Magnetically Coupled Resonance WPT: Review of Compensation Topologies, Resonator Structures with Misalignment, and EMI Diagnostics

Abstract

:1. Introduction

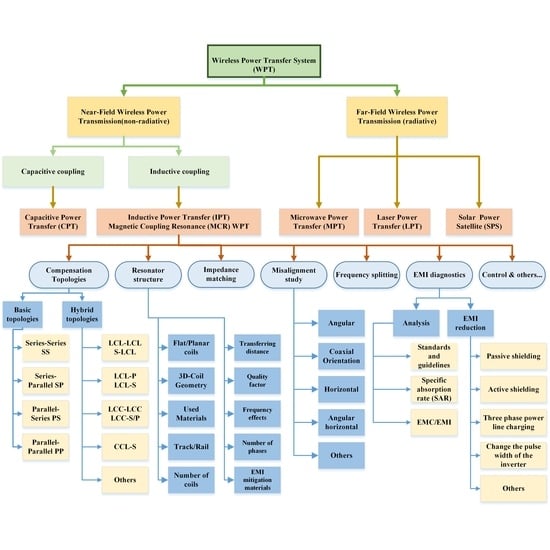

- Compensation topologies: Basic and hybrid compensation topologies are reported, and some commonly used topologies are compared based on application type.

- Research work related to the resonator structure is discussed as follows:

- Coil geometry is discussed in detail, including many resonator shapes, such as planar coils, three-dimensional (3D) structures, cavity structures, and coils with cores, etc., which are compared based on set criteria.

- The differences between single-phase WPT and three-phase WPT systems are highlighted, and some three-phase WPT projects are reported.

- Multi-coil systems, which are capable of charging multiple devices simultaneously, such as LEDs, are addressed.

- Operating frequency effects on the design of coil structure.

- Inductance of several resonator structures.

- Misalignment study: Several misalignment types are displayed and compared based on their resonator structure and effects, in addition to their advantages and disadvantages.

- Electromagnetic field interference (EMI) diagnostics, including WPT-related standards and guidelines. In addition, EMI and EMF reduction methods are reported and compared. Moreover, advantages and disadvantages of these methods are addressed.

- Basic applications of WPT systems are given. Next, a WPT case study is proposed. In the proposed winding method, a bio-inspired joint made of two spherical structures is given. The algorithm design is provided, and experiments are conducted to validate the obtained results by simulation and optimization.

2. Benchmark of the Research Work

3. Compensation Topologies

3.1. Basic and Hybrid Compensation Topologies

3.2. Review of Different WPT Systems Based on Topology and Application Type

4. The Resonator Structure

4.1. Shape of the Resonator

- Flat/planar-shaped coils, such as rectangular-shaped structure [89,98,110,111], octagonal resonator [101], and a double D coil (DD) [112]. In addition, defected ground structure (DGS) is presented in [113,114]. DGS means a “defect” has been integrated on the ground plane of a microwave planar circuit; this DGS technique is adopted to improve various parameters of a microwave circuit, such as low gain and narrow bandwidth [115]. Moreover, circular coils [116,117] and square coils [99,118,119] are discussed. There are planar printed spiral coils (PSC) [120,121,122,123] as well, the WPT system in the printed circuit board (PCB) [124,125,126,127], pancake coils [128], and planar shielded-loop resonators [129].

- Three-dimensional (3D) geometries are investigated, such as for instance, bowl-shaped transmitter coils [28], which are used for charging hearing aids, cylindrical coils [80], helix loop resonators [130,131,132,133], and conical coils [134]. In [135,136], the three-dimensional resonant cavity is presented, which offers a good way of charging multiple devices simultaneously. An orthogonal winding is discussed in [137], and a cylindrical cavity is given in [138]. In [139,140,141,142], the authors proposed an omnidirectional WPT system, and in [143], the authors discussed a ball joint structure.

- Coils’ materials are discussed, for example, a receiver coil made of aluminum is used in [125]. In [144], the authors proposed a helical-type coil made of superconductors in order to increase the quality factor of the coils. In [145], the authors applied an MCR WPT system (planar textile resonators, or PTRs) to wearable consumer electronics by using flexible materials.

- Coils with cores are given, such as dipole-type coils [64], which presented a WPT prototype that is capable of transferring the power up to a 5-m distance. For charging vehicles, buses, trams, and trains, long-track transmitter and short-individual tracks are used [16,17,90]. Moreover, E-core and U-core types are discussed [94,146].

4.2. Size and Number of the Resonators

4.3. Loop Inductance

4.4. Operating Frequency Effects on the Design of Coil Structure

5. Misalignment Study

6. EMI and EMF Diagnostics in the WPT System

6.1. WPT-Related Standards, Including the Safety Issues

6.2. EMF and EMI Mitigation Methods

7. WPT Applications: An Optimized Case Study

7.1. Optimization Method

- The size constraints: 0 ≤ zi ≤ rs; the turns cover the whole space of the hemisphere of the transmitter structure, which means: 0 ≤ Ɵ ≤ (π/2). On the other hand, 10 ≤ zj ≤ 2 rb; the turns cover the whole space of the small sphere, which means: 0 ≤ β ≤ (π). The pitch between turns is set to P = 0.5 mm.

- Initialize zi, β, and Ɵ as 0. Initialize zj = 10 mm (start z-position for Rx), N1 = 0, N2 = 0, m = 0, and n = 0.

- Enter the radius of the transmitter coil rs = 38.5 mm, the radius of the receiver coil rb = 28.5 mm, and the pitch between turns P.

- Enter β and Ɵ. // Measured in radian.

- Count: Ɵ = Ɵ + (1/36) π, β = β + (1/36) π, N1 = N1 + 1, N2 = N2 + 1, zim = zim + P, and zjn = zjn + P, n addition to m = m + 1 and n = n + 1. // Increment angles to determine the z-position and r for each turn of the transmitter and receiver coils. ((1/36) π is the assumed step). Increment N1 and N2 to find the number of turns for both coils. Move the turns in the z-direction with the pitch between coils equal to 0.5 mm. The number of turns can be calculated by N1 = zim/P and N2 = zjm/P.

- Calculate rim = rs sin (Ɵ), rjn = rb sin (β), zim = rs (1 − cos (Ɵ)), and zjn = rb (1 − cos (β)). // mm (based on angles).

- Calculate L1 and L2: the self-inductances of the transmitter coil and receiver coil, respectively. Calculate and maximize the mutual inductance M and the coefficient coupling k, and determine the required capacitors C1, C2. // In order to maximize the mutual inductance, the inductances will be adjusted based on the number of turns and the space between turns (pitch). The transferring distance between Tx and Rx will determine the coupling coefficient, which should be less than a certain value ks.

- With the available values of the frequency and coil resistance, calculate the quality factor, transferred power, and efficiency.

- Sweep the frequency and mutual inductance to maximize the efficiency and transferred power.

- Is k < ks, if yes, go to 11, or else go to step 13. The coupling coefficient should stay within a certain range to avoid cases with very low values or cases with very high coupling between Tx and Rx.

- Is Ɵ < π/2, if yes, go to step 12, or else go to step 13.

- Is β < π, if yes, go to step 3, or else proceed to step 13.

- End.

7.2. Simulations

7.3. Experiments of the Proposed WPT and Measurements

7.4. Cost Assessment of WPT Systems

8. Conclusions and Future Research

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, F.; Yang, Y.; Jiang, D.; Ruan, X.; Chen, X. Modeling and Optimization of Magnetically Coupled Resonant Wireless Power Transfer System with Varying Spatial Scales. IEEE Trans. Power Electron. 2017, 32, 3240–3250. [Google Scholar] [CrossRef]

- Miller, J.M.; Onar, O.C.; Chinthavali, M. Primary-side power flow control of wireless power transfer for electric vehicle charging. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 147–162. [Google Scholar] [CrossRef]

- Hsieh, Y.C.; Lin, Z.R.; Chen, M.C.; Hsieh, H.C.; Liu, Y.C.; Chiu, H.J. High-Efficiency Wireless Power Transfer System for Electric Vehicle Applications. IEEE Trans. Circuits Syst. II Exp. Briefs 2017, 64, 942–946. [Google Scholar] [CrossRef]

- Mou, X.; Groling, O.; Sun, H. Energy efficient and adaptive design for wireless power transfer in electric vehicles. IEEE Trans. Ind. Electron. 2017, 64, 7250–7260. [Google Scholar] [CrossRef]

- García, D.T.; Vázquez, J.; Roncero-Sánchez, P. Design, implementation issues and performance of an inductive power transfer system for electric vehicle chargers with series–series compensation. IET Power Electron. 2015, 8, 1920–1930. [Google Scholar] [CrossRef]

- Li, S.; Mi, C. Wireless power transfer for electric vehicle applications. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 4–17. [Google Scholar]

- Kim, S.; Park, H.H.; Kim, J.; Kim, J.; Ahn, S. Design and analysis of a resonant reactive shield for a wireless power electric vehicle. IEEE Trans. Microw. Theory Tech. 2014, 62, 1057–1066. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, F.; Hofmann, H.; Liu, W.; Mi, C. A Four-Plate Compact Capacitive Coupler Design and LCL-Compensated Topology for Capacitive Power Transfer in Electric Vehicle Charging Application. IEEE Trans. Power Electron. 2016, 31, 8541–8551. [Google Scholar]

- Dai, J.; Ludois, D.C. Capacitive power transfer through a conformal bumper for electric vehicle charging. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 1015–1025. [Google Scholar] [CrossRef]

- Choi, S.Y.; Gu, B.W.; Jeong, S.Y.; Rim, C.T. Advances in wireless power transfer systems for roadway-powered electric vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 18–36. [Google Scholar] [CrossRef]

- Mi, C.C.; Buja, G.; Choi, S.Y.; Rim, C.T. Modern advances in wireless power transfer systems for roadway powered electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6533–6545. [Google Scholar] [CrossRef]

- Zeng, H.; Yang, S.; Peng, F.Z. Design Consideration and Comparison of Wireless Power Transfer via Harmonic Current for PHEV and EV Wireless Charging. IEEE Trans. Power Electron. 2016, 32, 5943–5952. [Google Scholar] [CrossRef]

- Do Chung, Y.; Lee, C.Y.; Kang, H.; Park, Y.G. Design considerations of superconducting wireless power transfer for electric vehicle at different inserted resonators. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Near-Field Reduction in a Wireless Power Transfer System Using LCC Compensation. IEEE Trans. Electromag. Compat. 2017, 59, 686–694. [Google Scholar] [CrossRef]

- Lee, W.Y.; Huh, J.; Choi, S.Y.; Thai, X.V.; Kim, J.H.; Al-Ammar, E.A.; El-Kady, M.A.; Rim, C.T. Finite-width magnetic mirror models of mono and dual coils for wireless electric vehicles. IEEE Trans. Power Electron. 2013, 28, 1413–1428. [Google Scholar] [CrossRef]

- Kim, M.; Kim, H.; Kim, D.; Jeong, Y.; Park, H.H.; Ahn, S. A Three-Phase Wireless-Power-Transfer System for Online Electric Vehicles with Reduction of Leakage Magnetic Fields. IEEE Trans. Microw. Theory Tech. 2015, 63, 3806–3813. [Google Scholar] [CrossRef]

- Ko, Y.D.; Jang, Y.J. The optimal system design of the online electric vehicle utilizing wireless power transmission technology. IEEE Trans. Intell. Transp. Syst. 2013, 14, 1255–1265. [Google Scholar] [CrossRef]

- Li, W.; Zhao, H.; Li, S.; Deng, J.; Kan, T.; Mi, C.C. Integrated LCC Compensation Topology for Wireless Charger in Electric and Plug-in Electric Vehicles. IEEE Trans. Ind. Electron. 2015, 62, 4215–4225. [Google Scholar] [CrossRef]

- Do Chung, Y.; Lee, C.Y.; Kim, D.W.; Kang, H.; Park, Y.G.; Yoon, Y.S. Conceptual Design and Operating Characteristics of Multi-Resonance Antennas in the Wireless Power Charging System for Superconducting MAGLEV Train. IEEE Trans. Appl. Supercond. 2017, 27, 1–5. [Google Scholar] [CrossRef]

- Mirbozorgi, S.A.; Yeon, P.; Ghovanloo, M. Robust Wireless Power Transmission to mm-Sized Free-Floating Distributed Implants. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 692–702. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhong, Z.; Guo, Y.X. In Vivo High-Efficiency Wireless Power Transfer with Multisine Excitation. IEEE Trans. Microw. Theory Tech. 2017, 65, 3530–3540. [Google Scholar] [CrossRef]

- Li, X.; Tsui, C.Y.; Ki, W.H. A 13.56 MHz wireless power transfer system with reconfigurable resonant regulating rectifier and wireless power control for implantable medical devices. IEEE J. Solid-State Circuits 2015, 50, 978–989. [Google Scholar] [CrossRef]

- Das, R.; Yoo, H. A Multiband Antenna Associating Wireless Monitoring and Nonleaky Wireless Power Transfer System for Biomedical Implants. IEEE Trans. Microw. Theory Tech. 2017, 65, 2485–2495. [Google Scholar] [CrossRef]

- Kim, D.; Kim, J.; Park, Y.J. Optimization and Design of Small Circular Coils in a Magnetically Coupled Wireless Power Transfer System in the Megahertz Frequency. IEEE Trans. Microw. Theory Tech. 2016, 64, 2652–2663. [Google Scholar] [CrossRef]

- Tang, S.C.; Lun, T.L.T.; Guo, Z.; Kwok, K.W.; McDannold, N.J. Intermediate Range Wireless Power Transfer with Segmented Coil Transmitters for Implantable Heart Pumps. IEEE Trans. Power Electron. 2017, 32, 3844–3857. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.P.; Tsui, C.Y.; Ki, W.H. Wireless Power Transfer System with ΣΔ Modulated Transmission Power and Fast Load Response for Implantable Medical Devices. IEEE Trans. Circuits Syst. II Exp. Briefs 2017, 64, 279–283. [Google Scholar] [CrossRef]

- Xiao, C.; Wei, K.; Cheng, D.; Liu, Y. Wireless charging system considering eddy current in cardiac pacemaker shell: Theoretical modeling, experiments, and safety simulations. IEEE Trans. Ind. Electron. 2017, 64, 3978–3988. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Palandrani, F.; De Santis, V.; Hirata, A.; Feliziani, M. Wireless power transfer charging system for AIMDs and pacemakers. IEEE Trans. Microw. Theory Tech. 2016, 64, 633–642. [Google Scholar] [CrossRef]

- Kim, J.; Kim, D.H.; Choi, J.; Kim, K.H.; Park, Y.J. Free-positioning wireless charging system for small electronic devices using a bowl-shaped transmitting coil. IEEE Trans. Microw. Theory Tech. 2015, 63, 791–800. [Google Scholar] [CrossRef]

- Chen, Q.; Wong, S.C.; Tse, C.K.; Ruan, X. Analysis, design, and control of a transcutaneous power regulator for artificial hearts. IEEE Trans. Biomed. Circuits Syst. 2009, 3, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.; Dukju, A.; Ghovanloo, M. Three-phase time-multiplexed planar power transmission to distributed implants. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 263–272. [Google Scholar] [CrossRef] [PubMed]

- Fu, M.; Zhang, T.; Ma, C.; Zhu, X. Efficiency and optimal loads analysis for multiple-receiver wireless power transfer systems. IEEE Trans. Microw. Theory Tech. 2015, 63, 801–812. [Google Scholar] [CrossRef]

- Moon, J.; Hwang, H.; Jo, B.; Shin, H.A.; Kim, S.W. Design of a 5-W power receiver for 6.78 MHz resonant wireless power transfer system with power supply switching circuit. IEEE Trans. Consum. Electron. 2016, 62, 349–354. [Google Scholar] [CrossRef]

- Kang, S.H.; Choi, J.H.; Jung, C.W. Magnetic resonance wireless power transfer using three-coil system with single planar receiver for laptop applications. IEEE Trans. Consum. Electron. 2015, 61, 160–166. [Google Scholar]

- Kan, T.; Mai, R.; Mercier, P.P.; Mi, C.C. Design and Analysis of a Three-Phase Wireless Charging System for Lightweight Autonomous Underwater Vehicles. IEEE Trans. Power Electron. 2018, 33, 6622–6632. [Google Scholar] [CrossRef]

- He, X.; Shu, W.; Yu, B.; Ma, X. Wireless Power Transfer System for Rotary Parts Telemetry of Gas Turbine Engine. Electronics 2018, 7, 58. [Google Scholar] [CrossRef]

- Xie, L.; Shi, Y.; Hou, Y.T.; Lou, A. Wireless power transfer and applications to sensor networks. IEEE Wirel. Commun. 2013, 20, 140–145. [Google Scholar]

- Minnaert, B.; Thoen, B.; Plets, D.; Joseph, W.; Stevens, N. Wireless energy transfer by means of inductive coupling for dairy cow health monitoring. Comput. Electron. Agric. 2018, 152, 101–108. [Google Scholar] [CrossRef]

- Yao, W.; Li, M.; Wu, M.Y. Inductive charging with multiple charger nodes in wireless sensor networks. In Asia-Pacific Web Conference; Springer: Berlin, Germany, 2006; pp. 262–270. [Google Scholar]

- Caldeirinha, R.F.S.; Fernandes, T.R.; Richter, J.; Al-Nuaimi, M.O. Simplified RET model derived from path loss and directional spectrum measurements in vegetation media at 11.2 and 20 GHz. IET Microw. Antennas Propag. 2016, 11, 136–143. [Google Scholar] [CrossRef]

- Nariman, M.; Shirinfar, F.; Papio Toda, A.; Pamarti, S.; Rofougaran, A.; De Flaviis, F. A Compact 60-GHz Wireless Power Transfer System. IEEE Trans. Microw. Theory Tech. 2016, 64, 2664–2677. [Google Scholar] [CrossRef]

- Li, X.; Zhou, J.; Duan, B.; Yang, Y.; Zhang, Y.; Fan, J. Performance of Planar Arrays for Microwave Power Transmission with Position Errors. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 1794–1797. [Google Scholar] [CrossRef]

- Valenta, C.R.; Durgin, G.D. Harvesting wireless power: Survey of energy-harvester conversion efficiency in far-field, wireless power transfer systems. IEEE Microw. Mag. 2014, 15, 108–120. [Google Scholar]

- Zhou, W.; Ke, J. Optimal Photovoltaic Array Configuration under Gaussian Laser Beam Condition for Wireless Power Transmission. IEEE Trans. Power Electron. 2016, 32, 3662–3672. [Google Scholar] [CrossRef]

- Zhou, W.; Ke, J. Efficiency Evaluation of Laser Diode in Different Driving Modes for Wireless Power Transmission. IEEE Trans. Power Electron. 2015, 30, 6237–6244. [Google Scholar] [CrossRef]

- Wang, R.; Ye, D.; Dong, S.; Peng, Z.; Salamin, Y.; Shen, F.; Huangfu, J.; Li, C.; Ran, L. Optimal matched rectifying surface for space solar power satellite applications. IEEE Trans. Microw. Theory Tech. 2014, 62, 1080–1089. [Google Scholar] [CrossRef]

- Sato, D.; Noboru, Y.; Koji, T. Thermal Design of Photovoltaic/Microwave Conversion Hybrid Panel for Space Solar Power System. IEEE J. Photovolt. 2016, 7, 374–382. [Google Scholar] [CrossRef]

- Dai, X.; Li, L.; Yu, X.; Li, Y.; Sun, Y. A Novel Multi-degree Freedom Power Pickup Mechanism for Inductively Coupled Power Transfer System. IEEE Trans. Magn. 2017, 53, 8600107. [Google Scholar] [CrossRef]

- Covic, G.A.; Boys, J.T.; Kissin, M.L.G.; Lu, H.G. A three-phase inductive power transfer system for roadway-powered vehicles. IEEE Trans. Ind. Electron. 2007, 54, 3370–3378. [Google Scholar] [CrossRef]

- Kissin, M.L.G.; Boys, J.T.; Covic, G.A. Interphase mutual inductance in polyphase inductive power transfer systems. IEEE Trans. Ind. Electron. 2009, 56, 2393–2400. [Google Scholar] [CrossRef]

- McDonough, M. Integration of inductively coupled power transfer and hybrid energy storage system: A multiport power electronics interface for battery-powered electric vehicles. IEEE Trans. Power Electron. 2015, 30, 6423–6433. [Google Scholar] [CrossRef]

- Villa, J.L.; Sallan, J.; Sanz Osorio, J.F.; Llombart, A. High-misalignment tolerant compensation topology for ICPT systems. IEEE Trans. Ind. Electron. 2012, 59, 945–951. [Google Scholar] [CrossRef]

- Sallan, J.; Villa, J.L.; Llombart, A.; Sanz, J.F. Optimal design of ICPT systems applied to electric vehicle battery charge. IEEE Trans. Ind. Electron. 2009, 56, 2140–2149. [Google Scholar] [CrossRef]

- Pinuela, M.; Yates, D.C.; Lucyszyn, S.; Mitcheson, P.D. Maximizing DC-to-load efficiency for inductive power transfer. IEEE Trans. Power Electron. 2013, 28, 2437–2447. [Google Scholar] [CrossRef] [Green Version]

- Aldhaher, S.; Luk, P.C.K.; Whidborne, J.F. Electronic tuning of misaligned coils in wireless power transfer systems. IEEE Trans. Power Electron. 2014, 29, 5975–5982. [Google Scholar] [CrossRef]

- Fotopoulou, K.; Flynn, B.W. Wireless power transfer in loosely coupled links: Coil misalignment model. IEEE Trans. Magn. 2011, 47, 416–430. [Google Scholar] [CrossRef]

- Pantic, Z.; Bai, S.; Lukic, S.M. ZCS LCC-compensated resonant inverter for inductive-power-transfer application. IEEE Trans. Ind. Electron. 2011, 58, 3500–3510. [Google Scholar] [CrossRef]

- Inagaki, N. Theory of image impedance matching for inductively coupled power transfer systems. IEEE Trans. Microw. Theory Tech. 2014, 62, 901–908. [Google Scholar] [CrossRef]

- Mercier, P.P.; Chandrakasan, A.P. Rapid wireless capacitor charging using a multi-tapped inductively-coupled secondary coil. IEEE Trans. Circuits Syst. I 2013, 60, 2263–2272. [Google Scholar] [CrossRef]

- Safaee, A.; Woronowicz, K. Time-Domain Analysis of Voltage-Driven Series–Series Compensated Inductive Power Transfer Topology. IEEE Trans. Power Electron. 2017, 32, 4981–5003. [Google Scholar] [CrossRef]

- Ye, Z.H.; Sun, Y.; Dai, X.; Tang, C.S.; Wang, Z.H.; Su, Y.G. Energy efficiency analysis of U-Coil wireless power transfer system. IEEE Trans. Power Electron. 2016, 31, 4809–4817. [Google Scholar] [CrossRef]

- Buja, G.; Bertoluzzo, M.; Mude, K.N. Design and experimentation of WPT charger for electric city car. IEEE Trans. Ind. Electron. 2015, 62, 7436–7447. [Google Scholar] [CrossRef]

- Abdolkhani, A.; Hu, A.P.; Tian, J. Autonomous Polyphase Current-Fed Push–Pull Resonant Converter Based on Ring Coupled Oscillators. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 568–576. [Google Scholar] [CrossRef]

- Park, C.; Lee, S.; Cho, G.H.; Rim, C.T. Innovative 5-m-off-distance inductive power transfer systems with optimally shaped dipole coils. IEEE Trans. Power Electron. 2015, 30, 817–827. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Hofmann, H.; Mi, C.C. A Double-Sided LC Compensation Circuit for Loosely-Coupled Capacitive Power Transfer. IEEE Trans. Power Electron. 2018, 33, 1633–1644. [Google Scholar] [CrossRef]

- Lu, F.; Hua, Z.; Hofmann, H.; Mi, C.C. An inductive and capacitive combined wireless power transfer system with LC-compensated topology. IEEE Trans. Power Electron. 2016, 31, 8471–8482. [Google Scholar] [CrossRef]

- Huang, L.; Hu, A.P. Defining the mutual coupling of capacitive power transfer for wireless power transfer. Electron. Lett. 2015, 51, 1806–1807. [Google Scholar] [CrossRef]

- Dai, J.; Ludois, D.C. A survey of wireless power transfer and a critical comparison of inductive and capacitive coupling for small gap applications. IEEE Trans. Power Electron. 2015, 30, 6017–6029. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, F.; Hofmann, H.; Liu, W.; Mi, C. A Six-Plate Capacitive Coupler to Reduce Electric Field Emission in Large Air-Gap Capacitive Power Transfer. IEEE Trans. Power Electron. 2017, 33, 665–675. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.; Zhao, H.; Zhu, L.; Shuai, C.; Chen, Z. Wireless power transfer by electric field resonance and its application in dynamic charging. IEEE Trans. Ind. Electron. 2016, 63, 6602–6612. [Google Scholar] [CrossRef]

- Jegadeesan, R.; Agarwal, K.; Guo, Y.X.; Yen, S.C.; Thakor, N.V. Wireless Power Delivery to Flexible Subcutaneous Implants Using Capacitive Coupling. IEEE Trans. Microw. Theory Tech. 2016, 65, 280–292. [Google Scholar] [CrossRef]

- Mishra, S.K.; Adda, R.; Rathore, A.K.; Sekhar, S.; Joshi, A. Power transfer using portable surfaces in capacitively coupled power transfer technology. IET Power Electron. 2016, 9, 997–1008. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Mi, C. A Review on the Recent Development of Capacitive Wireless Power Transfer Technology. Energies 2017, 10, 1752. [Google Scholar] [CrossRef]

- Wake, K.; Laakso, I.; Hirata, A.; Chakarothai, J.; Onishi, T.; Watanabe, S.; Santis, V.D.; Feliziani, M.; Taki, M. Derivation of Coupling Factors for Different Wireless Power Transfer Systems: Inter-and Intralaboratory Comparison. IEEE Trans. Electromagn. Compat. 2017, 59, 677–685. [Google Scholar] [CrossRef]

- Hu, H.; Georgakopoulos, S.V. Multiband and Broadband Wireless Power Transfer Systems Using the Conformal Strongly Coupled Magnetic Resonance Method. IEEE Trans. Ind. Electron. 2017, 64, 3595–3607. [Google Scholar] [CrossRef]

- Assawaworrarit, S.; Yu, X.; Fan, S. Robust wireless power transfer using a nonlinear parity–time-symmetric circuit. Nature 2017, 546, 387–390. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Kuo, N.C.; Niknejad, A.M. A Gain Boosting Array Technique for Weakly-Coupled Wireless Power Transfer. IEEE Trans. Power Electron. 2017, 32, 7130–7139. [Google Scholar] [CrossRef]

- Kuo, N.C.; Bo, Z.; Niknejad, A.M. Bifurcation analysis in weakly-coupled inductive power transfer systems. IEEE Trans. Circuits Syst. I Regul. Pap. 2016, 63, 727–738. [Google Scholar] [CrossRef]

- Kurs, A.B.; Karalis, A.; Moffatt, R.; Joannopoulos, J.D.; Fisher, P.H.; Soljacic, M. Wireless Power Transfer via Strongly Coupled Magnetic Resonances. Science 2007, 317, 83–86. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, F.; Liu, J.; Mao, Z.; Sun, M. Mid-range wireless power transfer and its application to body sensor networks. Open J. Appl. Sci. 2012, 2, 35–46. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Z.; Li, J. A Magnetic Tank System for Wireless Power Transfer. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 443–445. [Google Scholar] [CrossRef]

- Moghadam, M.R.; Zhang, R. Node placement and distributed magnetic beamforming optimization for wireless power transfer. IEEE Trans. Signal Inf. Process. Netw. 2018, 4, 264–279. [Google Scholar] [CrossRef]

- Ahn, D.; Kim, S.; Moon, J.; Cho, I.K. Wireless power transfer with automatic feedback control of load resistance transformation. IEEE Trans. Power Electron. 2016, 31, 7876–7886. [Google Scholar] [CrossRef]

- Iguchi, S.; Yeon, P.; Fuketa, H.; Ishida, K.; Sakurai, T.; Takamiya, M. Wireless power transfer with zero-phase-difference capacitance control. IEEE Trans. Circuits Syst. I 2015, 62, 938–947. [Google Scholar] [CrossRef]

- Zhang, W.; Mi, C.C. Compensation topologies of high-power wireless power transfer systems. IEEE Trans. Veh. Technol. 2016, 65, 4768–4778. [Google Scholar] [CrossRef]

- Cheng, L.; Ki, W.H.; Lu, Y.; Yim, T.S. Adaptive on/off delay-compensated active rectifiers for wireless power transfer systems. IEEE J. Solid-State Circuits 2016, 51, 712–723. [Google Scholar]

- Zhang, W.; Wong, S.C.; Tse, C.K.; Chen, Q. Analysis and comparison of secondary series- and parallel-compensated inductive power transfer systems operating for optimal efficiency and load-independent voltage-transfer ratio. IEEE Trans. Power Electron. 2014, 29, 2979–2990. [Google Scholar] [CrossRef]

- Zhang, W.; White, J.C.; Malhan, R.K.; Mi, C.C. Loosely Coupled Transformer Coil Design to Minimize EMF Radiation in Concerned Areas. IEEE Trans. Veh. Technol. 2016, 65, 4779–4789. [Google Scholar] [CrossRef]

- Li, W.; Zhao, H.; Deng, J.; Li, S.; Mi, C.C. Comparison study on SS and double-sided LCC compensation topologies for EV/PHEV wireless chargers. IEEE Trans. Veh. Technol. 2016, 65, 4429–4439. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, B.S.; Lee, J.H. A New Design Methodology for a 300-kW, Low Flux Density, Large Air Gap, Online Wireless Power Transfer System. IEEE Trans. Ind. Appl. 2016, 52, 4234–4242. [Google Scholar] [CrossRef]

- Jegadeesan, R.; Guo, Y.X. Topology selection and efficiency improvement of inductive power links. IEEE Trans. Antennas Propag. 2012, 60, 4846–4854. [Google Scholar] [CrossRef]

- Hariri, A.O.; Youssef, T.; Elsayed, A.; Mohammed, O. A Computational Approach for a Wireless Power Transfer Link Design Optimization Considering Electromagnetic Compatibility. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, Y.; Chen, K.; Zhao, Z.; Yuan, L. A comparative study of load characteristics of resonance types in wireless transmission systems. In Proceedings of the 2016 IEEE Asia-Pacific International Symposium on Electromagnetic Compatibility (APEMC), Shenzhen, China, 17–21 May 2016; Volume 1, pp. 203–206. [Google Scholar]

- Wang, Y.; Yao, Y.; Liu, X.; Xu, D. S/CLC Compensation Topology Analysis and Circular Coil Design for Wireless Power Transfer. IEEE Trans. Transp. Electrif. 2017, 3, 496–507. [Google Scholar] [CrossRef]

- Samanta, S.; Rathore, A.K. A New Current-Fed CLC Transmitter and LC Receiver Topology for Inductive Wireless Power Transfer Application: Analysis, Design, and Experimental Results. IEEE Trans. Transp. Electrif. 2015, 1, 357–368. [Google Scholar] [CrossRef]

- Feng, H.; Cai, T.; Duan, S.; Zhao, J.; Zhang, X.; Chen, C. An LCC-Compensated Resonant Converter Optimized for Robust Reaction to Large Coupling Variation in Dynamic Wireless Power Transfer. IEEE Trans. Ind. Electron. 2016, 63, 6591–6601. [Google Scholar] [CrossRef]

- Kan, T.; Nguyen, T.D.; White, J.C.; Malhan, R.K.; Mi, C.C. A New Integration Method for an Electric Vehicle Wireless Charging System Using LCC Compensation Topology: Analysis and Design. IEEE Trans. Power Electron. 2017, 32, 1638–1650. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A double-sided LCC compensation network and its tuning method for wireless power transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Deng, J.; Li, W.; Nguyen, T.D.; Li, S.; Mi, C.C. Compact and efficient bipolar coupler for wireless power chargers: Design and analysis. IEEE Trans. Power Electron. 2015, 30, 6130–6140. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Hofmann, H.; Mi, C.C. A dynamic charging system with reduced output power pulsation for electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6580–6590. [Google Scholar] [CrossRef]

- Park, M.; Nguyen, V.T.; Yu, S.D.; Yim, S.W.; Park, K.; Min, B.D.; Kim, S.D.; Cho, J.G. A study of wireless power transfer topologies for 3.3 kW and 6.6 kW electric vehicle charging infrastructure. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo (ITEC Asia-Pacific), Busan, South Korea, 1–4 June 2016; pp. 689–692. [Google Scholar]

- Zaheer, A.; Neath, M.; Beh, H.Z.Z.; Covic, G.A. A dynamic EV charging system for slow moving traffic applications. IEEE Trans. Transp. Electrif. 2017, 3, 354–369. [Google Scholar] [CrossRef]

- Cirimele, V.; Freschi, F.; Guglielmi, P. Wireless power transfer structure design for electric vehicle in charge while driving. In Proceedings of the International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; pp. 2461–2467. [Google Scholar]

- Onar, O.C.; Miller, J.M.; Campbell, S.L.; Coomer, C.; White, C.P.; Seiber, L.E. A novel wireless power transfer for in-motion EV/PHEV charging. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Twenty-Eighth Annual, Long Beach, CA, USA, 17–21 March 2013; pp. 3073–3080. [Google Scholar]

- Cirimele, V.; Pichon, L.; Freschi, F. Electromagnetic modeling and performance comparison of different pad-to-pad length ratio for dynamic inductive power transfer. In Proceedings of the IECON 2016-42nd IEEE Annual Conference of the Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 4499–4503. [Google Scholar]

- Liao, C.; Li, J.; Li, S. Design of LCC impedance matching circuit for wireless power transfer system under rectifier load. CPSS Trans. Power Electron. Appl. 2017, 2, 237–245. [Google Scholar] [CrossRef]

- Imura, T.; Hori, Y. Maximizing air gap and efficiency of magnetic resonant coupling for wireless power transfer using equivalent circuit and Neumann formula. IEEE Trans. Ind. Electron. 2011, 58, 4746–4752. [Google Scholar] [CrossRef]

- Koh, K.E.; Beh, T.C.; Imura, T.; Hori, Y. Impedance matching and power division using impedance inverter for wireless power transfer via magnetic resonant coupling. IEEE Trans. Ind. Appl. 2014, 50, 2061–2070. [Google Scholar] [CrossRef]

- Niotaki, K.; Georgiadis, A.; Collado, A.; Vardakas, J.S. Dual-band resistance compression networks for improved rectifier performance. IEEE Trans. Microw. Theory Tech. 2014, 62, 3512–3521. [Google Scholar] [CrossRef]

- Hou, J.; Chen, Q.; Wong, S.C.; Tse, C.K.; Ruan, X. Analysis and control of series/series-parallel compensated resonant converter for contactless power transfer. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 124–136. [Google Scholar]

- Ahn, D.; Hong, S. A transmitter or a receiver consisting of two strongly coupled resonators for enhanced resonant coupling in wireless power transfer. IEEE Trans. Ind. Electron. 2014, 61, 1193–1203. [Google Scholar] [CrossRef]

- Zhang, W.; White, J.C.; Abraham, A.M.; Mi, C.C. Loosely coupled transformer structure and interoperability study for EV wireless charging systems. IEEE Trans. Power Electron. 2015, 30, 6356–6367. [Google Scholar] [CrossRef]

- Hekal, S.; Abdel-Rahman, A.B.; Jia, H.; Allam, A.; Barakat, A.; Pokharel, R.K. A Novel Technique for Compact Size Wireless Power Transfer Applications Using Defected Ground Structures. IEEE Trans. Microw. Theory Tech. 2017, 65, 591–599. [Google Scholar] [CrossRef]

- Hekal, S.; Abdel-Rahman, A.B.; Allam, A.; Jia, H.; Barakat, A.; Pokharel, R.K. Asymmetric wireless power transfer systems using coupled DGS resonators. IEICE Electron. Express 2016, 13, 20160591. [Google Scholar] [CrossRef]

- Khandelwal, M.K.; Kanaujia, B.K.; Kumar, S. Defected ground structure: Fundamentals, analysis, and applications in modern wireless trends. Int. J. Antennas Propag. 2017, 2017, 2018527. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, X.; Wang, C.; He, Y. Comparative Analysis of Two-Coil and Three-Coil Structures for Wireless Power Transfer. IEEE Trans. Power Electron. 2017, 32, 341–352. [Google Scholar] [CrossRef]

- Sample, A.P.; Meyer, D.A.; Smith, J.R. Analysis, experimental results, and range adaptation of magnetically coupled resonators for wireless power transfer. IEEE Trans. Ind. Electron. 2011, 58, 544–554. [Google Scholar] [CrossRef]

- Cabrera, F.L.; De Sousa, F.R. Achieving Optimal Efficiency in Energy Transfer to a CMOS Fully Integrated Wireless Power Receiver. IEEE Trans. Microw. Theory Tech. 2016, 64, 3703–3713. [Google Scholar] [CrossRef]

- Moon, S.; Moon, G.W. Wireless Power Transfer System with an Asymmetric Four-Coil Resonator for Electric Vehicle Battery Chargers. IEEE Trans. Power Electron. 2016, 31, 6844–6854. [Google Scholar]

- Koohestani, M.; Zhadobov, M.; Ettorre, M. Design methodology of a printed WPT system for HF-band mid-range applications considering human safety regulations. IEEE Trans. Micow. Theory Tech. 2017, 65, 270–279. [Google Scholar] [CrossRef]

- Jolani, F.; Yu, Y.; Chen, Z. A planar magnetically coupled resonant wireless power transfer system using printed spiral coils. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 1648–1651. [Google Scholar] [CrossRef]

- Chen, K.; Zhao, Z. Analysis of the double-layer printed spiral coil for wireless power transfer. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 114–121. [Google Scholar] [CrossRef]

- Lee, W.S.; Son, W.I.; Oh, K.S.; Yu, J.W. Contactless energy transfer systems using antiparallel resonant loops. IEEE Trans. Ind. Electron. 2013, 60, 350–359. [Google Scholar] [CrossRef]

- Mohan, S.S. The Design, Modeling and Optimization of On-Chip Inductor and Transformer Circuits. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 1999. [Google Scholar]

- Song, J.; Kim, S.; Bae, B.; Kim, J.J.; Jung, D.H.; Kim, J. Design and analysis of magnetically coupled coil structures for PCB-to-active interposer wireless power transfer in 2.5 D/3D-IC. In Proceedings of the IEEE Electrical Design of Advanced Packaging & Systems Symposium (EDAPS), Bangalore, India, 14–16 December 2014; pp. 1–4. [Google Scholar]

- Sandoval, F.S.; Delgado, S.M.; Moazenzadeh, A.; Wallrabe, U. Nulls-Free Wireless Power Transfer with Straightforward Control of Magnetoinductive Waves. IEEE Trans. Microw. Theory Tech. 2017, 65, 1087–1093. [Google Scholar] [CrossRef]

- Kim, S.; Jung, D.H.; Kim, J.J.; Bae, B.; Kong, S.; Ahn, S.; Kim, J.; Kim, J. High-efficiency PCB-and package-level wireless power transfer interconnection scheme using magnetic field resonance coupling. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 863–878. [Google Scholar]

- Yi, Y.; Buttner, U.; Fan, Y.; Foulds, I.G. Design and optimization of a 3-coil resonance-based wireless power transfer system for biomedical implants. Int. J. Circuit Theory Appl. 2015, 43, 1379–1390. [Google Scholar] [CrossRef]

- Tierney, B.B.; Grbic, A. Planar shielded-loop resonators. IEEE Trans. Antennas Propag. 2014, 62, 3310–3320. [Google Scholar] [CrossRef]

- Yang, C.; Tsunekawa, K. A Novel Parallel Double Helix Loop Resonator for Magnetic Coupled Resonance Wireless Power Transfer. In Proceedings of the PIERS Proceedings, Guangzhou, China, 25–28 August 2014; pp. 466–470. [Google Scholar]

- Zhang, Y.; Lu, T.; Zhao, Z.; Chen, K.; He, F.; Yuan, L. Wireless power transfer to multiple loads over various distances using relay resonators. IEEE Microw. Wirel. Compon. Lett. 2015, 25, 337–339. [Google Scholar] [CrossRef]

- Lee, K.; Cho, D.H. Diversity analysis of multiple transmitters in wireless power transfer system. IEEE Trans. Magn. 2013, 49, 2946–2952. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z.; Lu, T. Quantitative analysis of system efficiency and output power of four-coil resonant wireless power transfer. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 184–190. [Google Scholar] [CrossRef]

- Hadadtehrani, P.; Kamalinejad, P.; Molavi, R.; Mirabbasi, S. On the use of conical helix inductors in wireless power transfer systems. In Proceedings of the 2016 IEEE Canadian Conference on Electrical and Computer Engineering (CCECE), Vancouver, BC, Canada, 15–18 May 2016; pp. 1–4. [Google Scholar]

- Chabalko, M.J.; Sample, A.P. Resonant cavity mode enabled wireless power transfer. Appl. Phys. Lett. 2014, 105, 243902. [Google Scholar] [CrossRef]

- Chabalko, M.J.; Sample, A.P. Three-dimensional charging via multimode resonant cavity enabled wireless power transfer. IEEE Trans. Power Electron. 2015, 30, 6163–6173. [Google Scholar] [CrossRef]

- Chow, J.P.W.; Chen, N.; Chung, H.S.H.; Chan, L.L.H. An investigation into the use of orthogonal winding in loosely coupled link for improving power transfer efficiency under coil misalignment. IEEE Trans. Power Electron. 2015, 30, 5632–5649. [Google Scholar] [CrossRef]

- Mei, H.; Huang, Y.W.; Thackston, K.A.; Irazoqui, P.P. Optimal wireless power transfer to systems in an enclosed resonant cavity. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1036–1039. [Google Scholar] [CrossRef]

- Ng, W.M.; Zhang, C.; Lin, D.; Hui, S.R. Two- and three-dimensional omnidirectional wireless power transfer. IEEE Trans. Power Electron. 2014, 29, 4470–4474. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, D.; Hui, S.Y. Basic control principles of omnidirectional wireless power transfer. IEEE Trans. Power Electron. 2016, 31, 5215–5227. [Google Scholar]

- Ha-Van, N.; Seo, C. Analytical and Experimental Investigations of Omnidirectional Wireless Power Transfer using a Cubic Transmitter. IEEE Trans. Ind. Electron. 2017, 65, 1358–1366. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, C.; Hui, S.R. Mathematic Analysis of Omnidirectional Wireless Power Transfer—Part-II Three-Dimensional Systems. IEEE Trans. Power Electron. 2017, 32, 613–624. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, D.; Hui, S.Y. Ball-Joint Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2018, 33, 65–72. [Google Scholar] [CrossRef] [Green Version]

- Jeong, I.S.; Jung, B.I.; You, D.S.; Choi, H.S. Analysis of S-Parameters in Magnetic Resonance WPT Using Superconducting Coils. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Kang, S.H.; Jung, C.W. Textile Resonators with Thin Copper Wire for Wearable MR-WPT System. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 91–93. [Google Scholar] [CrossRef]

- Shin, J.; Shin, S.; Kim, Y.; Ahn, S.; Lee, S.; Jung, G.; Jeon, S.; Cho, D.H. Design and implementation of shaped magnetic-resonance-based wireless power transfer system for roadway-powered moving electric vehicles. IEEE Trans. Ind. Electron. 2014, 61, 1179–1192. [Google Scholar] [CrossRef]

- Huang, Y.; Clerckx, B. Relaying strategies for wireless-powered MIMO relay networks. IEEE Trans. Wirel. Commun. 2016, 15, 6033–6047. [Google Scholar] [CrossRef]

- Yang, G.; Moghadam, M.R.V.; Zhang, R. Magnetic MIMO Signal Processing and Optimization for Wireless Power Transfer. IEEE Trans. Signal Process. 2017, 65, 2860–2874. [Google Scholar] [CrossRef]

- Mirbozorgi, S.A.; Jia, Y.; Canales, D.; Ghovanloo, M. A Wirelessly-Powered Homecage with Segmented Copper Foils and Closed-Loop Power Control. IEEE Trans. Biomed. Circuits Syst. 2016, 10, 979–989. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.H.; Kang, S.H.; Jung, C.W. Transparent electrode resonators for MR-WPT. In Proceedings of the IEEE URSI Asia-Pacific Radio Science Conference (URSI AP-RASC), Seoul, Korea, 21–25 August 2016; pp. 716–718. [Google Scholar]

- Zhong, W.X.; Lee, C.K.; Hui, S.Y. Wireless power domino-resonator systems with noncoaxial axes and circular structures. IEEE Trans. Power Electron. 2012, 27, 4750–4762. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.K.; Zhong, W.X.; Hui, S.Y.R. Effects of magnetic coupling of nonadjacent resonators on wireless power domino-resonator systems. IEEE Trans. Power Electron. 2012, 27, 1905–1916. [Google Scholar] [CrossRef]

- Zhong, W.X.; Lee, C.K.; Hui, S.Y.R. General analysis on the use of tesla’s resonators in domino forms for wireless power transfer. IEEE Trans. Ind. Electron. 2013, 60, 261–270. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Ho, S.L.; Fu, W.N. Analysis and optimization of magnetically coupled resonators for wireless power transfer. IEEE Trans. Magn. 2012, 48, 4511–4514. [Google Scholar] [CrossRef]

- Fu, X.; Liu, F.; Chen, X. Optimization of coils for a three-phase magnetically coupled resonant wireless power transfer system oriented by the zero-voltage-switching range. In Proceedings of the Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 3708–3713. [Google Scholar]

- Liu, Z.; Chen, Z.; Li, J.; Guo, Y.; Xu, B. A Planar L-Shape Transmitter for a Wireless Power Transfer System. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 960–963. [Google Scholar] [CrossRef]

- Villa, J.; Sanz, J.; Peri, J.; Acerete, R. Victoria project: Static and dynamic wireless charging for electric buses. In Proceedings of the Business Intelligence on Emerging Technologies IDTechEX Conference, Berlin, Germany, 27–28 April 2016. [Google Scholar]

- Cirimele, V.; Freschi, F.; Mitolo, M. Inductive power transfer for automotive applications: State-of-the-art and future trends. In Proceedings of the IEEE Industry Applications Society Annual Meeting, Portland, OR, USA, 2–6 October 2016; pp. 1–8. [Google Scholar]

- Safaee, A.; Woronowicz, K. Tuning Scheme for Three-Phase Wireless Power Transfer Systems with Long Primary. In Proceedings of the International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 11–13 August 2014; pp. 1–9. [Google Scholar]

- Safaee, A.; Woronowicz, K.; Dickson, T. Reactive power compensation in three-phase high output inductive power transfer. In Proceedings of the IEEE Electrical Power and Energy Conference (EPEC), London, ON, Canada, 26–28 October 2015; pp. 375–380. [Google Scholar]

- Liu, D.; Hu, H.; Georgakopoulos, S. Misalignment Sensitivity of Strongly Coupled Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2016, 32, 5509–5519. [Google Scholar] [CrossRef]

- Cannon, B.L.; Hoburg, J.F.; Stancil, D.D.; Goldstein, S.C. Magnetic resonant coupling as a potential means for wireless power transfer to multiple small receivers. IEEE Trans. Power Electron. 2009, 24, 1819–1825. [Google Scholar] [CrossRef]

- Kim, Y.J.; Ha, D.; Chappell, W.J.; Irazoqui, P.P. Selective wireless power transfer for smart power distribution in a miniature-sized multiple-receiver system. IEEE Trans. Ind. Electron. 2016, 63, 1853–1862. [Google Scholar] [CrossRef]

- Thompson, M.C. Inductance Calculation Techniques-Part II: Approximations and Handbook Methods; CiteSeer: University Park, PA, USA, 1991. [Google Scholar]

- Grover, F.W. Inductance Calculations: Working Formulas and Tables; Courier Corporation: Washington, DC, USA, 2004. [Google Scholar]

- Hui, S.Y.; Zhong, W.; Lee, C.K. A critical review of recent progress in mid-range wireless power transfer. IEEE Trans. Power Electron. 2014, 29, 4500–4511. [Google Scholar] [CrossRef]

- Lyu, Y.L.; Meng, F.Y.; Yang, G.H.; Che, B.J.; Wu, Q.; Sun, L.; Erni, D.; Li, J.L. A method of using nonidentical resonant coils for frequency splitting elimination in wireless power transfer. IEEE Trans. Power Electron. 2015, 30, 6097–6107. [Google Scholar] [CrossRef]

- Park, J.; Tak, Y.; Kim, Y.; Nam, S. Investigation of adaptive matching methods for near-field wireless power transfer. IEEE Trans. Antennas Propag. 2011, 59, 1769–1773. [Google Scholar] [CrossRef]

- Beh, T.C.; Kato, M.; Imura, T.; Oh, S.; Hori, Y. Automated impedance matching system for robust wireless power transfer via magnetic resonance coupling. IEEE Trans. Ind. Electron. 2013, 60, 3689–3698. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, J. Range-adaptive wireless power transfer using multiloop and tunable matching techniques. IEEE Trans. Ind. Electron. 2015, 62, 6233–6241. [Google Scholar] [CrossRef]

- Lee, G.; Waters, B.H.; Shin, Y.G.; Smith, J.R.; Park, W.S. A reconfigurable resonant coil for range adaptation wireless power transfer. IEEE Trans. Microw. Theory Tech. 2016, 64, 624–632. [Google Scholar] [CrossRef]

- Fu, M.; Yin, H.; Zhu, X.; Ma, C. Analysis and tracking of optimal load in wireless power transfer systems. IEEE Trans. Power Electron. 2015, 30, 3952–3963. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Ho, S.L.; Fu, W.N.; Li, Y.; Yu, H.; Sun, M. Lateral and angular misalignments analysis of a new PCB circular spiral resonant wireless charger. IEEE Trans. Magn. 2012, 48, 4522–4525. [Google Scholar] [CrossRef]

- Song, C.; Kim, H.; Jung, D.H.; Kim, J.J.; Kong, S.; Ahn, S.; Kim, J.; Kim, J. Low EMF and EMI Design of a Tightly Coupled Handheld Resonant Magnetic Field (HH-RMF) Charger for Automotive Battery Charging. IEEE Trans. Electromagn. Compat. 2016, 58, 1194–1206. [Google Scholar] [CrossRef]

- Cirimele, V.; Freschi, F.; Giaccone, L.; Pichon, L.; Repetto, M. Human exposure assessment in dynamic inductive power transfer for automotive applications. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Laakso, I.; Hirata, A.; Fujiwara, O. Computational dosimetry for wireless charging of an electrical vehicle. In Proceedings of the International Symposium on Electromagnetic Compatibility EMC, Tokyo, Japan, 12–16 May 2014; pp. 202–205. [Google Scholar]

- Zang, M.; Clemens, M.; Cimala, C.; Streckert, J.; Schmuelling, B. Simulation of Inductive Power Transfer Systems Exposing a Human Body with Two-Step Scaled-Frequency FDTD Methods. IEEE Trans. Magn. 2017, 53, 7201804. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.; Song, C.; Kim, I.M.; Kim, Y.; Kim, J. Electromagnetic interference and radiation from wireless power transfer systems. In Proceedings of the 2014 IEEE International Symposium on Electromagnetic Compatibility (EMC), Raleigh, NC, USA, 4–8 August 2014; pp. 171–176. [Google Scholar]

- Wen, F.; Huang, X. Optimal magnetic field shielding method by metallic sheets in wireless power transfer system. Energies 2016, 9, 733. [Google Scholar] [CrossRef]

- Besnoff, J.; Chabalko, M.; Ricketts, D.S. A Frequency-Selective Zero-Permeability Metamaterial Shield for Reduction of Near-Field Electromagnetic Energy. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 654–657. [Google Scholar] [CrossRef]

- Oh, T.; Lee, B. Analysis of wireless power transfer using metamaterial slabs made of ring resonators at 13.56 MHz. J. Electromagn. Eng. Sci. 2013, 13, 259–262. [Google Scholar] [CrossRef]

- Cho, Y.; Kim, J.J.; Kim, D.-H.; Lee, S.; Kim, H.; Song, C.; Kong, S.; Kim, H.; Seo, C.; Ahn, S.; et al. Thin PCB-Type Metamaterials for Improved Efficiency and Reduced EMF Leakage in Wireless Power Transfer Systems. IEEE Trans. Microw. Theory Tech. 2016, 64, 353–364. [Google Scholar] [CrossRef]

- Cho, Y.; Lee, S.; Kim, D.H.; Kim, H.; Song, C.; Kong, S.; Park, J.; Seo, C.; Kim, J. Thin Hybrid Metamaterial Slab with Negative and Zero Permeability for High Efficiency and Low Electromagnetic Field in Wireless Power Transfer Systems. IEEE Trans. Electromagn. Compat. 2017, 60, 1001–1009. [Google Scholar] [CrossRef]

- Jo, M.; Sato, Y.; Kaneko, Y.; Abe, S. Methods for reducing leakage electric field of a wireless power transfer system for electric vehicles. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 1762–1769. [Google Scholar]

- Choi, S.Y.; Gu, B.W.; Lee, S.W.; Lee, W.Y.; Huh, J.; Rim, C.T. Generalized active EMF cancel methods for wireless electric vehicles. IEEE Trans. Power Electron. 2014, 29, 5770–5783. [Google Scholar] [CrossRef]

- Moon, H.; Kim, S.; Park, H.H.; Ahn, S. Design of a resonant reactive shield with double coils and a phase shifter for wireless charging of electric vehicles. IEEE Trans. Magn. 2015, 51. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.; Ahn, S.; Kim, I.; Kim, I.M.; Kim, Y.I.; Kim, J. Spread spectrum technology to reduce the EMI from the constant voltage source type wireless power transfer system. In Proceedings of the International Symposium on Antennas and Propagation, Jeju, Korea, 25–28 October 2011. [Google Scholar]

- Monteiro, R.; Borges, B.; Anunciada, V. EMI reduction by optimizing the output voltage rise time and fall time in high-frequency soft-switching converters. In Proceedings of the IEEE 35th Annual PESC 04, Aachen, Germany, 20–25 June 2004; Volume 2, pp. 1127–1132. [Google Scholar]

- Park, J.; Kim, D.; Hwang, K.; Park, H.H.; Kwak, S.I.; Kwon, J.H.; Ahn, S. A Resonant Reactive Shielding for Planar Wireless Power Transfer System in Smartphone Application. IEEE Trans. Electromagn. Compat. 2017, 59, 695–703. [Google Scholar] [CrossRef]

| Reference and Topology | f0/k/RL (kHz, Ω) | Pout, Vout | Efficiency | Resonators | Note | |||

|---|---|---|---|---|---|---|---|---|

| N1 Turn N2 Turn | D1 mm Length, Diameter mm | D2 mm width, Diameter mm | Gap mm | |||||

| [14] SS/LCC-LCC | f0 = 85 k = 0.135 RL = 2, 3, 5 | 1 kW 50 V | 95% for SS, and 93% for LCC | 10 8 | 500 diameter | 400 diameter | 200 | Based on EMI, LCC-LCC topology is considered more robust to EMI exposure. |

| [89] SS/LCC-LCC | f0 = 79 | 7.7 kW max. 270~405 V | For LCC: 96% | - | 800 | 600 | 200 | The LCC-LCC topology has higher efficiency when the mutual inductance is at minimum. |

| [101] SS/LCL-LCL | f0 = 85 k = 0.1 RL = 10 | 3.3 kW | 93.1% for SS, 89.5% for LCC | 20 × 3 layers 17 × 2 layers | 550 × 400 mm2 | 240 × 240 mm2 | 100 | Compared to SS topology, the LCL-LCL type has a high power factor. |

| [98] LCC-LCC | f0 = 79 k = 0.18~0.32 RL = 10~200 | 7.5 kW 450 V | 96% | 1 | 800 | 600 | 200 | Resonant frequency f0 is independent of the coupling coefficient and load conditions. |

| [99] LCC-LCC | f0 = 95 k = 0.14–0.30 | 5.6 kW 300~450 V | 95.36% | - | 600 | 600 | 150 | The extra integration-induced couplings give more space for magnetic cores. |

| 200 | 200 | |||||||

| [87] LCC-LCC | f0 = 85 k = 0.153 RL = 49.95 | 3.3 kW 405.7 V | 92.6% | 18 16 | 600 | 300 | 150 | Energy storage has no relation to topology type, but only with transferred power level and coupling coefficient. |

| [97] LCC-LCC | f0 = 85 k = 0.1877 | 3 kW 300 V | 95.5% | - | 600 × 450 × 4 mm3 | 400 × 300 × 4 mm3 | 150 | The compensated resonator design helps to eliminate or reduce the extra-coupling effects to a tiny level. |

| 640 × 496 × 8 mm3 | 480 × 352 × 8 mm3 | |||||||

| 711.2 × 558.8 × 2 mm3 | 508 × 406 × 2 mm3 | |||||||

| Reference and Topology | f0/k/RL (kHz, Ω) | Pout, Vout | Efficiency | Coils’ Dimensions and Number of Turns | Gap mm | Note |

|---|---|---|---|---|---|---|

| [96] LCL-S LCC-S | f0 = 140 k = 0.18–0.32 | Nominal power: 1 kW 80~90 V | Similar: LCC and LCL: 93% | Coil radius is 163 mm | 100 | The topology gives more robust power transfer character against the variation of k. |

| [100] Double-sided LCC | f0 = 85 k = 0.13 | 1.4 kW 150 V | 89.78% | 9 turns for each transmitter, Tx coil 6× (388 mm×400 mm), and for Rx: 485 mm×400 mm | 150 | This paper presented a continuous dynamic WPT system, which reduces the power pulsations. |

| [102] LCL | f0 = 85 k = 3.7–5.4% | 5 kW | - | The secondary: 0.35 m × 0.7 m N87 ferrite material (each 93 mm × 28 mm × 16 mm). | 240 | The system is designed to supply power along the whole length of the track by activating only one primary pad. |

| [103] SS | f0 = 85 k = 0.4 | 20 kW | 80% | Transmitter dimensions are 10 cm × 75 cm, number of turns: nine Receiver: 25 cm × 20 cm, number of turns: 12. | 100 | Downscale prototype operating at 85 kHz ± 2.5 kHz. |

| [104] SP | f0 = 23 RL = 2 | 2 kW | - | Coils diameter: 330 mm. Turns: seven turns for transmitter coil and five turns for receiver coil. | 100 | This paper presented technical aspects of in-motion WPTs for charging EVs and PHEVs. |

| [105] SS | f0 = 85 | - | 97.6% pads length ratio is 1:1 | Coil external width: 58 mm Coil inner width 38 Wire diameter 5 mm Number of turns: 8 turns. | 200 | Investigated the pad shape: influence of the variation of the ratio between Tx and Rx lengths with respect to the behavior of the coupling. |

| WPT System | Resonator Parameters | f0/k | Efficiency | Note | |||||

|---|---|---|---|---|---|---|---|---|---|

| Resonator Structure | Size of the Coils/Number of the Coils | N1/N2 Ratio | D1 mm | D2 mm | Gap mm | ||||

| [113] | H-shaped DGS | Symmetrical, two-coil resonance structure | 1 | 20 | 20 | 13 | 300 kHz/k = 0.025 | 68%/73% | Semi H-shaped DGS resonator is more robust to the coaxial orientation misalignment. |

| Semi-H-shaped DGS | 21 | 21 | 25 | ||||||

| [114] | Spiral-strips DGS | Symmetrical | 1 | 50 × 50 mm2 | 50 × 50 mm2 | 50 | 50 MHz | 84%/78% | Spiral-strips DGS provides a better quality factor other than H-shaped or semi-H-shaped DGS. |

| Asymmetrical | 50 × 50 mm2 | 30 × 30 mm2 | 40 | ||||||

| WPT System | Resonators | f0, RLPout, Vout, Efficiency % | Note | |||

|---|---|---|---|---|---|---|

| Resonator Structure | Size of the Coils/Number of Coils | Coils’ Dimensions and Number of Turns | Gap | |||

| [80] | Structures: cylindrical for Tx, Rx1, and planar rectangular for Rx2. | Asymmetrical/four-coil resonator structure | The diameter of Tx is 350 mm, the thickness is 0.35 mm, and the width is 29 mm besides a one-turn driving coil. The radius of Rx1: 80 mm, the height: 50 mm, besides a seven-turn coil that was used as the output coil. The area of Rx2 is 20.5 × 20 mm2, and the thickness is 0.35 mm. | 150 mm Tx1 | 7 MHz LED loads 80% | Tx is simply printed on the internal or external cover, or inserted in the clothes. |

| 200 mm Tx2 | ||||||

| [132] | Helical coils | Symmetrical/three-coil resonator structure | The radius is 0.325 m, the pitch is 0.05 m, and the number of turns is N = 5, d12 = 6 m | 2–4 m | 10 MHz 90% | Compared with a single-transmitter WPT system, a higher power transfer efficiency (PTE) was achieved stably for the angular aligned and the angular misaligned. |

| [29] | 3D structure/Bowl-shaped transmitter coil and spiral helical receiver coils | Asymmetrical/three-coil resonator structure | The Tx bowl-shaped, which is a combination of both a spiral coil (s) and a conical-shaped coil (c) with a big diameter of 58 mm, a thickness of 9.1 mm, and turns: NS = Nc = 7 turns. | Within 3D cavity | 6.78 MHz 2.5 to 4.3 V 60% | The proposed system can uniformly charge a pouch-type LIB of a hearing aid in spite of its position or arrangement. |

| The volume of the receiver coils Rx (spiral s1+ helical h) is 10.5 × 6.5 × 2.46 mm3 with Ns1 = Nh = 8 turns | ||||||

| 3D structure: WPT systems operating at higher frequencies: | ||||||

| [131] | 3D structure/Helical coils | Symmetrical/system with Relay resonator | Symmetrical relay resonator with multi load transfer and number of turns is 12 | - | 193 MHz 0.1~2.0 Ω Several dozen watts of power, 30~40% | The WPT system transfers the same power to multiple loads over a range of distances. |

| [136] | The Tx is a cavity resonator and the Rx is a square coil | Asymmetrical/multi-coil structure | The dimensions of the cavity resonator are a = 1.52 m, b = 1.42 m, and d = 1.83 m. Rx square coil has one turn 7.62 cm. (multi receivers) | 91 cm | 191.65 MHz 50-Ω 8-W LED 50% | The system is able to deliver power to many devices simultaneously, such as LEDs and toys in a box. |

| [138] | 3D structure/Cylindrical cavity resonator | Asymmetrical/two-coil structure | The radius of the Tx coil is 30 cm, and the height is 25.4 cm; the volume of the cavity is 0.072 m3. The radius of Rx is 2.5 mm, and the volume of the receiver coil is 13.75 mm3. | 10 cm | 375.32 MHz 50 Ω 33% | PTE of the optimal impedance-matching (IM) system can achieve 33.88%, which is four times the 7.68% that can be achieved without an optimal IM system. |

| WPT System | Resonator Parameters | f0/k/RL | Pout, Efficiency % | Note | |||

|---|---|---|---|---|---|---|---|

| Resonator Structure | Coils/Number of the Coils | Coils’ Dimensions and Number of Turns | Gap | ||||

| [116] | Flat structure/Circular coils (44-mm inner diameter) | Symmetrical/three-coil resonance structure | Two 76-mm diameter circular coils and a source coil with 36-mm diameter. | 62 mm | 684 kHz 20 Ω | 12.9 W 43% At 40 mm | The maximum efficiency of the three-coil system shows a significant advantage over that of the two-coil system. |

| [117] | Flat structure/Circular spiral coils | Asymmetrical/four-coil resonance structure | Six turns for each coil. Outer diameter for Tx is 590 mm; for Rx, it is 280 mm, and the drive loop diameter is 280 mm | 700 m | 7.65 MHz k = 0.1376 | 12 W Laptop 50% | Presented a WPT that maximizes the quality factor of the coils; by proper loading of the drive and load loops, efficiency will be better. |

| [122] | Double-layer printed spiral coil PSC (square spiral coil) | Symmetrical/four-coil resonance structure | Double-layered for each layer: 3.875 turns. Width: 288 mm, Substrate: 300 mm × 300 mm | 500 mm | 4.03 MHz | 150 W 50% | The printed spiral coil (PSC) has high precision, high stability, easy to design, and manufacture. |

| WPT System | Resonators | f0/k/RL | Pout, Vout, Efficiency % | Note | |||

|---|---|---|---|---|---|---|---|

| Resonator Structure | Size of the Coils/Number of Coils | Coils’ Dimensions and Number of Turns | Gap | ||||

| [64] | Coil with a core/Dipoles with cores | Symmetrical/two-coil resonance structure | Number of turns for Rx: 22. Number of turns for Tx: 86. The length of the core is 3 m, and the length of the coil is 1 m. | 3 m | 20 kHz k: (0.68%,0.39%, 0.26%) 40 Ω | 1403 W 29% | Coils with ferrite cores will minimize parasitic effects. The optimum-stepped core structure can reduce the core loss. |

| 4 m | 471 W 16% | ||||||

| 5 m | 209 W 8% | ||||||

| For roadway-powered moving electric vehicles (high power) | |||||||

| [146] | Coil with a core/Resonator with EE, UU core-type | Asymmetrical/multi-coil structure | Power line modules in addition to UU, EE cores. Pick up coils for EE: five coils total, center: 64 turns, left and right: 28 turns each. | 26 cm | 20 kHz | 100 kW 620 V 80% | The implementation cost of the power receiver unit/kW was about $89/kW. |

| WPT System | Resonator parameters | f0/RL | Pout, Efficiency % | Note | |

|---|---|---|---|---|---|

| Resonator Structure | Coils’ Dimensions and Number of Turns | ||||

| [151,152] | Symmetrical/circular coils/domino structure/ | The WPT has eight resonators, which have a radius of path r of 300/235 mm for three-resonator and four-resonator systems, respectively. The number of turns is 11. | 520 kHz (11.57~16.94) Ω | 14 W, 70.68~83% | The optimized operating frequency of this system is not the resonant frequency of the resonators. |

| Case | 1 | 2 | 3 | 4 | 6 |

|---|---|---|---|---|---|

| A/S/iC | A/2C | S/2C | S/2C | A/2C | S/2C |

| Topology | SS | LCL-S LCC-S | SP | LCC-LCC | SS |

| Size D1/D2 mm | 500/400 | 226/226 | 500/500 | 600/300 | 220/220 |

| Gap mm | 200 | 100 | 200 | 150 | 240 |

| Frequency | 85 kHz | 140 kHz | 20 kHz | 85 kHz | 200 kHz |

| Efficiency | 95% | 93% | 93% | 92.6% | 85% |

| Case | 1 | 2 | 4 |

|---|---|---|---|

| A/S | S | A | S |

| Topology | LCC-LCC | LCC-LCC | S-SP |

| Size mm2 | 800 × 600 | 600 × 450 400 × 300 | 500 × 600 |

| Gap mm | 200 | 150 | 100 |

| Frequency kHz | 79 | 85 | 40 |

| Efficiency | 96% | 95.5% | 95.2% |

| Resonator Type | Inductance | Comments |

|---|---|---|

| Straight conductor | l: Length, a: radius of the conductor. | |

| Square loop | Where N: The number of turns. | μr: Relative permeability. |

| Rectangular loop |  | |

| Circular | R: radius |  |

| Equilateral triangle |  | |

| Pancake coil (flat spiral coil) | where: W: the wire diameter. S: the separation between two turns. |  |

| Square spiral coil | where R = P/q q: thickness, P: the separation between turns. |  |

| On-chip inductor spiral loops L- (nH) [124] | where: xi—Factors from (layout depending, it is given in Table 11) |  φ—Fill factor |

| Layout | x1 | x2 | x3 | x4 |

|---|---|---|---|---|

| Square | 1.27 | 2.07 | 0.18 | 0.13 |

| Hexagonal | 1.09 | 2.23 | 0 | 0.17 |

| Octagonal | 1.07 | 2.29 | 0 | 0.19 |

| Circular | 1 | 2.46 | 0 | 0.2 |

| Case | The Resonator Structure | Misalignment Type | The Effect of Misalignments | Comments |

|---|---|---|---|---|

| [173] | Circular spiral coil | Lateral/Angular | The values of output voltage decrease with the misalignment. | According to the test, even if the lateral and angular misalignments happen. The efficiency at a 5 cm distance is up to 50%. |

| [161] | Circular | Lateral/Angular azimuth/Angular elevation | The proposed structures: 3D SCMR, HSCMR, and CSCMR are less sensitive to the misalignments than the standard SCMR system. | The system achieves an efficiency of 40% for the entire range of 360° in case of the angular misalignment. |

| [1] | Helical | Lateral/Angular general (angular horizontal) | M = x (Δ, α). N2: M is the mutual inductance, which increases linearly depending on the square of the coil turns. | x (Δ, α) is a variable coefficient that depends on the lateral misalignment Δ, and the angular misalignment α. The average value of the slope is (0−10 cm, 0~50°). |

| [99] | Double D (DD) bipolar pads | Horizontal | The efficiency is higher than 90%, even at a large misalignment in the x-direction. | For EV application, the x-misalignment is door-to-door, and the y-misalignment is front to rear. |

| [95] | UU type | Horizontal/Vertical | The self-inductance of the pads changes slowly with the misalignment of the coils, but the mutual inductance changes fast. | The current-fed compensation topology is a practical solution for WPT. |

| [132] | Helical coils | Angular | Compared to the single-transmitter WPT system, the proposed system gives a higher power transfer efficiency during the angular aligned and in case of the angular misaligned. | The paper proposed a multiple-transmitter WPT, which provides a power transfer diversity. |

| [113] | H-shaped DGS and semi-H-shaped | Horizontal shift/Coaxial orientation | Compared to H-shaped DGS, the semi-H-shaped DGS is more robust to misalignments. | These features boost the usage of the semi-H-shaped DGS in WPT applications. |

| [117] | Circular spiral coil | Angular | The case of a fixed frequency undergoes the same trend of process from the over coupled to critically coupled, and then under coupled system. | The receiver unit is placed on the axis at a fixed transferring distance of 50 cm. |

| [110] | Rectangular | Forward direction | Compared with SP-compensated WPT, the S/SP-compensated WPT is more robust to the misalignment. | The range of the output voltage of the SP-compensated WPT is almost double that of the S/SP-compensated WPT, |

| Standards | Substandard | Country | Frequency/Power | Application/Comments |

|---|---|---|---|---|

| Federal Communications Commission (FCC) | KDB 680106 Part 15B and part 18 | USA | Above 9 kHz are considered intentional radiators. | Radio frequency (RF) exposure wireless charging apps (wireless chargers, inductive chargers, and wireless charging pads). |

| Society of Automotive Engineers (SAE) | SAE J2954/J2836/6™ J2847/6-J2931/6 | J2954™ EVs and PHEVs use 85 kHz band. | Wireless charging task force, specific use cases, and specific protocols. | |

| The International Special Committee on Radiofrequency Interference (CISPR) | CISPR SC-B | International | From 9 kHz upwards, CISPR 11 range is 150 kHz up to 1 GHz. | Household appliances, ignition systems, and fluorescent lamps. |

| CISPR 11:2015 | Power electronics in the industrial, scientific and medical frequency band (ISM band): RF equipment used in WPT. | |||

| International Electrotechnical Commission (IEC) | IEC 61980-1:2015, IEC 62827-2:2017, IEC PAS 63095-1:2017(E) | For IEC PAS 63095-1:2017(E) baseline power profiles are (≤5 W) and extended power profile is (≤15 W). |

| |

| International Organization for Standardization (ISO) | ISO PAS 19363, 2017-1-1, (ISO/NP 19363 under development) | Close synchronization with IEC 61980 and SAE J2954. |

| |

| International Commission on Non-Ionizing Radiation Protection (ICNIRP) | ICNIRP 1998 ICNIRP 2009 ICNIRP 2010 | EM Field: (1 Hz–100 kHz)/2010 (1 Hz–300 kHz) 1998. |

| |

| European Telecommunication Standards Institute (ETSI) | ETSI EN 303 417 V1.1.0 (2017-9). | EU | For WPT systems that use frequency other than RF beam, and it has investigated ranges: [19–21 kHz, 59–61 kHz, 79–90 kHz, 100–300 kHz, and 6765–6795 kHz]. | Harmonized standard, which covers the essential requirements of article 3.2 of Directive 2014/53/EU. |

| China Communication Standard Association (CCSA) | CCSA TC9 | China | Part1: General; part2: Tightly coupled (ICPT); and part3: Resonance wireless power transfer (MCR WPT). | EMF evaluation methods for WPT and EMC limit and measurements. |

| YD/T 2654-2013 | Requirements and test methods of EMC of WPT equipment. | |||

| Association of Radio Industries and Businesses (ARIB); Broadband Wireless Forum (BWF) | ARIB STD-T113 (2015) | Japan | 6.78 MHz-band MCR WPT for mobile, 400 kHz–band for CPT. EV/PHEV WPT spectrum: (42 kHz~48 kHz, 52 kHz~58 kHz, 79~90 kHz, and 140.91~148.5 kHz). Power: 3 kW and 7.7 kW. | Study for WPT spectrum for all the applications and technologies.

|

| BWF TR-02 Edition 1.0/2016 | 100 kHz, 100–500 kHz, and 6.78 MHz. |

| ||

| Telecommunication Technology Association (TTA) | TTAR-06.162 (19/11/2015) | Korea | For EV in 2011, OLEV (19 kHz~21 kHz and 59 kHz~61 kHz).Normal Power: 100 kW.Frequency: 13.56 MHz band is used for 3D glasses WPT. |

|

| Alliance for Wireless Power (A4WP) | A4WP standards | Established in 2012 (Samsung, Qualcomm and others) | 6.78 MHz for power transfer and 2.4 GHz for the control signals. |

|

| Wireless Power Consortium Qi (WPC) | Qi standards Version 1.0.Version 1.1. | Industry group, since 2008 | Range: 110 kHz–205 kHz.Low power in the range of (0–5) W. Medium power is up to 120 W. |

|

| Power Matters Alliance (PMA) | PMA standard | Founded by Procter, Gamble and Powermat in 2012. | 277 kHz–357 kHz and up to 5–10 W. |

|

| Additional standards for electromagnetic compatibility EMC, immunity tests and measurements: Radiated and conducted emissions—CISPR 11. Compliance testing of wireless power transfer products ASNI C63.30. Radiated EM immunity—ISO 11451-2:2015-06 (E). | ||||

| WPT System | Country | Frequency Range under Consideration | Power Range under Considerations | Application |

|---|---|---|---|---|

| Inductive coupling (IPT): low power | Already in Japan, Korea | Japan: 110 kHz–205 kHz. Korea:100 kHz–205 kHz. | - | Mobile devices, portable devices, consumer electronics (CE), and industrial fields. |

| Inductive coupling (IPT): high power | Japan | Japan: 20.05 kHz–38 kHz, 42 kHz–58 kHz, and 62 kHz–100 kHz. | Japan: Several watts up to 1.5 kW. | Home appliances operating with high power, and office equipment. |

| Magnetically coupling resonant (MCR WPT) | Japan, Korea | Japan and Korea in the range of: (6.765–6.795) MHz. | Japan: Up to 100 W. Korea: Unlimited in-band emission limit | Mobile devices, tablets, note-PCs, and home appliances, which operate with low power. |

| Capacitive coupling (CPT) | Japan | Japan: 425 kHz–524 kHz. | Japan: Up to 100 W | Portable devices, tablets, and home appliances. |

| Case | Reduction Method | Advantages | Disadvantages | Notes | |

|---|---|---|---|---|---|

| [14] | Using ferrite bars | Ferrite acts as a partial magnetic core for coupled coils, and it improves the system performance. | Ferrite bars experience hysteresis losses and have extra costs. In addition, some applications do not have enough space. | LCC-compensated topology is more effective than SS-compensated topology, and it produces a lower magnetic field in the near-field area. | |

| [178] | Ferrimagnetic material | It can confine and guide the magnetic flux by providing a path close to magnetic field sources. | Using the ferrimagnetic material could be limited for some applications due to its cost, occupied space, and weight. | The EMF noise that is produced by CSPR topology is higher and worse than that of the CSSR noise. CSPR means constant current source CCO, series resonance for Tx, parallel resonance for Rx, and a resistive load (R). CSSR: constant current source (CCO), SS topology, and a resistive load (R). | |

| Metallic shielding (Aluminum), same case in [179] | The metallic shielding induces eddy currents, which result in magnetic fields cancelation. Therefore, the total magnetic field near the material is reduced. | Ferrite and metallic shields block a wide band of electromagnetic spectrum. Consequently, they have a lower power transfer efficiency, in addition to the thermal stress caused by eddy currents. | |||

| [180] | Near-field metamaterial zero-permeability shield | It does not cause significant extra losses, and it blocks the near-field radiation only at an exact frequency. | If the metamaterial is not placed between the coils, it will work as a shield, so it does not enhance the coupling. | The selective frequency technique blocks specific frequencies and allows other fields to pass. Consequently, this method could be used for human safety. | |

| [16] | Three-phase power line to reduce the leakage EMF | The current circulates in two wires for each phase. Therefore, the side and center parts of the power lines cancel each other. | The three-phase system has a higher input current compared to the single-phase system. | This system uses six overlaid power lines (three in the center and three to the side); they are ended to two y-connections. | |

| [185] | Active shielding | ISEC | It generates counter magnetic fields from the EMF cancel coil. In addition, it is suitable for high-power application, such as EVs, PHEVs, and road-powered type EVs. | Requires extra components, extra coils, and a power supply. | The linear time-invariant steady-state system, which means that the cores are unsaturated and the circuit parameters are constant. |

| 3DEC | |||||

| LFEC | |||||

| [7,186,189] | Reactive resonant (with one or two shielding coils) | The cancelation magnetic field is generated from the original magnetic field noise. Therefore, it does not require any power source. | Requires shielding coils and capacitors. | The shielding coils are connected to each other so that the primary shield coil can supply enough shield current for the second shield coil. Consequently, the leakage magnetic field is reduced. | |

| EMI mitigation methods | |||||

| [187] | Spread spectrum clock technology (SSC) | This method reduces the current spectrum, and as a result, the EMI is suppressed. | It requires a power supply, which occupies more space and weight. In addition, it is not simple to design. | Triangular modulation; the peak deviation ±1% and the modulation frequency is 156.25 Hz. | |

| [174] | The isolation inductor scheme to reduce EMI | The magnitude of the input impedance is increased at higher frequencies. At the resonant frequency, no change at the magnitude of the input impedance. | DC–DC and coil-to-coil efficiencies are decreased due to the coil and core losses of the isolation inductor. | Isolation inductors of Tx and Rx are made of shell-type ferrite cores’ coils. | |

| WPT | f0 | N1/N2 | L1/L2 (µH) | Resistances: R1, R2 (Ω) | Mutual Inductance M | Coupling Coefficient k | C1/C2 (nF) |

|---|---|---|---|---|---|---|---|

| Hemisphere (a) | 500 kHz | 21/16 | 21.14/7.8156 | 0.23/0.13 | 7.478 µH | 0.54 | 4.79/12.96 |

| Optimized model (b) | 34/22 | 50.699/31.83 | 0.19/0.1 | 3.6117 µH | 0.089 | 2/3.18 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abou Houran, M.; Yang, X.; Chen, W. Magnetically Coupled Resonance WPT: Review of Compensation Topologies, Resonator Structures with Misalignment, and EMI Diagnostics. Electronics 2018, 7, 296. https://doi.org/10.3390/electronics7110296

Abou Houran M, Yang X, Chen W. Magnetically Coupled Resonance WPT: Review of Compensation Topologies, Resonator Structures with Misalignment, and EMI Diagnostics. Electronics. 2018; 7(11):296. https://doi.org/10.3390/electronics7110296

Chicago/Turabian StyleAbou Houran, Mohamad, Xu Yang, and Wenjie Chen. 2018. "Magnetically Coupled Resonance WPT: Review of Compensation Topologies, Resonator Structures with Misalignment, and EMI Diagnostics" Electronics 7, no. 11: 296. https://doi.org/10.3390/electronics7110296

APA StyleAbou Houran, M., Yang, X., & Chen, W. (2018). Magnetically Coupled Resonance WPT: Review of Compensation Topologies, Resonator Structures with Misalignment, and EMI Diagnostics. Electronics, 7(11), 296. https://doi.org/10.3390/electronics7110296