Experimental Study on Dynamic and Thermal Behaviour of Chopped Glass, Sisal, and Flax Fiber-Reinforced Gears

Abstract

:1. Introduction

2. Experimentation

2.1. Design of Gear

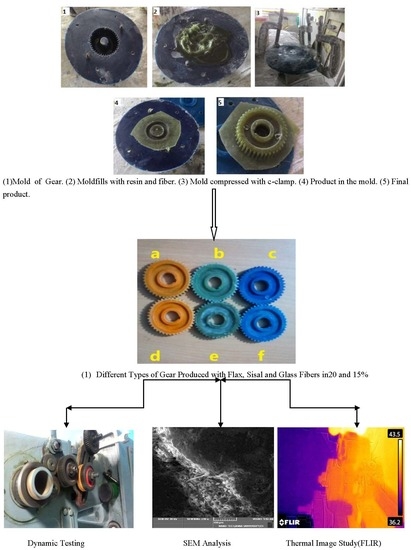

2.2. Fabrication of Composite Gears

2.3. Dynamic Testing

2.4. Scanning Electron Microscopic Analysis

3. Results and Discussion

3.1. Dynamic Test Results

3.2. Thermal Analysis Using FLIR Camera

4. Conclusions

- The fabrication of fiber-reinforced gear is very economical and simple by room temperature molding method.

- The SEM analysis shows that the reduction in tooth thickness after running the gear for 1 h is more in glass fiber-reinforced gear, even though it fails after 30 min, whereas the tooth wear is less for flax reinforced gears.

- The weight reduction of glass fiber-reinforced gears is 2%, whereas for natural fiber-reinforced gears, it is less than 1%.

- The temperature study using FLIR camera shows that the natural fiber-reinforced gears run until 42 °C, whereas the glass fiber gears failed at 37 °C.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| GFRPG-20 | 20% Glass Fiber-Reinforced Polyester Gear |

| FFRPG-20 | 20% Flax Fiber-Reinforced Polyester Gear |

| SFRPG-20 | 20% Sisal Fiber-Reinforced Polyester Gear |

| GFRPG-15 | 15% Glass Fiber-Reinforced Polyester Gear |

| FFRPG-15 | 15% Flax Fiber-Reinforced Polyester Gear |

| SFRPG-15 | 15% Sisal Fiber-Reinforced Polyester Gear |

References

- Hirogaki, T.; Aoyama, E.; Katayama, T.; Iwasaki, S.; Yagura, Y.; Sugimura, K. Design systems for gear elements made of cotton fiber-reinforced plastics. Compos. Struct. 2004, 66, 47–52. [Google Scholar] [CrossRef]

- Senthilvelan, S.; Gnanamoorthy, R. Influence of reinforcement on composite gear metrology. Mech. Mach. Theory 2008, 43, 1198–1209. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga Gregorio, G.C.; Wypych, F. Biodegradable composites based on lingo cellousic fibers—Anoverview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Joseph, M.I.K.; Thomas, S. Mechanical Performance of Short Banana/Sisal Hybrid Fiber Reinforced Polyester composite. J. Reinf. Plast. Compos. 2010, 29, 12. [Google Scholar] [CrossRef]

- Saxena, M.; Pappu, A.; Sharma, A.; Haque, R.; Wankhede, S. Composite materials from natural resource: Recent trends and future potentials. In Advance in Composite Materials—Analysis of Natural and Man-Made Materials; Intech: London, UK, 2011; pp. 121–162. ISBN 978-953-307-449-8. Available online: www.intechopen.com (accessed on 22 July 2015).

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Mechanical property evaluation of sisal–jute–glass fiber reinforced polyester composites. Compos. Part B Eng. 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M. Can Flax Replace E-Glass in structural composites? A small wind turbine blade case study. Compos. Part B Eng. 2013, 52, 172–181. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Sharavanan, R.; Chandrasekaran, M.; Elanchezhian, C.; Sathyanarayanan, R.; Raja, R.N.; Kokan, S.J. Experimental Determination of Mechanical Properties of Banana Jute Hybrid composite. Fiber Polym. 2015, 16, 164–172. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, S.; Ren, H.; Shi, S.Q.; Zhang, H.; Cai, L.; Li, J. Scalable Fabrication of Natural-Fiber Reinforced Composites with electromagnetic Interference Shielding Properties by Incorporating PowderedActivated Carbon. Materials 2016, 9, 10. [Google Scholar] [CrossRef] [PubMed]

- Xia, C.; Shi, S.Q.; Wu, Y.; Cai, L. High pressure-assisted magnesium carbonate impregnated natural fiber-reinforced composites. Ind. Crop. Prod. 2016, 86, 16–22. [Google Scholar] [CrossRef] [Green Version]

- Xia, C.; Garcia, A.C.; Shi1, S.Q.; Qiu, Y.; Warner, N.; Wu, Y.; Cai, L.; Rizvi, H.R.; D’Souza1, N.A.; Nie, X. Hybrid boron nitride-natural fiber composites for enhanced thermal conductivity. Sci. Rep. 2016, 6, 34726. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meenakshi, C.M.; Krishnamoorthy, A. Mechanical Characterization and Comparative Evaluation of the Different Combination of Natural and Glass Fiber Reinforced Hybrid Epoxy Composites. In Advanced Manufacturing and Materials Science. Lecture Notes on Multidisciplinary Industrial Engineering; Antony, K., Davim, J., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Kurian, A.J.; Mathew, V.; Sivasubramanian, P. Optimization of fiber length and fiber weight fraction in natural fiber reinforced composites. IJTARME 2014, 3, 2319–3182. [Google Scholar]

- Rahman, A.F.; Kumar, A.P.S.; Giriraj, B.; Arun, A.P.; Santhosh, R. Performance of Polymer gears reinforced with sisal woven rovings. Carbon Sci. Technol. 2014, 6, 41–48. [Google Scholar]

- Senthilvelan, S.; Gnanamoorthy, R. Effect of rotational speed on the performance of unreinforced and glass fiber reinforced Nylon 6 spur gears. Mater. Des. 2007, 28, 765–772. [Google Scholar] [CrossRef]

- Mahebub, V.; Kevin, V. Comparative Finite Element Analysis of Metallic and Non Metallic Spur Gear. IOSR J. Mech. Civ. Eng. 2014, 11, 136–145. [Google Scholar]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Mohammed, M.H.; Dauda, B. Unsaturated Polyester Resin Reinforced With Chemically Modified Natural Fibre. J. Polym. Text. Eng. 2014, 1, 31–38. [Google Scholar]

- Ghazali, W.M.; Idris, D.M.N.D.; Sofian, A.H.; Siregar, J.P.; Aziz, I.A.A. A review on failure characteristics of polymer gear. In Proceedings of the 2nd International Conference on Automotive Innovation and Green Vehicle, Cyberjaya, Malaysia, 2–3 August 2016. [Google Scholar] [CrossRef]

| Serial Number | Parameter | Value |

|---|---|---|

| 1 | Number of teeth (N) | 40 |

| 2 | Pitch circle diameter (PCD) | 64 mm |

| 3 | Base Circle Diameter | 60 mm |

| 4 | Module (m) | 1.6 |

| 5 | Face Width (b) | 16 mm |

| 6 | Diametrical Pitch | 0.625 mm |

| 7 | Addendum (A) | 1.6 mm |

| 8 | Dedendum (D) | 2 mm |

| Gear Type | Initial Temperature (°C) | Final Temperature (°C) |

|---|---|---|

| GFRPG-20 | 31.7–35.8 | 33.1–37.1 |

| FFRPG-20 | 35.1–41.5 | 35.4–42.6 |

| SFRPG-20 | 32.7–36.8 | 33.5–42.6 |

| GFRPG-15 | 33.5–37.2 | 36.2–43.5 |

| FFRPG-15 | 31.7–35.7 | 33.9–41.6 |

| SFRPG-15 | 32.7–41.3 | 34.8–42.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhanushkodi, C.M.M.; Arunagri, K. Experimental Study on Dynamic and Thermal Behaviour of Chopped Glass, Sisal, and Flax Fiber-Reinforced Gears. Fibers 2018, 6, 60. https://doi.org/10.3390/fib6030060

Dhanushkodi CMM, Arunagri K. Experimental Study on Dynamic and Thermal Behaviour of Chopped Glass, Sisal, and Flax Fiber-Reinforced Gears. Fibers. 2018; 6(3):60. https://doi.org/10.3390/fib6030060

Chicago/Turabian StyleDhanushkodi, C. M. Meenakshi, and Krishnamoorthy Arunagri. 2018. "Experimental Study on Dynamic and Thermal Behaviour of Chopped Glass, Sisal, and Flax Fiber-Reinforced Gears" Fibers 6, no. 3: 60. https://doi.org/10.3390/fib6030060

APA StyleDhanushkodi, C. M. M., & Arunagri, K. (2018). Experimental Study on Dynamic and Thermal Behaviour of Chopped Glass, Sisal, and Flax Fiber-Reinforced Gears. Fibers, 6(3), 60. https://doi.org/10.3390/fib6030060