love wave device for heavy metal detection. Biosens. Bioelectron. 2014, 57, 162–170. [Google Scholar] [CrossRef]

- r-biopharm®. RIDASCREEN® Set A, B, C, D, E; Art. No. R4101: Enzyme Immunoassay for Identification of Staphylococcus Enterotoxins A, B, C, D and E in Food and Bacterial Cultures. Available online: https://food.r-biopharm.com/products/ridascreen-set-abcde/ (accessed on 26 July 2022).

- Zhang, S.Y.; Garcia-D’Angeli, A.; Brennan, J.P.; Huo, Q. Predicting detection limits of enzyme-linked immunosorbent assay (ELISA) and bioanalytical techniques in general. Analyst 2014, 139, 439–445. [Google Scholar] [CrossRef] [PubMed]

- Luburić, D.B.; Bilandžić, N.; Varenina, I.; Varga, I.; Kolanović, B.S.; Vratarić, D.; Redovniković, I.R. The analysis of acidic and basic non-steroidal anti-inflammatory drugs in milk and muscle samples: A comprehensive analytical approach using UHPLC-MS/MS. Food Addit. Contam. Part A Chem. 2022, 39, 256–271. [Google Scholar] [CrossRef] [PubMed]

| Protein | Top Sensor Layer | LOD (Buffer) | Milk Sample: Pretreatment Steps | Achievements with Milk Samples |

|---|---|---|---|---|

| Immunoglobulin G (IgG) | Antibody | 46 ng/mL | Raw milk: spiked, diluted (1000×) | Results achieved with 569–1675 µg/mL IgG corresponded to radial immunodiffusion (reference method) results [12] |

| Milk fractions | SS2343 | n/a | Raw milk: untreated or processed to skim milk, whey, or permeate | Modeling milk protein adsorption (biofouling) on stainless steel in relation to milk composition and temperature at T = 25, 50, or 65 °C [65] |

| Phosphoproteins | Aminated titanium dioxide | 5.3 ng/mL α-casein | Non-fat milk (protein content 3%): centrifuged, diluted | Detection of phosphoproteins in 5× to 20× diluted milk, confirmation of peptides using MALDI-ToF MS [79] |

| Plasmin | Cleavabl:e peptide | 0.65 nM = 55 ng/mL | Milk, 2.6% fat: centrifuged, diluted, filtered, spiked | Spiking with 1, 10, or 20 nM plasmin resulted in an average recovery of 63.0% ± 0.6% [80] |

| β-casein | (167.16 ± 39.36) pM = (14.2 ± 3.3) ng/mL | Milk: centrifuged, filtered, spiked | Detection of active plasmin; 70% of the β-casein layer was removed by 20 nM plasmin [81] | |

| Staphylococcal enterotoxin A (SEA) | Antibody | 20 ng/mL | Skimmed milk powder mixed with water: spiked | Spiking with 97, 194, 485, or 970 ng/mL SEA resulted in observable frequency shifts from 194 ng/mL SEA upward [82] |

| Antibody | 0.4 ng/mL | Milk: acidified, centrifuged, neutralized, spiked | Spiking with 5 ng/mL and 10 ng/mL SEA resulted in a recoveries of 96% and 93%, respectively [83] | |

| SEA and staphylococcal enterotoxin B (SEB) | Corresponding MIPs | SEA: 7.97 ng/mL SEB: 2.25 ng/mL | Pasteurized milk: acidified, filtrated, neutralized, refiltered, spiked | Spiking with 5, 50, or 100 ng/mL enterotoxin resulted in recoveries ranging from 97.00% to 104.12% (SEA) and from 93.42% to 114.20% (SEB) [84] |

| SEB * | Antibody | 2.5 µg/mL | Fresh, low fat and skimmed milk: spiked | Spiking with 0, 2.5, 5, or 10 µg/mL SEB resulted in recoveries ranging from 80% to 140% [85] |

| Low-Molecular-Weight Analyte | Top Sensor Layer, Underlying Structure | LOD (Buffer) | Milk Sample: Pretreatment Steps | Achievements with Milk Samples |

|---|---|---|---|---|

| Chloramphenicol | MIP, none | 7 × 10−8 µg/mL = 7 × 10−5 ng/mL | Milk: diluted, filtered; standard addition method | Spiking with 1 µg/kg (≈1 ng/mL) chloramphenicol resulted in a recovery of 99.3% [86] |

| Ciprofloxacin, levofloxacin * | Antibody, multi-walled carbon nanotubes (MWCNTs) | Ciprofloxacin: 21 ng/mL; Levofloxacin: 25 ng/mL | Milk: diluted, mixed with organic solvent and ammonium sulfate, centrifuged; spike-and-recovery method | Spiking with 50, 100, or 300 ng/mL ciprofloxacin resulted in recoveries ranging from 98.0% to 99.0%; the same results were obtained for spiking with levofloxacin [87] |

| Endosulfan | MIP, microspheres | 5.59 ng/mL | Pasteurized milk: spiked, acidified, filtered, neutralized, refiltered | Spiking with 5, 50, or 100 ng/mL endosulfan resulted in recoveries ranging from 101.8% to 108.0% [88] |

| Enrofloxacin | MIP, none | 0.053 mg/L = 53 ng/mL | Pure milk: spiked, mixed with organic solvent, centrifuged, solid product extracted, supernatants filtered, dried, redissolved | LOD in milk 0.31 ng/mL; spiking with 10, 20, or 40 ng/mL enrofloxacin resulted in recoveries ranging from 77.2% to 84.2% [89] |

| Folic acid | MIP with metal chelate, none | 0.0080 μM = 3.5 ng/mL | Follow-on baby milk with a defined folic acid content: diluted using an organic solvent/water mixture | Folic acid content was 150 ng/mL and 180 ng/mL; recoveries obtained with QCM (HPLC-UV/VIS) were 91.9% and 94.0% (103.1% and 103.0%), respectively [90] |

| Melamine | MIP, none | 8 µM = 1 µg/mL | Skimmed milk (0.5% fat, 3.5% protein) and natural whey (0.1% fat, 0.6% protein): spiked, partly diluted or centrifuged | Observable frequency shifts after spiking with 3200 µg/mL melamine only in whey, in skimmed milk only after 10× dilution, or if the spiking was done after centrifugation; i.e., direct melamine detection is hindered by the interaction between melamine and protein [91] |

| MIP, none | 1.8 × 10−8 M = 2.3 ng/mL | Pasteurized milk: acidified, supernatant spiked and neutralized, mixed with an organic solvent, centrifuged, diluted | Higher frequency shifts with milk samples spiked with melamine up to 1000 ng/mL compared with non-spiked samples only if spiking was done after milk protein precipitation, avoiding joint precipitation of the proteins with melamine [92] | |

| Methimazole | MIP, hollow spheres | 3 ng/mL | Milk: spiked, incubated overnight, mixed with an organic solvent, centrifuged, extracted, dried, redissolved | Spiking with 50, 100, or 200 ng/mL methimazole resulted in recoveries ranging from 89.57% to 101.97% [93] |

| Tobramycin | MIP, none | 5.7 pM = 0.0027 ng/mL | Milk: acidified, centrifuged, precipitate extracted, supernatants centrifuged and filtered | Spiking with 10, 40, or 60 pM = 0.0047, 0.0187, or 0.0281 ng/mL tobramycin resulted in recoveries ranging from 97% to 98% [94] |

| Sensor Device | Assay Format | Low-Molecular-Weight Analyte | Top Sensor Layer | LOD (Buffer) | Milk Sample: Pretreatment Steps | Achievements with Milk Samples |

|---|---|---|---|---|---|---|

| QCM | Competitive | Ampicillin, penicillin G | Hapten–protein conjugate | Ampicillin 3.9 ng/mL; penicillin G 0.8 ng/mL | Milk: mixed with ammonium sulfate, centrifuged; added-found method | Spiking with 10 ng/mL or 20 ng/mL ampicillin and/or penicillin G led to recoveries of 126% and higher [95] |

| Chloramphenicol | Hapten–protein conjugate | 0.2 ng/mL | Milk: mixed with ammonium sulfate, centrifuged; added-found method | Spiking with 5 ng/mL and 10 ng/mL chloramphenicol resulted in recoveries of 80% and 90%, respectively [96] | ||

| Ciprofloxacin, levofloxacin * | Hapten–protein conjugate (via MWCNTs) | Ciprofloxacin: 8 ng/mL; levofloxacin: 9 ng/mL | Milk: diluted, mixed with organic solvent and ammonium sulfate, centrifuged; spike-and-recovery method | Spiking with 20, 50, or 70 ng/mL ciprofloxacin resulted in recoveries ranging from 95.5% to 103.2%; for spiking with the same concentrations of levofloxacin recoveries were 97.5% to 103.6% [87] | ||

| Zearalenone | Hapten–protein conjugate | 0.37 ng/mL | Milk: spiked, mixed with a diluted organic solvent, centrifuged, supernatant dried, redissolved | Spiking with 5, 50, or 100 ng/mL zearalenone resulted in recoveries ranging from 78.8% to 89.0%; comparable to HPLC-MS/MS with recoveries ranging from 80.1% to 90.5% [97] | ||

| Competitive with gold-labeled antibodies | Diethyl-stilbestrol * | Hapten–protein conjugate | 13 ng/mL | Milk: spiked, mixed with organic solvent, collection and dilution of supernatant | Spiking with 0.5, 5, or 50 ng/mL diethylstilbestrol resulted in recoveries ranging from 98.0% to 104.8%; comparable to HPLC-MS/MS with recoveries ranging from 102.0% to 104.9% [98] | |

| Indirect competitive | Aflatoxin B1 | Hapten–protein conjugate | 0.01 ng/mL | Whole fat milk, light milk or skim milk powder dissolved in water: spiked, mixed with an organic solvent, centrifuged, diluted | Spiking with 0.1 ng/mL and 10 ng/mL aflatoxin B1 and using gold-labeled secondary antibodies resulted in recoveries ranging from 95.0% to 107% [99] | |

| 0.01 ng/mL | Whole fat milk, light milk or skim milk powder dissolved in water: centrifuged, mixed with an organic solvent, filtered, diluted | Spiking with 0.1, 1, or 10 ng/mL aflatoxin B1 and using horseradish peroxidase (HRP)-labeled secondary antibodies for the biocatalyzed precipitation of an insoluble product resulted in recoveries ranging from 94.6% to 110% [100] | ||||

| SAW resonator | Binding inhibition | Penicillin G | Hapten–hydrogel | n/a | Low-fat milk (1.3% fat): untreated or centrifuged, spiked | Samples spiked with 0, 2, 4, 6, 8, or 10 ng/mL penicillin G could be classified to be below or above 4 ng/mL (maximum residue limit (MRL)) [13] |

| Sensor Device | Assay Format | Bacterium | Top Sensor Layer | LOD (Buffer) | Milk Sample: Pretreatment Steps | Achievements with Milk Samples |

|---|---|---|---|---|---|---|

| QCM | Direct detection | Bifidobacterium bifidum, Lactobacillus acidophilus | Corresponding antibody | 104 CFU/mL for each | Low-fat UHT milk (1.5% fat): spiked, some of them fermented (i.e., incubated) up to 24 h, all filtrated and diluted | Similar results for B. bifidum and L. acidophilus in 100× diluted spiked and fermented milk samples: LOD 103 CFU/mL; measuring range 103 CFU/mL to 5 × 105 CFU/mL, the cell numbers obtained via QCM measurements correlated with those from plate count [106] |

| Escherichia coli | Gold (QCM electrode) | 1.1 × 107 CFU/mL | Milk: spiked, incubated (5 h), centrifuged, cell pellet resuspended | Sample concentrations determined with QCM sensors were in the range of 9.18 × 107 CFU/mL to 1.93 × 108 CFU/mL, which was comparable to the results obtained from a plate count [108] | ||

| Parylene C | 102 cells/mL | Milk: spiked, incubated (3 h) | Time-resolved monitoring of cell population growth [109] | |||

| Antibody | 1.7 × 105 CFU/mL | Milk: untreated or diluted, spiked or inoculated with 102 CFU/mL E. coli and incubated (18 h) | Spiked and incubated milk samples containing 107 CFU/mL and 106 CFU/mL E. coli led to frequency shifts of 88.0 Hz ± 23.6 Hz and 52.0 Hz ± 23.1 Hz, respectively, which were higher than those obtained with untreated milk, i.e., 21.1 Hz ± 13.5 Hz [110] | |||

| Francisella tularensis | Antibody | 105 CFU/mL | Low-fat UHT milk (1.5% fat): spiked | LOD in milk 105 CFU/mL; spiking with 105 CFU/mL (108 CFU/mL) F. tularensis resulted in significantly higher signals than spiking with the same concentrations of E. coli and Bacillus subtilis [111] | ||

| Salmonella enterica | Antibody | n/a | Milk: spiked | Frequency shifts obtained by spiking with 1.2 × 107 CFU/mL to 4.8 × 107 CFU/mL S. enterica fitted within the calibration range obtained with 3.2 × 106 CFU/mL to 4.8 × 108 CFU/mL in a culture broth [112] | ||

| QCM | Displacement | Listeria monocytogenes | Cell-antibody complex | n/a | Milk (2% fat): spiked | Spiking with 3.19 × 106 and 6.38 × 106 Listeria cells resulted in significantly higher slopes than spiking with 6 × 106 cells of non-specific Serratia [113] |

| QCM | Sandwich, gold-labeled 2nd antibody | B. bifidum | Antibody | 2.1 × 102 CFU/mL | Fresh milk: diluted (1 g milk in 50 mL buffer), spiked, incubated (2 h) | Spiking with 104 CFU/mL of B. bifidum resulted in significantly higher signals than with non-specific L. acidophilus, L. monocytogenes, and E. coli [114] |

| EMPAS | Direct detection | E. coli | Aptamer | 35 CFU/mL | UHT milk (3.5% fat): spiked | LOD in milk 8 CFU/mL; recovery of 127.4% in spiked milk samples [115] |

| Bacterium | Top Sensor Layer | LOD (Buffer) | Milk Sample: Pretreatment Steps | Achievements with Milk Samples |

|---|---|---|---|---|

| Brucella melitensis | Aptamer | 102 CFU/mL | Milk: spiked, mixed with aptamer-coated magnetic particles, magnetic separation, washing and elution of captured bacteria | LOD in milk 103 CFU/mL; spiking with 11,780 cells of B. melitensis was evaluated as 10,052 cells with QCM sensor, while 9827 cells of non-specific bacteria of the same genus (B. suis) resulted in sensor signals below sensitivity [116] |

| E. coli * | Antibody | 23 CFU/mL | Milk: spiked, mixed with antibody-coated magnetic particles (anti-E. coli + biotin antibody), magnetic separation and washing; mixing with streptavidin–gold, magnetic separation and washing, catalytic growth of the gold, magnetic separation, washing, and resuspension of pellet consisting of particles, gold, and captured cells | LOD in milk 53 CFU/mL [117] |

| L. monocytogenes | Antibody | 3 cells per 200 µL sample, i.e., 15 cells/mL | UHT sterile milk (0.1% fat): spiked, mixed with antibody-coated magnetic particles, separation, washing and resuspension of pellet consisting of particles and captured cells | LOD in milk was 3 cells per 200 µL sample, i.e., 15 cells/mL; if magnetic particle enrichment was omitted, no frequency shift was obtained for milk spiked with Listeria up to 108 CFU/mL [118] |

| S. enterica | Aptamer | 102 CFU/mL | Milk (≥ 1.5% fat): spiked, mixed with aptamer-coated magnetic particles, magnetic separation, washing and elution of captured bacteria | Spiking with 104 CFU/mL Salmonella resulted in significantly higher signals than obtained with 104 CFU/mL non-specific Escherichia, but only if magnetic particle enrichment was applied [119] |

| Sensor Device | Bacterium | Top Sensor Layer | LOD (Buffer) | Milk Sample: Pretreatment Steps | Achievements with Milk Samples |

|---|---|---|---|---|---|

| QCM | E. coli | Oligonucleotide | Direct detection: 1.2 × 104 CFU/mL; sandwich assay with gold-labeled oligonucleotides: 1.2 × 102 CFU/mL | Pasteurized milk: spiked, mixed with proteinase K and Triton X-100 for 1 h, mixed with NaCl, centrifuged, collection and purification of cell pellet, passing pellet on to genomic DNA extraction and PCR | Spiking milk with 5.3 × 102 CFU/mL E. coli and application of sandwich hybridization with gold-labeled oligonucleotides resulted in significantly larger frequency shifts than obtained with non-spiked milk [120] |

| SAW delay line | S. enterica | Poly(L-lysine) | See “Achievements with milk samples” | Whole UHT milk (3.5% fat): spiked, mixed with antibody-coated magnetic particles, incubated (3 h), magnetic separation of pellet consisting of particles and captured bacteria, resuspension (buffer), lysis, LAMP | LOD in milk ~3 aM DNA target or 2 cells/µL; processing of 25 mL milk spiked with 1–25 CFU of S. enterica reveals a minimum detectable content of 1 cell in 25 mL milk [121] |

| S. enterica, E. coli, Bacillus cereus, Listeria | Poly(L-lysine) | See “Achievements with milk samples” | fresh milk (full fat): spiked, incubated (3 h), centrifuged, resuspension of bacteria pellet (buffer) and injection in a chip for bacteria to be captured using an antibody-coated zone, lysis, LAMP | Processing of 25 mL milk spiked with 1–5 CFU of bacteria allows for the detection of 1–5 cells in 25 mL milk [122] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Länge, K. Bulk and Surface Acoustic Wave Biosensors for Milk Analysis. Biosensors 2022, 12, 602. https://doi.org/10.3390/bios12080602

Länge K. Bulk and Surface Acoustic Wave Biosensors for Milk Analysis. Biosensors. 2022; 12(8):602. https://doi.org/10.3390/bios12080602

Chicago/Turabian StyleLänge, Kerstin. 2022. "Bulk and Surface Acoustic Wave Biosensors for Milk Analysis" Biosensors 12, no. 8: 602. https://doi.org/10.3390/bios12080602

APA StyleLänge, K. (2022). Bulk and Surface Acoustic Wave Biosensors for Milk Analysis. Biosensors, 12(8), 602. https://doi.org/10.3390/bios12080602