Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nonwoven Formation

- = Density of fibre [g/cm3]

- = Density of matrix [g/cm3]

- = Weight of fibres [g]

- = Weight of matrix [g]

2.3. Composite Fabrication

2.4. Optical Microscopy

2.5. Flexural Tests

- = flexural stress [MPa]

- F = load [N]

- L = length of span [mm]

- b = width of the specimen [mm]

- h = thickness of the specimen [mm]

- = flexural modulus of elasticity [MPa]

- = central deflection [mm]

2.6. Scanning Electron Microscopy

3. Results and Discussion

3.1. Morphological Observations

3.2. Analysis of the Cross-Section and Void Content

3.3. Flexural Tests

3.4. Surface Morphology and Failure Assessment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bunsell, A.R. Fibres for composite reinforcement: Properties and microstructures. In Composite Reinforcements for Optimum Performance; Woodhead Publishing: Sawston, UK, 2011; pp. 3–31. ISBN 9781845699659. [Google Scholar]

- Kuehnel, M.; Kraus, T. The Global CFRP Market 2016. In Proceedings of the International Composites Congress (ICC), Düsseldorf, Germany, 28 November 2016. [Google Scholar]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling of Carbon Fibers. In Handbook of Recycling: State-of-the-Art for Practitioners, Analysts, and Scientists; Worrell, E., Reuter, M.A., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 269–283. ISBN 9780123965066. [Google Scholar]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Russell, S.J. Handbook of Nonwovens; CRC Press: Boca Raton, FL, USA, 2006; ISBN 9781845691998. [Google Scholar]

- Pill, H.; Afflerbach, K. Wet Lay Method. In Nonwoven Fabrics; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2004; pp. 237–267. [Google Scholar]

- Akonda, M.H.; Lawrence, C.A.; Weager, B.M. Recycled carbon fibre-reinforced polypropylene thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 79–86. [Google Scholar] [CrossRef]

- Giannadakis, K.; Szpieg, M.; Varna, J. Mechanical Performance of a Recycled Carbon Fibre/PP Composite. Exp. Mech. 2011, 51, 767–777. [Google Scholar] [CrossRef]

- Szpieg, M.; Wysocki, M.; Asp, L.E. Reuse of polymer materials and carbon fibres in novel engineering composite materials. Plast. Rubber Compos. 2009, 38, 419–425. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J. On recycled carbon fibre composites manufactured through a liquid composite moulding process. J. Reinf. Plast. Compos. 2016, 35, 533–540. [Google Scholar] [CrossRef]

- Turner, T.A.; Warrior, N.A.; Pickering, S.J. Development of high value moulding compounds from recycled carbon fibres. Plast. Rubber Compos. 2010, 39, 151–156. [Google Scholar] [CrossRef]

- Nunna, S.; Chandra, P.R.; Shrivastava, S.; Jalan, A. A review on mechanical behavior of natural fiber based hybrid composites. J. Reinf. Plast. Compos. 2012, 31, 759–769. [Google Scholar] [CrossRef]

- Pil, L.; Bensadoun, F.; Pariset, J.; Verpoest, I. Why are designers fascinated by flax and hemp fibre composites? Compos. Part A Appl. Sci. Manuf. 2016, 83, 193–205. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials; Cambridge University Press: Cambridge, UK, 1996; ISBN 9781139170130. [Google Scholar]

- Chung, D.D.L. Carbon Fiber Composites; Butterworth-Heinemann: Oxford, UK, 1994; ISBN 9780080500737. [Google Scholar]

- Le Guen, M.J.; Newman, R.H.; Fernyhough, A.; Emms, G.W.; Staiger, M.P. The damping–modulus relationship in flax–carbon fibre hybrid composites. Compos. Part B Eng. 2016, 89, 27–33. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Assarar, M.; Zouari, W.; Sabhi, H.; Ayad, R.; Berthelot, J.M. Evaluation of the damping of hybrid carbon-flax reinforced composites. Compos. Struct. 2015, 132, 148–154. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical behavior of carbon/flax hybrid composites for structural applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef] [Green Version]

- Bos, H.L.; Müssig, J.; van den Oever, M.J.A. Mechanical properties of short-flax-fibre reinforced compounds. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1591–1604. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Roussière, F.; Baley, C.; Godard, G.; Burr, D. Compressive and Tensile Behaviours of PLLA Matrix Composites Reinforced with Randomly Dispersed Flax Fibres. Appl. Compos. Mater. 2012, 19, 171–188. [Google Scholar] [CrossRef]

- Fages, E.; Cano, M.; Gironés, S.; Boronat, T.; Fenollar, O.; Balart, R. The use of wet-laid techniques to obtain flax nonwovens with different thermoplastic binding fibers for technical insulation applications. Text. Res. J. 2013, 83, 426–437. [Google Scholar] [CrossRef]

- Fages, E.; Gironés, S.; Sánchez-Nacher, L.; García-Sanoguera, D.; Balart, R. Use of wet-laid techniques to form flax-polypropylene nonwovens as base substrates for eco-friendly composites by using hot-press molding. Polym. Compos. 2012, 33, 253–261. [Google Scholar] [CrossRef]

- Wong, K.H.; Syed Mohammed, D.; Pickering, S.J.; Brooks, R. Effect of coupling agents on reinforcing potential of recycled carbon fibre for polypropylene composite. Compos. Sci. Technol. 2012, 72, 835–844. [Google Scholar] [CrossRef]

- Pickering, S.; Liu, Z.; Turner, T.; Wong, K. Applications for carbon fibre recovered from composites. IOP Conf. Ser. Mater. Sci. Eng. 2016, 139. [Google Scholar] [CrossRef]

- Longana, M.L.; Yu, H.; Aryal, P.; Potter, K.D. The High Performance Discontinuous Fibre (HiPerDiF) Method for Carbon-Flax Hybrid Composites Manufacturing. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Longana, M.L.; Yu, H.; Potter, K.D. The High Performance Discontinuous Fibre (HiPerDif) Method for the Remanufacturing of Mixed Length Reclaimed Carbon Fibres. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Yu, H.; Potter, K.D.; Wisnom, M.R. A novel manufacturing method for aligned discontinuous fibre composites (High Performance-Discontinuous Fibre method). Compos. Part A Appl. Sci. Manuf. 2014, 65, 175–185. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Alimuzzaman, S.; Gong, R.H.; Akonda, M. Impact Property of PLA/Flax Nonwoven Biocomposite. Conf. Pap. Mater. Sci. 2013, 2013, 136861. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Effect of fibre orientations on the mechanical properties of kenaf–aramid hybrid composites for spall-liner application. Def. Technol. 2016, 12, 52–58. [Google Scholar] [CrossRef]

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| rCF [%] | 100 | 75 | 50 | 25 | 0 |

| Flax [%] | 0 | 25 | 50 | 75 | 100 |

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| rCF [g] | 0.71 | 0.54 | 0.37 | 0.19 | 0 |

| Flax [g] | 0 | 0.15 | 0.30 | 0.48 | 0.63 |

| PLA [g] | 1.29 | 1.31 | 1.33 | 1.33 | 1.37 |

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| No. of layers | 20 | 22 | 26 | 25 | 30 |

| Thickness [mm] | 1.95 | 1.98 | 2.09 | 1.95 | 2.03 |

| Measured density [g/cm3] | 1.07 | 1.33 | 1.39 | 1.32 | 1.32 |

| Calculated density [g/cm3] | 1.52 | 1.50 | 1.48 | 1.45 | 1.43 |

| Calculated void content [%] | 29.44 | 11.21 | 6.03 | 9.19 | 7.70 |

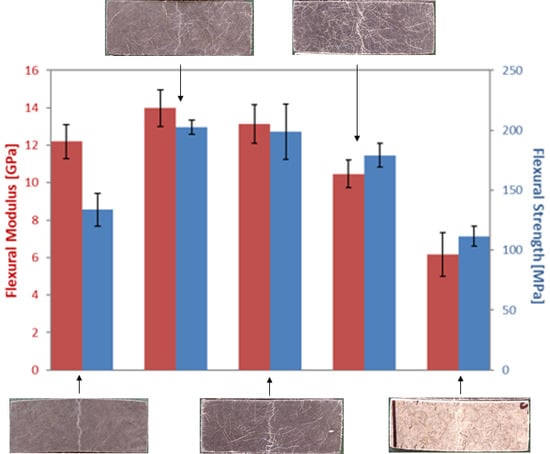

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Flexural Modulus [GPa] | 12.20 | 13.98 | 13.12 | 10.47 | 6.17 |

| S.D. | 0.90 | 0.97 | 1.03 | 0.73 | 1.17 |

| Flexural Strength [MPa] | 133.77 | 202.61 | 198.66 | 179.00 | 111.61 |

| S.D. | 13.70 | 5.9 | 23.21 | 9.84 | 8.40 |

| Flexural Failure Strain [%] | 2.26 | 2.08 | 2.04 | 2.26 | 2.47 |

| S.D. | 0.43 | 0.09 | 0.36 | 0.04 | 0.09 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tse, B.; Yu, X.; Gong, H.; Soutis, C. Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix. Aerospace 2018, 5, 120. https://doi.org/10.3390/aerospace5040120

Tse B, Yu X, Gong H, Soutis C. Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix. Aerospace. 2018; 5(4):120. https://doi.org/10.3390/aerospace5040120

Chicago/Turabian StyleTse, Barbara, Xueli Yu, Hugh Gong, and Constantinos Soutis. 2018. "Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix" Aerospace 5, no. 4: 120. https://doi.org/10.3390/aerospace5040120

APA StyleTse, B., Yu, X., Gong, H., & Soutis, C. (2018). Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix. Aerospace, 5(4), 120. https://doi.org/10.3390/aerospace5040120