The Development of Rocketry Capability in New Zealand—World Record Rocket and First of Its Kind Rocketry Course

Abstract

:1. Introduction

2. Methodology

2.1. Aims, Design and Manufacturing—Milly

2.1.1. Airframe, Fins and Nose Cone—Milly

2.1.2. Body and Motor Optimization—Milly

2.1.3. Rocket Recovery and Tracking Systems—Milly

2.2. Parachute Descent 3DOF Modelling—Milly

2.3. University of Canterbury Rocketry Design and Control Course—Smokey

| Category | Parameter | Value (Liftoff, Burnout) |

|---|---|---|

| Stability | Centre of Pressure | 0.80 m |

| Centre of Mass | 0.71 m, 0.66 m | |

| Stability | 1.2 Calibres, 1.8 Calibres | |

| Mass | 3.0 kg, 2.75 kg | |

| Geometry | Rocket Diameter | 0.08 m |

| Reference Area | 0.005 m2 | |

| Rocket Length | 1.52 m | |

| Canard Location | 0.3 m | |

| Tail Fin Location | 1.4 m | |

| Canard Radial Distance | 0.06 m | |

| Nozzle Location | 1.5 m | |

| Motor | Type | Aerotech I211W |

| Total impulse | 440 Ns | |

| Avg. thrust | 217 N | |

| Max. thrust | 386 N | |

| Burn time | 2.02 s | |

| Launch mass | 476 g | |

| Empty mass | 226 g |

2.3.1. Safety Protocols—Smokey

- NOTAM is lodged with Airways New Zealand

- Safety and Consent forms are filled for University of Canterbury administration

- High-visibility vests are worn by all on site

- Safety glasses are worn when working with or near explosive charges

- A fire blanket, fire extinguisher and water container are available on site

- First Aid certification must be held by someone on site

- The parachute charge is inside the nose cone; the nose must always be pointed away from other people when handling the rocket

- Continuity of the ignition leads is checked before connecting the explosive charge

- Check for aircraft immediately before launching

- Remain in the bunker during launch until it is deemed safe to leave

- Bring the fire extinguisher to the landing site when recovering the rocket

- If the rocket misfires, remain in the bunker for 60 s before approaching the launch guide

2.3.2. Electronic Housing 3D Printing Assignment—Smokey

2.3.3. Machining of Rocket Parts—Smokey

| Label | Part | Material |

|---|---|---|

| A | Motor Centering Ring | Aluminum |

| B | Actuator Housing Cover | Aluminum |

| C | Airframe Tube | PVC |

| D | Canard Shaft Bushings | Bronze |

| E | Encoder Spacers | Bronze |

| F | Actuator Base Disk | Aluminum |

| G | Canard Shafts | Stainless Steel |

| H | Chute Strop Pin | Stainless Steel |

| I | Chute Fair Lead | Aluminum |

| J | Drogue Barrel | Aluminum |

| K | Ejection Canister | Aluminum |

| L | Ejection Piston Base | Aluminum |

| M | Nose Cone Tip | Aluminum |

| N | Nose Cone Tie Tube | Aluminum |

2.3.4. Avionics—Smokey

Microprocessor Change to ARM Cortex-M4 STM32F4

Software Improvements

MPU6000 IMU Sensor

Combination of Functionality on One PCB

2.3.5. Actuation Mechanism—Smokey

2.3.6. Parachute Recovery—Smokey

2.3.7. Wind Tunnel Testing—Smokey

3. Results and Discussion

3.1. Rocket Launch Setup—Milly

3.2. World Record Results—Milly

3.3. Wind Tunnel PD Control Testing Results—Smokey

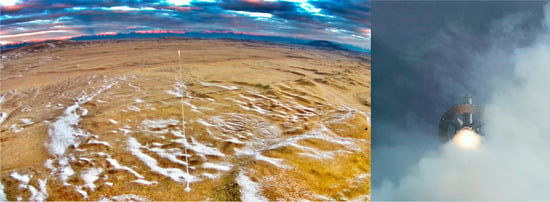

3.4. Kaitorete Spit Launch Site and Set up—Smokey

- A derivative controller on roll angle given by Equation (11), implemented throughout flight

- A PD controller on yaw angle given by Equations (12) and (13) but with Ryaw replaced by the measured yaw angle, four seconds after launch detect. Four seconds was chosen since the thrust burn was 2.2 s, and it gives sufficient time for effects of weather cocking and thrust off set to disappear and provides a more conservative test of the controller in conditions of a slower varying velocity.

- Three open-loop step responses of the yaw fin angle defined by:

- An equipment checklist was completed before going to the launch site, this included all gear needed to launch, safety equipment and documentation

- Launch guide was set up

- Rocketry electronics were powered on in idle state; this means there is no risk of the electronics performing in-flight tasks such as canard actuation, logging or parachute deployment

- Rocket was placed inside the launch guide

- Motor ignition cable was laid out and continuity tested

- Base station was set up inside the bunker, and communications were checked

- Motor ignition charge placed inside rocket motor, and armed at the launch guide

- All present assembled inside the bunker for final countdown

3.5. Flight Results—Smokey

4. Conclusions

Notation

| Fd | drag force (N) |

| ρ | air density (kg m−3) |

| Cd,p | drag coefficient of parachute (dimensionless) |

| M | mass of the rocket with parachute and no fuel |

| g | acceleration due to gravity (m s−1) |

| vx, vy, vz | velocities (m s−1) in East, North and vertical directions |

| x, y, z | East and North displacements and altitude above ground level respectively (m) |

| vx,R, vy,R, vz,R | relative wind velocities in East, North and vertical directions (m s−1) |

| wx, wy, wz | wind speeds in East, North and vertical directions (m s−1) |

| Ap | area of parachute (m2) |

| G | gravitational constant (m3 kg−1 s−2) |

| ME | mass of earth (kg) |

| rE | radius of earth (m) |

| x0, y0, z0, vx0, vy0, vz0 | initial conditions at apogee |

| finAngleRoll | fin angle actuating roll (rad) |

| finAngleYaw | fin angle actuating yaw (rad) |

| Kd,roll | derivative gain on roll (s) |

| Kp,yaw | proportional gain on yaw (no unit) |

| Kd,yaw | derivative gain on yaw (s) |

| Ryaw | reference yaw angle (°) |

| Abbreviations | |

|---|---|

| PD | Proportional-derivative |

| LEO | Low earth orbit |

| NASA | The National Aeronautics and Space Administration |

| UC | University of Canterbury |

| NZ | New Zealand |

| US | United States |

| 3D | Three dimensional |

| 3DOF | Three degrees of freedom |

| ASTOS | Aerospace Trajectory Optimization Software |

| DARE | Delft Aerospace Rocket Engineering |

| Ph.D. | Doctorate of Philosophy |

| STERN | Student experimental rocketry |

| CNES | National Centre for Space Studies |

| ARES | Advanced Rockets for Experimental Studies |

| PERSEUS | Projet Etudiant de Recherche Spatiale Europeèn Universitaire Et Scientifique |

| CUSF | Cambridge University Space Flight |

| CALVEIN | California Launch Vehicle Education Initiative |

Acknowledgments

Author Contributions

Conflicts of Interest

References

- UC Rocketry Project. Available online: http://ucrocketry.org/ (accessed on 21 February 2015).

- Rocket Lab Ltd. Available online: http://rocketlab.co.nz/ (accessed on 21 February 2015).

- Astos Solutions. Available online: https://www.astos.de/ (accessed on 21 February 2015).

- Rocket Motors and Propellants. Available online: http://www.cranfield.ac.uk/courses/training/rocket-motors-and-propellants.html (accessed on 21 February 2015).

- Bachelor of Engineering Honours (Mechatronic) (Space). Available online: http://sydney.edu.au/courses/bachelor-of-engineering-honours-mechatronic-space (accessed on 21 February 2015).

- Rojas, J.I.; Prats, X.; Montiaur, A.; Garcia-Berro, E. Model rocket workshop: A problem-based learning experience for engineering students. Int. J. Emerg. Technol. Learn. 2008, 3, 70–77. [Google Scholar] [CrossRef]

- Heath, M.T.; Dick, W.A. Virtual rocketry: Rocket science meets computer science. Computat. Sci. Eng. IEEE 1998, 5, 16–26. [Google Scholar] [CrossRef]

- UCT Engineering Students Launch Two Rockets. Available online: http://sastudy.co.za/article/uct-engineering-students-launch-two-rockets/ (accessed on 21 February 2015).

- Stratos II. Available online: http://dare.tudelft.nl/projects-and-teams/advanced-control/ (accessed on 21 February 2015).

- Farokhi, S. System design aspects of propulsion education in aerospace engineering curricula. Int. J. Turbo Jet Engines 1991, 8, 267–350. [Google Scholar] [CrossRef]

- Propulsion System Design Laboratory. Available online: https://explorecourses.stanford.edu/search?view=catalog&filter-coursestatus-Active=on&page=0&catalog=&academicYear=&q=AA284B&collapse (accessed on 21 February 2015).

- Stancato, F.; Racca, J.G.C. A 12 years Brazilian space education activity experience. Acta Astronaut. 2001, 48, 827–835. [Google Scholar] [CrossRef]

- MIT Rocket Team. Available online: http://rocketry.mit.edu/ (accessed on 21 February 2015).

- Jayaram, S.; Boyer, L.; George, J.; Ravindra, K.; Mitchell, K. Project-based introduction to aerospace engineering course: A model rocket. Acta Astronaut. 2010, 66, 1525–1533. [Google Scholar] [CrossRef]

- Cannon, R.L. Model rocketry as a teaching aid in science. Sch. Sci. Math 2010, 74, 471–475. [Google Scholar] [CrossRef]

- D’Alessio, M.; Lundquist, L. Computer supported Collaborative Rocketry: Teaching students to distinguish good and bad data like expert physicists. Phys. Teach. 2013, 51, 424–427. [Google Scholar] [CrossRef]

- NASA. Rockets Educator Guide; EG-2011–11–223-KSC; NASA: Washington, DC, USA, 2011. [Google Scholar]

- Tomita, N.; Watanabe, R.; Nebylov, A.V. Hands-on education system using water rocket. Acta Astronaut. 2007, 61, 1116–1120. [Google Scholar] [CrossRef]

- Stamminger, A. STERN—A rocket programme for German students. In Proceedings of the 21st ESA Symposium on European Rocket and Balloon Programmes and Related Research, Thun, Switzerland, 9–13 June 2013.

- Alger, S.; Ciezki, H.; Heislbetz, B.; Kitsche, W.; Schlechtriem, S. First Student-Hybrid-Thruster Test Campaign at German Aerospace Center (DLR). In Proceedings of the 52th Israel Annual Conference on Aerospace Science, Tel-Aviv and Haifa, Israel, 29 February–1 March 2012.

- Bellomo, N.; Barato, F.; Faenza, M.; Lazzarin, M.; Bettella, A.; Pavarin, D. Numerical and experimental investigation of unidirectional vortex injection in hybrid rocket engines. J. Propuls. Power 2013, 29, 1097–1113. [Google Scholar] [CrossRef]

- May, S.; Poppe, S.M.G.; Pöppelmann, M.; Sültrop, H.P.; Vörsmann, P. Development of a supersonic research rocket with hybrid rocket engine. In Proceedings of the European Conference for AeroSpace Sciences, Munich, Germany, 1–5 July 2013.

- Okninski, A.; Marciniak, B.; Bartkowiak, B.; Kaniewski, D.; Matyszewski, J.; Kindracki, J.; Wolanski, P. Development of the polish small sounding rocket program. Acta Astronaut. 2015, 108, 46–56. [Google Scholar] [CrossRef]

- Pernon, S.; Oswald, J.; Bec, R.; Hingre, H. Ares rockets demonstrators of french space agency project perseus. In Proceedings of the 20th ESA Symposium on European Rocket and Balloon Programmes and Related Research, Hyère, France, 22–26 May 2011.

- SERA1. Available online: http://www.sscspace.com/SERA1 (accessed on 21 February 2015).

- Cambridge University Space Flight. http://www.cusf.co.uk/ (accessed on 21 February 2015).

- California Launch Vehicle Education Initiative—Calvein. Available online: http://www.csulb.edu/colleges/coe/mae/views/projects/rocket/ (accessed on 21 February 2015).

- Culbertson, J.; Besnard, E.; Garvey, J. Application of wireless technology to CALVEIN launch vehicles. In Proceedings of the Fly by Wireless Workshop (FBW), Caneus, Orono, ME, USA; 2010. [Google Scholar]

- Xia, Y.; Lu, K.; Zhu, Z.; Mengyin, F. Adaptive back-stepping sliding mode attitude control of missile systems. Int. J. Robust Nonlinear Control 2013, 23, 1699–1717. [Google Scholar] [CrossRef]

- Ollerenshaw, D.; Costello, M. Model predictive control of a direct fire projectile equipped with canards. J. Dyn. Syst. Meas. Control 2008, 130, 1–11. [Google Scholar] [CrossRef]

- Hann, C.E.; Snowdon, M.; Rao, A.; Winn, O.; Wongvanich, N.; Chen, X. Minimal modeling approach to describe turbulent rocket roll dynamics in a vertical wind tunnel. Proc. Inst. Mech. Eng. G 2012, 226, 1042–1060. [Google Scholar] [CrossRef]

- Open source model rocket simulator. Available online: http://openrocket.sourceforge.net/download.html (accessed on 21 February 2015).

- Rogers Aeroscience RASAero Aerodynamic Analysis and Flight Simulation Software. Available online: http://www.rasaero.com/ (accessed on 21 February 2015).

- Rocket Drag and Stability. Available online: http://www.softpedia.com/get/science-CAD/aerolab.shtml (accessed on 21 February 2015).

- Box, S.; Bishop, C.M.; Hunt, H. Stochastic six-degree-of-freedom flight simulator for passively controlled high-power rockets. J. Aerosp. Eng. 2011, 24, 31–45. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buchanan, G.; Wright, D.; Hann, C.; Bryson, H.; Snowdon, M.; Rao, A.; Slee, A.; Sültrop, H.P.; Jochle-Rings, B.; Barker, Z.; et al. The Development of Rocketry Capability in New Zealand—World Record Rocket and First of Its Kind Rocketry Course. Aerospace 2015, 2, 91-117. https://doi.org/10.3390/aerospace2010091

Buchanan G, Wright D, Hann C, Bryson H, Snowdon M, Rao A, Slee A, Sültrop HP, Jochle-Rings B, Barker Z, et al. The Development of Rocketry Capability in New Zealand—World Record Rocket and First of Its Kind Rocketry Course. Aerospace. 2015; 2(1):91-117. https://doi.org/10.3390/aerospace2010091

Chicago/Turabian StyleBuchanan, George, David Wright, Christopher Hann, Hoani Bryson, Malcolm Snowdon, Avinash Rao, Adam Slee, Hans Philipp Sültrop, Bastian Jochle-Rings, Zane Barker, and et al. 2015. "The Development of Rocketry Capability in New Zealand—World Record Rocket and First of Its Kind Rocketry Course" Aerospace 2, no. 1: 91-117. https://doi.org/10.3390/aerospace2010091

APA StyleBuchanan, G., Wright, D., Hann, C., Bryson, H., Snowdon, M., Rao, A., Slee, A., Sültrop, H. P., Jochle-Rings, B., Barker, Z., McKinstry, A., Meffan, C., Xian, G., Mitchell, R., & Chen, X. (2015). The Development of Rocketry Capability in New Zealand—World Record Rocket and First of Its Kind Rocketry Course. Aerospace, 2(1), 91-117. https://doi.org/10.3390/aerospace2010091