Removable Pressure-Sensitive Adhesives Based on Acrylic Telomer Syrups

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- -

- monomers: n-butyl acrylate (BA), acrylic acid (AA BASF; Ludwigshafen, Germany), 4-acryloylooxybenzophenone (ABP, Chemitec, Scandicci, Italy)

- -

- telogens: tetrabromomethane (CBr4), bromotrichlomethane (CBrCl3), Merck, Warsaw, Poland)

- -

- radical photoinitiator: ethyl (2,4,6-trimethyl benzoyl)-phenyl-phosphinate (Omnirad TPOL, IGM Resins, Waalwijk, The Netherlands), i.e., acylphosphine-type (APO).

- -

- hydroxyl-terminated polybutadiene resin Hypro 1200X90 HTB (HTB, CVC Thermoset Specialties, Emerald Kalama Chemical, Kalama, WA, USA)

- -

- radical photoinitiator: ethyl (2,4,6-trimethyl benzoyl)-phenyl-phosphinate (Omnirad TPOL, IGM Resins, Waalwijk, The Netherlands).

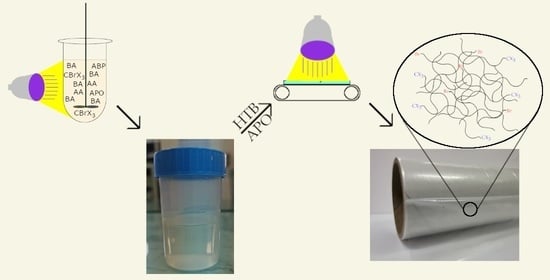

2.2. Synthesis and Characterization of Acrylic Telomer Syrups

2.3. Preparation and Characterization of Pressure-Sensitive Adhesives

3. Results and Discussion

3.1. The Physicochemical Properties of Acrylic Telomer Syrups and Dry Telomers

3.2. Properties of UV-Crosslinked PSA

4. Conclusions

- -

- CBr4 telogen allowed preparing of acrylic telomer syrup with significantly lower dynamic viscosity and slightly higher solids content than CBrCl3;

- -

- tBr-telomers are characterized by lower K-value compared to Cl-telomers.

- -

- A greeter concentration of telogens (both CBr4 and CBrCl3) results in the formation of much shorter telomer chains, which determines the use of a higher dose of UV radiation at the stage of cross-linking the adhesive films, but despite this, cohesive failure still occurs, and the cohesion values of such systems are low, especially in case of PSA based on Br-telomers.

- -

- The influence of terminal Br and Cl atoms and their amounts are consistent with the electrochemical theory of adhesion, but only in the range of low cross-linking densities of systems (small UV doses).

- -

- The excellent removable PSA was obtained using 7.5 mmol of CBr4/100 g of monomer mixtures, and after cross-linking of the adhesive film by 5 J/cm2 of UV dose, i.e., adhesion to steal was 1.3 N/25 mm, tack 1 N, cohesion at 20 and 70 °C >72 h and shear adhesion failure test ca. 160 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Benedek, I.; Feldstein, M.M. Fundamentals of Pressure Sensitivity, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 9781420059380. [Google Scholar]

- Taghizadeh, S.M.; Ghasemi, D. Rheological and Adhesion Properties of Acrylic Pressure-Sensitive Adhesives. J. Appl. Polym. Sci. 2011, 120, 411–418. [Google Scholar] [CrossRef]

- Park, H.W.; Seo, H.S.; Lee, J.H.; Shin, S. Adhesion Improvement of the Acrylic Pressure-Sensitive Adhesive to Low-Surface-Energy Substrates Using Silicone Urethane Dimethacrylates. Eur. Polym. J. 2020, 137, 109949. [Google Scholar] [CrossRef]

- Benedek, I.; Feldstein, M.M. Technology Pressure-Sensitive Adhesives and Products; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9781420059397. [Google Scholar]

- Ortega-Iguña, M.; Chludzinski, M.; Sánchez-Amaya, J.M. Comparative Mechanical Study of Pressure Sensitive Adhesives over Aluminium Substrates for Industrial Applications. Polymers 2022, 14, 4783. [Google Scholar] [CrossRef] [PubMed]

- Czech, Z. Solvent-Based Pressure-Sensitive Adhesives for Removable Products. Int. J. Adhes. Adhes. 2006, 26, 414–418. [Google Scholar] [CrossRef]

- Benedek, I. Pressure-Sensitive Adhesives and Applications, 2nd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2004; ISBN 0-8247-5059-4. [Google Scholar]

- Graham, P.D.; Lu, Y.-Y.; Romsos, J.D. Adhesive Composition Having Non-Tacky Microspheres and Sheets Made Therefrom. US Patent 2009/024647, 1 October 2009. [Google Scholar]

- Müller-Buschbaum, P.; Bauer, E.; Wunnicke, O.; Stamm, M. The Control of Thin Film Morphology by the Interplay of Dewetting, Phase Separation and microphase Separation. J. Phys. Condens. Matter 2005, 17, S363. [Google Scholar] [CrossRef]

- Müller-Buschbaum, P.; Ittner, T.; Maurer, E.; Körstgens, V.; Petry, W. Pressure-Sensitive Adhesive Blend Films for Low-Tack Applications. Macromol. Mater. Eng. 2007, 292, 825–834. [Google Scholar] [CrossRef]

- Chivers, R.A. Easy Removal of Pressure Sensitive Adhesives for Skin Applications. Int. J. Adhes. Adhes. 2001, 21, 381–388. [Google Scholar] [CrossRef]

- Czech, Z. Crosslinking of Pressure Sensitive Adhesive Based on Water-Borne Acrylate. Polym. Int. 2003, 52, 347–357. [Google Scholar] [CrossRef]

- Xue, J.; Wang, J.; Huang, H.; Wang, M.; Zhang, Y.; Zhang, L. Feasibility of Processing Hot-Melt Pressure-Sensitive Adhesive (HMPSA) with Solvent in the Lab. Processes 2021, 9, 1608. [Google Scholar] [CrossRef]

- Bae, J.H.; Won, J.C.; Lim, W.B.; Kim, B.J.; Lee, J.H.; Min, J.G.; Seo, M.J.; Mo, Y.H.; Huh, P. Tacky-Free Polyurethanes Pressure-Sensitive Adhesives by Molecular-Weight and HDI Trimer Design. Materials 2021, 14, 2164. [Google Scholar] [CrossRef]

- Lobo, S.; Sachdeva, S.; Goswami, T. Role of Pressure-Sensitive Adhesives in Transdermal Drug Delivery Systems. Ther. Deliv. 2015, 7, 33–48. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Liu, W.; Zhao, Y.; Jiang, L.; Xu, H.; Yang, X. Preparation and Characterization of PEG-Modified Polyurethane Pressure-Sensitive Adhesives for Transdermal Drug Delivery. Drug Dev. Ind. Pharm. 2009, 35, 704–711. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, Y.; Wang, L.; Shao, L.; Bai, Y. Polyacrylate Emulsion Containing IBOMA for Removable Pressure Sensitive Adhesives. J. Appl. Polym. Sci. 2016, 133, 42886. [Google Scholar] [CrossRef]

- Chu, H.H.; Wang, C.K.; Sein, C.K.; Chang, C.Y. Removable Acrylic Pressure-Sensitive Adhesives Activated by UV-Radiation. J. Polym. Res. 2014, 21, 472. [Google Scholar] [CrossRef]

- Kim, S.W.; Ju, Y.H.; Han, S.; Kim, J.S.; Lee, H.J.; Han, C.J.; Lee, C.R.; Jung, S.B.; Kim, Y.; Kim, J.W. A UV-Responsive Pressure Sensitive Adhesive for Damage-Free Fabrication of an Ultrathin Imperceptible Mechanical Sensor with Ultrahigh Optical Transparency. J. Mater. Chem. A Mater. 2019, 7, 22588–22595. [Google Scholar] [CrossRef]

- Chen, J.; Chalamet, Y.; Taha, M. Telomerization of Butyl Methacrylate and 1-Octadecanethiol by Reactive Extrusion. Macromol. Mater. Eng. 2003, 288, 357–364. [Google Scholar] [CrossRef]

- Bolshakov, A.I.; Kuzina, S.I.; Kiryukhin, D.P. Tetrafluoroethylene Telomerization Initiated by Benzoyl Peroxide. Russ. J. Phys. Chem. A 2017, 91, 482–489. [Google Scholar] [CrossRef]

- Boutevin, B. From Telomerization to Living Radical Polymerization. J. Polym. Sci. A Polym. Chem. 2000, 38, 3235–3243. [Google Scholar] [CrossRef]

- Kowalczyk, A.; Weisbrodt, M.; Schmidt, B.; Gziut, K. Influence of Acrylic Acid on Kinetics of UV-Induced Cotelomerization Process and Properties of Obtained Pressure-Sensitive Adhesives. Materials 2020, 13, 5661. [Google Scholar] [CrossRef]

- Weisbrodt, M.; Kowalczyk, A. Self-Crosslinkable Pressure-Sensitive Adhesives from Silicone-(Meth)Acrylate Telomer Syrups. Materials 2022, 15, 8924. [Google Scholar] [CrossRef]

- Weisbrodt, M.; Kowalczyk, A.; Kowalczyk, K. Structural Adhesives Tapes Based on a Solid Epoxy Resin and Multifunctional Acrylic Telomers. Polymers 2021, 13, 3561. [Google Scholar] [CrossRef] [PubMed]

- Kraśkiewicz, A.; Kowalczyk, A.; Kowalczyk, K.; Schmidt, B. Novel Solvent-Free UV-Photocurable Varnish Coatings Based on Acrylic Telomers—Synthesis and Properties. Prog. Org. Coat. 2023, 175, 107365. [Google Scholar] [CrossRef]

- Starks, C.M. Free Radical Telomerization; Academic Press: Cambridge, MA, USA, 1974; ISBN 9780126636505. [Google Scholar]

- Ouellette, R.J.; Rawn, J.D. 1-Structure of Organic Compounds. In Principles in Organic Chemistry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–32. [Google Scholar]

- Chen, R.; Huang, Y.; Tang, Q.; Bai, L. Modelling and Analysis of the Electrostatic Adhesion Performance Considering a Rotary Disturbance between the Electrode Panel and the Attachment Substrate. J. Adhes. Sci. Technol. 2016, 30, 2301–2315. [Google Scholar] [CrossRef]

| Syrups Acronym | Monomers (wt.%) | TPOL (wt. part) 2 | CBr4 | CBrCl3 | ||||

|---|---|---|---|---|---|---|---|---|

| BA | AA | ABP | (wt. parts) 2 | mmol 2 | (wt. parts) 2 | mmol 2 | ||

| RS 1 | 91.5 | 7.5 | 1 | 0.2 | — | — | — | — |

| Br-7.5 | 2.5 | 7.5 | — | — | ||||

| Br-15 | 5.0 | 15 | — | — | ||||

| Cl-7.5 | — | — | 1.5 | 7.5 | ||||

| Cl-15 | — | — | 3 | 15 | ||||

| ATS Acronym | SC (%) | Dynamic Viscosity (Pa·s) | K-Value (a.u.) |

|---|---|---|---|

| RS | n.d. | n.d. | n.d. |

| Br-7.5 | 79.2 | 13.8 | 26.3 |

| Br-15 | 81.5 | 7.3 | 18.1 |

| Cl-7.5 | 75.0 | 48.1 | 42.2 |

| Cl-15 | 79.4 | 23.5 | 30.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weisbrodt, M.; Kowalczyk, A. Removable Pressure-Sensitive Adhesives Based on Acrylic Telomer Syrups. Processes 2023, 11, 885. https://doi.org/10.3390/pr11030885

Weisbrodt M, Kowalczyk A. Removable Pressure-Sensitive Adhesives Based on Acrylic Telomer Syrups. Processes. 2023; 11(3):885. https://doi.org/10.3390/pr11030885

Chicago/Turabian StyleWeisbrodt, Mateusz, and Agnieszka Kowalczyk. 2023. "Removable Pressure-Sensitive Adhesives Based on Acrylic Telomer Syrups" Processes 11, no. 3: 885. https://doi.org/10.3390/pr11030885

APA StyleWeisbrodt, M., & Kowalczyk, A. (2023). Removable Pressure-Sensitive Adhesives Based on Acrylic Telomer Syrups. Processes, 11(3), 885. https://doi.org/10.3390/pr11030885