The Natural Growth of CaCO3 Crystals on Hemp Yarns: A Morphology Analysis and the Mechanical Effects on Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

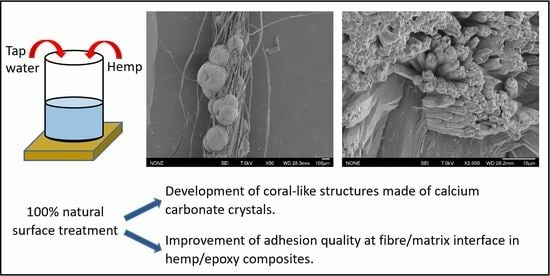

2.2. Surface Treatment

2.3. Differential Scanning Calorimetry

2.4. Microscopic Observations

2.5. Tensile Testing

3. Results and Discussion

3.1. Morphology Analysis of CaCO3 Crystals

3.2. Tensile Tests on Treated and Untreated Hemp Yarns

3.3. Characterisation of Composite Plates

3.4. Mechanical Comparison of Treated and Untreated Hemp Fabric/Epoxy Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zwawi, M. A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Zwawi, M.; Mehran, M.T.; Kanthasamy, R.; Bahadar, A. Jute based bio and hybrid composites and their applications. Fibers 2019, 7, 77. [Google Scholar] [CrossRef]

- Abdollahiparsa, H.; Shahmirzaloo, A.; Teuffel, P.; Blok, R. A review of recent developments in structural applications of natural fiber-Reinforced composites (NFRCs). Compos. Adv. Mater. 2023, 32, 26349833221147540. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial hemp fibers: An overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Marrot, L.; Alao, P.F.; Mikli, V.; Kers, J. Properties of Frost-Retted Hemp Fibers for the Reinforcement of Composites. J. Nat. Fibers 2021, 19, 16017–16028. [Google Scholar] [CrossRef]

- Madsen, B.; Hoffmeyer, P.; Lilholt, H. Hemp yarn reinforced composites—II. Tensile properties. Compos. Part A 2007, 38, 2204–2215. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crop. Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M.; Chen, L. Interface and bonding mechanisms of plant fibre composites: An overview. Compos. Part B 2016, 101, 31–45. [Google Scholar] [CrossRef]

- Palanikumar, K.; Natarajan, E.; Markandan, K.; Ang, C.K.; Franz, G. Targeted pre-treatment of hemp fibers and the effect on mechanical properties of polymer composites. Fibers 2023, 11, 43. [Google Scholar] [CrossRef]

- Mohit, H.; Selvan, V.A.M. A comprehensive review on surface modification, structure interface and bonding mechanism of plant cellulose fiber reinforced polymer based composites. Compos. Interfaces 2018, 25, 629–667. [Google Scholar] [CrossRef]

- Bartos, A.; Anggono, J.; Farkas, Á.E.; Kun, D.; Soetaredjo, F.E.; Móczó, J.; Purwaningsih, H.; Pukánszky, B. Alkali treatment of lignocellulosic fibers extracted from sugarcane bagasse: Composition, structure, properties. Polym. Test. 2020, 88, 106549. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Werchefani, M.; Lacoste, C.; Belguith, H.; Gargouri, A.; Bradai, C. Effect of chemical and enzymatic treatments of alfa fibers on polylactic acid bio-composites properties. J. Compos. Mater. 2020, 54, 4959–4967. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Paz, E.; Martinez, M.A. Influence of Low Pressure Plasma Treatment on the Durability of Thermoplastic Composites LDPE-flax/coconut under Thermal and Humidity Conditions. Fibers Polym. 2018, 19, 1327–1334. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Ma, H.; Cai, S.; Huang, X. Effect of processing temperature on the static and dynamic mechanical properties and failure mechanisms of flax fiber reinforced composites. Compos. Commun. 2020, 20, 100343. [Google Scholar] [CrossRef]

- Guillebaud-Bonnafous, C.; Vasconcellos, D.; Touchard, F.; Chocinski-Arnault, L. Experimental and numerical investigation of the interface between epoxy matrix and hemp yarn. Compos. Part A 2012, 43, 2046–2058. [Google Scholar] [CrossRef]

- ASTM C1557-20; Standard Test Method for Tensile Strength and Young’s Modulus of Fibers. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/standards/c1557 (accessed on 1 October 2023).

- Al-Maharma, A.Y.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. Effect of Moisture Absorption on the Mechanical Performance of Natural Fiber Reinforced Woven Hybrid Bio-Composites. J. Nat. Fibers 2020, 17, 84–100. [Google Scholar] [CrossRef]

- Malloum, A.; El Mahi, A.; Idriss, M. The Effects of Water Ageing on the Tensile Static and Fatigue Behaviors of Greenpoxy–Flax Fiber Composites. J. Compos. Mater. 2019, 53, 2927–2939. [Google Scholar] [CrossRef]

- Malpot, A.; Touchard, F.; Bergamo, S. Effect of relative humidity on mechanical properties of a woven thermoplastic composite for automotive application. Polym. Test. 2015, 48, 160–168. [Google Scholar] [CrossRef]

- Vidallon, M.L.P.; Yu, F.; Teo, B.M. Controlling the Size and Polymorphism of Calcium Carbonate Hybrid Particles Using Natural Biopolymers. Cryst. Growth Des. 2020, 20, 645–652. [Google Scholar] [CrossRef]

- Kato, T.; Sugawara, A.; Hosoda, N. Calcium carbonate-organic hybrid materials. Adv. Mat. 2002, 14, 869–877. [Google Scholar] [CrossRef]

- Liu, L.; He, D.; Wang, G.S.; Yu, S.H. Bioinspired Crystallization of CaCO3 Coatings on Electrospun Cellulose Acetate Fiber Scaffolds and Corresponding CaCO3 Microtube Networks. Langmuir 2011, 27, 7199–7206. [Google Scholar] [CrossRef]

- Wanga, R.F.; Denga, L.G.; Lia, K.; Fana, X.J.; Lib, W.; Lua, H.Q. Fabrication and characterization of sugarcane bagasse–calcium carbonate composite for the efficient removal of crystal violet dye from wastewater. Ceram. Int. 2020, 46, 27484–27492. [Google Scholar] [CrossRef]

- Ajikumar, P.K.; Lakshminarayanan, R.; Valiyaveettil, S. Controlled Deposition of Thin Films of Calcium Carbonate on Natural and Synthetic Templates. Cryst. Growth Des. 2004, 4, 331–335. [Google Scholar] [CrossRef]

- Jia, N.; Li, S.M.; Maa, M.G.; Suna, R.C.; Zhu, J.F. Hydrothermal fabrication, characterization, and biological activity of cellulose/CaCO3 bionanocomposites. Carbohydr. Polym. 2012, 88, 179–184. [Google Scholar] [CrossRef]

- Chen, X.; Qian, X.; An, X. Using calcium carbonate whiskers as papermaking filler. Bioresources 2011, 6, 2435–2447. [Google Scholar] [CrossRef]

- Subramanian, R.; Maloney, T.; Paulapuro, H. Calcium carbonate composite fillers. Tappi J. 2005, 4, 23–27. [Google Scholar]

- Alam, P.; Fagerlund, P.; Hägerstrand, P.; Töyrylä, J.; Amini, S.; Tadayon, M.; Miserez, A.; Kumar, V.; Pahlevan, M.; Toivakka, M. L-Lysine templated CaCO3 precipitated to flax develops flowery crystal structures that improve the mechanical properties of natural fibre reinforced composites. Compos. Part A 2015, 75, 84–88. [Google Scholar] [CrossRef]

- Stillfried, D.G.; Toivakka, M.; Alam, P. Crispatotrochus-mimicking coatings improve the flexural properties of organic fibres. J. Mater. Sci. 2013, 48, 8449–8453. [Google Scholar] [CrossRef]

- Alam, P.; Stillfried, D.G.; Celli, J.; Toivakka, M. Effects of fibre-surface morphology on the mechanical properties of Porifera-inspired rubber-matrix composites. Appl. Phys. A 2013, 111, 1031–1036. [Google Scholar] [CrossRef]

| Young’s Modulus (MPa) | Ultimate Stress (MPa) | Ultimate Strain (%) | |

|---|---|---|---|

| Composite with untreated hemp fabric | 4240 ± 200 | 45.0 ± 2.3 | 2.5 ± 0.2 |

| Composite with treated hemp fabric | 4850 ± 200 | 37.8 ± 1.9 | 1.7 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drouhet, Q.; Barbière, R.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D. The Natural Growth of CaCO3 Crystals on Hemp Yarns: A Morphology Analysis and the Mechanical Effects on Composites. Fibers 2023, 11, 88. https://doi.org/10.3390/fib11100088

Drouhet Q, Barbière R, Touchard F, Chocinski-Arnault L, Mellier D. The Natural Growth of CaCO3 Crystals on Hemp Yarns: A Morphology Analysis and the Mechanical Effects on Composites. Fibers. 2023; 11(10):88. https://doi.org/10.3390/fib11100088

Chicago/Turabian StyleDrouhet, Quentin, Romain Barbière, Fabienne Touchard, Laurence Chocinski-Arnault, and David Mellier. 2023. "The Natural Growth of CaCO3 Crystals on Hemp Yarns: A Morphology Analysis and the Mechanical Effects on Composites" Fibers 11, no. 10: 88. https://doi.org/10.3390/fib11100088

APA StyleDrouhet, Q., Barbière, R., Touchard, F., Chocinski-Arnault, L., & Mellier, D. (2023). The Natural Growth of CaCO3 Crystals on Hemp Yarns: A Morphology Analysis and the Mechanical Effects on Composites. Fibers, 11(10), 88. https://doi.org/10.3390/fib11100088