An Ultra-Wideband Sensing Board for Radio Frequency Front-End in IoT Transmitters

Abstract

:1. Introduction

2. Sensing Board Design

2.1. Six-Port Junction Design

2.2. Detector Design

2.3. Calibration Algorithm

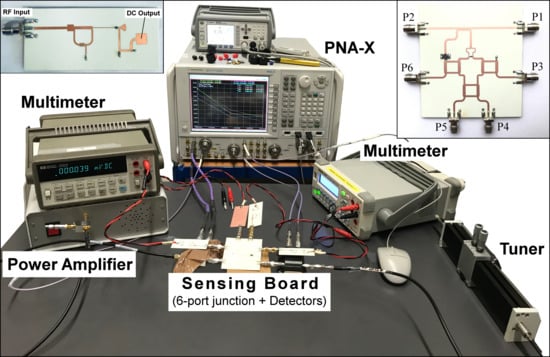

3. Measurement Section

3.1. Validation of the Fabricated Boards

3.2. Validation of the Impedance Detection

3.3. Sensing Board Validation with Large-Signal Measurements

3.3.1. Nonlinearity of Detectors and Sensing Board

3.3.2. Bandwidth of the Detector

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bandyopadhyay, D.; Sen, J. Internet of Things: Applications and Challenges in Technology and Standardization. Wirel. Pers. Commun. 2011, 58, 49–69. [Google Scholar] [CrossRef]

- Jo, M.; Maksymyuk, T.; Batista, R.L.; Maciel, T.F.; de Almeida, A.L.F.; Klymash, M. A survey of converging solutions for heterogeneous mobile networks. IEEE Wirel. Commun. 2014, 21, 54–62. [Google Scholar]

- Minoli, D.; Occhiogrosso, B. Ultrawideband (UWB) Technology for Smart Cities IoT Applications. In Proceedings of the IEEE International Smart Cities Conference, Kansas City, MO, USA, 16–19 September 2018; pp. 1–8. [Google Scholar]

- ETSI EN 301 893. 5 GHz RLAN; Harmonised Standard Covering the Essential Requirements of Article 3.2 of Directive 2014/53/EU; ETSI EN: Sophia Antipolis, France, 2014. [Google Scholar]

- Huang, C.P.; Christainsen, K.; Nabokin, S.; Mirzayantz, R.; Allum, J.; Chen, A.; Lam, L.; McPartlin, M.; Doherty, M.; Vaillancourt, B. A highly integrated single chip 5–6 GHz front-end IC based on SiGe BiCMOS that enhances 802.11ac WLAN radio front-end designs. In Proceedings of the IEEE Radio Frequency Integrated Circuits Symposium (RFIC), Phoenix, AZ, USA, 17–19 May 2015; pp. 227–230. [Google Scholar]

- Salpietro, R.; Bedogni, L.; di Felice, M.; Bononi, L. Park Here! a smart parking system based on smartphones’ embedded sensors and short range Communication Technologies. In Proceedings of the IEEE 2nd World Forum on Internet of Things (WF-IoT), Milan, Italy, 14–16 December 2015; pp. 18–23. [Google Scholar]

- Lukić, M.; Mihajlović, Ž.; Mezei, I. Data Flow in Low-Power Wide-Area IoT Applications. In Proceedings of the 26th Telecommunications Forum (TELFOR), Belgrade, Serbia, 21–22 November 2018; pp. 1–4. [Google Scholar]

- Pal, A.; Kant, K. NFMI: Connectivity for Short-Range IoT Applications. Computer 2019, 52, 63–67. [Google Scholar] [CrossRef]

- ETSI EN 302 065-5. Short Range Devices (SRD) Using Ultra Wide Band Technology (UWB); Harmonised Standard Covering the Essential Requirements of Article 3.2 of Directive 2014/53/EU; Part 5: Devices using UWB technology onboard aircraft; ETSI EN: Sophia Antipolis, France, 2014. [Google Scholar]

- Ramos, A.; Lazaro, A.; Girbau, D.; Villarino, R. RFID and Wireless Sensors Using Ultra-Wideband Technology; ISTE Press—Elsevier: London, UK, 2016; pp. 14–16. [Google Scholar]

- Raffo, A.; di Falco, S.; Sozzi, G.; Menozzi, R.; Schreurs, D.M.M.-P.; Vannini, G. Analysis of the gate current as a suitable indicator for FET degradation under nonlinear dynamic regime. Microelectron. Reliab. 2011, 51, 235–239. [Google Scholar] [CrossRef]

- Vadalà, V.; Bosi, G.; Raffo, A.; Vannini, G.; Avolio, G.; Schreurs, D.M.P. Influence of the gate current dynamic behaviour on GaAs HEMT reliability issues. In Proceedings of the 7th European Microwave Integrated Circuit Conference, Amsterdam, The Netherlands, 29–30 October 2012; pp. 258–261. [Google Scholar]

- Pozar, D.M. Microwave Engineering, Reading; Addison-Wesley: Boston, MA, USA, 1990; pp. 529–565. [Google Scholar]

- Mohamed, A.M.M.; Boumaiza, S.; Mansour, R.R. Novel Reconfigurable Fundamental/Harmonic Matching Network for Enhancing the Efficiency of Power Amplifier. In Proceedings of the 40th European Microwave Conference, Paris, France, 28–30 September 2010; pp. 1122–1125. [Google Scholar]

- Nawaz, A.A.; Albrecht, J.D.; Ulusoy, A.C. A Ka-Band Power Amplifier with Reconfigurable Impedance Matching Network. In Proceedings of the IEEE 19th Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems (SiRF), Orlando, FL, USA, 20–23 January 2019; pp. 1–3. [Google Scholar]

- Chen, H.; Hsieh, Y.; Lu, L. A 5.5-GHz multi-mode power amplifier with reconfigurable output matching network. In Proceedings of the IEEE Radio Frequency Integrated Circuits Symposium (RFIC), Phoenix, AZ, USA, 17–19 May 2015; pp. 203–206. [Google Scholar]

- Lu, Y.; Peroulis, D.; Mohammadi, S.; Katehi, L.P.B. A MEMS reconfigurable matching network for a class AB amplifier. IEEE Microw. Wirel. Compon. Lett. 2003, 13, 437–439. [Google Scholar]

- Baroni, A.; Nepa, P.; Rogier, H. Wearable self-tuning antenna for emergency rescue operations. IET Microw. Antennas Propag. 2016, 10, 173–183. [Google Scholar] [CrossRef]

- Hur, B.; Eisenstadt, W.R.; Melde, K.L. Testing and Validation of Adaptive Impedance Matching System for Broadband Antenna. Electronics 2019, 8, 1055. [Google Scholar] [CrossRef]

- Ji, D.; Jeon, J.; Kim, J. A Novel Load Insensitive RF Power Amplifier Using a Load Mismatch Detection and Curing Technique. In Proceedings of the 2013 IEEE Radio Frequency Integrated Circuits Symposium (RFIC), Seattle, WA, USA, 2–4 June 2013; pp. 341–344. [Google Scholar]

- Curticipean, F.; Niittylahti, J. An Improved Digital Quadrature Frequency Down-Converter Architecture. In Proceedings of the 1977 11th Asilomar Conference on Circuits, Systems and Computers, Pacific Grove, CA, USA, 7–9 November 1977; Conference Record; IEEE: Piscataway, NI, USA, 2001; Volume 2, pp. 1318–1321. [Google Scholar]

- Analog Devices. LF-2.7 GHz RF/IF Gane and Phase Detector (AD8302 Datasheet); Analog Devices: Norwood, MA, USA, 2008. [Google Scholar]

- Engen, G.F. The Six-Port Reflectometer: An Alternative Network Analyzer. IEEE Trans. Microw. Theory Tech. 1977, 25, 1075–1080. [Google Scholar] [CrossRef]

- Engen, F. An Improved Circuit for Implementing the Six-Port Technique of Microwave Measurements. IEEE Trans. Microw. Theory Tech. 1977, 25, 1080–1083. [Google Scholar] [CrossRef]

- Wang, M.; Xue, B.; Wang, W.; Yang, J. The design of multi-user indoor UWB localization system. In Proceedings of the 2nd International Conference on Frontiers of Sensors Technologies (ICFST), Shenzhen, China, 14–16 April 2017; pp. 322–326. [Google Scholar]

- Ghannouchi, F.M.; Mohammadi, A. The Six-Port Technique with Microwave and Wireless Application; Artech House: Norwood, MA, USA, 2009. [Google Scholar]

- Petrocchi, A.; Raffo, A.; Avolio, G.; Lukasik, K.; Resca, D.; Vannini, G.; Lamey, S.; Caytan, O.; Agneessens, S.; Rogier, H.; et al. An ultra-wideband sensing board for IoT. In Proceedings of the 2017 13th International Conference on Advanced Technologies, Systems and Services in Telecommunications (TELSIKS), Nis, Serbia, 18–20 October 2017; pp. 174–177. [Google Scholar]

- Available online: https://www.keysight.com/en/pc-1297113/advanced-design-system-ads?cc=US&lc=eng (accessed on 6 October 2019).

- Michler, F.; Lindner, S.; Lurz, F.; Erhardt, S.; Weigel, R.; Koelpin, A. Zero-Bias Schottky Power Detector Design for Six-Port based Radar Systems. In Proceedings of the2017 47th European Microwave Conference (EuMC), Nuremberg, Germany, 10–12 October 2017; pp. 228–231. [Google Scholar]

- Fan, X.; Pei, X.; Xiong, X. Zero bias Schottky diodes use in high performance detection circuits. In Proceedings of the 2011 International Conference on Electronics and Optoelectronics, Dalian, China, 29–31 July 2011; pp. V3-27–V3-30. [Google Scholar]

- Agilent Technologies. The Zero Bias Schottky Diode Detector at Temperature Extremes—Problems and Solutions (Application Note 1090); Agilent Technologies: Santa Clara, CA, USA, 1999. [Google Scholar]

- Ikalainen, P.K. An RLC Matching and Application in 1-20 GHz Monolithic Amplifier. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest, Long Beach, CA, USA, 13–15 June 1989; Volume 3, pp. 1115–1118. [Google Scholar]

- Ghannouchi, F.M.; Bosisio, R.G. An Alternative Explicit Six-Port Matrix Calibration Formalism Using Five Standards. IEEE Trans. Microw. Theory Tech. 1988, 36, 494–498. [Google Scholar] [CrossRef]

- Lemey, S.; Castel, T.; Van Torre, P.; Vervust, T.; Vanfleteren, J.; Demeester, P.; Ginste, D.V.; Rogier, H. Threefold Rotationally Symmetric SIW Antenna Array for Ultra-Short-Range MIMO Communication. IEEE Trans. Antennas Propag. 2016, 64, 1689–1699. [Google Scholar] [CrossRef]

- Madonna, G.; Ferrero, A.; Pirola, M. Design of a Broadband Multiprobe Reflectometer. IEEE Trans. Instrum. Meas. 1999, 48, 622–625. [Google Scholar] [CrossRef]

- Petrocchi, A.; Raffo, A.; Bosi, G.; Vannini, G.; Kapusuz, K.Y.; Lamey, S.; Rogier, H.; Avolio, G.; Schreurs, D. An ultra-wideband setup to monitor antenna-impedance variations in low-cost IoT transmitters. In Proceedings of the 2018 International Workshop on Integrated Nonlinear Microwave and Millimetre-Wave Circuits (INMMIC), Brive La Gaillarde, France, 5–6 July 2018; pp. 1–3. [Google Scholar]

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| 43.57 + j 11.45 | 0.821 + j 98.678 | 65 | 0.03 − j 25.7 | 21.8 − j 39.68 |

| Frequency (GHz) | Tuner Impedances (Ω) | Retrieved Values from the Sensing Board (Ω) |

|---|---|---|

| 5 | 43.6 + j 12.04 | 40.3 + j 12.0 |

| 5.1 | 30.5 + j 1.32 | 34.9 + j 7.5 |

| 5.2 | 48.1 − j 12.1 | 44.4 − j 6.0 |

| 5.3 | 48.6 + j 4.2 | 45.7 + j 2.5 |

| 5.4 | 30.9 + j 3.9 | 36.6 + j 6.6 |

| 5.5 | 45.9 − j 8.8 | 44.7 − j 10.9 |

| 5.6 | 38.4 + j 16.9 | 40.7 + j 17.3 |

| 5.7 | 32.5 − j 1.9 | 33.2 − j 2.4 |

| 5.8 | 54.4 + j 7.4 | 52.5 + j 5.5 |

| 5.9 | 37.2 + j 10.3 | 38.2 + j 12.4 |

| 6 | 49.4 + j 4.8 | 49.9 + j 1.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrocchi, A.; Raffo, A.; Bosi, G.; Avolio, G.; Resca, D.; Vannini, G.; Schreurs, D. An Ultra-Wideband Sensing Board for Radio Frequency Front-End in IoT Transmitters. Electronics 2019, 8, 1191. https://doi.org/10.3390/electronics8101191

Petrocchi A, Raffo A, Bosi G, Avolio G, Resca D, Vannini G, Schreurs D. An Ultra-Wideband Sensing Board for Radio Frequency Front-End in IoT Transmitters. Electronics. 2019; 8(10):1191. https://doi.org/10.3390/electronics8101191

Chicago/Turabian StylePetrocchi, Alessandra, Antonio Raffo, Gianni Bosi, Gustavo Avolio, Davide Resca, Giorgio Vannini, and Dominique Schreurs. 2019. "An Ultra-Wideband Sensing Board for Radio Frequency Front-End in IoT Transmitters" Electronics 8, no. 10: 1191. https://doi.org/10.3390/electronics8101191

APA StylePetrocchi, A., Raffo, A., Bosi, G., Avolio, G., Resca, D., Vannini, G., & Schreurs, D. (2019). An Ultra-Wideband Sensing Board for Radio Frequency Front-End in IoT Transmitters. Electronics, 8(10), 1191. https://doi.org/10.3390/electronics8101191