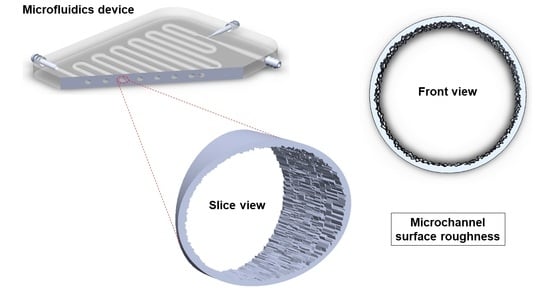

Surface Roughness Analysis of Microchannels Featuring Microfluidic Devices Fabricated by Three Different Materials and Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microfluid Device Design

2.2. MFD Fabrication Materials and Methods

2.2.1. Fabrication Method Using Polydimethylsiloxane (PDMS)

2.2.2. Fabrication Method Using a PLA Filament

2.2.3. Fabrication Method Using Photopolymerizable Resin

2.3. Modeling

- u = velocity (m/s);

- t = time (s);

- P = pressure (Pa);

- = interfacial tension force (mN/m);

- I = identity square matrix (order 3);

- T = matrix transposition;

- = level set function;

- = reset parameter;

- = thickness control parameter.

- = coefficient of surface tension (N/m);

- n = unit normal to the interface;

- k = curvature;

- = delta of Dirac located at the interface (m);

- = gradient surface operator.

3. Results

3.1. PDMS Image Analysis

3.2. PLA Image Analysis

3.3. UV Resin Image Analysis

3.4. Simulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MFD | Microfluidic device |

| PEGDA | Polyethylene glycol diacrylate |

| PDMS | Polydimethylsiloxane |

| PLA | Polylactic acid |

| UV | Ultraviolet light |

| SU-8 | Bisphenol A novolac epoxy |

| Dispersed phase flow | |

| Continuous phase flow | |

| CFD | Computational fluid dynamics |

| SEM | Scanning electron microscopy |

References

- Cortelezzi, L.; Ferrari, S.; Dubini, G. A scalable active micro-mixer for biomedical applications. Microfluid. Nanofluidics 2017, 21, 1–16. [Google Scholar] [CrossRef]

- Zhu, Y.; Fang, Q. Analytical detection techniques for droplet microfluidics—A review. Anal. Chim. Acta 2013, 787, 24–35. [Google Scholar] [CrossRef] [PubMed]

- Mohammed Adham, A.; Mohd-Ghazali, N.; Ahmad, R. Thermal and hydrodynamic analysis of microchannel heat sinks: A review. Renew. Sustain. Energy Rev. 2013, 21, 614–622. [Google Scholar] [CrossRef]

- Moreira, A.; Carneiro, J.; Campos, J.B.; Miranda, J.M. Production of hydrogel microparticles in microfluidic devices: A review. Microfluid. Nanofluidics 2021, 25, 1–24. [Google Scholar] [CrossRef]

- Lopez-Juárez, B.P.; Garcia-Ramirez, M.A.; Perez-Luna, V.H.; Gonzalez-Reynoso, O. Formation of PEG-DA polymerized microparticles by different microfluidics devices: A T-junction device and a flow focusing device. Mater. Today Proc. 2019, 13, 374–378. [Google Scholar] [CrossRef]

- M, K.R.; Chakraborty, S. PDMS microfluidics: A mini review. J. Appl. Polym. Sci. 2020, 137, 48958. [Google Scholar] [CrossRef]

- Tullius, J.F.; Vajtai, R.; Bayazitoglu, Y. A review of cooling in microchannels. Heat Transf. Eng. 2011, 32, 527–541. [Google Scholar] [CrossRef]

- Cheng, S.; Wu, Z. Microfluidic electronics. Lab A Chip 2012, 12, 2782–2791. [Google Scholar] [CrossRef]

- Zhang, Y. On Study of Application of Micro-reactor in Chemistry and Chemical Field. IOP Conf. Ser. Earth Environ. Sci. 2018, 113. [Google Scholar] [CrossRef]

- Singh, R.K.; Kumar, A.; Kant, R.; Gupta, A.; Suresh, E.; Bhattacharya, S. Design and fabrication of 3-dimensional helical structures in polydimethylsiloxane for flow control applications. Microsyst. Technol. 2014, 20, 101–111. [Google Scholar] [CrossRef]

- Sackmann, J.; Burlage, K.; Gerhardy, C.; Memering, B.; Liao, S.; Schomburg, W.K. Review on ultrasonic fabrication of polymer micro devices. Ultrasonics 2015, 56, 189–200. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, T.; Fu, B. Surface roughness study on microchannels of CO2 laser fabricating PMMA-based microfluidic chip. Surf. Rev. Lett. 2017, 24, 1–7. [Google Scholar] [CrossRef]

- Scott, S.M.; Ali, Z. Fabrication methods for microfluidic devices: An overview. Micromachines 2021, 12, 319. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, L. Review in manufacturing methods of nanochannels of bio-nanofluidic chips. Sens. Actuators B Chem. 2018, 254, 648–659. [Google Scholar] [CrossRef]

- Kwon, K.K.; Song, K.Y.; Seo, J.M.; Chu, C.N.; Ahn, S.H. Precise glass microstructuring with laser induced backside wet etching using error-compensating scan path. J. Mater. Process. Technol. 2021, 291, 117046. [Google Scholar] [CrossRef]

- Gottmann, J.; Hermans, M.; Repiev, N.; Ortmann, J. Selective laser-induced etching of 3D precision quartz glass components for microfluidic applications-up-scaling of complexity and speed. Micromachines 2017, 8, 110. [Google Scholar] [CrossRef]

- Niino, H.; Kawaguchi, Y.; Sato, T.; Narazaki, A.; Kurosaki, R. Surface microstructures of silica glass by laser-induced backside wet etching. In Proceedings of the SPIE, San Jose, CA, USA, 19–24 January 2008; Volume 6879, p. 68790C. [Google Scholar] [CrossRef]

- Otuka, A.J.; Tomazio, N.B.; Paula, K.T.; Mendonça, C.R. Two-photon polymerization: Functionalized microstructures, micro-resonators, and bio-scaffolds. Polymers 2021, 13, 1994. [Google Scholar] [CrossRef]

- Desponds, A.; Banyasz, A.; Montagnac, G.; Andraud, C.; Baldeck, P.; Parola, S. Microfabrication by two-photon lithography, and characterization, of SiO2/TiO2 based hybrid and ceramic microstructures. J. Sol.-Gel Sci. Technol. 2020, 95, 733–745. [Google Scholar] [CrossRef]

- Butkutė, A.; Jonušauskas, L. 3d manufacturing of glass microstructures using femtosecond laser. Micromachines 2021, 12, 499. [Google Scholar] [CrossRef]

- Ackerl, N.; Fisch, G.; Auerswald, J.; Wegener, K. Evolution of microstructures on stainless steel induced by ultra-short pulsed laser ablation. SN Appl. Sci. 2020, 2, 652. [Google Scholar] [CrossRef]

- Gower, M.C.; Davies, E.; Holmes, A.S. Optical modeling of laser ablation for microstructure fabrication. J. Laser Micro Nanoeng. 2013, 8, 56–64. [Google Scholar] [CrossRef]

- Dai, B.; Li, M.; Ma, Y. Effect of surface roughness on liquid friction and transition characteristics in micro- and mini-channels. Appl. Therm. Eng. 2014, 67, 283–293. [Google Scholar] [CrossRef]

- Dharaiya, V.V.; Kandlikar, S.G. A numerical study on the effects of 2d structured sinusoidal elements on fluid flow and heat transfer at microscale. Int. J. Heat Mass Transf. 2013, 57, 190–201. [Google Scholar] [CrossRef]

- Yuan, X.; Tao, Z.; Li, H.; Tian, Y. Experimental investigation of surface roughness effects on flow behavior and heat transfer characteristics for circular microchannels. Chin. J. Aeronaut. 2016, 29, 1575–1581. [Google Scholar] [CrossRef]

- Ranjan, P. Investigations on the flow behaviour in microfluidic device due to surface roughness: A computational fluid dynamics simulation. Microsyst. Technol. 2019, 25, 3779–3789. [Google Scholar] [CrossRef]

- Jia, J.; Song, Q.; Liu, Z.; Wang, B. Effect of wall roughness on performance of microchannel applied in microfluidic device. Microsyst. Technol. 2019, 25, 2385–2397. [Google Scholar] [CrossRef]

- Chakaneh, J.; Javid, M. Surface roughness effect on droplet impact characterization: Experimental and theoretical study. J. Mech. Eng. Sci. 2019, 13, 5104–5125. [Google Scholar] [CrossRef]

- Daly, A.C.; Riley, L.; Segura, T.; Burdick, J.A. Hydrogel microparticles for biomedical applications. Nat. Rev. Mater. 2020, 5, 20–43. [Google Scholar] [CrossRef]

- Li, W.; Zhang, L.; Ge, X.; Xu, B.; Zhang, W.; Qu, L.; Choi, C.H.; Xu, J.; Zhang, A.; Lee, H.; et al. Microfluidic fabrication of microparticles for biomedical applications. Chem. Soc. Rev. 2018, 47, 5646–5683. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Xia, H.; Tan, X.; Song, S.; Zhang, S.; Meng, D.; Chen, Q.; Jin, Y. The potential applications of microparticles in the diagnosis, treatment, and prognosis of lung cancer. J. Transl. Med. 2022, 20, 404. [Google Scholar] [CrossRef]

- Sherstneva, A.A.; Demina, T.S.; Monteiro, A.P.; Akopova, T.A.; Grandfils, C.; Ilangala, A.B. Biodegradable Microparticles for Regenerative Medicine: A State of the Art and Trends to Clinical Application. Polymers 2022, 14, 1314. [Google Scholar] [CrossRef] [PubMed]

- Acosta-Cuevas, J.M.; Gonzalez-Garcaa, J.; Garcia-Ramirez, M.; Perez-Luna, V.H.; Cisneros-Lopez, E.O.; Gonzalez-Nuñez, R.; González-Reynoso, O. Generation of photopolymerized microparticles based on pegda using microfluidic devices. Part 1. initial gelation time and mechanical properties of the material. Micromachines 2021, 12, 293. [Google Scholar] [CrossRef] [PubMed]

- Dow Corning. Sylgard® 182 Silicone Elastomer Datasheet. In Silicone Elastomer Technical Data Sheet; 2018; pp. 1–5. Available online: https://www.dow.com/es-es/document-viewer.html?docPath=/content/dam/dcc/documents/en-us/productdatasheet/11/11-12/11-1251-01-sylgard-182-silicone-elastomer.pdf (accessed on 15 September 2023).

- Bowman, A.T.; Metters, K.A. Fundamental studies of a novel, biodegradable PEG-b-PLA hydrogel. J. Biomed. Mater. Res. Part A 2000, 91, 3993–4005. [Google Scholar] [CrossRef]

- Peters, F.; Arabali, D. Interfacial tension between oil and water measured with a modified contour method. Colloids Surfaces A Physicochem. Eng. Asp. 2013, 426, 1–5. [Google Scholar] [CrossRef]

- Katopodes, N.D. Level Set Method. Free-Surface Flow 2019, 13, 804–828. [Google Scholar] [CrossRef]

- COMSOL. Microfluidics Interfaces: The Level Set Method. In COMSOL Multiphysics User’s Guide; CMU Guide: Burlington, MA, USA, 2016; pp. 203–211. [Google Scholar]

- Wong, V.L.; Yau, K.H.; Loizou, K.; Lau, P.L.; Richard, S.; Hewakandamby, B.N. Numerical Study of Shear-Thinning Droplet Breakup Dynamics at Microfluidics T-Junction using Level-Set Method. SEGi Univ. 2015, 1, 23. [Google Scholar]

| Basic Material Characteristics [COMSOL] | ||

|---|---|---|

| Feature | Hydrogel Solution | Mineral Oil |

| (Pa · s) | 8.9 × | 3.0 × |

| (kg/m) | 1.0 × | 8.7 × |

| Thermal conductivity (W/m k) | 0.598 | 0.106 |

| Thermal capacity (J/kg k) | 4184 | 1670 |

| Adiabatic expansion coefficient | 1.0 | 1.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acosta-Cuevas, J.M.; García-Ramírez, M.A.; Hinojosa-Ventura, G.; Martínez-Gómez, Á.J.; Pérez-Luna, V.H.; González-Reynoso, O. Surface Roughness Analysis of Microchannels Featuring Microfluidic Devices Fabricated by Three Different Materials and Methods. Coatings 2023, 13, 1676. https://doi.org/10.3390/coatings13101676

Acosta-Cuevas JM, García-Ramírez MA, Hinojosa-Ventura G, Martínez-Gómez ÁJ, Pérez-Luna VH, González-Reynoso O. Surface Roughness Analysis of Microchannels Featuring Microfluidic Devices Fabricated by Three Different Materials and Methods. Coatings. 2023; 13(10):1676. https://doi.org/10.3390/coatings13101676

Chicago/Turabian StyleAcosta-Cuevas, José M., Mario A. García-Ramírez, Gabriela Hinojosa-Ventura, Álvaro J. Martínez-Gómez, Víctor H. Pérez-Luna, and Orfil González-Reynoso. 2023. "Surface Roughness Analysis of Microchannels Featuring Microfluidic Devices Fabricated by Three Different Materials and Methods" Coatings 13, no. 10: 1676. https://doi.org/10.3390/coatings13101676

APA StyleAcosta-Cuevas, J. M., García-Ramírez, M. A., Hinojosa-Ventura, G., Martínez-Gómez, Á. J., Pérez-Luna, V. H., & González-Reynoso, O. (2023). Surface Roughness Analysis of Microchannels Featuring Microfluidic Devices Fabricated by Three Different Materials and Methods. Coatings, 13(10), 1676. https://doi.org/10.3390/coatings13101676