Recycling of Coal Ash in Concrete as a Partial Cementitious Resource

Abstract

:1. Introduction

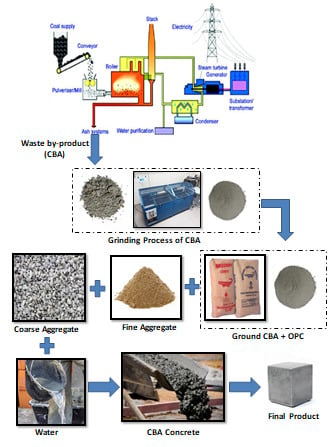

2. Materials and Methods

2.1. Materials

2.2. Physical Properties of CBA

2.3. Chemical Composition of CBA

2.4. Concrete Mix Proportion

2.5. Sample Preparation

3. Results and Discussion

3.1. Workability

3.2. Compressive Strength

3.3. Splitting Tensile Strength

3.4. Compressive and Tensile Strength Relationship

- fcu: The compressive strength (MPa)

- ft: The split tensile strength (MPa)

4. Conclusions

- In this study, three types of ground CBA were produced: A, B and C (through three different grinding periods: 20, 30 and 40 h, respectively). It was experimentally demonstrated that CBA type A and B had good and satisfactory strength performance as compared to the CBA type C.

- The workability of the concrete was found to decrease with the increase in the amount of ground CBA as a cement replacement. It was noticed that the increase in the fineness of the ground CBA particles absorbed more water in the mixture.

- It was experimentally observed that concrete compressive strength was not developed with ground CBA at early ages. The compressive strength reduced with the addition of ground CBA as a cement replacement. Considering the results of different mixes, the optimum results were recorded with 10% of ground CBA in M1 and M4 at curing periods of 28 days, when both mixes achieved the targeted strength of 35 MPa.

- Similarly, the tensile strength of the concrete also reduced as the amount of ground CBA increased in the concrete mix, because the pozzolanic reaction was not yet initiated at an age of 28 days.

- It was experimentally explored that 10% ground CBA, having a particle fineness around 65% to 75%, passed through a 63 µm sieve, could achieve the adequate compressive and tensile strength of concrete.

Author Contributions

Funding

Conflicts of Interest

References

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on workability and strength properties of concrete. J. Cleaner Prod. 2016, 112, 132–135. [Google Scholar] [CrossRef]

- Isaia, G.; Gastaldini, A.L.; Moraes, R. Physical and pozzolanic action of mineral additions on the mechanical strength of high-performance concrete. Cem. Concr. Compos. 2003, 25, 69–76. [Google Scholar] [CrossRef]

- Manz, O.E. Worldwide production of coal ash and utilization in concrete and other products. Fuel 1997, 76, 691–696. [Google Scholar] [CrossRef]

- Baite, E.; Messan, A.; Hannawi, K.; Tsobnang, F.; Prince, W. Physical and transfer properties of mortar containing coal bottom ash aggregates from Tefereyre (Niger). Constr. Build. Mater. 2016, 125, 919–926. [Google Scholar] [CrossRef]

- Mangi, S.A.; Jamaluddin, N.; Wan Ibrahim, M.H.; Abdullah, A.H.; Abdul Awal, A.S.M.; Sohu, S.; Ali, N. Utilization of sugarcane bagasse ash in concrete as partial replacement of cement. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271. [Google Scholar] [CrossRef]

- Ahmad Maliki, A.I.F.; Shahidan, S.; Ali, N.; Ramzi Hannan, N.I.R.; Mohd Zuki, S.S.; Wan Ibrahim, M.H.; Mohammad Azmi, M.A.; Abdul Rahim, M. Compressive and tensile strength for concrete containing coal bottom ash. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012055. [Google Scholar] [CrossRef] [Green Version]

- Hamzah, A.F.; Wan Ibrahim, M.H.; Jamaluddin, N.; Jaya, R.P.; Arshad, M.F.; Abidin, N.E.Z. Fresh characteristic and mechanical compressive strength development of self-compacting concrete integrating coal bottom ash as partial fine aggregates replacement. Int. J. Mech. Mechatron. Eng. 2105, 15, 61–67. [Google Scholar]

- Hamzah, A.F.; Wan Ibrahim, M.H.; Jamaluddin, N.; Jaya, R.P.; Arshad, M.F.; Abidin, N.E.Z.; Manan, E.A.; Omar, N.A. Nomograph of self-compacting concrete mix design incorporating coal bottom ash as partial replacement of fine aggregates. J. Eng. Appl. Sci. 2016, 11, 1671–1675. [Google Scholar]

- Argiz, C.; Moragues, A.; Menéndez, E. Use of ground coal bottom ash as cement constituent in concretes exposed to chloride environments. J. Cleaner Prod. 2018, 170, 25–33. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Wang, X.; Liao, S.; Lin, H. Ultrafine grinding of fly ash with grinding aids: Impact on particle characteristics of ultrafine fly ash and properties of blended cement containing ultrafine fly ash. Constr. Build. Mater. 2015, 78, 250–259. [Google Scholar] [CrossRef]

- Jaya, R.P.; Bakar, B.H.A.; Johari, M.A.M.; Wan Ibrahim, M.H. Engineering properties of normal concrete grade 40 containing rice husk ash at different grinding times. Int. J. Technol. 2011, 2, 10–19. [Google Scholar]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Memon, S.A.; Shahidan, S. Effects of grinding process on the properties of the coal bottom ash and cement Paste. J. Eng. Technol. Sci. 2019, 51, 1–13. [Google Scholar] [CrossRef]

- Turu’allo, G. Using GGBS for Partial Cement Replacement in Concrete: Effects of Water-Binder Ratio and GGBS Level on Activation Energy. Int. J. Technol. 2018, 6, 790–799. [Google Scholar] [CrossRef]

- ASTM C618-05. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2005; Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C618-05.htm (accessed on 14 May 2019).

- ASTM E1621-13. Standard Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Ramezanianpour, A.M.; Hooton, R.D. Thaumasite sulfate attack in Portland and Portland-limestone cement mortars exposed to sulfate solution. Constr. Build. Mater. 2013, 40, 162–173. [Google Scholar] [CrossRef]

- ASTM C192/C192M-18. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2018; Available online: https://www.astm.org/Standards/C192 (accessed on 14 May 2019).

- Arun Kumar, R.S.A. Comparison of Fresh and Hardened Properties of Normal, Self Compacting and Smart Dynamic Concrete. Int. J. Technol. 2018, 9, 707–714. [Google Scholar] [CrossRef]

- ASTM C143/C143M-15a. Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015; Available online: https://www.astm.org/Standards/C143 (accessed on 14 May 2019).

- Vinay Chandwani, S.S.; Agrawal, V.; Nagar, R. Modeling slump of ready mix concrete using artificial neural network. Int. J. Technol. 2015, 6, 207–216. [Google Scholar] [CrossRef]

- Kurama, H.; Kaya, M. Usage of coal combustion bottom ash in concrete mixture. Constr. Build. Mater. 2008, 22, 1922–1928. [Google Scholar] [CrossRef]

- Khan, R.A.; Ganesh, A. The effect of coal bottom ash (CBA) on mechanical and durability characteristics of concrete. J. Build. Mater. Struct. 2016, 3, 31–42. [Google Scholar]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Shahidan, S.; Arshad, M.F.; Memon, S.A.; Jaya, R.P.; Mudjanarko, S.W.; Setiawan, M.I. Influence of ground coal bottom ash on the properties of concrete. Int. J. Sustainable Constr. Eng. Technol. 2019, 9, 26–34. [Google Scholar] [CrossRef]

- Sena da Fonseca, B.; Castela, A.; Neves, R.; Duarte, R.; Galhano, C.; Montemor, M. Saving Raw Materials for Cement Manufacture and Reusing an Untreated Waste from the Petrochemical Industry. Resources 2018, 7, 56. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Jaya, R.P. Effects of ground coal bottom ash on the properties of concrete. J. Eng. Sci. Technol. 2019, 14, 338–350. [Google Scholar]

| Properties | OPC | CBA with Different Fineness | ||

|---|---|---|---|---|

| Type—A | Type—B | Type—C | ||

| Specific surface area (m2/kg) | 487.081 | 383.575 | 389.484 | 463.778 |

| Specific gravity | 3.10 | 2.41 | 2.44 | 2.50 |

| Passing (%) from sieve 63 µm | 100 | 65.47 | 75.40 | 85.73 |

| Color | Grey | Grey | Dark grey | Dark grey |

| Grinding period (h) | - | 20 | 30 | 40 |

| Sample | OPC | CBA |

|---|---|---|

| Chemical Content | % | % |

| Silica dioxide (SiO2) | 20.61 | 53.80 |

| Aluminum Trioxide (Al2O3) | 3.95 | 18.10 |

| Ferric Oxide (Fe2O3) | 3.46 | 8.70 |

| Calcium Oxide (CaO) | 63.95 | 5.30 |

| Titanium dioxide (TiO2) | 0.20 | 1.20 |

| Carbon (C) | - | 0.10 |

| Potassium Oxide (K2O) | - | 0.85 |

| Magnesia/Magnesium Oxide (MgO) | 1.93 | 0.58 |

| Strontium oxide (SrO) | - | 0.35 |

| Phosphorus pentoxide (P2O5) | - | 0.29 |

| Sulfur trioxide (SO3) | 3.62 | 0.90 |

| Barium oxide (BaO) | - | 0.18 |

| Zirconium dioxide (ZrO2) | - | 0.15 |

| Sodium superoxide (Na2O) | - | 0.17 |

| Loss on ignition (LOI) | 2.18 | 4.02 |

| Notation | CBA Type | % Replacement | Cement | Ground CBA | Sand | Coarse Aggregate | Water |

|---|---|---|---|---|---|---|---|

| CM | - | 0 | 440 | 0 | 805 | 828 | 220 |

| M1 | A | 10 | 396 | 44 | 805 | 828 | 220 |

| M2 | 20 | 352 | 88 | 805 | 828 | 220 | |

| M3 | 30 | 308 | 132 | 805 | 828 | 220 | |

| M4 | B | 10 | 396 | 44 | 805 | 828 | 220 |

| M5 | 20 | 352 | 88 | 805 | 828 | 220 | |

| M6 | 30 | 308 | 132 | 805 | 828 | 220 | |

| M7 | C | 10 | 396 | 44 | 805 | 828 | 220 |

| M8 | 20 | 352 | 88 | 805 | 828 | 220 | |

| M9 | 30 | 308 | 132 | 805 | 828 | 220 |

| Sample Code | % Replacement | Compressive Strength | Splitting Tensile Strength | Total Specimens | ||

|---|---|---|---|---|---|---|

| Curing Period (days) | 7 | 28 | 7 | 28 | ||

| CM | 0 | 3 | 3 | 3 | 3 | 120 |

| M1 | 10 | 3 | 3 | 3 | 3 | |

| M2 | 20 | 3 | 3 | 3 | 3 | |

| M3 | 30 | 3 | 3 | 3 | 3 | |

| M4 | 10 | 3 | 3 | 3 | 3 | |

| M5 | 20 | 3 | 3 | 3 | 3 | |

| M6 | 30 | 3 | 3 | 3 | 3 | |

| M7 | 10 | 3 | 3 | 3 | 3 | |

| M8 | 20 | 3 | 3 | 3 | 3 | |

| M9 | 30 | 3 | 3 | 3 | 3 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Mudjanarko, S.W. Recycling of Coal Ash in Concrete as a Partial Cementitious Resource. Resources 2019, 8, 99. https://doi.org/10.3390/resources8020099

Mangi SA, Wan Ibrahim MH, Jamaluddin N, Arshad MF, Mudjanarko SW. Recycling of Coal Ash in Concrete as a Partial Cementitious Resource. Resources. 2019; 8(2):99. https://doi.org/10.3390/resources8020099

Chicago/Turabian StyleMangi, Sajjad Ali, Mohd Haziman Wan Ibrahim, Norwati Jamaluddin, Mohd Fadzil Arshad, and Sri Wiwoho Mudjanarko. 2019. "Recycling of Coal Ash in Concrete as a Partial Cementitious Resource" Resources 8, no. 2: 99. https://doi.org/10.3390/resources8020099

APA StyleMangi, S. A., Wan Ibrahim, M. H., Jamaluddin, N., Arshad, M. F., & Mudjanarko, S. W. (2019). Recycling of Coal Ash in Concrete as a Partial Cementitious Resource. Resources, 8(2), 99. https://doi.org/10.3390/resources8020099