Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars

Abstract

:1. Introduction

1.1. Curauá Fibers

1.2. Use of Natural Fibers as Reinforcement for Cementitious Composites

1.3. Objective and Originality of the Research

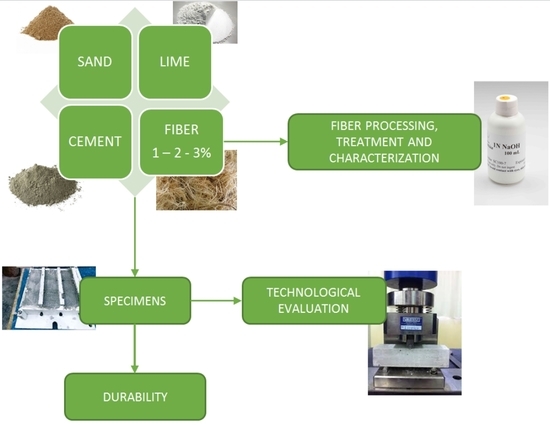

2. Materials and Methods

3. Results and Discussion

3.1. Physical and Chemical Characterization of the Fiber

3.2. Technological Characterization in the Fresh State of the Mortar

3.3. Technological Characterization in the Hardened State of the Mortar

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Manzhilevskaya, S.E. Organizational and economic problems of ecological safety in construction. Constr. Mater. Prod. 2019, 2, 73–78. [Google Scholar]

- De Azevedo, A.R.G.; Alexandre, J.; Marvila, M.T.; de Xavier, G.C.; Monteiro, S.N.; Pedroti, L.G. Technological and environmental comparative of the processing of primary sludge waste from paper industry for mortar. J. Clean. Prod. 2020, 229, 119336. [Google Scholar] [CrossRef]

- Kilinç, A.Ç.; Durmuşkahya, C.; Seydibeyoğlu, M.Ö. Natural fibers. In Fiber Technology for Fiber-Reinforced Composites; Woodhead Publishing: Sawston, UK, 2017; ISBN 9780081009932. [Google Scholar]

- Fediuk, R.S.; Lesovik, V.S.; Svintsov, A.P.; Mochalov, A.V.; Kulichkov, S.V.; Stoyushko, N.Y.; Gladkova, N.A.; Timokhin, R.A. Self-compacting concrete using pretreatmented rice husk ash. Mag. Civ. Eng. 2018, 79. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2020, 33, 101675. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Khezhev, T.A.; Pukharenko, Y.V.; Klyuev, A.V. To the question of fiber reinforcement of concrete. Mater. Sci. Forum 2018, 945, 25–29. [Google Scholar] [CrossRef]

- Ibragimov, R.; Fediuk, R. Improving the early strength of concrete: Effect of mechanochemical activation of the cementitious suspension and using of various superplasticizers. Constr. Build. Mater. 2019, 226, 839–848. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Cecchin, D.; Costa, J.M.; Xavier, G.C.; de Fátima do Carmo, D.; Monteiro, S.N. Durability of coating mortars containing açaí fibers. Case Stud. Constr. Mater. 2020, 13, e00406. [Google Scholar] [CrossRef]

- Cherevatova, A.V.; Zhernovskaya, I.V.; Alehin, D.A.; Kozhukhova, M.I.; Kozhukhova, N.I.; Yakovlev, E.A. Theoretical aspects of development of composite nanostructured gypsum binder characterized by increased heat resistance. Constr. Mater. Prod. 2019, 2, 5–13. [Google Scholar]

- Strokova, V.V.; Babaev, V.B.; Markov, A.Y.; Sobolev, K.G.; Nelyubova, V.V. Comparative evaluation of road pavement structures using cement concrete. Constr. Mater. Prod. 2019, 2, 56–63. [Google Scholar]

- Fediuk, R.; Smoliakov, A.; Muraviov, A. Mechanical properties of fiber-reinforced concrete using composite binders. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Klyuev, S.V.; Khezhev, T.A.; Pukharenko, Y.V.; Klyuev, A.V. Experimental study of fiber-reinforced concrete structures. Mater. Sci. Forum 2018, 945, 115–119. [Google Scholar] [CrossRef]

- De Picanço, M.S.; Ghavami, K. Comportamento à compressão de argamassas reforçadas com fibras vegetais da Amazônia. REM Rev. Esc. Minas 2008, 61, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Maciel, N.D.O.R.; Ferreira, J.B.; Vieira, J.D.S.; Ribeiro, C.G.D.; Lopes, F.P.D.; Margem, F.M.; Monteiro, S.N.; Vieira, C.M.F.; Silva, L.C. Da Comparative tensile strength analysis between epoxy composites reinforced with curaua fiber and glass fiber. J. Mater. Res. Technol. 2018, 7, 561–565. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Louro, L.H.L.; Trindade, W.; Elias, C.N.; Ferreira, C.L.; de Sousa Lima, E.; Weber, R.P.; Miguez Suarez, J.C.; da Silva Figueiredo, A.B.H.; Pinheiro, W.A.; et al. Natural Curaua Fiber-Reinforced Composites in Multilayered Ballistic Armor. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 4567–4577. [Google Scholar] [CrossRef]

- Silva, R.V.; Aquino, E.M.F. Curaua fiber: A new alternative to polymeric composites. J. Reinf. Plast. Compos. 2008, 27, 103–112. [Google Scholar] [CrossRef]

- Soltan, D.G.; das Neves, P.; Olvera, A.; Savastano Junior, H.; Li, V.C. Introducing a curauá fiber reinforced cement-based composite with strain-hardening behavior. Ind. Crops Prod. 2017, 103, 1–12. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- De Souza, L.O.; de Souza, L.M.S.; de Andrade Silva, F. Mechanical autogenous recovery and crack sealing of natural curauá textile reinforced concrete. Constr. Build. Mater. 2020, 235, 117476. [Google Scholar] [CrossRef]

- Marvila, M.T.; Alexandre, J.; Azevedo, A.R.G.; Zanelato, E.B.; Xavier, G.C.; Monteiro, S.N. Study on the replacement of the hydrated lime by kaolinitic clay in mortars. Adv. Appl. Ceram. 2019, 118, 373–380. [Google Scholar] [CrossRef]

- Fediuk, R.S. Mechanical Activation of Construction Binder Materials by Various Mills. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 125, p. 012019. [Google Scholar]

- Técnicas, A.B.D.N. NBR 7211:2009—Agregados para concreto—Especificação. Rio Janeiro 2009. [Google Scholar]

- Fediuk, R.; Pak, A.; Kuzmin, D. Fine-Grained Concrete of Composite Binder. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 262. [Google Scholar]

- Akhtyamova, L.; Sabitov, L.S.; Mailyan, A.L.; Mailyan, L.R.; Radaykin, O.V. Technological and design features of designing a modular reinforced concrete foundation for a high-rise building of various types. Constr. Mater. Prod. 2019, 2, 5–11. [Google Scholar]

- Fediuk, R.; Smoliakov, A.; Stoyushko, N. Increase in composite binder activity. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 156. [Google Scholar]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Klyuev, A.V.; Khezhev, T.A.; Pukharenko, Y.V. Technogenic sands as effective filler for fine-grained fibre concrete. J. Phys. Conf. Ser. 2018, 1118, 012020. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Klyuev, A.V.; Shorstova, E.S. The micro silicon additive effects on the fine-grassed concrete properties for 3-d additive technologies. Mater. Sci. Forum 2019, 974, 131–135. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Smoliakov, A.K.; Timokhin, R.A.; Batarshin, V.O.; Yevdokimova, Y.G. Using thermal power plants waste for building materials. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 87. [Google Scholar]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Filho, R.D.T. Influence of an impregnation treatment on the morphology and mechanical behaviour of flax yarns embedded in hydraulic lime mortar. Fibers 2019, 7, 30. [Google Scholar] [CrossRef] [Green Version]

- Arce, C.; Garzón, E.; Sánchez-Soto, P.J. Phyllite clays as raw materials replacing cement in mortars: Properties of new impermeabilizing mortars. Constr. Build. Mater. 2019, 224, 348–358. [Google Scholar] [CrossRef]

- Todkar, S.S.; Patil, S.A. Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos. Part B Eng. 2019, 174, 106927. [Google Scholar] [CrossRef]

- Feduik, R. Reducing permeability of fiber concrete using composite binders. Spec. Top. Rev. Porous Media 2018, 9, 79–89. [Google Scholar] [CrossRef]

- Rebelo, V.; da Silva, Y.; Ferreira, S.; Toledo Filho, R.; Giacon, V. Effects of mercerization in the chemical and morphological properties of amazon piassava. Polímeros 2019, 29. [Google Scholar] [CrossRef]

- Lima, P.R.L.; Toledo Filho, R.D.; Neumann, R.; Barros, J.A.O. Efeito do envelhecimento acelerado sobre as propriedades de microconcreto reforçado com fibras longas de sisal. Ambient. Construído 2019, 19, 7–20. [Google Scholar] [CrossRef]

- Rodier, L.; da Costa Correia, V.; Savastano Junior, H. Elaboration of eco-efficient vegetable fibers reinforced cement-based composites using glass powder residue. Cem. Concr. Compos. 2020, 110, 103599. [Google Scholar] [CrossRef]

- Raju, B.S.; Manjunatha, L.H.; Santosh; Jagadeeswaran, N. Fabrication & characterization of ZnS micro particulate filled glass and jute fibre reinforced hybrid polymer composites. Mater. Today Proc. 2020, 20, 125–133. [Google Scholar] [CrossRef]

- Syed, H.; Nerella, R.; Madduru, S.R.C. Role of coconut coir fiber in concrete. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Ruan, P.; Raghavan, V.; Du, J.; Gariepy, Y.; Lyew, D.; Yang, H. Effect of radio frequency pretreatment on enzymatic retting of flax stems and resulting fibers properties. Ind. Crops Prod. 2020, 146, 112204. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Mandegari, M.; Mostofinejad, D.; Abtahi, S.M. A review on performance of polyester fibers in alkaline and cementitious composites environments. Constr. Build. Mater. 2020, 241, 117998. [Google Scholar] [CrossRef]

- Marvila, M.T.; Alexandre, J.; de Azevedo, A.R.G.; Zanelato, E.B. Evaluation of the use of marble waste in hydrated lime cement mortar based. J. Mater. Cycles Waste Manag. 2019, 21, 1250–1261. [Google Scholar] [CrossRef]

- Parre, A.; Karthikeyan, B.; Balaji, A.; Udhayasankar, R. Investigation of chemical, thermal and morphological properties of untreated and NaOH treated banana fiber. Mater. Today Proc. 2020, 22, 347–352. [Google Scholar] [CrossRef]

- Buson, R.F.; Melo, L.F.L.; Oliveira, M.N.; Rangel, G.A.V.P.; Deus, E.P. Physical and mechanical characterization of surface treated bamboo fibers. Sci. Technol. Mater. 2018, 30, 67–73. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation of natural fiber in ternary blended cement composites containing metakaolin and montmorillonite. Corros. Sci. 2017, 120, 42–60. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015. [Google Scholar] [CrossRef]

- Zanelato, E.B.; Alexandre, J.; de Azevedo, A.R.G.; Marvila, M.T. Evaluation of roughcast on the adhesion mechanisms of mortars on ceramic substrates. Mater. Struct. Constr. 2019, 52, 53. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Marvila, M.T.; Barroso, L.S.; Zanelato, E.B.; Alexandre, J.; Xavier, G.C.; Monteiro, S.N. Effect of granite residue incorporation on the behavior of mortars. Materials 2019, 12, 1449. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amaral, L.F.; Girondi Delaqua, G.C.; Nicolite, M.; Marvila, M.T.; de Azevedo, A.R.G.; Alexandre, J.; Fontes Vieira, C.M.; Monteiro, S.N. Eco-friendly mortars with addition of ornamental stone waste—A mathematical model approach for granulometric optimization. J. Clean. Prod. 2020, 248, 119283. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Alexandre, J.; Zanelato, E.B.; Marvila, M.T. Influence of incorporation of glass waste on the rheological properties of adhesive mortar. Constr. Build. Mater. 2017, 148. [Google Scholar] [CrossRef]

- Tolstoy, A.D.; Lesovik, V.S.; Glagolev, E.S.; Krymova, A.I. Synergetics of hardening construction systems. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 327, p. 032056. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Monteiro, S.N. Verification of the application potential of the mathematical models of lyse, abrams and molinari in mortars based on cement and lime. J. Mater. Res. Technol. 2020, 9, 7327–7334. [Google Scholar] [CrossRef]

- Akinyemi, A.B.; Omoniyi, E.T.; Onuzulike, G. Effect of microwave assisted alkali pretreatment and other pretreatment methods on some properties of bamboo fibre reinforced cement composites. Constr. Build. Mater. 2020, 245, 118405. [Google Scholar] [CrossRef]

- Poongodi, K.; Murthi, P. Impact strength enhancement of banana fibre reinforced lightweight self-compacting concrete. Mater. Today Proc. 2020, 27, 1203–1209. [Google Scholar] [CrossRef]

- Azevedo, A.R.; Marvila, M.T.; Zanelato, E.B.; Alexandre, J. Development of mortar for laying and coating with pineapple fibers e revestimento com fibras de abacaxi. Rev. Bras. Eng. Agrícola Ambient. 2020, 24, 187–193. [Google Scholar] [CrossRef]

- Mathavan, M.; Sakthieswaran, N.; Ganesh Babu, O. Experimental investigation on strength and properties of natural fibre reinforced cement mortar. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Galicia-Aldama, E.; Mayorga, M.; Arteaga-Arcos, J.C.; Romero-Salazar, L. Rheological behaviour of cement paste added with natural fibres. Constr. Build. Mater. 2019, 198, 148–157. [Google Scholar] [CrossRef]

- Salazar, M.A.H.; Velez, M.F.M.; Cuellar, K.J.Q. Mechanical Behavior of Polyethylene Aluminum Composite Reinforced with Continuos Agro Fique Fibers. Rev. Latin Am. Metal. Mat. 2011, 31, 187–194. [Google Scholar]

- Bidegain, B.F.; Castro, C.; Eceiza, A. Alginate Fibers Obtained by Coagulation Spinning with Multivalent Metal Sulphates. Rev. Latin Am. Metal. Mat. 2015, 35, 189–200. [Google Scholar]

- Singh Bahra, M.; Gupta, V.K.; Aggarwal, L. Effect of Fibre Content on Mechanical Properties and Water Absorption Behaviour of Pineapple/HDPE Composite. Mater. Today Proc. 2017, 4, 3207–3214. [Google Scholar] [CrossRef]

- Gu, H. Tensile behaviours of the coir fibre and related composites after NaOH treatment. Mater. Des. 2009, 30, 3931–3934. [Google Scholar] [CrossRef]

| Mixture | Cement (g) | Lime (g) | Sand River (g) | Fiber (g) | Water/Cement Ratio |

|---|---|---|---|---|---|

| Reference | 500 | 500 | 3000 | - | 0.80 |

| Untreated fiber—1% | 495 | 500 | 3000 | 5 | 0.82 |

| Untreated fiber—2% | 490 | 500 | 3000 | 10 | 0.84 |

| Untreated fiber—3% | 485 | 500 | 3000 | 15 | 0.85 |

| Treated fiber—1% | 495 | 500 | 3000 | 5 | 0.78 |

| Treated fiber—2% | 490 | 500 | 3000 | 10 | 0.80 |

| Treated fiber—3% | 485 | 500 | 3000 | 15 | 0.82 |

| Physical Properties | Results |

|---|---|

| Density of untreated fiber (g/cm3) | 1.42 ± 0.05 |

| Density of treated fiber (g/cm3) | 1.49 ± 0.09 |

| Water absorption of untreated fiber (%) | 285.7 ± 1.23 |

| Water absorption of treated fiber (%) | 121.1 ± 0.89 |

| Moisture absorption of untreated fiber (%) | 18.4 ± 0.63 |

| Moisture absorption of treated fiber (%) | 13.1 ± 0.35 |

| Mechanical tensile strength of untreated fiber (MPa) | 495.9 ± 2.33 |

| Mechanical tensile strength of treated fiber (MPa) | 602.5 ± 3.89 |

| Module of elasticity of untreated fiber (GPa) | 35.2 ± 1.88 |

| Module of elasticity of treated fiber (GPa) | 42.3 ± 1.12 |

| Type | Cellulose (%) | Lignin (%) | Hemicellulose (%) | Wax (%) | Ashes (%) |

|---|---|---|---|---|---|

| Untreated fiber | 56.43 | 26.10 | 13.51 | 0.98 | 2.71 |

| Treated fiber | 64.81 | 21.12 | 11.87 | 0.50 | 1.23 |

| Composition | Consistency (mm) | Water Retention (%) | Incorporated Air (%) |

|---|---|---|---|

| Reference | 263.33 ± 1.24 | 91.77 ± 0.78 | 7.89 ± 0.22 |

| 1% Untreated fiber | 257.23 ± 2.33 | 95.46 ± 1.08 | 8.23 ± 0.31 |

| 2% Untreated fiber | 253.21 ± 1.67 | 97.42 ± 0.65 | 8.25 ± 0.20 |

| 3% Untreated fiber | 249.44 ± 1.80 | 98.89 ± 0.81 | 8.98 ± 0.18 |

| 1% Treated fiber | 261.22 ± 0.97 | 92.34 ± 0.33 | 7.92 ± 0.27 |

| 2% Treated fiber | 257.54 ± 2.01 | 94.45 ± 0.67 | 7.84 ± 0.35 |

| 3% Treated fiber | 254.23 ± 2.12 | 95.67 ± 0.56 | 7.80 ± 0.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azevedo, A.R.G.d.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; Lima, T.E.S.d.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. https://doi.org/10.3390/fib8110069

Azevedo ARGd, Klyuev S, Marvila MT, Vatin N, Alfimova N, Lima TESd, Fediuk R, Olisov A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers. 2020; 8(11):69. https://doi.org/10.3390/fib8110069

Chicago/Turabian StyleAzevedo, Afonso R. G. de, Sergey Klyuev, Markssuel T. Marvila, Nikolai Vatin, Nataliya Alfimova, Thuany E.S. de Lima, Roman Fediuk, and Andrej Olisov. 2020. "Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars" Fibers 8, no. 11: 69. https://doi.org/10.3390/fib8110069

APA StyleAzevedo, A. R. G. d., Klyuev, S., Marvila, M. T., Vatin, N., Alfimova, N., Lima, T. E. S. d., Fediuk, R., & Olisov, A. (2020). Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers, 8(11), 69. https://doi.org/10.3390/fib8110069