Pollution Flashover Characteristics of Coated Insulators under Different Profiles of Coating Damage

Abstract

:1. Introduction

2. Room Temperature Vulcanizing (RTV) Coating Characteristics

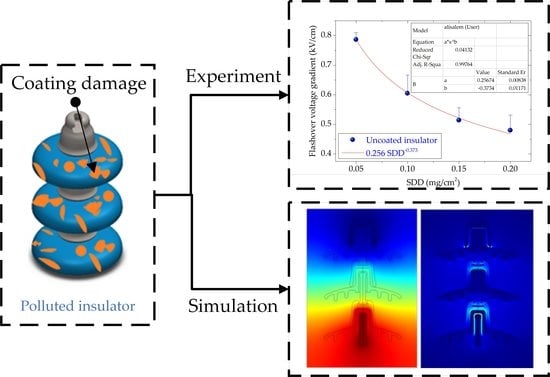

3. Laboratory Work

3.1. Test Samples

3.2. Experimental Setup

3.3. Sample Preparation

3.4. Test Procedure

4. Experimental Results

4.1. Flashover Test Result of Clean Insulator under RTV Coating

4.2. Flashover Test Result of Polluted Insulator under RTV Coating

4.3. Flashover Test Result under Different RTV Damage Profiles

- The highest relative standard deviation (σ) among all test results is 4.7%. The flashover voltage gradient has a low dispersion rate, indicating that the approach used in the testing is satisfactory.

- Under the same r and damage profile, the AC flashover voltage gradient EF of a porcelain insulator string subsides sharply as SDD rises.

- 3.

- The flashover voltage gradient of coated insulators is related to the rate of area damage on the insulator surface r. The rate of damaged area r has a dramatic influence on the flash-over voltage gradient. With an increase in r, the EF gradually decreases. For example, when the coating damage profile is profile 1 and the SDD is 0.15 mg/cm2, the EF reduces from 0.916 kV/cm to 0.845 kV/cm, to 0.767 kV/cm as r increases from 10% to 20%, and subsequently to 30%. The outcomes demonstrate that there is a reduction of 7.7% and 16.3% on the EF when the r increases from 10% to 20% and from 10% to 30%, respectively. The type of coating damage profile of the porcelain insulator string also affects the flashover voltage gradient EF. There is a significant change in the flashover voltage gradient when the coating damage profile changes. For example, when r is 20%, SDD is 0.1 mg/cm2, and the coating damage profile is 1, 2, 3, and 4, the EF is 1.017 kV/cm, 0.889 kV/cm, 0.761 kV/cm, 0.807 kV/cm correspondingly, which indicates that the EF of profile 2, profile 3 and profile 4 changes by 12.5%, 25.2%, and 20.6%, respectively if compared to the flashover voltage gradient of profile 1.

- The correlation R2 values for all fitting lines are greater than 0.95, indicating that the EF and SDD for coated insulators under various levels of pollution match the power function efficiently. The value of “a” is affected not only by the air pressure and insulator material but also by the ratio of coating damage area r and coating damage profile. For illustration, when r is 20% and the profile of coating damage is profile 1, profile 2, profile 3, and profile 4, the corresponding values of a are 0.444, 0.431, 0.344, and 0.315, indicating that the value of a changes by 2.93%, 29.1% and 22.5% as the profile of coating damage changes from profile 1 to profile 2, profile 3, and profile 4, respectively.

- The difference in the coating damage profile of coated insulator and r have no significant effects on the pollution characteristic index n.

4.4. Flashover Test Result of Coated Insulators under Different Humidity Levels

5. Numerical Modeling

5.1. Finite Element Method (FEM) Technique

5.2. Electric Fields and Potential Calculation

5.3. Numerical Simulation Results and Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| RTV | Room Temperature Vulcanizing |

| HTV | High Temperature Vulcanizing |

| FEM | Finite Element Method |

| STRI | Sweden Transmission Research Institute |

| HC | Hydrophobic |

| AC | Alternating Current |

| NaCl | Sodium chloride salt |

| SDD | Salt Deposit Density |

| NSDD | Non-Soluble Deposit Density |

| DOF | Degrees Of Freedom |

| H | High insulator |

| D | Diameter insulator |

| L | Length insulator |

| Interfacial tensions between the surface and air | |

| Interfacial tensions between surface and liquid | |

| Interfacial tensions between liquid and air | |

| Angle at which the liquid makes contact with the insulator surface | |

| Conductivity of layer pollution at 20 °C | |

| Solution volume | |

| Area of polluted surface | |

| Ratio of coating damage area to whole insulator surface area | |

| Coating damage area | |

| Whole area of coated surface of insulator | |

| Flashover voltage | |

| Applied voltage | |

| Number which was carried out at the applied voltage Ui | |

| Total test number | |

| Standard deviation | |

| EF | Flashover voltage gradient |

| a | Constant determined by factors such as the insulator’s shape, air pressure |

| b | Insulator’s characteristic contamination index |

| Electrical permittivity | |

| Electrical resistivity | |

| Relative permittivity |

References

- Marzinotto, M.; Mazzanti, G.; Cherney, E.A.; Pirovano, G. An innovative procedure for testing RTV and composite insulators sampled from service in search ofdiagnostic quantities. IEEE Elect. Insul. Mag. 2018, 34, 27–38. [Google Scholar] [CrossRef]

- Marzinotto, M.; Mazzanti, G.; Cherney, E.A.; Pirovano, G. A test-ing procedure for RTV pre-coated glass cap-and-pin and composite insulators sampled from field. In Proceedings of the IEEE Conf. Elect. Insul. Dielectr. Phenomenon (CEIDP), Fort Worth, TX, USA, 22–25 October 2017; pp. 421–424. [Google Scholar]

- Taghvaei, M.; Sedighizadeh, M.; NayebPashaee, N.; Fini, A.S. Reliability assessment of RTV and nano-RTV-coated insulators concerning contamination severity. Electr. Power Syst. Res. 2021, 191, 106892. [Google Scholar] [CrossRef]

- Majid Hussain, M.; Farokhi, S.; McMeekin, S.G.; Farzaneh, M. Contamination performance of high voltage outdoor insulators in harsh marine pollution environment. In Proceedings of the 2017 IEEE 21st International Conference on Pulsed Power (PPC), Brighton, UK, 18–22 June 2017; pp. 1–6. [Google Scholar]

- Taghvaei, M.; Sedighizadeh, M.; NayebPashaee, N.; Fini, A.S. Thermal stability of nano RTV vs. RTV coatings in porcelain insulators. Therm. Sci. Eng. Prog. 2020, 20, 100696. [Google Scholar] [CrossRef]

- Hussain, M.M.; Farokhi, S.; McMeekin, S.G.; Farzaneh, M. Risk assessment of failure of outdoor high voltage polluted insulators under combined stresses near shoreline. Energies 2017, 10, 1661. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Jia, Z.; Ouyang, X. Effects of asymmetrical algal distribution on the AC flashover characteristics of bio-contaminated silicone rubber insulators. Electr. Power Syst. Res. 2019, 172, 296–302. [Google Scholar] [CrossRef]

- Jia, Z.; Chen, C.; Wang, X.; Lu, H.; Yang, C.; Li, T. Leakage current analysis on RTV coated porcelain insulators during long term fog experiments. IEEE Trans. Dielectr. Electr. Insulat. 2014, 21, 1547–1553. [Google Scholar]

- Jia, Z.; Fang, S.; Gao, H.F.; Guan, Z.C.; Wang, L.M.; Xu, Z.H. Development of RTV Silicone Coatings in China: Overview and Bibliography. IEEE Electr. Insul. Mag. 2008, 24, 28–41. [Google Scholar]

- George, J.M.; Prat, S.; Lumb, C.; Virlogeux, F.; Gutman, I.; Lundengard, J.; Marzinotto, M. Field experience and laboratory investigation of glass insulators having a factory-applied silicone rubber coating. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2594–2601. [Google Scholar] [CrossRef]

- Su, H.; Jia, Z.; Guan, Z.; Li, L. Durability of RTV-coated insulators used in subtropical areas. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 767–774. [Google Scholar] [CrossRef]

- Sorqvist, T. Long-term field experience with RTV coated porcelain insulators. In Proceedings of the Conference Record of the 2000 IEEE International Symposium on Electrical Insulation (Cat. No.00CH37075), Boston, MA, USA, 5 April 2000; pp. 201–206. [Google Scholar]

- Gao, H.; Jia, Z.; Guan, Z.; Wang, L.; Zhu, K. Investigation on field-aged RTV-coated insulators used in heavily contaminated areas. IEEE Trans. Power Del. 2007, 22, 1117–1124. [Google Scholar] [CrossRef]

- Ilomuanya, C.S.; Farokhi, S.; Nekahi, A. Electrical Power Dissipation on the Surface of a Ceramic Insulator under Pollution Condition. In Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21–24 October 2018; pp. 199–202. [Google Scholar]

- Xing, Y.; Wang, Y.; Chi, J.; Liu, H.; Li, J. Study on Improving Interface Performance of HVDC Composite Insulators by Plasma Etching. Coatings 2020, 10, 1036. [Google Scholar] [CrossRef]

- Wu, X.; Li, X.; Hao, L.; Wen, X.; Lan, L.; Yuan, X. Effect of vulcanization temperature and humidity on the properties of RTV silicone rubber. IOP. Conf. Ser. Mater. Sci. Eng. 2017, 207, 012011. [Google Scholar] [CrossRef]

- Hussain, M.M.; Chaudhary, M.A.; Razaq, A. Mechanism of Saline Deposition and Surface Flashover on High-Voltage Insulators near Shoreline: Mathematical Models and Experimental Validations. Energies 2019, 12, 3685. [Google Scholar] [CrossRef] [Green Version]

- Isa, M.; Othman, M.; Abdullah, A.Z.; Piah, M.A.M.; Rahman, N.A.; Mazlee, M.N. Characteristics of RTV Coating on Ceramic Insulator. In Proceedings of the 2019 IEEE International Conference on Automatic Control and Intelligent Systems, Selangor, Malaysia, 29 June 2019; pp. 114–117. [Google Scholar]

- Artificial Pollution Tests on High-Voltage Ceramic and Glass Insu-lators to be Used on A.C. Systems, 3rd ed.; Standard IEC 60507; International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Salem, A.A.; Abd-Rahman, R.; Al-Gailani, S.A.; Kamarudin, M.S.; Salam, Z. The leakage current components as a diagnostic tool to estimate contamination level on high voltage insulators. IEEE Access 2020, 8, 92514–92528. [Google Scholar]

- Salem, A.A.; Abd-Rahman, R.; Al-Gailani, S.A.; Salam, Z.; Kamarudin, M.S.; Zainuddin, H.; Yousof, M.F.M. Risk assessment of polluted glass insulator using leakage current index under different operating conditions. IEEE Access 2020, 8, 175827–175839. [Google Scholar] [CrossRef]

- Arshad, A.; Ahmad, J.; Tahir, A.; Stewart, B.G.; Nekahi, A. Forecasting flashover parameters of polymeric insulators under contaminated conditions using the machine learning technique. Energies 2020, 13, 3889. [Google Scholar] [CrossRef]

- Abd-Rahman, R.; Haddad, A.; Harid, N.; Griffiths, H. Stress control on polymeric outdoor insulators using Zinc oxide microvaristor composites. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 705–713. [Google Scholar] [CrossRef]

- Salem, A.; Abd-Rahman, R.; Ghanem, W.; Al-Gailani, S.; Al-Ameri, S. Prediction flashover voltage on polluted porcelain insulator using ANN. Comput. Mater. Contin. 2021, 68, 3755–3771. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd-Rahman, R.; Ahmad, H.; Kamarudin, M.S.; Jamal, N.A.M.; Othman, N.A.; Ishak, M.T. A New Flashover Prediction on Outdoor Polluted Insulator Using Leakage Current Harmonic Components. In Proceedings of the 2018 IEEE 7th International Conference on Power and Energy (PECon), Kuala Lumpur, Malaysia, 3–4 December 2018; pp. 413–418. [Google Scholar]

- Salem, A.A.; Abd-Rahman, R.; Rahiman, W.; Al-Gailani, S.A.; Al-Ameri, S.; Ishak, M.T. Pollution flashover under different contamination profiles on high voltage insulator: Numerical and experiment investigation. IEEE Access 2021, 9, 37800–37812. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, S.; Jiang, X.; Qiao, X.; Xiang, Y.; Zhang, D. DC Flashover Dynamic Model of Post Insulator under Non-Uniform Pollution between Windward and Leeward Sides. Energies 2019, 12, 2345. [Google Scholar] [CrossRef] [Green Version]

- Hussain, M.; Farokhi, S.; McMeekin, S.; Farzaneh, M. The effects of salt contamination deposition on HV insulators under environmental stresses. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, NSW, Australia, 19–22 July 2015; pp. 616–619. [Google Scholar]

| Insulator Type | H (mm) | D (mm) | L (mm) | Schematic |

|---|---|---|---|---|

| Porcelain XP-70 | 146 | 255 | 305 |  |

| Surface Dry Time (min) | Cure Time (min) | Solid Content (%) | Dielectric Strength (kV/mm) | Tensile Strength (MPa) | Shear Strength (Pa) | Tear Strength (N/m) | Durable Years (Outdoors) |

|---|---|---|---|---|---|---|---|

| 27 | 300 | 55.1 | 24.7–25.3 | 3.951 | 0.003574 | 15,200 | 15 |

| r | Salt Deposit Density SDD (mg/cm2) | Profile | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||||||

| EF (kV/cm) | Σ (%) | EF (kV/cm) | Σ (%) | EF (kV/cm) | Σ (%) | EF (kV/cm) | Σ (%) | ||

| 10% | 0.05 | 1.327 | 3.1 | 1.138 | 4.1 | 1.053 | 3.3 | 1.088 | 4.7 |

| 0.1 | 1.102 | 4.3 | 0.964 | 2.2 | 0.825 | 3.6 | 0.875 | 3.6 | |

| 0.15 | 0.916 | 2.9 | 0.825 | 2.8 | 0.683 | 2.6 | 0.720 | 4.2 | |

| 0.2 | 0.814 | 2.6 | 0.742 | 3.1 | 0.629 | 3.7 | 0.666 | 3.6 | |

| 20% | 0.05 | 1.224 | 4.6 | 1.049 | 2.3 | 0.971 | 3.4 | 1.003 | 2.8 |

| 0.1 | 1.017 | 3.6 | 0.889 | 4.7 | 0.761 | 4.1 | 0.807 | 3.6 | |

| 0.15 | 0.845 | 2.2 | 0.761 | 2.6 | 0.630 | 2.8 | 0.664 | 4.3 | |

| 0.2 | 0.750 | 3.6 | 0.685 | 3.4 | 0.580 | 2.8 | 0.614 | 2.6 | |

| 30% | 0.05 | 1.111 | 2.8 | 0.951 | 3.3 | 0.88 | 2.5 | 0.91 | 3.6 |

| 0.1 | 0.923 | 2.6 | 0.805 | 4.2 | 0.69 | 2.2 | 0.732 | 4.3 | |

| 0.15 | 0.767 | 4.3 | 0.689 | 3.9 | 0.571 | 3.6 | 0.602 | 3.3 | |

| 0.2 | 0.681 | 3.2 | 0.62 | 2.6 | 0.526 | 2.8 | 0.557 | 4.3 | |

| r | Fitting Values | Profile 1 | Profile 2 | Profile 3 | Profile 4 |

|---|---|---|---|---|---|

| 10% | a | 0.484 | 0.465 | 0.341 | 0.375 |

| b | 0.34 | 0.302 | 0.367 | 0.348 | |

| R2 | 0.972 | 0.976 | 0.994 | 0.989 | |

| 20% | a | 0.444 | 0.431 | 0.315 | 0.344 |

| b | 0.342 | 0.298 | 0.371 | 0.351 | |

| R2 | 0.978 | 0.98 | 0.995 | 0.99 | |

| 30% | a | 0.403 | 0.391 | 0.285 | 0.311 |

| b | 0.342 | 0.304 | 0.369 | 0.35 | |

| R2 | 0.973 | 0.976 | 0.992 | 0.985 |

| Types of Material | Relative Permittivity, εr | Conductivity, σ (S/m) |

|---|---|---|

| Air | 1 | 0 |

| Cement | 15 | |

| Pollution layer | 7.1 | |

| Water | 80 | 5.5 × |

| Insulator | 4.2 | 0 |

| Insulator cap | 1000 | |

| Insulator pin | 1000 | |

| RTV | 2.9 | 1 × |

| Profile Name | Type of Element | Degrees of Freedom DOF | ||

|---|---|---|---|---|

| Domain | Boundary | Vertex | ||

| Uncoated | 59,778 | 3645 | 320 | 119,641 |

| Undamaged | 150,130 | 10,941 | 702 | 300,343 |

| Profile 1 | 121,925 | 8453 | 598 | 244,127 |

| Profile 2 | 124,886 | 8615 | 550 | 249,877 |

| Profile 3 | 149,960 | 10,856 | 690 | 206,943 |

| Profile 4 | 142,435 | 9157 | 602 | 284,954 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salem, A.A.; Lau, K.Y.; Rahiman, W.; Al-Gailani, S.A.; Abdul-Malek, Z.; Abd Rahman, R.; Al-Ameri, S.M.; Sheikh, U.U. Pollution Flashover Characteristics of Coated Insulators under Different Profiles of Coating Damage. Coatings 2021, 11, 1194. https://doi.org/10.3390/coatings11101194

Salem AA, Lau KY, Rahiman W, Al-Gailani SA, Abdul-Malek Z, Abd Rahman R, Al-Ameri SM, Sheikh UU. Pollution Flashover Characteristics of Coated Insulators under Different Profiles of Coating Damage. Coatings. 2021; 11(10):1194. https://doi.org/10.3390/coatings11101194

Chicago/Turabian StyleSalem, Ali Ahmed, Kwan Yiew Lau, Wan Rahiman, Samir A. Al-Gailani, Zulkurnain Abdul-Malek, Rahisham Abd Rahman, Salem Mgammal Al-Ameri, and Usman Ullah Sheikh. 2021. "Pollution Flashover Characteristics of Coated Insulators under Different Profiles of Coating Damage" Coatings 11, no. 10: 1194. https://doi.org/10.3390/coatings11101194

APA StyleSalem, A. A., Lau, K. Y., Rahiman, W., Al-Gailani, S. A., Abdul-Malek, Z., Abd Rahman, R., Al-Ameri, S. M., & Sheikh, U. U. (2021). Pollution Flashover Characteristics of Coated Insulators under Different Profiles of Coating Damage. Coatings, 11(10), 1194. https://doi.org/10.3390/coatings11101194