Quality Improvement in Mackerel Fillets Caused by Brine Salting Combined with High-Pressure Processing

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Mackerel Fillets

2.2. High-Pressure Processing Treatment

2.3. Analysis of Microbial Counts

2.4. Texture

2.5. Colour

2.6. Total Volatile Basic Nitrogen (TVBN)

2.7. Salt and Moisture Contents

2.8. Statistical Analysis

3. Results and Discussion

3.1. The Microbial Counts of Mackerel Fillet

3.2. The Texture of the Mackerel Fillet

3.3. The Color Values of Mackerel Fillet

3.4. The Total Volatile Basic Nitrogen (TVBN), Salt, and Moisture Contents of Mackerel Fillets

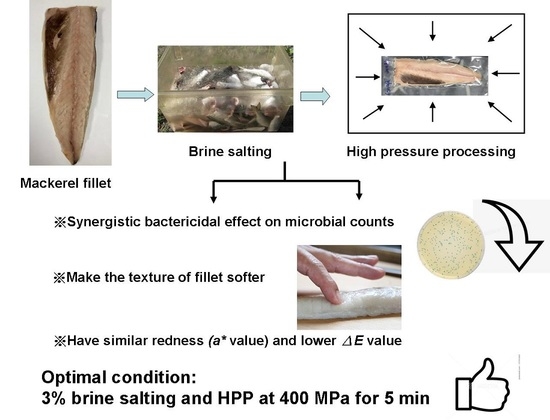

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, Y.C.; Hsieh, C.Y.; Chen, M.L.; Wang, C.Y.; Lin, C.S.; Tsai, Y.H. High pressure inactivation of histamine-forming bacteria Morganella morganii and Photobacterium phosphoreum. J. Food Prot. 2020, 83, 621–627. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.Y.; Huang, H.W.; Hsu, C.P.; Yang, B.B. Recent advances in food processing using high hydrostatic pressure technology. Crit. Rev. Food Sci. Nutr. 2016, 56, 527–540. [Google Scholar] [CrossRef]

- Considine, K.M.; Kelly, A.L.; Fitzgerald, G.F.; Hill, C.; Sleator, R.D. High-pressure processing -effects on microbial food safety and food quality. FEMS Microbiol. Lett. 2008, 281, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Romero, M.; Smiddy, M.; Hill, C.; Kerry, J.P.; Kelly, A.L. Effects of high pressure treatment on physicochemical characteristics of fresh oysters (Crassostrea gigas). Innov. Food Sci. Emerg. Technol. 2004, 5, 161–169. [Google Scholar] [CrossRef]

- Kung, H.F.; Lin, C.S.; Liu, S.S.; Huang, C.Y.; Chiu, K.; Lee, Y.C.; Tsai, Y.H. High pressure processing extend the shelf life of milkfish flesh during refrigerated storage. Food Control 2022, 134, 108768. [Google Scholar] [CrossRef]

- Thorarinsdottir, K.A.; Arason, S.; Sigurgisladottir, S.; Gunnlaugsson, V.N.; Johannsdottir, J.; Tornberg, E. The effects of salt-curing and salting procedures on the microstructure of cod (Gadus morhua) muscle. Food Chem. 2011, 126, 109–115. [Google Scholar] [CrossRef]

- Ros-Polski, V.; Koutchma, T.; Xue, J.; Defelice, C.; Balamurugan, S. Effects of high hydrostatic pressure processing parameters and NaCl concentration on the physical properties, texture and quality of white chicken meat. Innov. Food Sci. Emerg. Technol. 2015, 30, 31–42. [Google Scholar] [CrossRef]

- Hwang, C.C.; Lee, Y.C.; Huang, C.Y.; Kung, H.F.; Cheng, H.H.; Tsai, Y.H. Effect of brine concentrations on the bacteriological and chemical quality and histamine content of brined and dried milkfish. Foods 2020, 9, 1597. [Google Scholar] [CrossRef]

- Leistner, L.; Gorris, G.M. Food preservation by hurdle technology. Trends Food Sci. Technol. 1995, 6, 41–46. [Google Scholar] [CrossRef]

- Balamurugan, S.; Ahmeda, R.; Chibeu, A.; Gao, A.; Koutchma, T.; Strange, P. Effect of salt types and concentrations on the high-pressure inactivation of Listeria monocytogenes in ground chicken. Int. J. Food Microbiol. 2016, 218, 51–56. [Google Scholar] [CrossRef]

- Crehan, C.M.; Troy, D.J.; Buckley, D.J. Effects of salt level and high hydrostatic pressure processing on frankfurters formulated with 1.5 and 2.5% salt. Meat Sci. 2000, 55, 123–130. [Google Scholar] [CrossRef]

- Tzeng, T.D. Morphological variation between populations of spotted mackerel (Scomber australasicus) off Taiwan. Fish. Res. 2004, 68, 45–55. [Google Scholar] [CrossRef]

- Lin, C.S.; Lee, Y.C.; Chiu, J.W.; Hwang, C.C.; Kung, H.F.; Tsai, Y.H. Inhibitory effects of high pressure processing on microbial growth and histamine formation in spotted mackerel (Scomber australasicus) during refrigerated storage. CYTA-J. Food 2021, 19, 762–770. [Google Scholar] [CrossRef]

- Lee, Y.C.; Tseng, P.H.; Hwang, C.C.; Kung, H.F.; Huang, Y.L.; Lin, C.S.; Wei, C.I.; Tsai, Y.H. Effect of vacuum packaging on histamine production in Japanese spanish mackerel (Scomberomorus niphonius) stored at various temperatures. J. Food Prot. 2019, 82, 1931–1937. [Google Scholar] [CrossRef]

- Tsai, Y.H.; Kung, H.F.; Lin, C.S.; Hwang, C.C.; Lou, S.S.; Huang, C.Y.; Chang, S.K.C.; Lee, Y.C. Combined effect of brine salting and high-hydrostatic-pressure processing to improve the microbial quality and physicochemical properties of milkfish fillet. Int. J. Food Prop. 2022, 25, 872–884. [Google Scholar] [CrossRef]

- Sae-leaw, T.; Benjakul, S.; Vongkamjam, K. Retardation of melanosis and quality loss of pre-cooked pacific white shrimp using epigallocatechin gallate with the aid of uultrasound. Food Control. 2018, 84, 75–82. [Google Scholar] [CrossRef]

- Chouhan, A.; Kaur, B.P.; Rao, P.S. Effect of high pressure processing and thermal treatment on quality of hilsa (Tenualosa ilisha) fillets during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2015, 29, 151–160. [Google Scholar] [CrossRef]

- Cobb, B.F.; Alaniz, I.A.; Thompson, C.A. Biochemical and microbial studies on shrimp: Nitrogen and amine nitrogen analysis. J. Food Sci. 1973, 38, 431–435. [Google Scholar] [CrossRef]

- AOAC. Official Method of Analysis, 18th ed.; Association of Officiating Analytical Chemists: Washington, DC, USA, 2005. [Google Scholar]

- Pszczola, D.E. Tacking meat issues in a lean economy. Food Technol. 2010, 64, 49–58. [Google Scholar]

- Yagiz, Y.; Kristinsson, H.G.; Balaban, M.O.; Marshall, M.R. Effect of high pressure treatment on the quality of rainbow trout (Oncorhynchus mykiss) and mahi mahi (Coryphaena hippurus). J. Food Sci. 2007, 72, 509–515. [Google Scholar] [CrossRef]

- Christensen, L.B.; Hovda, M.B.; Rode, T.M. Quality changes in high pressure processed cod, salmon and mackerel during storage. Food Control. 2017, 72, 90–96. [Google Scholar] [CrossRef]

- Yang, W.; Shi, W.; Qu, Y.; Wang, Z.; Shen, S.; Tu, L.; Huang, H.; Wu, H. Research on the quality changes of grass carp during brine salting. Food Sci. Nutr. 2020, 8, 2968–2983. [Google Scholar] [CrossRef]

- Lauritzsen, K.; Akse, L.; Gundersen, B.; Olsen, R.L. Effects of calcium, magnesium and pH during salt curing of cod (Gadus morhua L.). J. Sci. Food Agric. 2004, 84, 683–692. [Google Scholar] [CrossRef]

- Ahn, D.U.; Maurer, A.J. Effects of added nitrite, sodium chloride, and phosphate on color, nitrosoheme pigment, total pigment, and residual nitrite in oven-roasted turkey breast. Poult. Sci. 1989, 68, 100–106. [Google Scholar] [CrossRef]

- Ledward, D.A. High-pressure processing of meat and fish. In Fresh Novel Foods by High-Pressure; Espoo, A.K., Ed.; VVT Biotechnology and Food Research: Helsinki, Finland, 1998; pp. 165–175. [Google Scholar]

- Teixeira, B.; Fidalgo, L.; Mendes, R.; Costa, G.; Cordeiro, C.; Marques, A.; Saraiva, J.A.; Nunes, M.L. Effect of high pressure processing in the quality of sea bass (Dicentrarchus labrax) fillets. Pressurization rate, pressure level and holding time. Innov. Food Sci. Emerg. Technol. 2014, 22, 31–39. [Google Scholar] [CrossRef]

- Fulladosa, E.; Serra, X.; Gou, P.; Arnau, J. Effects of potassium lactate and high pressure on transglutaminase restructured dry-cured hams with reduced salt content. Meat Sci. 2009, 82, 213–218. [Google Scholar] [CrossRef]

- O’Neill, C.M.; Cruz-Romero, C.; Duffy, G.; Kerry, J.P. Shelf Life Extension of vacuum-packed salt reduced frankfurters and cooked ham through the combined application of high pressure processing and organic acid. Food Packag. Shelf Life 2018, 17, 120–128. [Google Scholar] [CrossRef]

- Bonfim, R.C.; Oliveira, F.A.D.; Godoy, R.L.D.O.; Rosenthal, A. A review on high hydrostatic pressure for bivalve mollusk processing: Relevant aspects concerning safety and quality. Food Sci. Technol. 2019, 39, 515–523. [Google Scholar] [CrossRef] [Green Version]

| Brine Concentration (%) | Control (0.1 MPa) | HPP Treatment (MPa) | |||

|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | ||

| Raw fillet | 4.82 ± 0.08 *1aA | 4.72 ± 0.06 aA (0.10) *2 | 2.32 ± 0.10 b (2.50) | <2.0 (4.82) | <2.0 (4.82) |

| 3.0 | 4.63 ± 0.06 aB (0.19) | 4.23 ± 0.08 bB (0.59) | <2.0 (4.82) | <2.0 (4.82) | <2.0 (4.82) |

| 9.0 | 4.05 ± 0.15 C (0.77) | <2.0 (4.82) | <2.0 (4.82) | <2.0 (4.82) | <2.0 (4.82) |

| Brine Concentration (%) | Control (0.1 MPa) | HPP Treatment (MPa) | |||

|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | ||

| Raw fillet | 4.66 ± 0.05 *1aA | 4.54 ± 0.07 bA (0.12) *2 | 2.11 ± 0.10 c (2.55) | <2.0 (4.66) | <2.0 (4.66) |

| 3.0 | 4.45 ± 0.19 aB (0.21) | 4.29 ± 0.14 bB (0.37) | <2.0 (4.66) | <2.0 (4.66) | <2.0 (4.66) |

| 9.0 | 4.10 ± 0.19 C (0.56) | <2.0 (4.66) | <2.0 (4.66) | <2.0 (4.66) | <2.0 (4.66) |

| Texture Properties | Brine Concentration (%) | Control (0.1 MPa) | HPP Treatment (MPa) | |||

|---|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | |||

| Hardness (N) | Raw fillet | 1.16 ± 0.39 *1dA | 3.65 ± 0.16 cA | 3.85 ± 0.21 cA | 5.09 ± 0.08 bA | 5.52 ± 0.23 aA |

| 3.0 | 0.76 ± 0.07 dB | 3.36 ± 0.11 cB | 3.60 ± 0.09 cB | 4.15 ± 0.33 bB | 5.61 ± 0.21 aA | |

| 9.0 | 0.71 ± 0.03 dB | 3.35 ± 0.16 cB | 3.50 ± 0.24 cB | 4.25 ± 0.20 bB | 5.86 ± 0.16 aA | |

| Cohesiveness | Raw fillet | 0.69 ± 0.03 bA | 0.70 ± 0.03 bA | 0.77 ± 0.05 aA | 0.80 ± 0.05 aA | 0.75 ± 0.03 aB |

| 3.0 | 0.66 ± 0.03 bA | 0.68 ± 0.07 bA | 0.73 ± 0.03 abA | 0.76 ± 0.03 abA | 0.81 ± 0.02 aA | |

| 9.0 | 0.64 ± 0.03 cA | 0.65 ± 0.04 cA | 0.71 ± 0.03 bA | 0.74 ± 0.07 bA | 0.86 ± 0.04 aA | |

| Springiness (mm) | Raw fillet | 7.00 ± 0.15 bA | 9.90 ± 0.14 aA | 6.54 ± 0.06 cC | 6.55 ± 0.07 cB | 7.39 ± 0.22 bB |

| 3.0 | 6.68 ± 0.22 dB | 10.13 ± 0.10 aA | 10.02 ± 0.14 aA | 9.07 ± 0.24 bA | 8.37 ± 0.13 cA | |

| 9.0 | 6.84 ± 0.30 cAB | 9.66 ± 0.27 aB | 9.22 ± 0.24 aB | 8.78 ± 0.15 bA | 8.16 ± 0.13 bA | |

| Chewiness (mJ) | Raw fillet | 7.45 ± 0.07 cA | 24.52 ± 0.04 bA | 25.12 ± 1.65 bA | 25.62 ± 0.51 bA | 28.84 ± 0.97 aA |

| 3.0 | 7.23 ± 0.05 dB | 22.48 ± 0.14 cB | 22.67 ± 0.29 cB | 24.21 ± 0.19 bB | 26.49 ± 0.26 aB | |

| 9.0 | 7.33 ± 0.05 cB | 23.31 ± 0.22 bB | 23.49 ± 0.37 bB | 24.12 ± 0.73 bB | 26.67 ± 0.11 aB | |

| Colour | Brine Concentration (%) | Control (0.1 MPa) | HPP Treatment (MPa) | |||

|---|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | |||

| L* | Raw fillet | 57.06 ± 0.48 *1dB | 62.03 ± 0.17 cA | 62.09 ± 0.13 cA | 65.45 ± 0.26 bA | 66.10 ± 0.28 aA |

| 3.0 | 61.01 ± 0.75 cA | 61.68 ± 0.42 cA | 62.25 ± 0.31 bA | 64.85 ± 0.52 aA | 65.82 ± 0.30 aA | |

| 9.0 | 60.39 ± 0.54 cA | 62.72 ± 0.35 bA | 63.19 ± 0.61 abA | 64.07 ± 0.24 aA | 65.78 ± 0.16 aA | |

| a* | Raw fillet | 6.43 ± 0.29 aA | 5.53 ± 0.36 bA | 4.96 ± 0.17 cA | 4.25 ± 0.03 dA | 4.11 ± 1.00 dA |

| 3.0 | 6.48 ± 0.26 aA | 5.38 ± 0.18 bA | 4.90 ± 0.25 cA | 3.68 ± 0.35 dB | 3.59 ± 0.29 dB | |

| 9.0 | 6.07 ± 0.07 aA | 5.15 ± 0.19 bA | 4.47 ± 0.32 cA | 3.54 ± 0.34 dB | 3.51 ± 0.29 dB | |

| b* | Raw fillet | 15.25 ± 0.38 aA | 15.54 ± 0.45 aA | 15.15 ± 0.14 aA | 14.53 ± 0.16 bA | 14.42 ± 0.45 bA |

| 3.0 | 16.09 ± 0.42 aA | 14.79 ± 0.39 bB | 14.99 ± 0.18 bA | 14.85 ± 0.32 bA | 15.07 ± 0.30 bA | |

| 9.0 | 15.54 ± 0.33 aA | 14.54 ± 0.38 bB | 14.93 ± 0.20 aA | 15.01 ± 0.25 aA | 14.70 ± 0.31 bA | |

| ΔE | Raw fillet | - | 6.68 | 8.00 | 8.47 | 9.15 |

| 3.0 | - | 1.83 | 2.28 | 4.97 | 6.48 | |

| 9.0 | - | 2.56 | 3.06 | 4.30 | 5.79 | |

| Brine Concentration (%) | Control (0.1 MPa) | HPP Treatment (MPa) | |||

|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | ||

| Raw fillet | 5.27 ± 0.51 *1aA | 5.53 ± 0.40 aA | 4.85 ± 0.26 aA | 5.55 ± 0.49 aA | 5.37 ± 0.62 aA |

| 3.0 | 5.58 ± 0.65 aA | 5.04 ± 0.39 aA | 4.90 ± 0.41 aA | 5.09 ± 0.39 aA | 4.99 ± 0.50 aA |

| 9.0 | 4.90 ± 0.46 aA | 4.99 ± 0.44 aA | 5.11 ± 0.15 aA | 5.65 ± 0.76 aA | 5.39 ± 0.38 aA |

| Brine Concentration (%) | Control (0.1 MPa) | HPP Treatment (MPa) | ||||

|---|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | |||

| Salt content | Raw fillet | 0.38 ± 0.04 *1a | 0.36 ± 0.02 a | 0.35 ± 0.05 a | 0.39 ± 0.02 a | 0.37 ± 0.03 a |

| 3.0 | 0.93 ± 0.02 a | 0.85 ± 0.05 b | 0.86 ± 0.03 b | 0.81 ± 0.03 b | 0.79 ± 0.02 b | |

| 9.0 | 1.88 ± 0.01 a | 1.79 ± 0.03 b | 1.82 ± 0.03 b | 1.77 ± 0.02 b | 1.82 ± 0.03 b | |

| Moisture content | Raw fillet | 49.33 ± 0.48 a | 50.20 ± 0.64 a | 48.92 ± 0.78 a | 50.61 ± 0.92 a | 50.49 ± 0.74 a |

| 3.0 | 57.43 ± 0.78 a | 58.85 ± 0.96 a | 54.90 ± 0.81 b | 48.44 ± 1.61 c | 46.92 ± 0.86 c | |

| 9.0 | 56.09 ± 0.46 a | 57.25 ± 1.00 a | 55.12 ± 0.51 b | 55.07 ± 1.19 b | 47.82 ± 1.00 c | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-H.; Lin, C.-S.; Lee, Y.-C.; Ciou, J.-W.; Kuo, C.-H.; Huang, C.-Y.; Tseng, C.-H.; Tsai, Y.-H. Quality Improvement in Mackerel Fillets Caused by Brine Salting Combined with High-Pressure Processing. Biology 2022, 11, 1307. https://doi.org/10.3390/biology11091307

Huang C-H, Lin C-S, Lee Y-C, Ciou J-W, Kuo C-H, Huang C-Y, Tseng C-H, Tsai Y-H. Quality Improvement in Mackerel Fillets Caused by Brine Salting Combined with High-Pressure Processing. Biology. 2022; 11(9):1307. https://doi.org/10.3390/biology11091307

Chicago/Turabian StyleHuang, Chih-Hsiung, Chung-Saint Lin, Yi-Chen Lee, Jhih-Wei Ciou, Chia-Hung Kuo, Chun-Yung Huang, Chih-Hua Tseng, and Yung-Hsiang Tsai. 2022. "Quality Improvement in Mackerel Fillets Caused by Brine Salting Combined with High-Pressure Processing" Biology 11, no. 9: 1307. https://doi.org/10.3390/biology11091307

APA StyleHuang, C. -H., Lin, C. -S., Lee, Y. -C., Ciou, J. -W., Kuo, C. -H., Huang, C. -Y., Tseng, C. -H., & Tsai, Y. -H. (2022). Quality Improvement in Mackerel Fillets Caused by Brine Salting Combined with High-Pressure Processing. Biology, 11(9), 1307. https://doi.org/10.3390/biology11091307