Cracking Behavior of Atmospheric Plasma-Sprayed 8YSZ Thermal Barrier Coatings during Thermal Shock Test

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Evaluation of Coating Properties and Characterizations

3. Results and Discussion

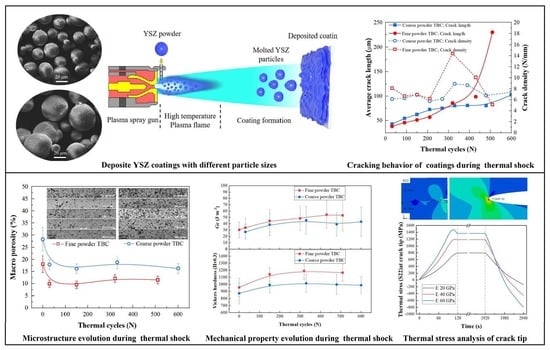

3.1. Microstructure and Fracture Toughness of Coating

3.2. Thermal Shock Spalling Behavior of Coating

3.3. Cracking Behavior of Coating

3.4. Effect of Strain Tolerance on Thermal Stress of Coating

3.5. Thermal Shock Resistant Analysis of Coating

4. Conclusions

- (1)

- The effect of particle size of YSZ powder on the microstructure of the coating is mainly reflected in the porosity and pore size. The porosity of the coating prepared by fine powder is low, the pore size is small, and the small pores in the coating are easy to be sintered during thermal shock, which further reduces the porosity of the coating. The porosity and pore size of the coating prepared by coarse powder are relatively larger, the larger pores are difficult to be sintered after thermal shock, and the porosity of the coating is relatively high.

- (2)

- The particle size of YSZ powder does not affect the phase structure of the atmospheric plasma-sprayed 8YSZ coating. The YSZ coatings prepared by coarse and fine particles are tetragonal zirconia.

- (3)

- The particle size of the powder leads to the difference of the pore structure of the coating, which in turn affects the fracture toughness and strain tolerance of the coating. The change of porosity influences the fracture toughness and strain tolerance of the coating in opposite direction, that is, when the fracture toughness of the coating is increased by reducing the porosity, the strain tolerance of the coating will become worse. The coating prepared by fine powder has high fracture toughness because of its compact structure, but the strain tolerance of the coating is poor. Due to the existence of many pores, the fracture toughness of the coating prepared by coarse powder is relatively lower, but the strain tolerance of the coating is better.

- (4)

- The fracture toughness and strain tolerance of the ceramic layer play an important role in the thermal shock life of the coating. Although the coating prepared by fine powder has relatively high fracture toughness, its lower strain tolerance will increase the cracking driving force on the crack tip of the coating during thermal shock. In the process of thermal shock, the cracks of the coating propagate and merge at a faster speed, and the thermal shock life is short. Although the larger porosity and pore size in the coating prepared by coarse particle size powder reduce the fracture toughness of the coating to a certain extent, the increase of sintering resistance and strain tolerance reduces the crack growth rate in the coating, and the coating has a longer life.

- (5)

- The results of this study provide guidance for the development and design of high performance TBCs. When adjusting the pore structure of the coating, attention should be paid to the improvement of anti-cracking ability and strain tolerance at the same time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Babu, P.S.; Madhavi, Y.; Krishna, L.R.; Sivakumar, G.; Rao, D.S.; Padmanabham, G. Thermal Spray Coatings for Erosion–Corrosion Resistant Applications. Trans. Indian Inst. Met. 2020, 73, 2141–2159. [Google Scholar] [CrossRef]

- Cinca, N.; Lima, C.R.C.; Guilemany, J.M. An overview of intermetallics research and application: Status of thermal spray coatings. J. Mater. Res. Technol. 2013, 2, 75–86. [Google Scholar] [CrossRef] [Green Version]

- Hardwicke, C.U.; Lau, Y.-C. Advances in thermal spray coatings for gas turbines and energy generation: A review. J. Therm. Spray Technol. 2013, 22, 564–576. [Google Scholar] [CrossRef] [Green Version]

- Paleu, C.C.; Munteanu, C.; Istrate, B.; Bhaumik, S.; Vizureanu, P.; Bălţatu, M.S.; Paleu, V. Microstructural Analysis and Tribological Behavior of AMDRY 1371 (Mo–NiCrFeBSiC) Atmospheric Plasma Spray Deposited Thin Coatings. Coatings 2020, 10, 1186. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mahapatra, M.; Mulik, R.S. Thermal barrier coatings—A state of the art review. Met. Mater. Int. 2021, 27, 1947–1968. [Google Scholar] [CrossRef]

- Wee, S.; Do, J.; Kim, K.; Lee, C.; Seok, C.; Choi, B.-G.; Choi, Y.; Kim, W. Review on mechanical thermal properties of superalloys and thermal barrier coating used in gas turbines. Appl. Sci. 2020, 10, 5476. [Google Scholar] [CrossRef]

- Darolia, R. Thermal barrier coatings technology: Critical review, progress update, remaining challenges and prospects. Int. Mater. Rev. 2013, 58, 315–348. [Google Scholar] [CrossRef]

- Mehta, A.; Vasudev, H.; Singh, S.; Prakash, C.; Saxena, K.K.; Linul, E.; Buddhi, D.; Xu, J. Processing and Advancements in the development of thermal barrier coatings: A Review. Coatings 2022, 12, 1318. [Google Scholar] [CrossRef]

- Kumar, V.; Balasubramanian, K. Progress update on failure mechanisms of advanced thermal barrier coatings: A review. Prog. Org. Coat. 2016, 90, 54–82. [Google Scholar] [CrossRef]

- Song, D.; Song, T.; Paik, U.; Lyu, G.; Jung, Y.-G.; Choi, B.-G.; Kim, I.-S.; Zhang, J. Crack-growth behavior in thermal barrier coatings with cyclic thermal exposure. Coatings 2019, 9, 365. [Google Scholar] [CrossRef]

- Ahmadian, S.; Jordan, E.H. Explanation of the effect of rapid cycling on oxidation, rumpling, microcracking and lifetime of air plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2014, 244, 109–116. [Google Scholar] [CrossRef]

- Dong, H.; Yang, G.-J.; Cai, H.-N.; Li, C.-X.; Li, C.-J. Propagation feature of cracks in plasma-sprayed YSZ coatings under gradient thermal cycling. Ceram. Int. 2015, 41, 3481–3489. [Google Scholar] [CrossRef]

- Ahmadian, S.; Thistle, C.; Jordan, E.H.; Hsueh, C.H. Experimental and Finite Element Study of an Air Plasma Sprayed Thermal Barrier Coating under Fixed Cycle Duration at Various Temperatures. J. Am. Ceram. Soc. 2013, 96, 3210–3217. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Yu, J.; Wu, L.; Feng, Z. Effect of Particle Size on the Micro-cracking of Plasma-Sprayed YSZ Coatings During Thermal Cycle Testing. J. Therm. Spray Technol. 2017, 26, 755–763. [Google Scholar] [CrossRef]

- Viswanathan, V.; Dwivedi, G.; Sampath, S. Engineered Multilayer Thermal Barrier Coatings for Enhanced Durability and Functional Performance. J. Am. Ceram. Soc. 2014, 97, 2770–2778. [Google Scholar] [CrossRef]

- Viswanathan, V.; Dwivedi, G.; Sampath, S. Multilayer, multimaterial thermal barrier coating systems: Design, synthesis, and performance assessment. J. Am. Ceram. Soc. 2015, 98, 1769–1777. [Google Scholar] [CrossRef]

- Li, C.J.; Li, Y.; Yang, G.J.; Li, C.X. Evolution of Lamellar Interface Cracks During Isothermal Cyclic Test of Plasma-Sprayed 8YSZ Coating with a Columnar-Structured YSZ Interlayer. J. Therm. Spray Technol. 2013, 22, 1374–1382. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Lu, X.; Liu, S.; Li, C. Influence of lamellar interface morphology on cracking resistance of plasma-sprayed YSZ coatings. Coatings 2018, 8, 187. [Google Scholar] [CrossRef] [Green Version]

- Dwivedi, G.; Viswanathan, V.; Sampath, S.; Shyam, A.; Lara-Curzio, E. Fracture Toughness of Plasma-Sprayed Thermal Barrier Ceramics: Influence of Processing, Microstructure, and Thermal Aging. J. Am. Ceram. Soc. 2014, 97, 2736–2744. [Google Scholar] [CrossRef]

- Mauer, G.; Du, L.; Vaßen, R. Atmospheric Plasma Spraying of Single Phase Lanthanum Zirconate Thermal Barrier Coatings with Optimized Porosity. Coatings 2016, 6, 49. [Google Scholar] [CrossRef]

- Huang, J.B.; Wang, W.Z.; Li, Y.J.; Fang, H.J.; Ye, D.D.; Zhang, X.C.; Tu, S.T. A novel strategy to control the microstructure of plasma-sprayed YSZ thermal barrier coatings. Surf. Coat. Technol. 2020, 402, 126304. [Google Scholar] [CrossRef]

- Huang, J.B.; Wang, W.Z.; Li, Y.J.; Fang, H.J.; Ye, D.D.; Zhang, X.C.; Tu, S.T. Novel-structured plasma-sprayed thermal barrier coatings with low thermal conductivity, high sintering resistance and high durability—ScienceDirect. Ceram. Int. 2020, 47, 5156–5167. [Google Scholar] [CrossRef]

- Bakan, E.; Vaßen, R. Ceramic Top Coats of Plasma-Sprayed Thermal Barrier Coatings: Materials, Processes, and Properties. J. Therm. Spray Technol. 2017, 26, 992–1010. [Google Scholar] [CrossRef]

- Odhiambo, J.G.; Li, W.; Zhao, Y.; Li, C. Porosity and its significance in plasma-sprayed coatings. Coatings 2019, 9, 460. [Google Scholar] [CrossRef] [Green Version]

- Medřický, J.; Curry, N.; Pala, Z.; Vilemova, M.; Chraska, T.; Johansson, J.; Markocsan, N. Optimization of High Porosity Thermal Barrier Coatings Generated with a Porosity Former. J. Therm. Spray Technol. 2015, 24, 622–628. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Li, Y.; Fang, H.; Ye, D.; Zhang, X.; Tu, S. Improve durability of plasma-splayed thermal barrier coatings by decreasing sintering-induced stiffening in ceramic coatings. J. Eur. Ceram. Soc. 2019, 40, 1433–1442. [Google Scholar] [CrossRef]

- Cheng, B.; Yang, N.; Zhang, Q.; Zhang, Y.-M.; Chen, L.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Sintering induced the failure behavior of dense vertically crack and lamellar structured TBCs with equivalent thermal insulation performance. Ceram. Int. 2017, 43, 15459–15465. [Google Scholar] [CrossRef]

- Zou, Z.; Xing, C.; He, L.; Shan, X.; Luo, L.; Zhao, X.; Guo, F.; Xiao, P. A Highly Strain and Damage Tolerant Thermal Barrier Coating Fabricated by Electro: Prayed Zirconia Hollow Spheres. J. Am. Ceram. Soc. 2018, 101, 4375–4386. [Google Scholar] [CrossRef]

- Bakan, E.; Mack, D.E.; Mauer, G.; Mücke, R.; Vaßen, R. Porosity–Property Relationships of Plasma-Sprayed Gd2Zr2O7/YSZ Thermal Barrier Coatings. J. Am. Ceram. Soc. 2015, 98, 2647–2654. [Google Scholar] [CrossRef]

- Lin, X.; Zeng, Y.; Lee, S.W.; Ding, C. Characterization of alumina–3 wt.% titania coating prepared by plasma spraying of nanostructured powders. J. Am. Ceram. Soc. 2004, 24, 627–634. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Lu, X.; Hu, D.; Feng, Z.; Guo, T. Effect of Particle Size on the Thermal Shock Resistance of Plasma-Sprayed YSZ Coatings. Coatings 2017, 7, 150. [Google Scholar] [CrossRef] [Green Version]

- Li, G.R.; Li, C.X.; Li, C.J.; Yang, G.J. Sintering characteristics of plasma-sprayed TBCs: Experimental analysis and an overall modelling. Ceram. Int. 2018, 44, 2982–2990. [Google Scholar] [CrossRef]

- Yan, J.; Wang, X.; Chen, K.; Lee, K.N. Sintering modeling of thermal barrier coatings at elevated temperatures: A review of recent advances. Coatings 2021, 11, 1214. [Google Scholar] [CrossRef]

- Markocsan, N.; Nylen, P.; Wigren, J.; Li, X.; Tricoire, A. Effect of thermal aging on microstructure and functional properties of zirconia-base thermal barrier coatings. J. Therm. Spray Technol. 2009, 18, 201–208. [Google Scholar] [CrossRef]

- Erdogan, G.; Ustel, F.; Bobzin, K.; Öte, M.; Linke, T.F.; Zhao, L. Influence of long time post annealing on thermal stability and thermophysical properties of plasma sprayed La2Zr2O7 coatings. J. Alloys Compd. 2017, 695, 2549–2555. [Google Scholar] [CrossRef]

- Liu, T.; Chen, X.; Yang, G.-J.; Li, C.-J. Properties evolution of plasma-sprayed La 2 Zr 2 O 7 coating induced by pore structure evolution during thermal exposure. Ceram. Int. 2016, 42, 15485–15492. [Google Scholar] [CrossRef]

- Nakamura, T.; Qian, G.; Berndt, C.C. Effects of Pores on Mechanical Properties of Plasma-Sprayed Ceramic Coatings. J. Am. Ceram. Soc. 2000, 83, 578–584. [Google Scholar] [CrossRef] [Green Version]

- Białas, M. Finite element analysis of stress distribution in thermal barrier coatings. Surf. Coat. Technol. 2008, 202, 6002–6010. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, B.; Wang, W.; Adjei, R.A.; Zhao, X.; Liu, Y. Finite element analysis of the effects of thermally grown oxide thickness and interface asperity on the cracking behavior between the thermally grown oxide and the bond coat. J. Eng. Gas Turbines Power 2017, 139, 022504. [Google Scholar] [CrossRef]

- Rad, M.R.; Farrahi, G.; Azadi, M.; Ghodrati, M. Stress analysis of thermal barrier coating system subjected to out-of-phase thermo-mechanical loadings considering roughness and porosity effect. Surf. Coat. Technol. 2015, 262, 77–86. [Google Scholar]

| Materials | Temperature (oC) | Elastic Modulus (GPa) | Thermal Expansion Coefficient (10−6 °C−1) | Poisson’s Ratio | Yield Strength (GPa) | ||

|---|---|---|---|---|---|---|---|

| Substrate | 20 | 123 | 12 | 0.36 | 888 | ||

| 420 | 108 | 12.5 | 0.37 | 887 | |||

| 820 | 92 | 14.7 | 0.38 | 910 | |||

| 1020 | 84 | 15.8 | 0.38 | 470 | |||

| BC | 20 | 152 | 12.3 | 0.32 | 426 | ||

| 420 | 145 | 15.2 | 0.33 | 396 | |||

| 820 | 109 | 16.3 | 0.35 | 284 | |||

| 1020 | 72 | 17.6 | 0.35 | 150 | |||

| YSZ | 20 | 20 | 40 | 60 | 9.7 | 0.2 | - |

| 420 | 20 | 40 | 60 | 9.7 | 0.2 | - | |

| 820 | 20 | 40 | 60 | 10 | 0.2 | - | |

| 1020 | 20 | 40 | 60 | 10.4 | 0.2 | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Sun, W.; Huang, R.; Ma, W. Cracking Behavior of Atmospheric Plasma-Sprayed 8YSZ Thermal Barrier Coatings during Thermal Shock Test. Coatings 2023, 13, 243. https://doi.org/10.3390/coatings13020243

Huang J, Sun W, Huang R, Ma W. Cracking Behavior of Atmospheric Plasma-Sprayed 8YSZ Thermal Barrier Coatings during Thermal Shock Test. Coatings. 2023; 13(2):243. https://doi.org/10.3390/coatings13020243

Chicago/Turabian StyleHuang, Jibo, Wen Sun, Renzhong Huang, and Wenhua Ma. 2023. "Cracking Behavior of Atmospheric Plasma-Sprayed 8YSZ Thermal Barrier Coatings during Thermal Shock Test" Coatings 13, no. 2: 243. https://doi.org/10.3390/coatings13020243

APA StyleHuang, J., Sun, W., Huang, R., & Ma, W. (2023). Cracking Behavior of Atmospheric Plasma-Sprayed 8YSZ Thermal Barrier Coatings during Thermal Shock Test. Coatings, 13(2), 243. https://doi.org/10.3390/coatings13020243