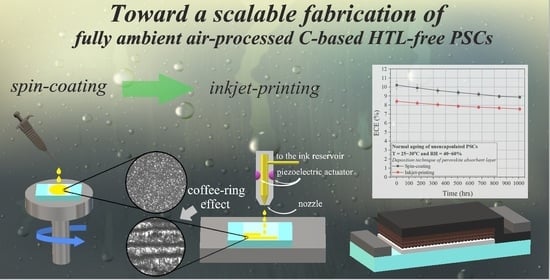

Toward a Scalable Fabrication of Perovskite Solar Cells under Fully Ambient Air Atmosphere: From Spin-Coating to Inkjet-Printing of Perovskite Absorbent Layer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of the Solar Cells

2.3. Characterization

3. Results and Discussion

3.1. Characteristics of the Perovskite Absorbent Layer

3.2. Characteristics of the Solar Cells

4. Conclusions

Author Contributions

Funding

Attributions

Conflicts of Interest

References

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.-H. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Zhang, N.; Jiang, T.; Guo, C.; Qiao, L.; Ji, Q.; Yin, L.; Yu, L.; Murto, P.; Xu, X. High-performance semitransparent polymer solar cells floating on water: Rational analysis of power generation, water evaporation and algal growth. Nano Energy 2020, 77, 105111. [Google Scholar] [CrossRef]

- Deng, H.; Sun, Q.; Yang, Z.; Li, W.; Yan, Q.; Zhang, C.; Zheng, Q.; Wang, X.; Lai, Y.; Cheng, S. Novel symmetrical bifacial flexible CZTSSe thin film solar cells for indoor photovoltaic applications. Nat. Commun. 2021, 12, 3107. [Google Scholar] [CrossRef] [PubMed]

- Chalkias, D.A.; Charalampopoulos, C.; Andreopoulou, A.K.; Karavioti, A.; Stathatos, E. Spectral engineering of semi-transparent dye-sensitized solar cells using new triphenylamine-based dyes and an iodine-free electrolyte for greenhouse-oriented applications. J. Power Sources 2021, 496, 229842. [Google Scholar] [CrossRef]

- Jean, J.; Brown, P.R.; Jaffe, R.L.; Buonassisi, T.; Bulović, V. Pathways for solar photovoltaics. Energy Environ. Sci. 2015, 8, 1200–1219. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory: Photovoltaic Research. Available online: https://www.nrel.gov/pv/ (accessed on 28 January 2021).

- Kojima, A.; Teshima, K.; Shirai, Y.; Miyasaka, T. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 2009, 131, 6050–6051. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Yang, S. Carbon-based perovskite solar cells without hole transport materials: The front runner to the market? Adv. Mater. 2017, 29, 1603994. [Google Scholar] [CrossRef]

- Mohammed, M.K.A. High-performance hole conductor-free perovskite solar cell using a carbon nanotube counter electrode. RSC Adv. 2020, 10, 35831–35839. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, J.; Li, N.; Li, X.; Zheng, Y.-Z.; Tao, X. Efficient all-air processed mixed cation carbon-based perovskite solar cells with ultra-high stability. J. Mater. Chem. A 2019, 7, 17594–17603. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Z.; Ng, W.K.; Zhang, L.; Zhang, H.; Meng, X.; Bai, Y.; Xiao, S.; Zhang, T.; Hu, C.; et al. An ultrathin ferroelectric perovskite oxide layer for high-performance hole transport material free carbon based halide perovskite solar cells. Adv. Funct. Mater. 2019, 29, 1806506. [Google Scholar] [CrossRef] [Green Version]

- Tufail Chaudhary, K. Thin film deposition: Solution based approach. In Thin Films [Working Title]; IntechOpen: London, UK, 2021. [Google Scholar]

- Yang, Z.; Chueh, C.-C.; Zuo, F.; Kim, J.H.; Liang, P.-W.; Jen, A.K.-Y. High-performance fully printable perovskite solar cells via blade-coating technique under the ambient condition. Adv. Energy Mater. 2015, 5, 1500328. [Google Scholar] [CrossRef]

- Hwang, K.; Jung, Y.-S.; Heo, Y.-J.; Scholes, F.H.; Watkins, S.E.; Subbiah, J.; Jones, D.J.; Kim, D.-Y.; Vak, D. Toward large scale roll-to-roll production of fully printed perovskite solar cells. Adv. Mater. 2015, 27, 1241–1247. [Google Scholar] [CrossRef]

- Barrows, A.T.; Pearson, A.J.; Kwak, C.K.; Dunbar, A.D.F.; Buckley, A.R.; Lidzey, D.G. Efficient planar heterojunction mixed-halide perovskite solar cells deposited via spray-deposition. Energy Environ. Sci. 2014, 7, 2944–2950. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, S.; Wang, X.; Wang, D.; Li, Y.; Ai, Q.; Sun, X.; Chen, J.; Li, Y.; Jiang, X.; et al. Ambient inkjet-printed high-efficiency perovskite solar cells: Manipulating the spreading and crystallization behaviors of picoliter perovskite droplets. Sol. RRL 2021, 5, 2100106. [Google Scholar] [CrossRef]

- Peng, X.; Yuan, J.; Shen, S.; Gao, M.; Chesman, A.S.R.; Yin, H.; Cheng, J.; Zhang, Q.; Angmo, D. Perovskite and organic solar cells fabricated by inkjet printing: Progress and prospects. Adv. Funct. Mater. 2017, 27, 1703704. [Google Scholar] [CrossRef]

- Li, S.G.; Jiang, K.J.; Su, M.J.; Cui, X.P.; Huang, J.H.; Zhang, Q.Q.; Zhou, X.Q.; Yang, L.M.; Song, Y.L. Inkjet printing of CH3NH3PbI3 on a mesoscopic TiO2 film for highly efficient perovskite solar cells. J. Mater. Chem. A 2015, 3, 9092–9097. [Google Scholar] [CrossRef]

- Li, P.; Liang, C.; Bao, B.; Li, Y.; Hu, X.; Wang, Y.; Zhang, Y.; Li, F.; Shao, G.; Song, Y. Inkjet manipulated homogeneous large size perovskite grains for efficient and large-area perovskite solar cells. Nano Energy 2018, 46, 203–211. [Google Scholar] [CrossRef]

- Eggers, H.; Schackmar, F.; Abzieher, T.; Sun, Q.; Lemmer, U.; Vaynzof, Y.; Richards, B.S.; Hernandez-Sosa, G.; Paetzold, U.W. Inkjet-printed micrometer-thick perovskite solar cells with large columnar grains. Adv. Energy Mater. 2020, 10, 1903184. [Google Scholar] [CrossRef] [Green Version]

- Wei, Z.; Chen, H.; Yan, K.; Yang, S. Inkjet printing and instant chemical transformation of a CH3NH3PbI3/nanocarbon electrode and interface for planar perovskite solar cells. Angew. Chem. Int. Ed. 2014, 53, 13239–13243. [Google Scholar] [CrossRef]

- Hashmi, S.G.; Tiihonen, A.; Martineau, D.; Ozkan, M.; Vivo, P.; Kaunisto, K.; Ulla, V.; Zakeeruddin, S.M.; Grätzel, M. Long term stability of air processed inkjet infiltrated carbon-based printed perovskite solar cells under intense ultra-violet light soaking. J. Mater. Chem. A 2017, 5, 4797–4802. [Google Scholar] [CrossRef] [Green Version]

- Hashmi, S.G.; Martineau, D.; Li, X.; Ozkan, M.; Tiihonen, A.; Dar, M.I.; Sarikka, T.; Zakeeruddin, S.M.; Paltakari, J.; Lund, P.D.; et al. Air processed inkjet infiltrated carbon based printed perovskite solar cells with high stability and reproducibility. Adv. Mater. Technol. 2017, 2, 1600183. [Google Scholar] [CrossRef]

- Chalkias, D.A.; Laios, A.I.; Petala, A.; Papanicolaou, G.C. Evaluation of the limiting factors affecting large-sized, flexible, platinum-free dye-sensitized solar cells performance: A combined experimental and equivalent circuit analysis. J. Mater. Sci. Mater. Electron. 2018, 29, 9621–9634. [Google Scholar] [CrossRef]

- Lv, Y.; Jin, Y.; Cai, W.; Zhang, Z.; Zhou, X.; Chen, H. Air-processed carbon-based perovskite solar cells with enhanced efficiency and stability: Effect of temperature control and using CuSCN. J. Alloys Compd. 2020, 821, 153272. [Google Scholar] [CrossRef]

- Chalkias, D.A.; Karavioti, A.; Kalarakis, A.N.; Stathatos, E. Unveiling the importance of dripping temperature control of hybrid organic-inorganic perovskite precursor solution for the fabrication of fully ambient air-processed perovskite solar cells. Sol. Energy 2021, 224, 1017–1027. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, P.; Shen, W.; Mei, A.; Xiong, S.; Jiang, X.; Rong, Y.; Tang, Y.; Hu, Y.; Han, H. A low-temperature carbon electrode with good perovskite compatibility and high flexibility in carbon based perovskite solar cells. Chem. Commun. 2019, 55, 2765–2768. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhou, Z.; Ru, P.; Chen, H.; Yang, X.; Han, L. Reliable measurement of perovskite solar cells. Adv. Mater. 2019, 31, 1803231. [Google Scholar] [CrossRef] [PubMed]

- Oku, T. Crystal structures of CH3NH3PbI3 and related perovskite compounds used for solar cells. In Solar Cells-New Approaches and Reviews; Kosyachenko, L.A., Ed.; InTech: London, UK, 2015. [Google Scholar]

- Asl, H.Z.; Rozati, S.M. High-quality spray-deposited fluorine-doped tin oxide: Effect of film thickness on structural, morphological, electrical, and optical properties. Appl. Phys. A Mater. Sci. Process. 2019, 125, 689. [Google Scholar] [CrossRef]

- Zhang, Y.; Kirs, A.; Ambroz, F.; Lin, C.; Bati, A.S.R.; Parkin, I.P.; Shapter, J.G.; Batmunkh, M.; Macdonald, T.J. Ambient fabrication of organic–inorganic hybrid perovskite solar cells. Small Methods 2021, 5, 2000744. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-ray Diffraction, 2nd ed.; Addison-Wesley: Boston, MA, USA, 1978. [Google Scholar]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Contact line deposits in an evaporating drop. Phys. Rev. E Stat. Phys. Plasmas Fluids Relat. Interdiscip. Top. 2000, 62, 756–765. [Google Scholar] [CrossRef] [Green Version]

- Liang, C.; Li, P.; Gu, H.; Zhang, Y.; Li, F.; Song, Y.; Shao, G.; Mathews, N.; Xing, G. One-Step inkjet printed perovskite in air for efficient light harvesting. Sol. RRL 2018, 2, 1700217. [Google Scholar] [CrossRef]

- Mohamad Noh, M.F.; Arzaee, N.A.; Nawas Mumthas, I.N.; Mohamed, N.A.; Mohd Nasir, S.N.F.; Safaei, J.; Yusoff, A.R.B.M.; Nazeeruddin, M.K.; Mat Teridi, M.A. High-humidity processed perovskite solar cells. J. Mater. Chem. A 2020, 8, 10481–10518. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, T.; Wang, Y.; Liu, D.; Zhang, P.; Chen, H.; Ji, L.; Chen, L.; Chen, Z.D.; Wu, J.; et al. Steering the crystallization of perovskites for high-performance solar cells in ambient air. J. Mater. Chem. A 2019, 7, 12166–12175. [Google Scholar] [CrossRef]

- Schackmar, F.; Eggers, H.; Frericks, M.; Richards, B.S.; Lemmer, U.; Hernandez-Sosa, G.; Paetzold, U.W. Perovskite solar cells with all-inkjet-printed absorber and charge transport layers. Adv. Mater. Technol. 2021, 6, 2000271. [Google Scholar] [CrossRef]

- Sheikh, A.D.; Bera, A.; Haque, M.A.; Rakhi, R.B.; Del Gobbo, S.; Alshareef, H.N.; Wu, T. Atmospheric effects on the photovoltaic performance of hybrid perovskite solar cells. Sol. Energy Mater. Sol. Cells 2015, 137, 6–14. [Google Scholar] [CrossRef]

- Leguy, A.M.A.; Azarhoosh, P.; Alonso, M.I.; Campoy-Quiles, M.; Weber, O.J.; Yao, J.; Bryant, D.; Weller, M.T.; Nelson, J.; Walsh, A.; et al. Experimental and theoretical optical properties of methylammonium lead halide perovskites. Nanoscale 2016, 8, 6317–6327. [Google Scholar] [CrossRef] [Green Version]

- Kang, D.; Park, N. On the current–voltage hysteresis in perovskite solar cells: Dependence on perovskite composition and methods to remove hysteresis. Adv. Mater. 2019, 31, 1805214. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, A.O.; Arcas, R.; Aranda, C.A.; Bethencourt, L.; Mas-Marzá, E.; Saliba, M.; Fabregat-Santiago, F. Negative capacitance and inverted hysteresis: Matching features in perovskite solar cells. J. Phys. Chem. Lett. 2020, 11, 8417–8423. [Google Scholar] [CrossRef]

- Huang, J.; Xiang, S.; Yu, J.; Li, C.Z. Highly efficient prismatic perovskite solar cells. Energy Environ. Sci. 2019, 12, 929–937. [Google Scholar] [CrossRef]

- Bou, A.; Pockett, A.; Raptis, D.; Watson, T.; Carnie, M.J.; Bisquert, J. Beyond impedance spectroscopy of perovskite solar cells: Insights from the spectral correlation of the electrooptical frequency techniques. J. Phys. Chem. Lett. 2020, 11, 8654–8659. [Google Scholar] [CrossRef]

- Riquelme, A.; Bennett, L.J.; Courtier, N.E.; Wolf, M.J.; Contreras-Bernal, L.; Walker, A.B.; Richardson, G.; Anta, J.A. Identification of recombination losses and charge collection efficiency in a perovskite solar cell by comparing impedance response to a drift-diffusion model. Nanoscale 2020, 12, 17385–17398. [Google Scholar] [CrossRef]

- Khenkin, M.V.; Katz, E.A.; Abate, A.; Bardizza, G.; Berry, J.J.; Brabec, C.; Brunetti, F.; Bulović, V.; Burlingame, Q.; Di Carlo, A.; et al. Consensus statement for stability assessment and reporting for perovskite photovoltaics based on ISOS procedures. Nat. Energy 2020, 5, 35–49. [Google Scholar] [CrossRef]

- Christians, J.A.; Miranda Herrera, P.A.; Kamat, P.V. Transformation of the excited state and photovoltaic efficiency of CH3NH3PbI3 perovskite upon controlled exposure to humidified air. J. Am. Chem. Soc. 2015, 137, 1530–1538. [Google Scholar] [CrossRef] [PubMed]

| Deposition Technique | Scan Mode | JSC (mA/cm2) | VOC (mV) | FF (−) | PCE (%) | HI (%) |

|---|---|---|---|---|---|---|

| Spin-coating | Forward | 23.05 ± 0.67 | 881 ± 15 | 0.50 ± 0.02 | 10.22 ± 0.42 | −5.65 ± 2.3 |

| Reverse | 21.75 ± 1.06 | 885 ± 9 | 0.52 ± 0.01 | 10.01 ± 0.46 | ||

| Inkjet-printing | Forward | 21.58 ± 0.43 | 813 ± 10 | 0.48 ± 0.01 | 8.42 ± 0.24 | 1.17 ± 0.6 |

| Reverse | 22.02 ± 0.51 | 818 ± 8 | 0.47 ± 0.01 | 8.40 ± 0.20 |

| Deposition Technique | Rs (Ohm) | RHF (Ohm) | τe (10−6 s) |

|---|---|---|---|

| Spin-coating | 16 | 1910 | 4.68 |

| Inkjet-printing | 18 | 1660 | 3.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karavioti, A.; Chalkias, D.A.; Katsagounos, G.; Mourtzikou, A.; Kalarakis, A.N.; Stathatos, E. Toward a Scalable Fabrication of Perovskite Solar Cells under Fully Ambient Air Atmosphere: From Spin-Coating to Inkjet-Printing of Perovskite Absorbent Layer. Electronics 2021, 10, 1904. https://doi.org/10.3390/electronics10161904

Karavioti A, Chalkias DA, Katsagounos G, Mourtzikou A, Kalarakis AN, Stathatos E. Toward a Scalable Fabrication of Perovskite Solar Cells under Fully Ambient Air Atmosphere: From Spin-Coating to Inkjet-Printing of Perovskite Absorbent Layer. Electronics. 2021; 10(16):1904. https://doi.org/10.3390/electronics10161904

Chicago/Turabian StyleKaravioti, Aggeliki, Dimitris A. Chalkias, Giannis Katsagounos, Argyroula Mourtzikou, Alexandros N. Kalarakis, and Elias Stathatos. 2021. "Toward a Scalable Fabrication of Perovskite Solar Cells under Fully Ambient Air Atmosphere: From Spin-Coating to Inkjet-Printing of Perovskite Absorbent Layer" Electronics 10, no. 16: 1904. https://doi.org/10.3390/electronics10161904

APA StyleKaravioti, A., Chalkias, D. A., Katsagounos, G., Mourtzikou, A., Kalarakis, A. N., & Stathatos, E. (2021). Toward a Scalable Fabrication of Perovskite Solar Cells under Fully Ambient Air Atmosphere: From Spin-Coating to Inkjet-Printing of Perovskite Absorbent Layer. Electronics, 10(16), 1904. https://doi.org/10.3390/electronics10161904