Mechanical Behavior of Briquettes Made from a Mixture of Sawdust and Rice Husks for Commercialization

Abstract

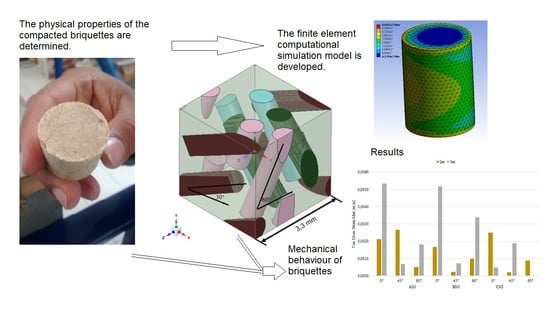

:1. Introduction

2. Materials and Methods

2.1. Determination of Experimental Parameters

2.2. Computational Modelling

2.3. Simulation Process

3. Results

3.1. Simulation of Compression Test

3.2. Free Fall Test

4. Discussion

4.1. Mechanical Behavior of the Densified Material

4.2. Compressive Strength

4.3. Impact Tests

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Jungers, J.M.; Fargione, J.E.; Sheaffer, C.C.; Wyse, D.L.; Lehman, C. Energy potential of biomass from conservation grasslands in Minnesota, USA. PLoS ONE 2013, 8, e61209. [Google Scholar] [CrossRef]

- Bridgwater, T. Biomass for energy. J. Sci. Food Agric. 2006, 86, 1755–1768. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Jen, T.C.; Mahamood, R.M.; Akinlabi, E.T. Densification of agro-residues for sustainable energy generation: An overview. Bioresour. Bioprocess. 2021, 8, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Espinoza-Tellez, T.; Montes, J.B.; Quevedo-León, R.; Valencia-Aguilar, E.; Vargas, H.A.; Díaz-Guineo, D.; Díaz-Carrasco, O. Agricultural, forestry, textile and food waste used in the manufacture of biomass briquettes: A review. Sci. Agropecu. 2020, 11, 427–437. [Google Scholar] [CrossRef]

- Qi, J.; Li, H.; Wang, Q.; Han, K. Combustion Characteristics, Kinetics, SO2 and NO Release of Low-Grade Biomass Materials and Briquettes. Energies 2021, 14, 2655. [Google Scholar] [CrossRef]

- Cabrales, H.; Arzola, N.; Araque, O. The effects of moisture content, fiber length and compaction time on African oil palm empty fruit bunches briquette quality parameters. Heliyon 2020, 6, e05607. [Google Scholar] [CrossRef]

- Boada, L.E.A.; Vargas, F.S. Caracterización Fisíco-Química de Pellets Producidos a Partir de Mezclas 50/50 Carbón Bituminoso/Madera Residual. Inf. Técnico 2015, 79, 18–25. [Google Scholar] [CrossRef] [Green Version]

- Cayuela, M.L.; Sánchez-Monedero, M.A.; Roig, A.; Sinicco, T.; Mondini, C. Biochemical changes and GHG emissions during composting of lignocellulosic residues with different N-rich by-products. Chemosphere 2012, 88, 196–203. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Lim, C.J.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Zepeda-Cepeda, C.O.; Goche-Télles, J.R.; Palacios-Mendoza, C.; Moreno-Anguiano, O.; Núñez-Retana, V.D.; Heya, M.N.; Carrillo-Parra, A. Effect of sawdust particle size on physical, mechanical, and energetic properties of pinus durangensis briquettes. Appl. Sci. 2021, 11, 3805. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A.; Lubwama, H.N. Effects and interactions of the agricultural waste residues and binder type on physical properties and calorific values of carbonized briquettes. Biomass Convers. Biorefinery 2020, 1–21. Available online: https://link.springer.com/article/10.1007/s13399-020-01001-8 (accessed on 7 March 2022). [CrossRef]

- Solís, M.E.; Lisperguer, J.H. Impact and Tensile Strength of Wood-Plastic Composite; Informacon Tecnologica: La Serena, Chile, 2005; Volume 16, pp. 21–25. Available online: https://www.scielo.cl/scielo.php?script=sci_arttext&pid=S0718-07642005000600004&lng=es&nrm=iso&tlng=es (accessed on 7 March 2022).

- Garab, J.; Keunecke, D.; Hering, S.; Szalai, J.; Niemz, P. Measurement of standard and off-axis elastic moduli and Poisson’s ratios of spruce and yew wood in the transverse plane. Wood Sci. Technol. 2010, 44, 451–464. [Google Scholar] [CrossRef]

- Flores-Hernandez, M.A.; González, I.R.; Lomeli-Ramirez, M.G.; Fuentes-Talavera, F.J.; Silva-Guzman, J.A.; Cerpa-Gallegos, M.A.; Garcia-Enriquez, S. Physical and mechanical properties of wood plastic composites polystyrene-white oak wood flour. J. Compos. Mater. 2014, 48, 209–217. [Google Scholar] [CrossRef]

- Gong, A.; Kamdem, D.; Harichandran, R. Compression tests on wood-cement particle composites made of CCA-treated wood removed from service. In Environmental Impacts of Preservative-Treated Wood Conference (on Line); 2004; pp. 8–11. Available online: http://ccaresearch.org/ccaconference/post/pdf/Presentation_Kamdem.pdf (accessed on 29 January 2020).

- Arjmandi, R.; Hassan, A.; Majeed, K.; Zakaria, Z. Rice husk filled polymer composites. Int. J. Polym. Sci. 2015, 2015, 1–32. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Szczukowski, S.; Tworkowski, J.; Krzyżaniak, M.; Gulczyński, P.; Mleczek, M. Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renew. Energy 2013, 57, 20–26. [Google Scholar] [CrossRef]

- Dyjakon, A.; Sobol, Ł.; Krotowski, M.; Mudryk, K.; Kawa, K. The Impact of Particles Comminution on Mechanical Durability of Wheat Straw Briquettes. Energies 2020, 13, 6186. [Google Scholar] [CrossRef]

- Meng, L.; Alengebawy, A.; Ai, P.; Jin, K.; Chen, M.; Pan, Y. Techno-economic assessment of three modes of large-scale crop residue utilization projects in china. Energies 2020, 13, 3729. [Google Scholar] [CrossRef]

- Romallosa, A.R.D.; Kraft, E. Feasibility of biomass briquette production from municipal waste streams by integrating the informal sector in the Philippines. Resources 2017, 6, 12. [Google Scholar] [CrossRef]

- Sofia, D.; Giuliano, A.; Barletta, D. Techno-economic assessment of co-gasification of coal-petcoke and biomass in IGCC power plants. Chem. Eng. Trans. 2013, 32, 1231–1236. [Google Scholar] [CrossRef]

- Holm, J.K.; Henriksen, U.B.; Hustad, J.E.; Sørensen, L.H. Toward an understanding of controlling parameters in softwood and hardwood pellets production. Energy Fuels 2006, 20, 2686–2694. [Google Scholar] [CrossRef]

- Jearanaisilawong, P.; Eahkanong, S.; Phungsara, B.; Manonukul, A. Determination of in-plane elastic properties of rice husk composite. Mater. Des. 2015, 76, 55–63. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, Y.; Shivkumar, S. Microstructure and tensile properties of various varieties of rice husk. J. Sci. Food Agric. 2018, 98, 1061–1070. [Google Scholar] [CrossRef] [PubMed]

- Niño, A.; Arzola, N.; Araque, O. Experimental study on the mechanical properties of biomass briquettes from a mixture of rice husk and pine sawdust. Energies 2020, 13, 1060. [Google Scholar] [CrossRef] [Green Version]

- Cardozo, J. Evaluación mecánica por simulación computacional de la mezcla de aserrín y cascarilla de arroz. Bachelor’s Thesis, Universidad de Ibagué, Ibagué, Colombia, 2020. [Google Scholar]

- Trubetskaya, A.; Leahy, J.J.; Yazhenskikh, E.; Müller, M.; Layden, P.; Johnson, R.; Monaghan, R.F. Characterization of woodstove briquettes from torrefied biomass and coal. Energy 2019, 171, 853–865. [Google Scholar] [CrossRef]

- Sharma, A.; Wang, S.; Pareek, V.; Yang, H.; Zhang, D. CFD modeling of mixing/segregation behavior of biomass and biochar particles in a bubbling fluidized bed. Chem. Eng. Sci. 2014, 106, 264–274. [Google Scholar] [CrossRef]

- Anggraeni, S.; Girsang, G.C.S.; Nandiyanto, A.B.D.; Bilad, M.R. Effects of particle size and composition of sawdust/carbon from rice husk on the briquette performance. J. Eng. Sci. Technol. 2021, 16, 2298–2311. [Google Scholar]

- Gama, N.; Ferreira, A.; Barros-Timmons, A.; Evtuguin, D. Polyamide 6/modified pine bark particle composites for additive manufacturing. J. Mater. Sci. 2021, 56, 1–13. [Google Scholar] [CrossRef]

- Muralikrishna MV, V.; Kumari, T.S.; Gopi, R.; Loganathan, G.B. Development of mechanical properties in banana fiber composite. Mater. Today Proc. 2020, 22, 541–545. [Google Scholar] [CrossRef]

- Kumar, S.S.; Muthalagu, R.; Chakravarthy, C.N. Effects of fiber loading on mechanical characterization of pineapple leaf and sisal fibers reinforced polyester composites for various applications. Mater. Today Proc. 2021, 44, 546–553. [Google Scholar] [CrossRef]

- Quiceno Villada, D.; Mosquera Gutiérrez, M.Y. Alternativas Tecnológicas Para El Uso de la Cascarilla de Arroz Como Combustible [En Línea]. 2010. Available online: https://red.uao.edu.co/bitstream/10614/1327/1/TME00462.pdf (accessed on 25 September 2020).

- Fávaro, S.L.; Lopes, M.S.; de Carvalho Neto, A.G.V.; de Santana, R.R.; Radovanovic, E. Chemical, morphological, and mechanical analysis of rice husk/post-consumer polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 154–160. [Google Scholar] [CrossRef]

- Ramasamy, S.; Ismail, H.; Munusamy, Y. Effect of rice husk powder on compression behavior and thermal stability of natural rubber latex foam. BioResources 2013, 8, 4258–4269. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Bańda, M.; Gondek, E. Mechanical properties of sawdust and woodchips. Fuel 2015, 159, 900–908. [Google Scholar] [CrossRef]

- Oveisi, E.; Lau, A.; Sokhansanj, S.; Lim, C.J.; Bi, X.; Larsson, S.H.; Melin, S. Breakage behavior of wood pellets due to free fall. Powder Technol. 2013, 235, 493–499. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S. Mechanical and morphological properties of wood plastic biocomposites prepared from toughened poly (lactic acid) and rubber wood sawdust (Hevea brasiliensis). J. Bionic Eng. 2014, 11, 630–637. [Google Scholar] [CrossRef]

- Montiano, M.G.; Díaz-Faes, E.; Barriocanal, C. Partial briquetting vs direct addition of biomass in coking blends. Fuel 2014, 137, 313–320. [Google Scholar] [CrossRef] [Green Version]

- Thliza, B.A.; Abdulrahman, F.I.; Akan, J.C.; Chellube, Z.M.; Kime, B. Determination of compressive strength and combustibility potential of agricultural waste briquette. Chem. Sci. Int. J. 2020, 29, 30–46. [Google Scholar] [CrossRef]

- Demirbas, A.; Sahin-Demirbas, A.Y.S.E. Briquetting properties of biomass waste materials. Energy Sources 2004, 26, 83–91. [Google Scholar] [CrossRef]

- Bello, R.S.; Onilude, M.A. Physico-mechanical characteristics of high density briquettes produced from composite sawdust. J. Appl. Sci. Environ. Manag. 2020, 24, 779–787. [Google Scholar] [CrossRef]

- Panwar, V.; Prasad, B.; Wasewar, K.L. Biomass residue briquetting and characterization. J. Energy Eng. 2011, 137, 108–114. [Google Scholar] [CrossRef]

- Brand, M.A.; Jacinto, R.C.; Antunes, R.; da Cunha, A.B. Production of briquettes as a tool to optimize the use of waste from rice cultivation and industrial processing. Renew. Energy 2017, 111, 116–123. [Google Scholar] [CrossRef]

- Jamradloedluk, J.; Wiriyaumpaiwong, S. Production and characterization of rice husk based charcoal briquettes. Eng. Appl. Sci. Res. 2007, 34, 391–398. [Google Scholar]

| Species | Modulus of Elasticity EL (MPa) | Density (kg/m3) | Poisson’s Ration |

|---|---|---|---|

| Softwood pine | 6634 | 383 | 0.337 |

| Physical-Mechanical Properties of Briquettes | Samples | ||

|---|---|---|---|

| AIO | BIO | CIO | |

| Mass % of Rice Husks | 25 | 50 | 75 |

| Compression time (s) | 20.00 | 20.00 | 20.00 |

| Compaction temperature (°C) | 90.00 | 90.00 | 90.00 |

| Average Bulk density (kg/m3) | 1124.25 | 1097.08 | 1069.91 |

| Density of pine sawdust (kg/m3) | 396.36 | 396.36 | 396.36 |

| Density of rice husk (kg/m3) | 279.75 | 279.75 | 279.75 |

| Compressive force (KN) | 56.44 | 56.44 | 56.44 |

| Average Young’s modulus (MPa) | 719.82 | 818.71 | 917.59 |

| Poisson’s Coefficient | 0.13 | 0.13 | 0.13 |

| Average Height (mm) | 47.63 | 48.67 | 49.54 |

| Average Diameter (mm) | 30.18 | 30.17 | 30.20 |

| Samples | ΔV | ||

|---|---|---|---|

| AIO | 3.13 | 1241.41 | 876.18 |

| BIO | 3.34 | 1325.73 | 935.70 |

| CIO | 3.54 | 991.22 | 991.22 |

| Samples | %Vfiber | ||

|---|---|---|---|

| AIO | 71.90 | 33.96 | 0.32 |

| BIO | 47.94 | 67.92 | 0.59 |

| CIO | 23.97 | 101.88 | 0.81 |

| Samples | mfu (µg) | ||

|---|---|---|---|

| AIO | 3.5 | 8.44 | 8.46 |

| BIO | 3.5 | 8.17 | 8.74 |

| CIO | 3.5 | 7.94 | 9.00 |

| Samples | |||

|---|---|---|---|

| AIO | 0.12 | 1.50 | 37,627 × time |

| BIO | 0.11 | 1.30 | 43,415 × time |

| CIO | 0.10 | 1.16 | 48,655 × time |

| Samples | Young’s Module Ey (MPa) | Poisson’s Coefficient vxy |

|---|---|---|

| AIO | 651.61 | 0.08 |

| BIO | 758.86 | 0.08 |

| CIO | 813.10 | 0.08 |

| Samples | Equivalent Stress Von Mises Max. (MPa) | Equivalent Strain Von Mises Max. (m/m) |

|---|---|---|

| AIO | 90.09 | 0.12518 |

| BIO | 88.41 | 0.10802 |

| CIO | 87.82 | 0.09573 |

| Samples | Height of Fall (m) | Impact Angle | Von Mises Stress Max. (MPa) | Von Mises Strain Max. (m/m) | ||

|---|---|---|---|---|---|---|

| Concrete | S. Steel | Concrete | S. Steel | |||

| AIO | 2 | 0° | 1.412 | 1.527 | 0.001962 | 0.002122 |

| 45° | 0.146 | 0.069 | 0.000301 | 0.002675 | ||

| 90° | 0.886 | 0.376 | 0.001234 | 0.000523 | ||

| 5 | 0° | 4.182 | 3.845 | 0.005811 | 0.005342 | |

| 45° | 0.306 | 0.276 | 0.001119 | 0.000666 | ||

| 90° | 2.160 | 1.306 | 0.003004 | 0.001823 | ||

| BIO | 2 | 0° | 1.360 | 1.359 | 0.001662 | 0.001660 |

| 45° | 0.141 | 0.141 | 0.000229 | 0.000230 | ||

| 90° | 0.812 | 0.813 | 0.000992 | 0.000993 | ||

| 5 | 0° | 4.234 | 4.236 | 0.005172 | 0.005174 | |

| 45° | 0.180 | 0.180 | 0.000732 | 0.000733 | ||

| 90° | 2.1780 | 2.182 | 0.002661 | 0.002666 | ||

| CIO | 2 | 0° | 2.3013 | 2.300 | 0.002508 | 0.002507 |

| 45° | 0.1558 | 0.156 | 0.000210 | 0.000210 | ||

| 90° | 0.8250 | 0.825 | 0.000900 | 0.000901 | ||

| 5 | 0° | 3.1178 | 3.122 | 0.003398 | 0.00340 | |

| 45° | 0.2228 | 0.223 | 0.000499 | 0.000499 | ||

| 90° | 1.7178 | 1.7220 | 0.001873 | 0.001877 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Araque, O.; Arzola, N.; Gallego, L. Mechanical Behavior of Briquettes Made from a Mixture of Sawdust and Rice Husks for Commercialization. Resources 2022, 11, 32. https://doi.org/10.3390/resources11030032

Araque O, Arzola N, Gallego L. Mechanical Behavior of Briquettes Made from a Mixture of Sawdust and Rice Husks for Commercialization. Resources. 2022; 11(3):32. https://doi.org/10.3390/resources11030032

Chicago/Turabian StyleAraque, Oscar, Nelson Arzola, and Laura Gallego. 2022. "Mechanical Behavior of Briquettes Made from a Mixture of Sawdust and Rice Husks for Commercialization" Resources 11, no. 3: 32. https://doi.org/10.3390/resources11030032

APA StyleAraque, O., Arzola, N., & Gallego, L. (2022). Mechanical Behavior of Briquettes Made from a Mixture of Sawdust and Rice Husks for Commercialization. Resources, 11(3), 32. https://doi.org/10.3390/resources11030032