Increasing the Life Span of Tools Applied in Cheese Cutting Machines via Appropriate Micro-Blasting

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Used Tools and the Employed Devices

2.2. The Developed Device for Cheese Cutting

2.3. The Developed 3D-FEA Models for Simulating Cheese Cutting

3. Results

3.1. Hardness Characterization of the Untreated and Micro-Blasted Tools

3.2. Cutting Edge Radius of the Untreated and Micro-Blasted Tools

3.3. Mechanical Properties of the Untreated and Micro-Blasted Tools

3.4. Cutting Results

3.5. FEA Results during Cheese Cutting

4. Discussion

5. Conclusions

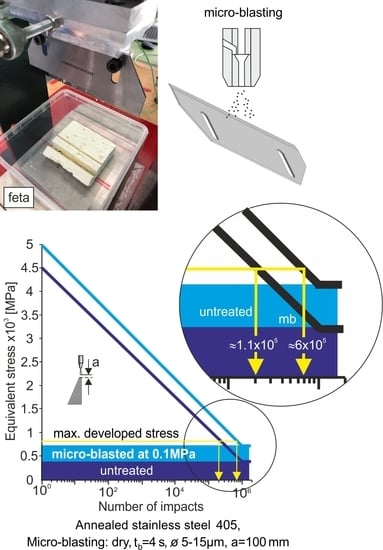

- The conduct of dry micro-blasting at a pressure of 0.1 MPa using Al2O3 grains can increase the number of impacts that the tool can withstand, more than three times, until the fatigue fracture initiation.

- Experimental cutting investigations on semi-hard cheese using an untreated tool verify the capability of the developed methodology to predict the critical number of impacts for fatigue damage imitation.

- The proposed methodology can be applied to different tool geometries and materials since a parametric FEA model was developed.

- The issue of the tool replacement prior to its fatigue fracture is very important. Despite the cheese cleanness process after the production of standard pieces of cheese concerning weight, the whole process became more secure since any possibility of damaged parts being inserted into the cheese was avoided. Moreover, by assuring an unworn cutting-edge geometry of the tool, the surface integrity of the cheese was expected to be improved, and wasted material during cutting was minimized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bouzakis, K.-D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. Manuf. Technol. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Xiaowei, L.; Hanlin, W.; Liuyang, F.; Huiyong, B. Low-cycle fatigue behavior for stainless-clad 304 + Q235B bimetallic steel. Int. J. Fatigue 2022, 159, 106831. [Google Scholar]

- Knotek, O.; Bosserhoff, B.; Schrey, A.; Leyendecker, T.; Lemmer, O.; Esser, S. A New Technique for Testing the Impact Load of Thin Films: The Coating Impact Test. Surf. Coat. Technol. 1992, 54–55, 102–107. [Google Scholar] [CrossRef]

- Gothivarekar, S.; Coppieters, S.; Talemi, R.; Debruyne, D. Effect of bending process on the fatigue behaviour of high strength steel. J. Constr. Steel Res. 2021, 182, 106662. [Google Scholar] [CrossRef]

- Bin, Z.; Ali, H.; Xiaoman, Z.; Jikui, Z.; Shao, S.; Khonsari, M.M.; Guo, S.; Meng, W.J. On the failure mechanisms of Cr-coated 316 stainless steel in bending fatigue tests. Int. J. Fatigue 2020, 139, 105733. [Google Scholar]

- Guodong, W.; Yafei, M.; Zhongzhao, G.; Hanbing, B.; Lei, W.; Jianren, Z. Fatigue life assessment of high-strength steel wires: Beach marks test and numerical investigation. Constr. Build. Mater. 2022, 323, 126534. [Google Scholar]

- Skordaris, G.; Bouzakis, K.-D.; Charalampous, P.; Kotsanis, T.; Bouzakis, E.; Bejjani, R. Bias voltage effect on the mechanical properties, adhesion and milling performance of PVD films on cemented carbide inserts. Wear 2018, 404–405, 50–61. [Google Scholar] [CrossRef]

- Yu, W.; Yin, Y.; Zhou, J.; Xu, Q.; Feng, X.; Nan, H.; Zuo, J.; Wang, X.; Ding, X. Surface Condition Evolution and Fatigue Evaluation after Different Surface Processes for TiAl47Cr2Nb2 Alloy. Materials 2022, 15, 5491. [Google Scholar] [CrossRef]

- Avcu, Y.Y.; Gönül, B.; Yetik, O.; Sönmez, F.; Cengiz, A.; Guney, M.; Avcu, E. Modification of Surface and Subsurface Properties of AA1050 Alloy by Shot Peening. Materials 2021, 14, 6575. [Google Scholar] [CrossRef]

- Rautio, T.; Jaskari, M.; Gundgire, T.; Iso-Junno, T.; Vippola, M.; Järvenpää, A. The Effect of Severe Shot Peening on Fatigue Life of Laser Powder Bed Fusion Manufactured 316L Stainless Steel. Materials 2022, 15, 3517. [Google Scholar] [CrossRef]

- Matuszak, J.; Zaleski, K.; Skoczylas, A.; Ciecielag, K.; Kecik, K. Influence of Semi-Random and Regular Shot Peening on Selected Surface Layer Properties of Aluminum Alloy. Materials 2021, 14, 7620. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Shi, M.; Gan, J.; Wang, X.; Yang, Y.; Ren, X. The Effects of Shot Distance and Impact Sequence on the Residual Stress Field in Shot Peening Finite Element Model. Metals 2021, 11, 462. [Google Scholar] [CrossRef]

- Efe, Y.; Karademir, I.; Husem, F.; Maleki, E.; Karimbaev, R.; Amanov, A.; Unal, O. Enhancement in microstructural and mechanical performance of AA7075 aluminum alloy via severe shot peening and ultrasonic nanocrystal surface modification. Appl. Surf. Sci. 2020, 528, 146922. [Google Scholar] [CrossRef]

- Chung, Y.-H.; Chen, T.-C.; Lee, H.-B.; Tsay, L.-W. Effect of Micro-Shot Peening on the Fatigue Performance of AISI 304 Stainless Steel. Metals 2021, 11, 1408. [Google Scholar] [CrossRef]

- Barbatti, C.; Garcia, J.; Pitonak, R.; Pinto, H.; Kostka, A.; Di Prinzio, A.; Staia, M.H.; Pyzalla, A.R. Influence of micro-blasting on the microstructure and residual stresses of CVD j-Al2O3 coatings. Surf. Coat. Technol. 2009, 203, 3708–3717. [Google Scholar] [CrossRef]

- Jacob, A.; Gangopadhyay, S.; Satapathy, A.; Mantry, S.; Jha, B.B. Influences of micro-blasting as surface treatment technique on properties and performance of AlTiN coated tools. J. Manuf. Process. 2017, 29, 407–418. [Google Scholar] [CrossRef]

- Gadge, M.; Lohar, G.; Chinchanikar, S. A review on micro-blasting as surface treatment technique for improved cutting tool performance. Mater. Today Proc. 2022, 64, 725–730. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Klocke, F.; Skordaris, G.; Bouzakis, E.; Gerardis, S.; Katirtzoglou, G.; Makrimallakis, S. Influence of dry micro-blasting grain quality on wear behaviour of TiAlN coated tools. Wear 2011, 271, 783–791. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Tsouknidas, A.; Skordaris, G.; Bouzakis, E.; Makrimallakis, S.; Gerardis, S.; Katirtzoglou, G. Optimization of wet or dry microblasting on PVD films by various Al2O3 grain sizes for improving the coated tools’ cutting performance. Tribol. Ind. 2011, 33, 49–56. [Google Scholar]

- Astakhov, V.P. Cutting Force Modeling Genesis, State of the Art, and Development. In Mechanical and Industrial Engineering: Historical Aspects and Future Directions; Davim, J.P., Ed.; Springer Nature: Cham, Switzerland, 2022; pp. 39–93. [Google Scholar]

- Astakhov, V.P. Authentication of FEM in Metal Cutting, Chapter 1. In Finite Element Method in Manufacturing Processes; Davim, J.P., Ed.; Wiley: Hoboken, NJ, USA, 2011; pp. 1–43. [Google Scholar]

- Impact-BZ Ltd. Available online: www.impact-bz.com (accessed on 21 August 2022).

- Bouzakis, K.-D.; Michailidis, N.; Hadjiyiannis, S.; Skordaris, G.; Erkens, G. A continuous FEM simulation of the nanoindentation to determine actual indenter tip geometries, material elastoplastic deformation laws and universal hardness. Z. Fuer Met./Mater. Res. Adv. Tech. 2002, 93, 862–869. [Google Scholar]

- ASTM STP 889; American Society for Testing and Materials: Philadelphia, PA, USA, 1986; pp. 72–89.

- Bouzakis, K.-D.; Skordaris, G.; Klocke, F.; Bouzakis, E. A FEM-based Analytical–Experimental Method for Determining Strength Properties Gradation in Coatings after Micro-blasting. Surf. Coat. Technol. 2009, 203, 2946–2953. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Skordaris, G.; Kombogiannis, S.; Hadjiyiannis, S.; Efstathiou, K.; Pavlidou, E.; Erkens, G.; Rambadt, S.; Wirth, I. Optimisation of the cutting edge roundness and its manufacturing procedures of cemented carbide inserts, to improve their milling performance after a PVD coating deposition. Surf. Coat. Technol. 2003, 163–164, 625–630. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skordaris, G.; Vogiatzis, K.; Kakalis, L.; Mirisidis, I.; Paralidou, V.; Paralidou, S. Increasing the Life Span of Tools Applied in Cheese Cutting Machines via Appropriate Micro-Blasting. Coatings 2022, 12, 1343. https://doi.org/10.3390/coatings12091343

Skordaris G, Vogiatzis K, Kakalis L, Mirisidis I, Paralidou V, Paralidou S. Increasing the Life Span of Tools Applied in Cheese Cutting Machines via Appropriate Micro-Blasting. Coatings. 2022; 12(9):1343. https://doi.org/10.3390/coatings12091343

Chicago/Turabian StyleSkordaris, Georgios, Konstantinos Vogiatzis, Leonidas Kakalis, Ioannis Mirisidis, Vasiliki Paralidou, and Soultana Paralidou. 2022. "Increasing the Life Span of Tools Applied in Cheese Cutting Machines via Appropriate Micro-Blasting" Coatings 12, no. 9: 1343. https://doi.org/10.3390/coatings12091343

APA StyleSkordaris, G., Vogiatzis, K., Kakalis, L., Mirisidis, I., Paralidou, V., & Paralidou, S. (2022). Increasing the Life Span of Tools Applied in Cheese Cutting Machines via Appropriate Micro-Blasting. Coatings, 12(9), 1343. https://doi.org/10.3390/coatings12091343