How Spatial Analysis Can Help Enhance Material Stocks and Flows Analysis?

Abstract

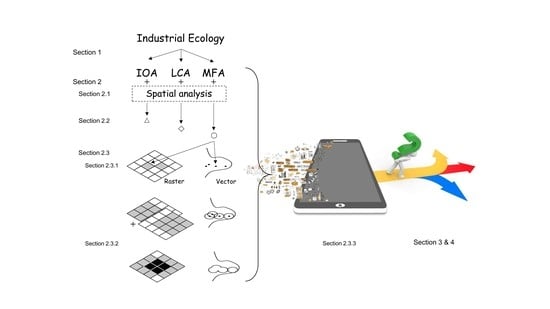

:1. The Importance of Space in the Industrial Ecology

2. What can Spatial Analysis Offer to Industrial Ecology?

2.1. What Is Spatial Analysis?

2.2. What Are the Relations Between Spatial Analysis and Typical Tools Used in Industrial Ecology?

2.3. Combining Material Flow Analysis with Spatial Analysis

2.3.1. Improving Data Structure

2.3.2. Spatializing Material Data

2.3.3. Building A Dynamic and Spatially Explicit Model to Simulate Material Stocks and Flows

3. Limitations

3.1. Scaling

3.2. Hidden Flows in Spatio-Temporal Perspectives

4. Conclusions and Outlooks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Raschio, G.; Smetana, S.; Contreras, C.; Heinz, V.; Mathys, A. Spatio-Temporal Differentiation of Life Cycle Assessment Results for Average Perennial Crop Farm: A Case Study of Peruvian Cocoa Progression and Deforestation Issues. J. Ind. Ecol. 2018, 22, 1378–1388. [Google Scholar] [CrossRef]

- Sun, M.; Mao, J. Quantitative Analysis of the Anthropogenic Spatial Transfer of Lead in China. J. Ind. Ecol. 2018, 22, 155–165. [Google Scholar] [CrossRef]

- VandeWeghe, J.R.; Kennedy, C. A Spatial Analysis of Residential Greenhouse Gas Emissions in the Toronto Census Metropolitan Area. J. Ind. Ecol. 2007, 11, 133–144. [Google Scholar] [CrossRef]

- Wang, X.; Du, L. Carbon Emission Performance of China’s Power Industry: Regional Disparity and Spatial Analysis. J. Ind. Ecol. 2017, 21, 1323–1332. [Google Scholar] [CrossRef]

- Lane, R. Understanding the Dynamic Character of Value in Recycling Metals from Australia. Resources 2014, 3, 416–431. [Google Scholar] [CrossRef] [Green Version]

- Lechner, M.A.; Devi, B.; Schleger, A.; Brown, G.; McKenna, P.; Ali, H.S.; Rachmat, S.; Syukril, M.; Rogers, P. A Socio-Ecological Approach to GIS Least-Cost Modelling for Regional Mining Infrastructure Planning: A Case Study from South-East Sulawesi, Indonesia. Resources 2017, 6, 7. [Google Scholar] [CrossRef]

- Świąder, M.; Szewrański, S.; Kazak, K.J.; van Hoof, J.; Lin, D.; Wackernagel, M.; Alves, A. Application of Ecological Footprint Accounting as a Part of an Integrated Assessment of Environmental Carrying Capacity: A Case Study of the Footprint of Food of a Large City. Resources 2018, 7, 52. [Google Scholar] [CrossRef]

- Schiller, F.; Penn, A.; Druckman, A.; Basson, L.; Royston, K. Exploring Space, Exploiting Opportunities. J. Ind. Ecol. 2014, 18, 792–798. [Google Scholar] [CrossRef]

- Chen, W.Q.; Graedel, T.E. In-use product stocks link manufactured capital to natural capital. Proc. Natl. Acad. Sci. USA 2015, 112, 6265–6270. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Darmofal, D. Spatial Analysis for the Social Sciences; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2015. [Google Scholar]

- Zhu, X. GIS and Urban Mining. Resources 2014, 3, 235–247. [Google Scholar] [CrossRef]

- Chen, W.Q.; Graedel, T.E.; Nuss, P.; Ohno, H. Building the Material Flow Networks of Aluminum in the 2007 U.S. Economy. Environ. Sci. Technol. 2016, 50, 3905–3912. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, S.; Kondo, Y.; Kagawa, S.; Matsubae, K.; Nakajima, K.; Nagasaka, T. MaTrace: Tracing the Fate of Materials over Time and Across Products in Open-Loop Recycling. Environ. Sci. Technol. 2014, 48, 7207–7214. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Song, T.; Chahine, T. Spatial representations and policy implications of industrial co-agglomerations, a case study of Beijing. Habitat Int. 2016, 55, 32–45. [Google Scholar] [CrossRef] [Green Version]

- Augiseau, V.; Barles, S. Studying construction materials flows and stock: A review. Resour. Conserv. Recycl. 2017, 123, 153–164. [Google Scholar] [CrossRef]

- Canning, D. A Database of World Stocks of Infrastructure, 1950–95. World Bank Econo. Rev. 1998, 12, 529–547. [Google Scholar] [CrossRef]

- Xu, M.; Cai, H.; Liang, S. Big Data and Industrial Ecology. J. Ind. Ecol. 2015, 19, 205–210. [Google Scholar] [CrossRef]

- Han, J.; Xiang, W.-N. Analysis of material stock accumulation in China’s infrastructure and its regional disparity. Sustain. Sci. 2013, 8, 553–564. [Google Scholar] [CrossRef]

- Kleemann, F.; Lederer, J.; Rechberger, H.; Fellner, J. GIS-based Analysis of Vienna’s Material Stock in Buildings. J. Ind. Ecol. 2017, 21, 368–380. [Google Scholar] [CrossRef]

- Meinel, G.; Hecht, R.; Herold, H. Analyzing building stock using topographic maps and GIS. Build. Res. Inf. 2009, 37, 468–482. [Google Scholar] [CrossRef]

- Tanikawa, H.; Fishman, T.; Okuoka, K.; Sugimoto, K. The Weight of Society Over Time and Space: A Comprehensive Account of the Construction Material Stock of Japan, 1945–2010. J. Ind. Ecol. 2015, 19, 778–791. [Google Scholar] [CrossRef]

- Tanikawa, H.; Hashimoto, S. Urban stock over time: spatial material stock analysis using 4d-GIS. Build. Res. Inf. 2009, 37, 483–502. [Google Scholar] [CrossRef]

- Wu, J. Hierarchy and scaling: Extrapolating information along a scaling ladder. Can. J. Remote Sens. 1999, 25, 367–380. [Google Scholar] [CrossRef]

- Armstrong, M.; Champigny, N. A study on kriging small blocks. Cim. Bulletin 1989, 82, 128–133. [Google Scholar]

- Lyons, D.I. A Spatial Analysis of Loop Closing Among Recycling, Remanufacturing, and Waste Treatment Firms in Texas. J. Ind. Ecol. 2007, 11, 43–54. [Google Scholar] [CrossRef]

- Hubacek, K.; Feng, K.; Minx, J.C.; Pfister, S.; Zhou, N. Teleconnecting Consumption to Environmental Impacts at Multiple Spatial Scales. J. Ind. Ecol. 2014, 18, 7–9. [Google Scholar] [CrossRef]

- Saravanan, V.S.; Mavalankar, D.; Kulkarni, S.P.; Nussbaum, S.; Weigelt, M. Metabolized-Water Breeding Diseases in Urban India: Sociospatiality of Water Problems and Health Burden in Ahmedabad City. J. Ind. Ecol. 2015, 19, 93–103. [Google Scholar] [CrossRef]

- Wu, S.R.; Li, X.; Apul, D.; Breeze, V.; Tang, Y.; Fan, Y.; Chen, J. Agent-Based Modeling of Temporal and Spatial Dynamics in Life Cycle Sustainability Assessment. J. Ind. Ecol. 2017, 21, 1507–1521. [Google Scholar] [CrossRef] [Green Version]

- Bergsdal, H.; Brattebø, H.; Bohne, R.A.; Müller, D.B. Dynamic material flow analysis for Norway’s dwelling stock. Build. Res. Inf. 2007, 35, 557–570. [Google Scholar] [CrossRef]

- Hu, D.; You, F.; Zhao, Y.; Yuan, Y.; Liu, T.; Cao, A.; Wang, Z.; Zhang, J. Input, stocks and output flows of urban residential building system in Beijing city, China from 1949 to 2008. Resour. Conserv. Recycl. 2010, 54, 1177–1188. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Bergsdal, H.; van der Voet, E.; Huppes, G.; Müller, D.B. Dynamics of urban and rural housing stocks in China. Build. Res. Inf. 2010, 38, 301–317. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Voet, E.V.D.; Huppes, G. Dynamic Material Flow Analysis for Strategic Construction and Demolition Waste Management in Beijing. J. Ind. Ecol. 2010, 14, 440–456. [Google Scholar] [CrossRef]

- Huang, C.; Han, J.; Chen, W.-Q. Changing patterns and determinants of infrastructures’ material stocks in Chinese cities. Resour. Conserv. Recycl. 2017, 123, 47–53. [Google Scholar] [CrossRef]

- Huang, T.; Shi, F.; Tanikawa, H.; Fei, J.; Han, J. Materials demand and environmental impact of buildings construction and demolition in China based on dynamic material flow analysis. Resour. Conserv. Recycl. 2013, 72, 91–101. [Google Scholar] [CrossRef]

- Miatto, A.; Schandl, H.; Wiedenhofer, D.; Krausmann, F.; Tanikawa, H. Modeling material flows and stocks of the road network in the United States 1905–2015. Resour. Conserv. Recycl. 2017, 127, 168–178. [Google Scholar] [CrossRef]

- Müller, D. Stock dynamics for forecasting material flows—Case study for housing in The Netherlands. Ecolo. Econ. 2006, 59, 142–156. [Google Scholar] [CrossRef]

- Wiedenhofer, D.; Steinberger, J.K.; Eisenmenger, N.; Haas, W. Maintenance and Expansion: Modeling Material Stocks and Flows for Residential Buildings and Transportation Networks in the EU25. J. Ind. Ecol. 2015, 19, 538–551. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, W.; Kohler, N. Simulation of the evolution of the Chinese building and infrastructure stock. Build. Res. Inf. 2008, 36, 1–19. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Koehler, A.; Althaus, H.-J.; Hellweg, S. Scaling Relationships in Life Cycle Assessment. J. Ind. Ecol. 2014, 18, 393–406. [Google Scholar] [CrossRef]

- Patrício, J.; Kalmykova, Y.; Rosado, L.; Lisovskaja, V. Uncertainty in Material Flow Analysis Indicators at Different Spatial Levels. J. Ind. Ecol. 2015, 19, 837–852. [Google Scholar] [CrossRef]

- Rauch, J.N. Global mapping of Al, Cu, Fe, and Zn in-use stocks and in-ground resources. Proc. Natl. Acad. Sci. USA 2009, 106, 18920–18925. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van Ewijk, S.; Stegemann, J.A.; Ekins, P. Global Life Cycle Paper Flows, Recycling Metrics, and Material Efficiency. J. Ind. Ecol. 2017, 22, 686–693. [Google Scholar] [CrossRef] [Green Version]

- Kohler, N.; Hassler, U. The building stock as a research object. Build. Res. Inf. 2002, 30, 226–236. [Google Scholar] [CrossRef] [Green Version]

| Data Structures | Table (e.g., for Each Administrative Entity) | Grid | Vector | References | |

|---|---|---|---|---|---|

| Analysis Processes | Data sources | *** | ** | ** | [15,16,17] |

| Data/results demonstration | ** | *** | *** | [11,18] | |

| Spatial analyzing/modelling | * | *** | *** | [8,11,15,19,20,21,22] | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Chen, W.-Q.; Lin, T.; Gao, L. How Spatial Analysis Can Help Enhance Material Stocks and Flows Analysis? Resources 2019, 8, 46. https://doi.org/10.3390/resources8010046

Liu Y, Chen W-Q, Lin T, Gao L. How Spatial Analysis Can Help Enhance Material Stocks and Flows Analysis? Resources. 2019; 8(1):46. https://doi.org/10.3390/resources8010046

Chicago/Turabian StyleLiu, Yupeng, Wei-Qiang Chen, Tao Lin, and Lijie Gao. 2019. "How Spatial Analysis Can Help Enhance Material Stocks and Flows Analysis?" Resources 8, no. 1: 46. https://doi.org/10.3390/resources8010046

APA StyleLiu, Y., Chen, W. -Q., Lin, T., & Gao, L. (2019). How Spatial Analysis Can Help Enhance Material Stocks and Flows Analysis? Resources, 8(1), 46. https://doi.org/10.3390/resources8010046