Effect of Gradient Multilayer Design on Tribological Performance of TiN/TiSiN Coatings Prepared by Cathodic Arc Ion Plating

Abstract

:1. Introduction

2. Experimental Details

2.1. Preparation and Characterization of TiN/TiSiN Coatings

2.2. Microstructure and Component Tests

2.3. Mechanical and Tribological Tests

3. Results and Discussion

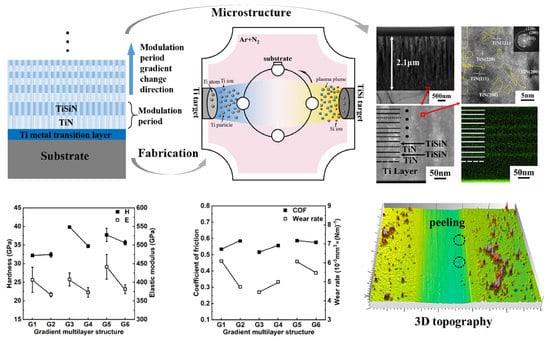

3.1. Phase Composition and Microstructure

3.2. Mechanical Properties of Coatings

3.3. Tribological Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bai, Y.; Guo, T.; Wang, J.; Gao, J.; Gao, K.; Pang, X. Stress-sensitive fatigue crack initiation mechanisms of coated titanium alloy. Acta Mater. 2021, 217, 9. [Google Scholar] [CrossRef]

- Çam, A.S.; Ergüder, T.O.; Kaya, G.; Yıldız, F. Improvement of structural/tribological properties and milling performances of tungsten carbide cutting tools by bilayer TiAlN/TiSiN and monolayer AlCrSiN ceramic films. Ceram. Int. 2022, 48, 26342–26350. [Google Scholar] [CrossRef]

- Tillmann, W.; Dildrop, M. Influence of Si content on mechanical and tribological properties of TiAlSiN PVD coatings at elevated temperatures. Surf. Coat. Technol. 2017, 321, 448–454. [Google Scholar] [CrossRef]

- Huang, X.; Etsion, I.; Shao, T. Effects of elastic modulus mismatch between coating and substrate on the friction and wear properties of TiN and TiAlN coating systems. Wear 2015, 338–339, 54–61. [Google Scholar] [CrossRef]

- Wo, P.C.; Zhao, X.L.; Munroe, P.R.; Zhou, Z.F.; Li, K.Y.; Habibi, D.; Xie, Z.H. Extremely hard, damage-tolerant ceramic coatings with functionally graded, periodically varying architecture. Acta Mater. 2013, 61, 193–204. [Google Scholar] [CrossRef]

- Xie, Z.H.; Hoffman, M.; Munroe, P.; Bendavid, A.; Martin, P.J. Deformation mechanisms of TiN multilayer coatings alternated by ductile or stiff interlayers. Acta Mater. 2008, 56, 852–861. [Google Scholar] [CrossRef]

- Vereschaka, A.; Milovich, F.; Andreev, N.; Sotova, C.; Alexandrov, I.; Muranov, A.; Mikhailov, M.; Tatarkanov, A. Investigation of the structure and phase composition of the microdroplets formed during the deposition of PVD coatings. Surf. Coat. Technol. 2022, 441, 128574. [Google Scholar] [CrossRef]

- Liu, Z.R.; Pei, F.; Chen, L.; Mayrhofer, P.H. Effect of Si-addition on structure and thermal stability of Ti-Al-N coatings. J. Alloys Compd. 2022, 917, 165483. [Google Scholar] [CrossRef]

- Diserens, M.; Patscheider, J.; Lévy, F. Mechanical properties and oxidation resistance of nanocomposite TiN–SiNx physical-vapor-deposited thin films. Surf. Coat. Technol. 1999, 120, 158–165. [Google Scholar] [CrossRef]

- Chen, Z.; Lou, M.; Geng, D.; Xu, Y.X.; Wang, Q.; Zheng, J.; Zhu, R.; Chen, Y.; Kim, K.H. Effect of the modulation geometry on mechanical and tribological properties of TiSiN/TiAlN nano-multilayer coatings. Surf. Coat. Technol. 2021, 423, 127586. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Gannon, P.; Jiang, J.C.; Meletis, E.I.; Bowman, C.; Gorokhovsky, V. Influence of Si content on the structure and internal stress of the nanocomposite TiSiN coatings deposited by large area filtered arc deposition. J. Phys. D Appl. Phys. 2009, 42, 125415. [Google Scholar] [CrossRef]

- Anderson, P.M.; Li, C. Hall-Petch relations for multilayered materials. Nanostructured Mater. 1995, 5, 349–362. [Google Scholar] [CrossRef]

- Jang, T.J.; Choi, W.S.; Kim, D.W.; Choi, G.; Jun, H.; Ferrari, A.; Kormann, F.; Choi, P.P.; Sohn, S.S. Shear band-driven precipitate dispersion for ultrastrong ductile medium-entropy alloys. Nat. Commun. 2021, 12, 4703. [Google Scholar] [CrossRef] [PubMed]

- Szajewski, B.A.; Crone, J.C.; Knap, J. Analytic model for the Orowan dislocation-precipitate bypass mechanism. Materialia 2020, 11, 100671. [Google Scholar] [CrossRef]

- Misra, A.; Hirth, J.P.; Hoagland, R.G. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 2005, 53, 4817–4824. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, P.; Liu, M.; Wang, F.; Xu, K.; Lu, T. Grain and interface boundaries governed strengthening mechanisms in metallic multilayers. J. Alloys Compd. 2017, 698, 906–912. [Google Scholar] [CrossRef]

- Yu, K.Y.; Liu, Y.; Rios, S.; Wang, H.; Zhang, X. Strengthening mechanisms of Ag/Ni immiscible multilayers with fcc/fcc interface. Surf. Coat. Technol. 2013, 237, 269–275. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chiu, W.-T.; Hung, J.-P. Mechanical properties and high temperature oxidation of CrAlSiN/TiVN hard coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2016, 303, 18–24. [Google Scholar] [CrossRef]

- Wan, Q.; Yang, B.; Liu, H.D.; Chen, J.; Zhang, J. Microstructure and adhesion of MeN/TiSiN (Me=Ti, Cr, Zr, Mo, NbxAl1−x) multilayered coatings deposited by cathodic arc ion plating. Appl. Surf. Sci. 2019, 497, 143602. [Google Scholar] [CrossRef]

- Vereschaka, A.; Aksenenko, A.; Sitnikov, N.; Migranov, M.; Shevchenko, S.; Sotova, C.; Batako, A.; Andreev, N. Effect of adhesion and tribological properties of modified composite nano-structured multi-layer nitride coatings on WC-Co tools life. Tribol. Int. 2018, 128, 313–327. [Google Scholar] [CrossRef]

- Kameneva, A.; Kichigin, V. Corrosion, wear, and friction behavior of a number of multilayer two-, three- and multicomponent nitride coatings on different substrates, depending on the phase and elemental composition gradient. Appl. Surf. Sci. 2019, 489, 165–174. [Google Scholar] [CrossRef]

- Ali, R.; Sebastiani, M.; Bemporad, E. Influence of Ti–TiN multilayer PVD-coatings design on residual stresses and adhesion. Mater. Des. 2015, 75, 47–56. [Google Scholar] [CrossRef]

- Ecker, W.; Keckes, J.; Krobath, M.; Zalesak, J.; Daniel, R.; Rosenthal, M.; Todt, J. Nanoscale evolution of stress concentrations and crack morphology in multilayered CrN coating during indentation: Experiment and simulation. Mater. Des. 2020, 188, 108478. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Zhu, X.; Zhang, K.; Ma, F.; Liu, X.; Chen, X.; He, D. Si content dependent microstructure and mechanical properties of CrN/TiSiN nanomultilayered films. Mater. Sci. Eng. A 2014, 610, 28–32. [Google Scholar] [CrossRef]

- Wo, P.C.; Munroe, P.R.; Zhou, Z.F.; Li, K.Y.; Xie, Z.H. Effects of TiN sublayers on the response of TiSiN nanocomposite coatings to nanoidentation and scratching contacts. Mater. Sci. Eng. A 2010, 527, 4447–4457. [Google Scholar] [CrossRef]

- Chang, C.-L.; Chen, W.-C.; Tsai, P.-C.; Ho, W.-Y.; Wang, D.-Y. Characteristics and performance of TiSiN/TiAlN multilayers coating synthesized by cathodic arc plasma evaporation. Surf. Coat. Technol. 2007, 202, 987–992. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Meng, J.; Zhang, K.; Ma, F.; Liu, X.; Chen, X.; He, D. Microstructure and mechanical property of TiSiN nanocomposite film with inserted CrAlN nanomultilayers. Surf. Coat. Technol. 2016, 286, 313–318. [Google Scholar] [CrossRef]

- Wan, Q.; Yang, B.; Chen, Y.M.; Cai, Y.; Liu, Y.; Meng, L.; Gao, D.X. Effect of bilayer period on microstructure and mechanical properties of TiSiN/TiN coatings. Materialia 2018, 3, 260–264. [Google Scholar] [CrossRef]

- Bartosik, M.; Arndt, M.; Rachbauer, R.; Krywka, C.; Koller, C.M.; Keckes, J.; Mayrhofer, P.H. Cross-sectional X-ray nano-diffraction and -reflectivity analysis of multilayered AlTiN–TiSiN thin films: Correlation between residual strain and bi-layer period. Scr. Mater. 2015, 107, 153–156. [Google Scholar] [CrossRef]

- Uysal, M.U. Numerical Modeling of Functional Graded TiB Coating in Nanoindentation on Determination of Mechanical Properties. Mater. Today Proc. 2015, 2, 217–223. [Google Scholar] [CrossRef]

- Rao, H.; Jayasekara, I.; Dutta, B.; Maurice, D. Segregation phenomena during deposition of functionally graded zirconia-based ceramics with Stellite 21 on a steel substrate. Surf. Coat. Technol. 2020, 383, 125270. [Google Scholar] [CrossRef]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, Applications and Future Challenges. Compos. Part B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Amrutwar, S. Effect of Plasma Nitriding Pretreatment on the Mechanical Properties of AlCrSiN-Coated Tool Steels. Materials 2019, 12, 795. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.-Y.; Chang, H.; Jhao, L.-J.; Chuang, C.-C. Tribological and mechanical properties of multilayered TiVN/TiSiN coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2018, 350, 1071–1079. [Google Scholar] [CrossRef]

- Cui, W.; Qin, G.; Duan, J.; Wang, H. A graded nano-TiN coating on biomedical Ti alloy: Low friction coefficient, good bonding and biocompatibility. Mater. Sci. Eng. C 2017, 71, 520–528. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.J.G. Industrial applications of superhard nanocomposite coatings. Surf. Coat. Technol. 2008, 202, 5063–5073. [Google Scholar] [CrossRef]

- Tu, R.; Yang, M.; Yuan, Y.; Min, R.; Li, Q.; Yang, M.; Ji, B.; Zhang, S. Sandwich Structure to Enhance the Mechanical and Electrochemical Performance of TaN/(Ta/Ti)/TiN Multilayer Films Prepared by Multi-Arc Ion Plating. Coatings 2022, 12, 694. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Callisti, M.; Vronka, M.; Karlik, M.; Duchoň, J.; Čech, J.; Havránek, V.; Polcar, T. Revealing nanoscale strain mechanisms in ion-irradiated multilayers. Acta Mater. 2022, 229, 117807. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Čížek, J.; Lorinčík, J.; Karlík, M.; Callisti, M.; Čech, J.; Havránek, V.; Li, B.; Krsjak, V.; et al. Characterizing heavy ions-irradiated Zr/Nb: Structure and mechanical properties. Mater. Des. 2022, 219, 110732. [Google Scholar] [CrossRef]

- Moritz, Y.; Saringer, C.; Tkadletz, M.; Stark, A.; Schell, N.; Letofsky-Papst, I.; Czettl, C.; Pohler, M.; Schalk, N. Oxidation behavior of arc evaporated TiSiN coatings investigated by in-situ synchrotron X-ray diffraction and HR-STEM. Surf. Coat. Technol. 2020, 404, 126632. [Google Scholar] [CrossRef]

- Dang, C.; Yao, Y.; Olugbade, T.; Li, J.; Wang, L. Effect of multi-interfacial structure on fracture resistance of composite TiSiN/Ag/TiSiN multilayer coating. Thin Solid Films 2018, 653, 107–112. [Google Scholar] [CrossRef]

- Chourasia, A.R.; Chopra, D.R. X-ray photoelectron study of TiN/SiO2 and Ti/Si interfaces. Thin Solid Films 1995, 266, 298–301. [Google Scholar] [CrossRef]

- Gonbeau, D.; Guimon, C.; Pfister-Guillouzo, G.; Levasseur, A. XPS study of thin films of titanium oxysulfides. Surf. Sci. 1991, 254, 81–89. [Google Scholar] [CrossRef]

- Dementjev, A.P.; Ivanova, O.P.; Vasilyev, L.A.; Naumkin, A.V.; Nemirovsky, D.M.; Shalaev, D.Y. Altered layer as sensitive initial chemical state indicator. J. Vac. Sci. Technol. A 1994, 12, 423–427. [Google Scholar] [CrossRef]

- Veprek, S.; Niederhofer, A.; Moto, K.; Bolom, T.; Männling, H.D.; Nesladek, P.; Dollinger, G.; Bergmaier, A. Composition, nanostructure and origin of the ultrahardness. Surf. Coat. Technol. 2000, 152, 133–134. [Google Scholar]

- Kimura, T.; Yoshida, R.; Azuma, K. Titanium Silicon Nitride Films With Low Silicon Content Deposited via Reactive High-Power Pulsed Sputtering Penning Discharge. IEEE Trans. Plasma Sci. 2021, 49, 53–60. [Google Scholar] [CrossRef]

- Oliveira, J.C.; Fernandes, F.; Ferreira, F.; Cavaleiro, A. Tailoring the nanostructure of Ti–Si–N thin films by HiPIMS in deep oscillation magnetron sputtering (DOMS) mode. Surf. Coat. Technol. 2015, 264, 140–149. [Google Scholar] [CrossRef]

- Miletić, A.; Panjan, P.; Škorić, B.; Čekada, M.; Dražič, G.; Kovač, J. Microstructure and mechanical properties of nanostructured Ti–Al–Si–N coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2014, 241, 105–111. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, J.; Tian, X.; Gong, C.; Zheng, W.; He, Y.; Gao, Z. Microstructure, adhesion, mechanical and corrosion properties of TiN coatings deposited by high energy pulse-enhanced vacuum arc evaporation. J. Adhes. Sci. Technol. 2019, 34, 1040–1061. [Google Scholar] [CrossRef]

- Zhu, L.-H.; Song, C.; Ni, W.-Y.; Liu, Y.-X. Effect of 10% Si addition on cathodic arc evaporated TiAlSiN coatings. Trans. Nonferrous Met. Soc. China 2016, 26, 1638–1646. [Google Scholar] [CrossRef]

- Li, P.; Chen, L.; Wang, S.Q.; Yang, B.; Du, Y.; Li, J.; Wu, M.J. Microstructure, mechanical and thermal properties of TiAlN/CrAlN multilayer coatings. Int. J. Refract. Met. Hard Mater. 2013, 40, 51–57. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Yan, S.J.; Han, B.; Yang, B.; Lin, B.Z.; Zhang, Z.D.; Ai, Z.W.; Pelenovich, V.O.; Fu, D.J. Influence of modulation period and modulation ratio on structure and mechanical properties of TiBN/CrN coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2015, 351, 1116–1121. [Google Scholar] [CrossRef]

- Gao, Z.C.; Buchinger, J.; Koutna, N.; Wojcik, T.; Hahn, R.; Mayrhofer, P.H. Ab initio supported development of TiN/MoN superlattice thin films with improved hardness and toughness. Acta Mater. 2022, 231, 117871. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, J.-W.; Duh, J.-G. Mechanical strengthening in self-lubricating CrAlN/VN multilayer coatings for improved high-temperature tribological characteristics. Surf. Coat. Technol. 2016, 303, 12–17. [Google Scholar] [CrossRef]

- Kim, Y.J.; Byun, T.J.; Han, J.G. Bilayer period dependence of CrN/CrAlN nanoscale multilayer thin films. Superlattices Microstruct. 2009, 45, 73–79. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Akhter, R.; Zhou, Z.; Xie, Z.; Munroe, P. Influence of substrate bias on the scratch, wear and indentation response of TiSiN nanocomposite coatings. Surf. Coat. Technol. 2021, 425, 127687. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Tu, R.; Yuan, Y.; Yang, M.; Min, R.; Jiao, J.; Li, Q.; Yang, M.; Ji, B.; Zhang, S. Effect of Negative Bias of HiPIMS and AIP Hybrid Deposition on Microstructure, Mechanical and Anti-Corrosive Properties of Cr2N/TiN Multilayer Coatings. Coatings 2022, 122, 845. [Google Scholar] [CrossRef]

- Akhter, R.; Zhou, Z.; Xie, Z.; Munroe, P. TiN versus TiSiN coatings in indentation, scratch and wear setting. Appl. Surf. Sci. 2021, 563, 150356. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Johansson, M.P.; Andersson, J.M. Wear mechanisms of PVD-coated PCBN cutting tools. Wear 2013, 302, 1219–1229. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, F.; Zhang, M. The enhancement of individual friction and corrosion properties of CrSiN coatings by Mo doping in seawater. Surf. Coat. Technol. 2022, 432, 128069. [Google Scholar] [CrossRef]

- Fernandes, F.; Al-Rjoub, A.; Cavaleiro, D.; Polcar, T.; Cavaleiro, A. Room and High Temperature Tribological Performance of Multilayered TiSiN/TiN and TiSiN/TiN(Ag) Coatings Deposited by Sputtering. Coatings 2020, 10, 1191. [Google Scholar] [CrossRef]

- Zha, X.; Wang, T.; Chen, F.; Wang, J.; Lin, L.; Lin, F.; Xie, H.; Jiang, F. Investigation the fatigue impact behavior and wear mechanisms of bilayer micro-structured and multilayer nano-structured coatings on cemented carbide tools in milling titanium alloy. Int. J. Refract. Met. Hard Mater. 2022, 103, 105738. [Google Scholar] [CrossRef]

- Geng, D.; Zeng, R.; Wu, Z.; Wang, Q. An investigation on microstructure and milling performance of arc-evaporated TiSin/AlTiN film. Thin Solid Film. 2020, 709, 138243. [Google Scholar] [CrossRef]

- Yuan, Y.; Qin, Z.; Yu, D.; Wang, C.; Sui, J.; Lin, H.; Wang, Q. Relationship of microstructure, mechanical properties and hardened steel cutting performance of TiSiN-based nanocomposite coated tool. J. Manuf. Process. 2017, 28, 399–409. [Google Scholar] [CrossRef]

- Frank, F.; Kainz, C.; Tkadletz, M.; Czettl, C.; Pohler, M.; Schalk, N. Microstructural and micro-mechanical investigation of cathodic arc evaporated ZrN/TiN multilayer coatings with varying bilayer thickness. Surf. Coat. Technol. 2022, 432, 128070. [Google Scholar] [CrossRef]

- Li, C.; Wang, L.; Shang, L.; Cao, X.; Zhang, G.; Yu, Y.; Li, W.; Zhang, S.; Hu, H. Mechanical and high-temperature tribological properties of CrAlN/TiSiN multilayer coating deposited by PVD. Ceram. Int. 2021, 47, 29285–29294. [Google Scholar] [CrossRef]

- Huang, S.-H.; Chen, S.-F.; Kuo, Y.-C.; Wang, C.-J.; Lee, J.-W.; Chan, Y.-C.; Chen, H.-W.; Duh, J.-G.; Hsieh, T.-E. Mechanical and tribological properties evaluation of cathodic arc deposited CrN/ZrN multilayer coatings. Surf. Coat. Technol. 2011, 206, 1744–1752. [Google Scholar] [CrossRef]

- Chang, C.-L.; Huang, C.-H.; Lin, C.-Y.; Yang, F.-C.; Tang, J.-F. Mechanical properties of amorphous and crystalline CrN/CrAlSiN multilayer coating fabricated using HPPMS. Surf. Interfaces 2022, 31, 102064. [Google Scholar] [CrossRef]

- Vogli, E.; Tillmann, W.; Selvadurai-Lassl, U.; Fischer, G.; Herper, J. Influence of Ti/TiAlN-multilayer designs on their residual stresses and mechanical properties. Appl. Surf. Sci. 2011, 257, 8550–8557. [Google Scholar] [CrossRef]

- Sheng, L.; Xiao, Y.; Jiao, C.; Du, B.; Li, Y.; Wu, Z.; Shao, L. Influence of layer number on microstructure, mechanical properties and wear behavior of the TiN/Ti multilayer coatings fabricated by high-power magnetron sputtering deposition. J. Manuf. Process. 2021, 70, 529–542. [Google Scholar] [CrossRef]

- Yang, S.-M.; Chang, Y.-Y.; Lin, D.-Y.; Wang, D.-Y.; Wu, W. Mechanical and tribological properties of multilayered TiSiN/CrN coatings synthesized by a cathodic arc deposition process. Surf. Coat. Technol. 2008, 202, 2176–2181. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, Y.; Ding, H.; Peng, Y.; Zhang, S.; Yu, L.; Zhang, P. Combining magnetic filtered cathodic arc deposition with ion beam sputtering to afford superhard TiSiN multilayer composite films with tunable microstructure and mechanical properties. Vacuum 2016, 125, 6–12. [Google Scholar] [CrossRef]

- Wu, Z.; Zheng, G.; Yan, J.; Cheng, X.; Liu, H.; Yang, X. Effect of TiAlSiN coating residual stress on its sliding wear and cutting wear performance. Int. J. Adv. Manuf. Technol. 2022, 123, 3885–3900. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Maier, H.J.; Heidenblut, T.; Kahra, C.; Carlet, M. Influence of residual stresses in hard tool coatings on the cutting performance. J. Manuf. Process. 2021, 69, 340–350. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Browne, T.; Heckerman, B.; Meletis, E.I. Mechanical and tribological properties of nanocomposite TiSiN coatings. Surf. Coat. Technol. 2010, 204, 2123–2129. [Google Scholar] [CrossRef]

| Parameter | Values |

|---|---|

| Target materials | Ti and Ti75Si25 |

| Target current of Ti (A) | 120 |

| Target current of Ti75Si25 (A) | 110 |

| Operation pressure (Pa) | 1.3 |

| Deposition temperature (°C) | 350 |

| Nitrogen partial pressure (Pa) | 0.9 |

| Deposition time (min) | 50 |

| Bias voltage (V) | −150 |

| Specimens | Total Deposition Time (min) | Ti Layer Deposition Time (min) | Rotation Speed (Rs, rpm) | Deposition Time per Rs (min) |

|---|---|---|---|---|

| G1 | 50 | 2 | Increasing from 1 to 6 | 8 |

| G2 | 50 | 2 | Decreasing from 6 to 1 | 8 |

| G3 | 50 | 2 | Decreasing from 6 to 1, then increasing to 6 | 4 |

| G4 | 50 | 2 | Increasing from 1 to 6, then decreasing to 1 | 4 |

| G5 | 50 | 2 | Decreasing–increasing–decreasing–increasing | 2 |

| G6 | 50 | 2 | Increasing–decreasing–increasing–decreasing | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, R.; Jiao, J.; Jiang, M.; Yang, M.; Ji, B.; Gao, T.; Li, Q.; Zhang, S.; Zhang, L. Effect of Gradient Multilayer Design on Tribological Performance of TiN/TiSiN Coatings Prepared by Cathodic Arc Ion Plating. Coatings 2023, 13, 836. https://doi.org/10.3390/coatings13050836

Tu R, Jiao J, Jiang M, Yang M, Ji B, Gao T, Li Q, Zhang S, Zhang L. Effect of Gradient Multilayer Design on Tribological Performance of TiN/TiSiN Coatings Prepared by Cathodic Arc Ion Plating. Coatings. 2023; 13(5):836. https://doi.org/10.3390/coatings13050836

Chicago/Turabian StyleTu, Rong, Jiao Jiao, Mingquan Jiang, Mai Yang, Baifeng Ji, Tenghua Gao, Qizhong Li, Song Zhang, and Lianmeng Zhang. 2023. "Effect of Gradient Multilayer Design on Tribological Performance of TiN/TiSiN Coatings Prepared by Cathodic Arc Ion Plating" Coatings 13, no. 5: 836. https://doi.org/10.3390/coatings13050836

APA StyleTu, R., Jiao, J., Jiang, M., Yang, M., Ji, B., Gao, T., Li, Q., Zhang, S., & Zhang, L. (2023). Effect of Gradient Multilayer Design on Tribological Performance of TiN/TiSiN Coatings Prepared by Cathodic Arc Ion Plating. Coatings, 13(5), 836. https://doi.org/10.3390/coatings13050836