The Degradation of Cellulose by Radio Frequency Plasma

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Plasma Treatment

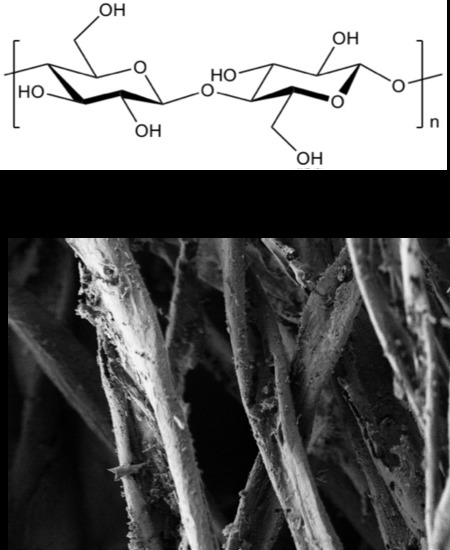

2.3. Field Emission Scanning Electron Microscopy (FE-SEM)

2.4. Tensile Testing for Load at Break

2.5. X-ray Photoelectron Spectroscopy (XPS)

2.6. Gel Permeation Chromatography (GPC)

3. Results and Discussion

3.1. Visual Yarn Degradation

3.2. Load at Break for Yarns

3.3. Molecular Weight

3.4. Evaluation of C1s Deconvoluted Peaks

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mu, B.; Xu, H.; Yang, Y. Accelerated hydrolysis of substituted cellulose for potential biofuel production: Kinetic study and modeling. Bioresour. Technol. 2015, 196, 332–338. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horn, S.; Vaaje-Kolstad, G.; Westereng, B.; Eijsink, V.G. Novel enzymes for the degradation of cellulose. Biotechnol. Biofuels 2012, 5, 45. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-H.; Chang, Y.-H.; Hsu, Y.-H. Degradation of cotton cellulose treated with hydrochloric acid either in water or in ethanol. Food Hydrocoll. 2009, 23, 1548–1553. [Google Scholar] [CrossRef]

- Mukherjee, S.M.; Woods, H.J. X-ray and electron microscope studies of the degradation of cellulose by sulphuric acid. Biochim. Biophys. Acta 1953, 10, 499–511. [Google Scholar] [CrossRef]

- Morent, R.; De Geyter, N.; Vershuren, J.; De Clerck, K.; Kiekens, P.; Leys, C. Non-thermal plasma treatment of textiles. Surf. Coat. Technol. 2008, 202, 3427–3449. [Google Scholar] [CrossRef]

- Pekárek, S. Non-Thermal Plasma Ozone Generation. Acta Polytech. 2003, 43, 47–51. [Google Scholar]

- Bhat, N.V.; Netravali, A.N.; Gore, A.V.; Sathianarayanan, M.P.; Arolkar, G.A.; Deshmukh, R.R. Surface modification of cotton fabrics using plasma technology. Text. Res. J. 2011, 81, 1014–1026. [Google Scholar] [CrossRef]

- Peng, S.; Gao, Z.; Sun, J.; Yao, L.; Qiu, Y. Influence of argon/oxygen atmospheric dielectric barrier discharge treatment on desizing and scouring of poly (vinyl alcohol) on cotton fabrics. Appl. Surf. Sci. 2009, 255, 9458–9462. [Google Scholar] [CrossRef]

- Benoit, M.; Rodrigues, A.; De Oliveira Vigier, K.; Fourré, E.; Barrault, J.; Tatibouët, J.-M.; Jérôme, F. Combination of ball-milling and non-thermal atmospheric plasma as physical treatments for the saccharification of microcrystalline cellulose. Green Chem. 2012, 14, 2212. [Google Scholar] [CrossRef]

- Mihailović, D.; Šaponjić, Z.; Radoičić, M.; Lazović, S.; Baily, C.J.; Jovančić, P.; Nedeljković, J.; Radetić, M. Functionalization of cotton fabrics with corona/air rf plasma and colloidal tio2 nanoparticles. Cellulose 2011, 18, 811–825. [Google Scholar] [CrossRef]

- Hua, Z.Q.; Sitaru, R.; Denes, F.; Young, R.A. Mechanisms of oxygen- and argon-rf-plasma-induced surface chemistry of cellulose. Plasmas Polym. 1997, 2, 199–224. [Google Scholar] [CrossRef]

- Jinka, S.; Turaga, U.; Singh, V.; Behrens, R.L.; Gumeci, C.; Korzeniewski, C.; Anderson, T.; Wolf, R.; Ramkumar, S. Atmospheric Plasma Effect on Cotton Nonwovens. Ind. Eng. Chem. Res. 2014, 53, 12587–12593. [Google Scholar] [CrossRef]

- Karahan, H.A.; Ozdogan, E.; Demir, A.; Ayhan, H.; Seventekin, N. Effects of Atmospheric Pressure Plasma Treatments on Certain Properties of Cotton Fabrics. Fibres Text. East. Eur. 2009, 17, 19–22. [Google Scholar]

- Sun, D.; Stylios, G.K. Investigating the plasma modification of natural fiber fabrics-the effect on fabric surface and mechanical properties. Text. Res. J. 2005, 75, 639–644. [Google Scholar] [CrossRef]

- Inbakumar, S.; Morent, R.; De Geyter, N.; Desmet, T.; Anukaliani, A.; Dubruel, P.; Leys, C. Chemical and physical analysis of cotton fabrics plasma-treated with a low pressure dc glow discharge. Cellulose 2009, 17, 417–426. [Google Scholar] [CrossRef]

- Karahan, H.A.; Ozdogan, E. Improvements of surface functionality of cotton fibers by atmospheric plasma treatment. Fibers Polym. 2008, 9, 21–26. [Google Scholar] [CrossRef]

- Topalovic, T.; Nierstrasz, V.A.; Bautista, L.; Jocic, D.; Navarro, A.; Warmoeskerken, M.M.C.G. Xps and contact angle study of cotton surface oxidation by catalytic bleaching. Colloids Surf. A Physicochem. Eng. Asp. 2007, 296, 76–85. [Google Scholar] [CrossRef]

- Sun, D.; Stylios, G.K. Fabric surface properties affected by low temperature plasma treatment. J. Mater. Process. Technol. 2006, 173, 172–177. [Google Scholar] [CrossRef]

- Vasiljević, J.; Gorjanc, M.; Jerman, I.; Tomšič, B.; Modic, M.; Mozetič, M.; Orel, B.; Simončič, B. Influence of oxygen plasma pre-treatment on the water repellency of cotton fibers coated with perfluoroalkyl-functionalized polysilsesquioxane. Fibers Polym. 2016, 17, 695–704. [Google Scholar] [CrossRef]

- D’Agostino, R.; Favia, P.; Fracassi, F. Plasma Processing of Polymers; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1997. [Google Scholar]

- Brushwood, D.E.; Perkins, H.H. Determining the metal content of cotton. Text. Chem. Color. 1994, 26, 32–35. [Google Scholar]

| Exposure Time (min) | Radio Frequency (RF) Power (W) | Power Density (W/cm2) | O2 Flowrate (cc/min) |

|---|---|---|---|

| 15 | 500 | 0.46 | 75 |

| 15 | 500 | 0.46 | 200 |

| 30 | 500 | 0.46 | 200 |

| 60 | 500 | 0.46 | 200 |

| 90 | 500 | 0.46 | 200 |

| Yarn Type | Exposure Time (min) | C-C/C-H (C1) (%) | C-O (C2) (%) | C=O/O-C-O (C3) (%) | O-C=O (C4) (%) | O:C Atomic Ratio |

|---|---|---|---|---|---|---|

| Greige | 0 | 84.6 | 10.0 | 5.47 | 0 | 0.136 |

| 15 a | 40.2 | 36.8 | 12.1 | 10.9 | 0.748 | |

| 15 | 47.4 | 27.3 | 14.5 | 10.8 | 0.733 | |

| 30 | 44.1 | 32.6 | 11.7 | 11.5 | 0.782 | |

| 60 | 32.2 | 38.9 | 4.61 | 14.3 | 0.852 | |

| 90 | 32.9 | 40.8 | 18.7 | 7.63 | 0.929 | |

| Scoured | 0 | 72.1 | 18.8 | 6.38 | 2.75 | 0.258 |

| 15 a | 43.0 | 33.8 | 10.5 | 12.7 | 0.582 | |

| 15 | 38.2 | 37.9 | 11.4 | 12.5 | 0.754 | |

| 30 | 45.8 | 32.9 | 11.1 | 10.2 | 0.620 | |

| 60 | 29.8 | 44.2 | 14.2 | 11.8 | 0.800 | |

| 90 | 30.9 | 42.9 | 13.3 | 12.9 | 0.765 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shepherd, L.M.; Frey, M.W. The Degradation of Cellulose by Radio Frequency Plasma. Fibers 2018, 6, 61. https://doi.org/10.3390/fib6030061

Shepherd LM, Frey MW. The Degradation of Cellulose by Radio Frequency Plasma. Fibers. 2018; 6(3):61. https://doi.org/10.3390/fib6030061

Chicago/Turabian StyleShepherd, Larissa Marie, and Margaret Wilde Frey. 2018. "The Degradation of Cellulose by Radio Frequency Plasma" Fibers 6, no. 3: 61. https://doi.org/10.3390/fib6030061

APA StyleShepherd, L. M., & Frey, M. W. (2018). The Degradation of Cellulose by Radio Frequency Plasma. Fibers, 6(3), 61. https://doi.org/10.3390/fib6030061